Brazing method for silicon carbide ceramics

A technology of silicon carbide ceramics and brazing method, which is applied in the direction of welding equipment, manufacturing tools, metal processing equipment, etc., and can solve the problems of intensified reaction between aluminum and silicon carbide ceramics, low bonding strength of brazed joints, and insignificant improvement of wettability etc. to reduce costs, achieve firm bonding, and improve wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

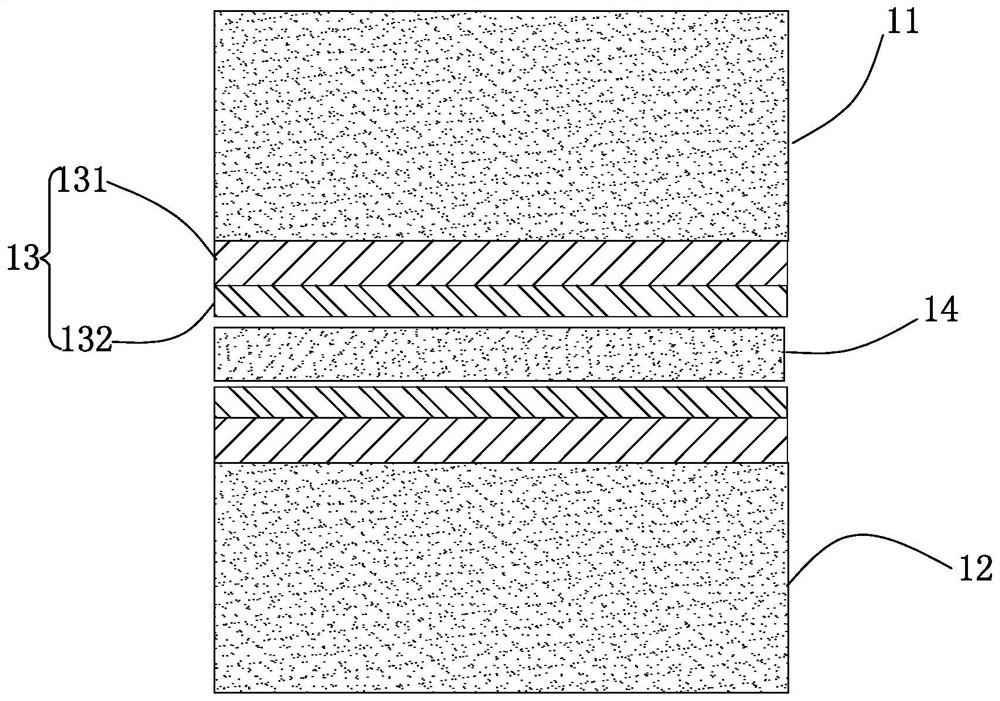

Image

Examples

Embodiment 1

[0042] A brazing method for silicon carbide ceramics, comprising the steps of:

[0043] Step S1, metallographically polish the silicon carbide ceramics with 400 mesh, 800 mesh or 1000 mesh sandpaper on a metallographic grinder until the surface is smooth; then use diamond abrasive paste with a particle size of 1 μm to perform mechanical polishing until the surface is bright; polish The finished silicon carbide ceramics were ultrasonically cleaned in acetone solution for 20 minutes, put into an oven, heated to 80°C and kept warm for 60 minutes;

[0044]Step S2, place the silicon carbide ceramics dried in step S1 in the vacuum chamber of a vacuum magnetron sputtering coating machine equipped with a Ni target and an Al target, and wait until the vacuum degree is evacuated to 5×10 -3 After Pa, feed Ar gas with a purity of 99.999% into the vacuum chamber, keep the pressure at 0.6 Pa, then turn on the Ni target (purity is 99.99%) power supply, adjust the working voltage to 300V, the...

Embodiment 2

[0050] A brazing method for silicon carbide ceramics, comprising the steps of:

[0051] Step S1, metallographically polish the silicon carbide ceramics with 400 mesh, 800 mesh or 1000 mesh sandpaper on a metallographic grinder until the surface is smooth; then use diamond abrasive paste with a particle size of 1 μm to perform mechanical polishing until the surface is bright; polish The finished SiC ceramics were ultrasonically cleaned in acetone solution for 20 minutes, then placed in an oven and heated to 100°C for 80 minutes;

[0052] Step S2, placing the silicon carbide ceramics dried in step S1 in the chamber of the vacuum evaporation equipment, and placing the metal Ti target (purity: 99.99%) and the metal Al target (purity: 99.99%) to be evaporated in the evaporation source On, vacuum up to 4×10 -3 After Pa, vapor deposition is carried out. The specific process is: first heat the silicon carbide ceramic sheet to 350°C, keep it warm for 10 minutes, then turn on the heat...

Embodiment 3

[0056] A brazing method for silicon carbide ceramics, comprising the steps of:

[0057] Step S1, metallographically polish the silicon carbide ceramics with 400 mesh, 800 mesh or 1000 mesh sandpaper on a metallographic grinder until the surface is smooth; then use diamond abrasive paste with a particle size of 1 μm to perform mechanical polishing until the surface is bright; polish The finished silicon carbide ceramics were ultrasonically cleaned in acetone solution for 20 minutes, then placed in an oven and heated to 80°C for 60 minutes;

[0058] Step S2, place the silicon carbide ceramics dried in step S1 in the chamber of the arc ion plating equipment, use Zr target and Al target respectively, and wait for the vacuum degree to be 4×10 -3 Pass into the Ar gas that purity is 99.999% in the vacuum chamber behind Pa, keep pressure and be 0.2Pa, then open Zr target (purity is 99.99%) power supply, adopt arc current to be 70A and pulse negative bias to be 200V, deposition tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com