Method for preparing multi-component flocculant and co-producing composite white carbon black by using red mud

A technology of flocculant and white carbon black, which is applied in the direction of flocculation/sedimentation water/sewage treatment, silicon dioxide, silicon oxide, etc. It can solve the problems of complex process, high cost, poor implementability, etc., and achieve wide source of raw materials, flocculation Body dense and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

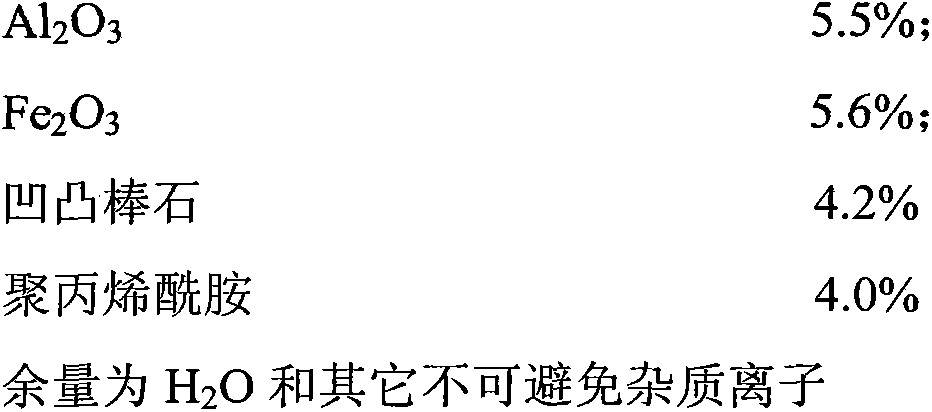

[0019] Add 25g of red mud and 75ml of 30% hydrochloric acid into a three-necked flask, stir at 100°C for 2 hours, and suction-filter to obtain the acid leaching solution and acid leaching residue; add 3g of calcium aluminate to the acid leaching solution, and stir at 60°C for 4 hours. After aging for 24 hours, the polymerized aluminum-iron flocculant was obtained; 4g of polyacrylamide, 10g of hydrated attapulgite, and 86g of polymerized aluminum-iron flocculant were mixed and reacted, and the multi-component flocculant was obtained after stirring at 50°C for 1 hour; Under drying for 6 hours, composite white carbon black was obtained. SiO in composite silica 2 The content is 70.1%; the mass percentage of each component in the multi-component flocculant is:

[0020]

Embodiment 2

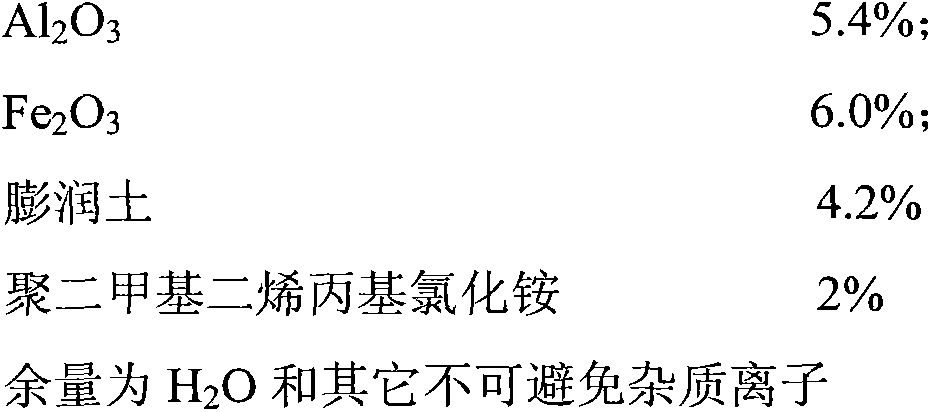

[0022] Add 25g of red mud, 25ml of 30% hydrochloric acid and 25ml of 75% sulfuric acid into a three-neck flask, stir at 90°C for 2 hours, and filter with suction to obtain acid leaching solution and acid leaching residue; slowly add 60ml of NaOH (1M) solution to the rapidly stirred acid In the immersion solution, react at 75°C for 2 hours, and after aging for 24 hours, the polymerized aluminum-iron flocculant is obtained; 2g of polydimethyldiallyl ammonium chloride, 5g of bentonite, and 93g of polymerized aluminum-iron flocculant are mixed and reacted at 40°C After stirring at low temperature for 0.5h, a multi-component flocculant was obtained; the acid leaching residue was dried at 200°C for 3h to obtain composite white carbon black. SiO in composite silica 2 The content is 77.5%; the mass percentage of each component in the multi-component flocculant is:

[0023]

Embodiment 3

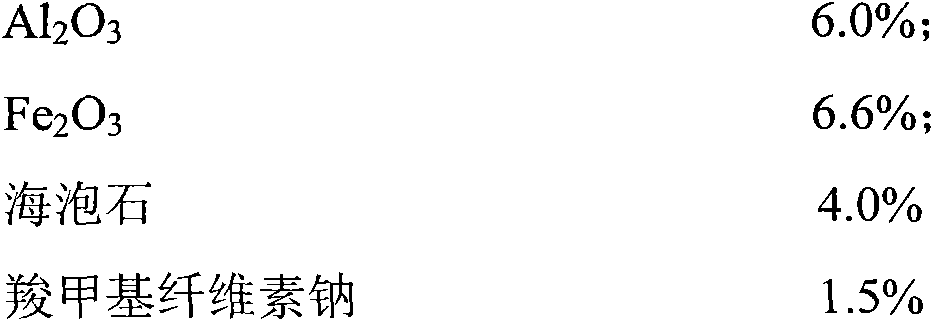

[0025] Add 25g of red mud and 75ml of 75% sulfuric acid into a three-necked flask, stir at 80°C for 2 hours, and suction-filter to obtain pickling solution and pickling residue; slowly add 40ml of NaOH (1M) solution to the rapidly stirring pickling solution, React at 80°C for 2 hours, then add 4g calcium aluminate, continue to react for 2 hours, and obtain polyaluminium-iron flocculant after aging for 12 hours; mix 1.5g sodium carboxymethyl cellulose, 5g sepiolite, and 93.5g polyaluminium-iron flocculant Reaction, react at 50°C for 0.5h to obtain a multi-component flocculant; dry the acid leaching residue at 250°C for 2h to obtain composite white carbon black. SiO in composite silica 2 The content is 85.0%; the mass percentage of each component in the multi-component flocculant is:

[0026]

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com