Method for directly writing magneto-optic waveguide on diamagnetic photosensitive glass by using femtosecond laser

A photosensitive glass and femtosecond laser technology, which is applied in the field of femtosecond laser preparation of optical devices, can solve the problems that it cannot be used outdoors, harsh environments, and unfavorable magneto-optical waveguide applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

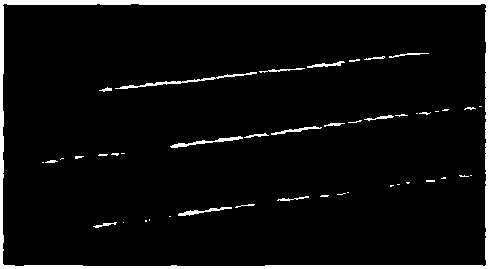

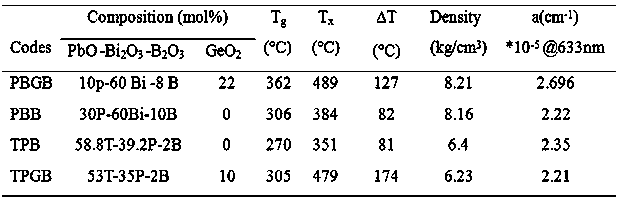

[0020] 1) The magneto-optical photosensitive glass to be written is ground and polished to make the surface roughness of the glass not greater than 50 microns, and the glass is fixed on the three-dimensional mobile platform. 2) Import the magneto-optical waveguide pattern into the computer after being drawn by software. 3) Focus the femtosecond laser on the upper surface or inside of the inverse magnetophotosensitive glass to be written. The laser system works at a repetition rate of 100kHz and the corresponding current range is 21A. The laser scans the microstructure repeatedly 4 times. Use a 40× objective (NA 0.6) and a 520 μm slit placed in front of the objective to focus the incident laser light in a direction orthogonal to the sample & spread the laser beam. 4) Move the laser beam at a speed of 1.5mm / min according to a preset pattern (the irradiation depth is 170µm), and test with a pulse energy of 150nJ until a three-dimensional magneto-optical waveguide is written on t...

Embodiment 2

[0025] 1) The magneto-optical photosensitive glass to be written is ground and polished to make the surface roughness of the glass not greater than 50 microns, and the glass is fixed on the three-dimensional mobile platform. 2) Import the magneto-optical waveguide pattern into the computer after being drawn by software. 3) Focus the femtosecond laser on the upper surface or inside of the inverse magnetophotosensitive glass to be written. The laser system works at a repetition rate of 100kHz and the corresponding current range is 21A. The laser scans the microstructure repeatedly 4 times. Use a 40× objective (NA 0.6) and a 520 μm slit placed in front of the objective to focus the incident laser light in a direction orthogonal to the sample & spread the laser beam. 4) Move the laser beam at a speed of 1.5mm / min according to a preset pattern (the irradiation depth is 170µm), and test with a pulse energy of 150nJ until a three-dimensional magneto-optical waveguide is written on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com