Method for extracting DHA algae oil from algae cells

A technology of algae cells and algae oil, which is applied in the direction of fat oil/fat production, fat production, etc., can solve the problem of low extraction rate of DHA, achieve the effect of no organic solvent residue, improve extraction efficiency, and increase extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

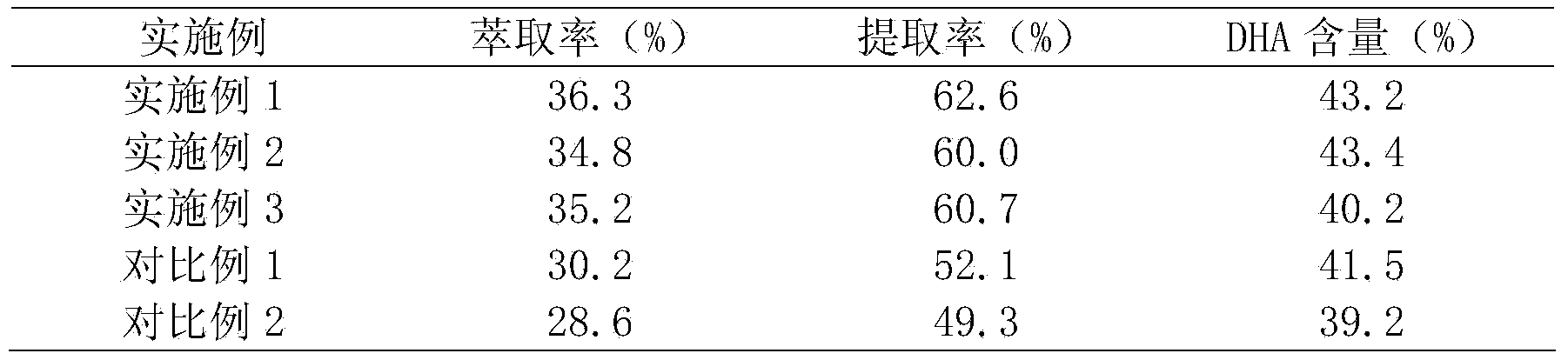

Examples

Embodiment 1

[0042] A method for extracting DHA algae oil from Schizochytrium, comprising the steps of:

[0043] (1) After the Schizochytrium fermented liquid is centrifuged and spray-dried, the Schizochytrium dry powder is prepared, and then the Schizochytrium dry powder and absolute ethanol are mixed evenly according to the mass volume ratio of 1:5, and the unit is kg / L, stand still for 30min, then carry out high-pressure homogeneous wall breaking under the condition of pressure of 100Mpa, and cycle breaking the wall 3 times to obtain the broken wall ethanol solution;

[0044] (2) Evaporating the broken-wall ethanol solution prepared in step (1) at a temperature of 45°C and a pressure of -0.08Mpa in a low-temperature vacuum to remove ethanol to obtain broken-wall bacteria;

[0045] (3) Get the broken-walled thalline that step (2) makes, carry out CO 2 Supercritical extraction to obtain DHA algae oil.

[0046] The Schizochytrium fermented liquid in described step (1), preparation steps...

Embodiment 2

[0059] A method for extracting DHA algae oil from Schizochytrium, comprising the steps of:

[0060] (1) After the Schizochytrium fermented liquid is centrifuged and spray-dried, the Schizochytrium dry powder is prepared, and then the Schizochytrium dry powder and absolute ethanol are mixed evenly according to the mass volume ratio of 1:6, and the unit is kg / L, stand still for 25min, then carry out high-pressure homogeneous wall breaking under the condition of pressure of 80Mpa, and circulate wall breaking 4 times to obtain broken wall ethanol solution;

[0061] (2) Evaporating the broken-wall ethanol solution prepared in step (1) at a temperature of 40°C and a pressure of -0.12Mpa in a low-temperature vacuum to remove ethanol to obtain broken-wall bacteria;

[0062] (3) Get the broken-walled thalline that step (2) makes, carry out CO 2 Supercritical extraction to obtain DHA algae oil.

[0063] The Schizochytrium fermented liquid in described step (1), preparation steps are ...

Embodiment 3

[0076] A method for extracting DHA algae oil from Schizochytrium, comprising the steps of:

[0077] (1) After the Schizochytrium fermented liquid is centrifuged and spray-dried, the Schizochytrium dry powder is prepared, and then the Schizochytrium dry powder and absolute ethanol are mixed uniformly according to the mass volume ratio of 1:4, and the unit is kg / L, stand still for 40min, then carry out high-pressure homogeneous wall breaking under the condition of pressure of 120Mpa, and circulate wall breaking 2 times to obtain broken wall ethanol solution;

[0078] (2) Evaporating the broken-wall ethanol solution prepared in step (1) at a temperature of 50°C and a pressure of -0.05Mpa in a low-temperature vacuum to remove ethanol to obtain broken-wall bacteria;

[0079] (3) Get the broken-walled thalline that step (2) makes, carry out CO 2 Supercritical extraction to obtain DHA algae oil.

[0080] The Schizochytrium fermented liquid in described step (1), preparation steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com