Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Good bulletproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft stab-proof/bulletproof material

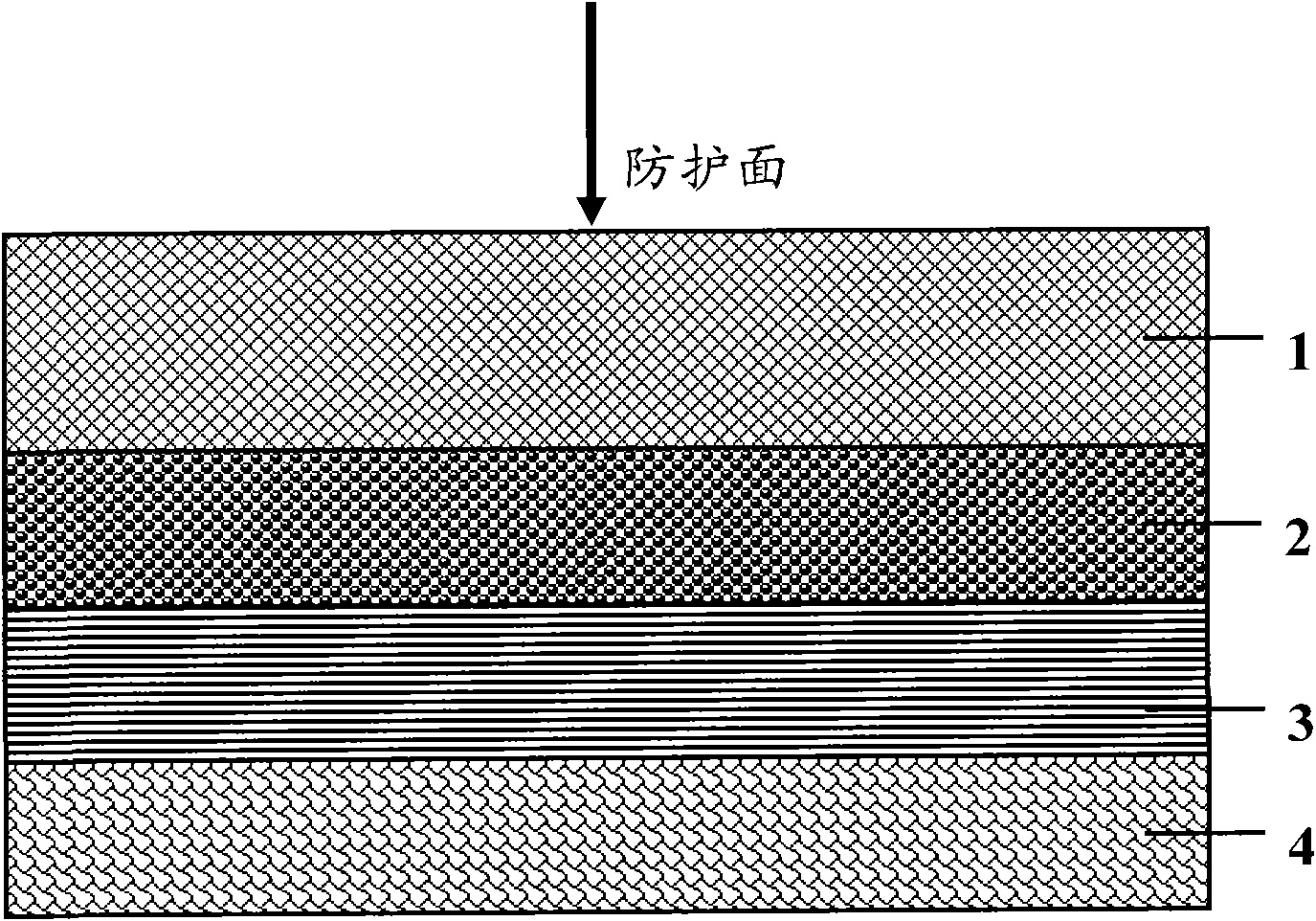

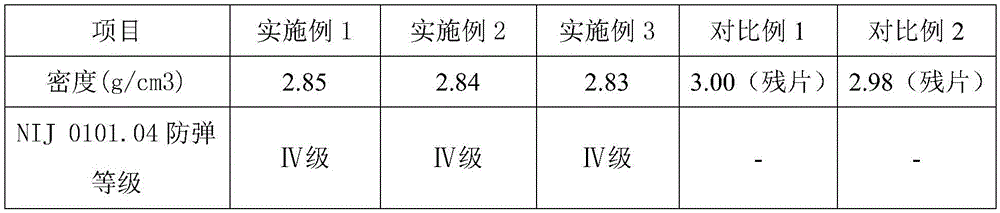

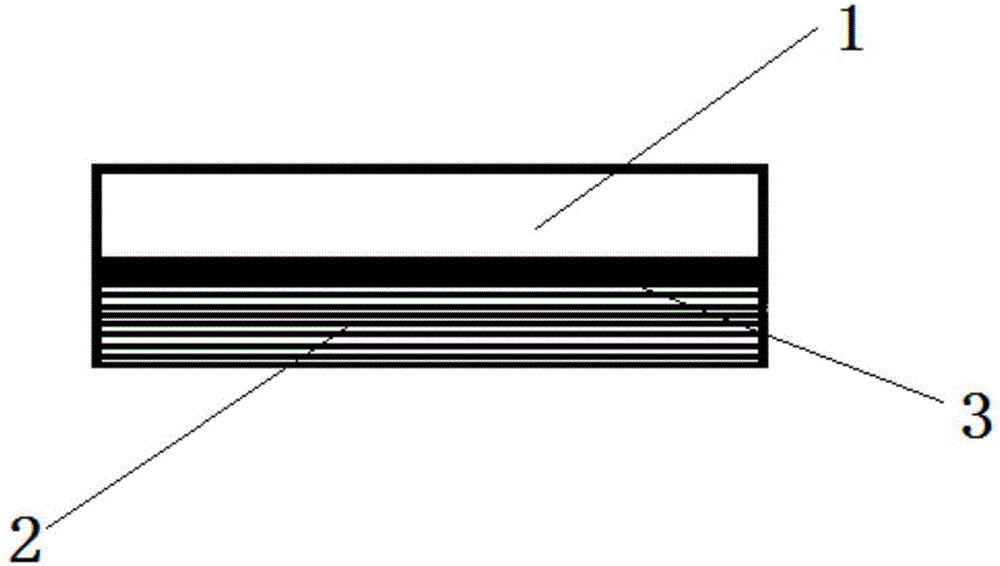

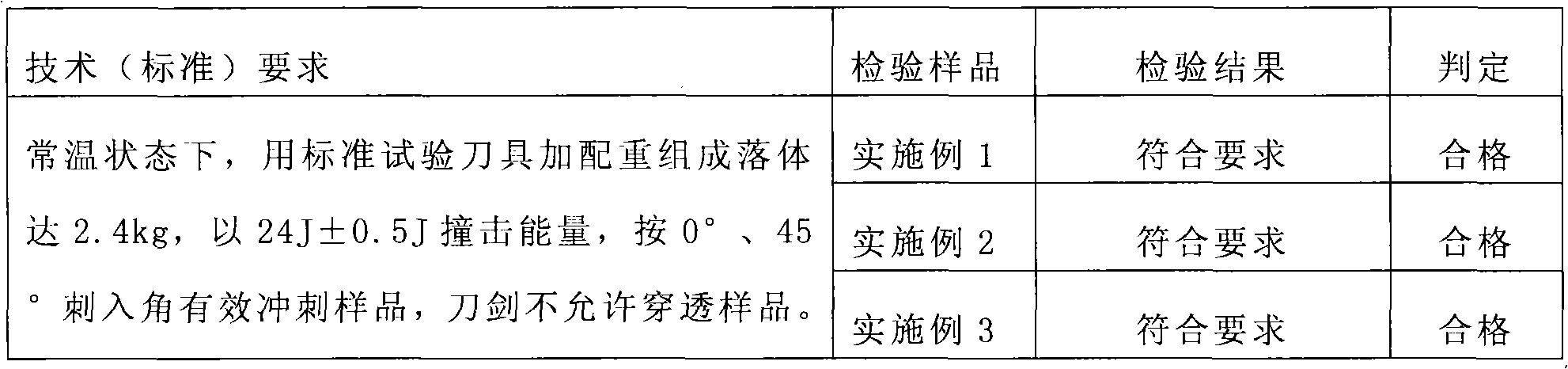

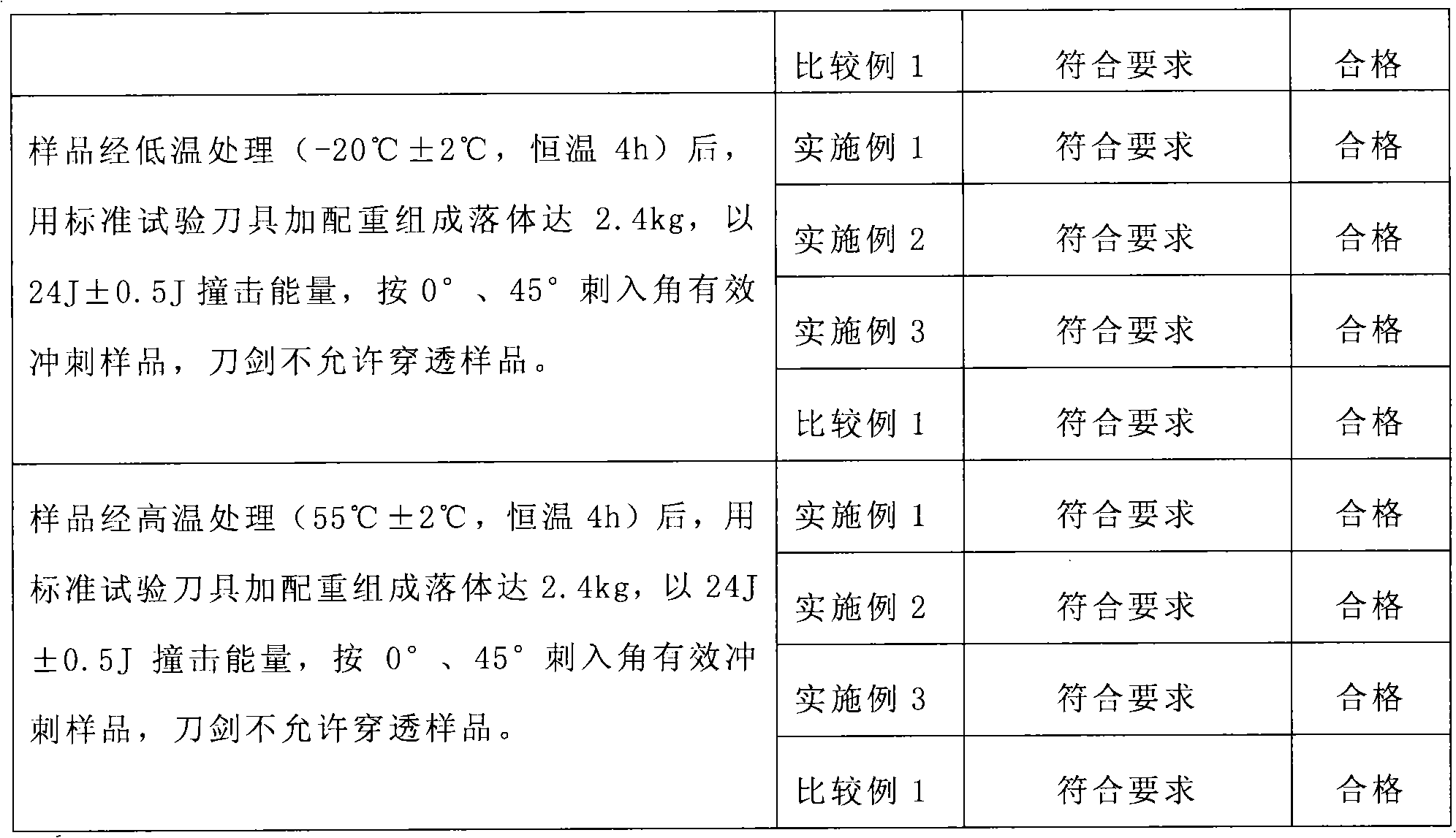

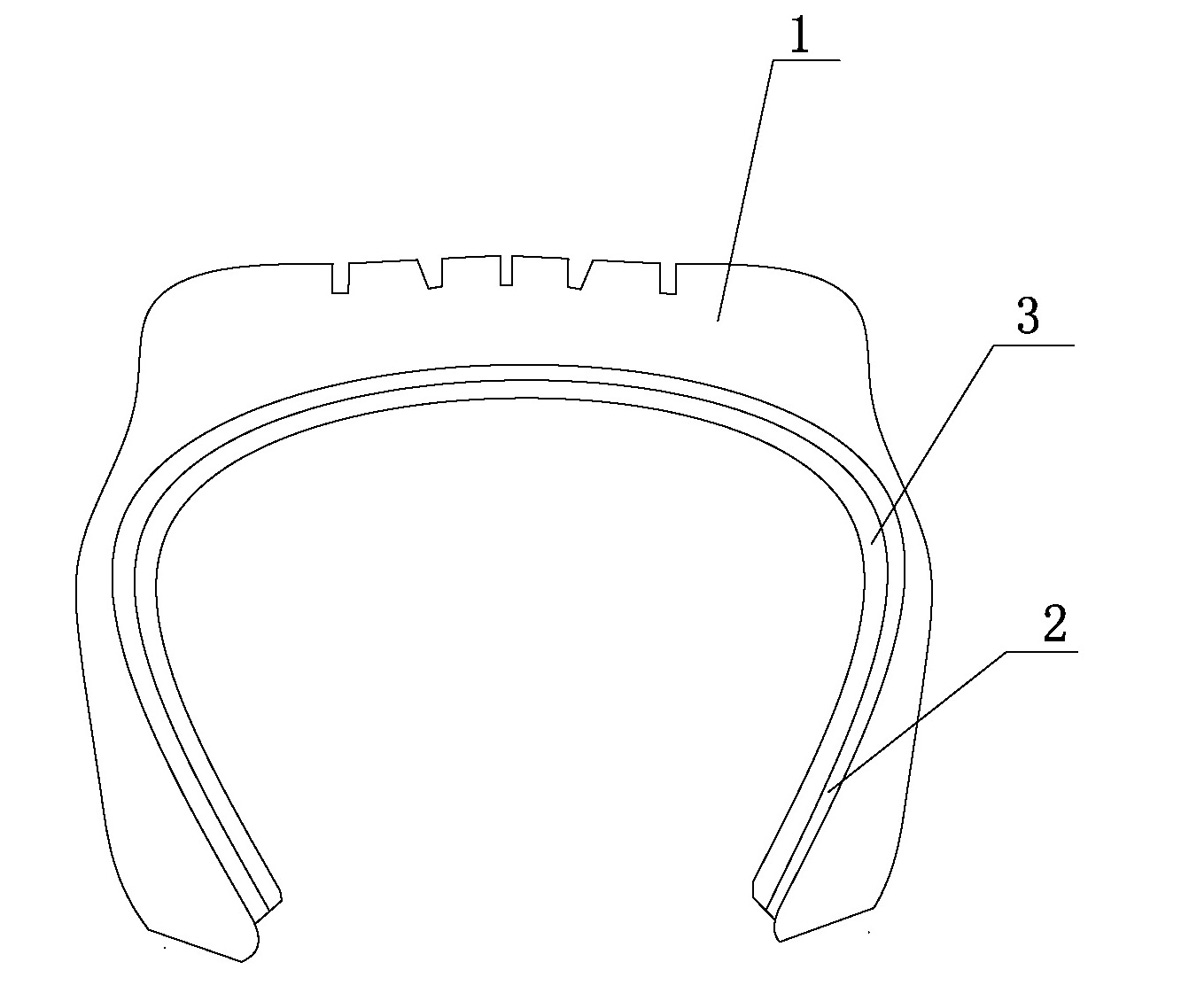

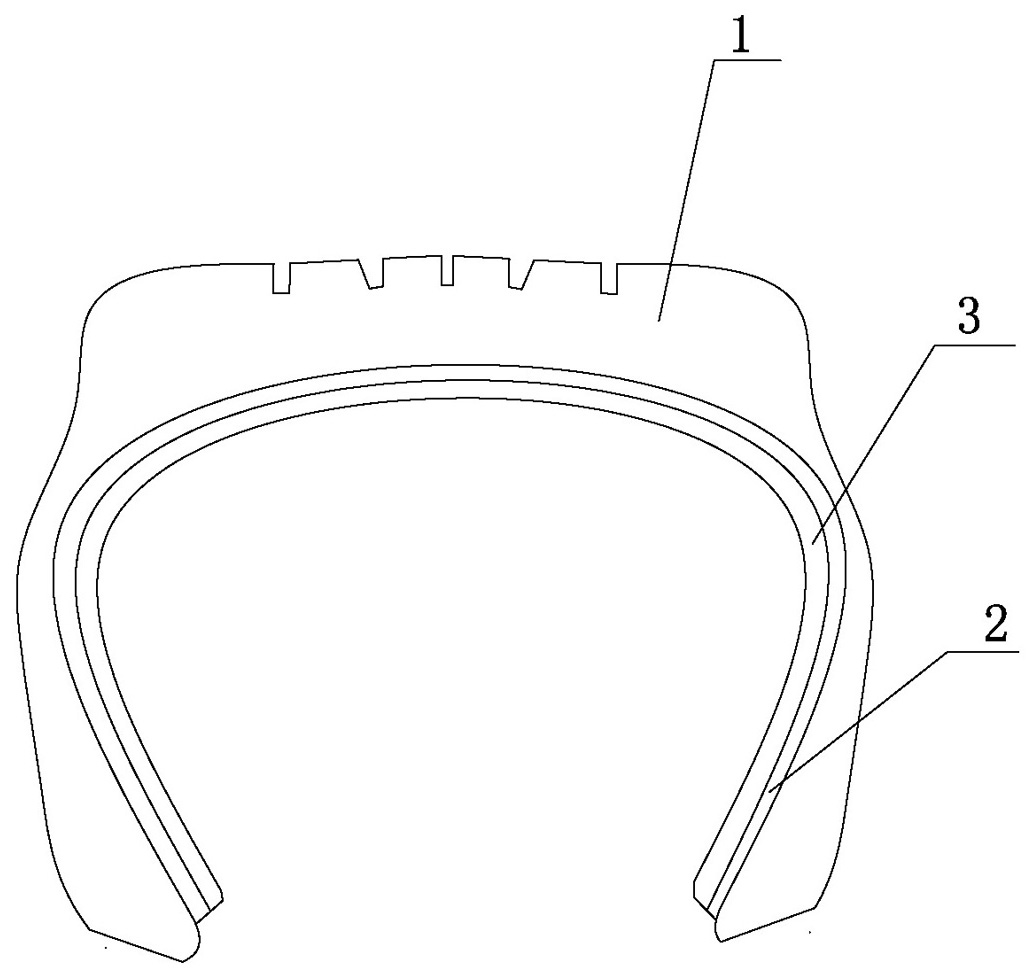

InactiveCN101871748AGood bulletproof performanceIncrease consumptionPersonal protection gearThickened fluidsComposite structure

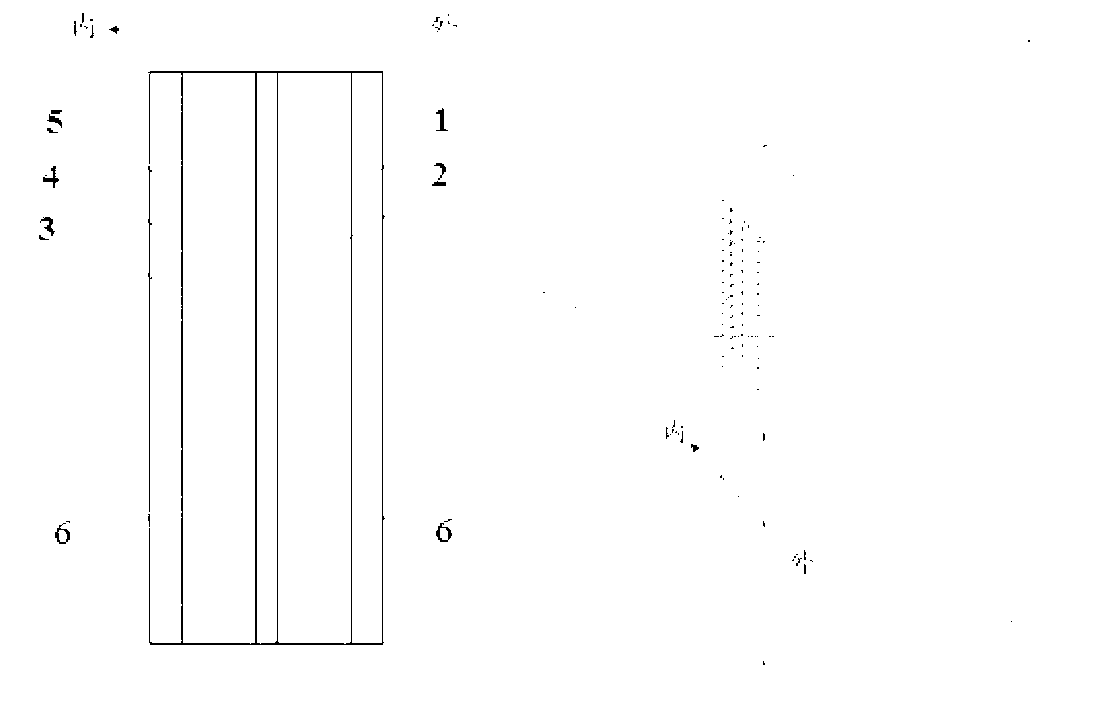

The invention discloses a soft stab-proof / bulletproof material, which comprises a bulletproof fabric layer (1), an STF (Shear Thickening Fluid) composite fabric layer (2) and a thermoplastic resin composite fabric layer (3) which are sequentially overlaid, wherein the bulletproof fabric layer (1) has excellent bulletproof performance; the shear thickening fluid (STF) has a special rheological characteristic and can absorb the quick impact energy; and the resin composite fabric can restrain the movement of fibers, and the destruction of the fabric mainly refers to fiber breakage, which can increase the consumption of the energy. By adopting overlaid bulletproof fabric, STF composite fabric and thermoplastic resin composite fabric layers, the soft stab-proof / bulletproof material of the invention is designed with different stab-proof / bulletproof composite structures, and has the advantages of realizing the complementary advantages of various materials, effectively ensuring the characteristics (include light weight, softness and comfortableness) of the protective materials and having excellent stab-proof / bulletproof performance.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

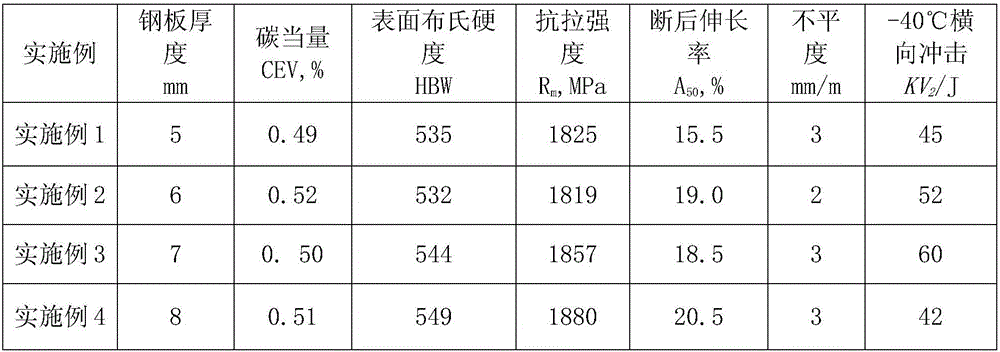

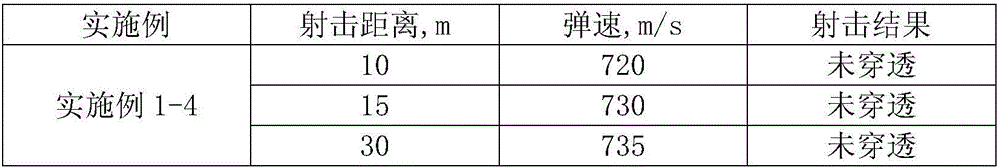

Three-layer composite steel plate and manufacturing method thereof

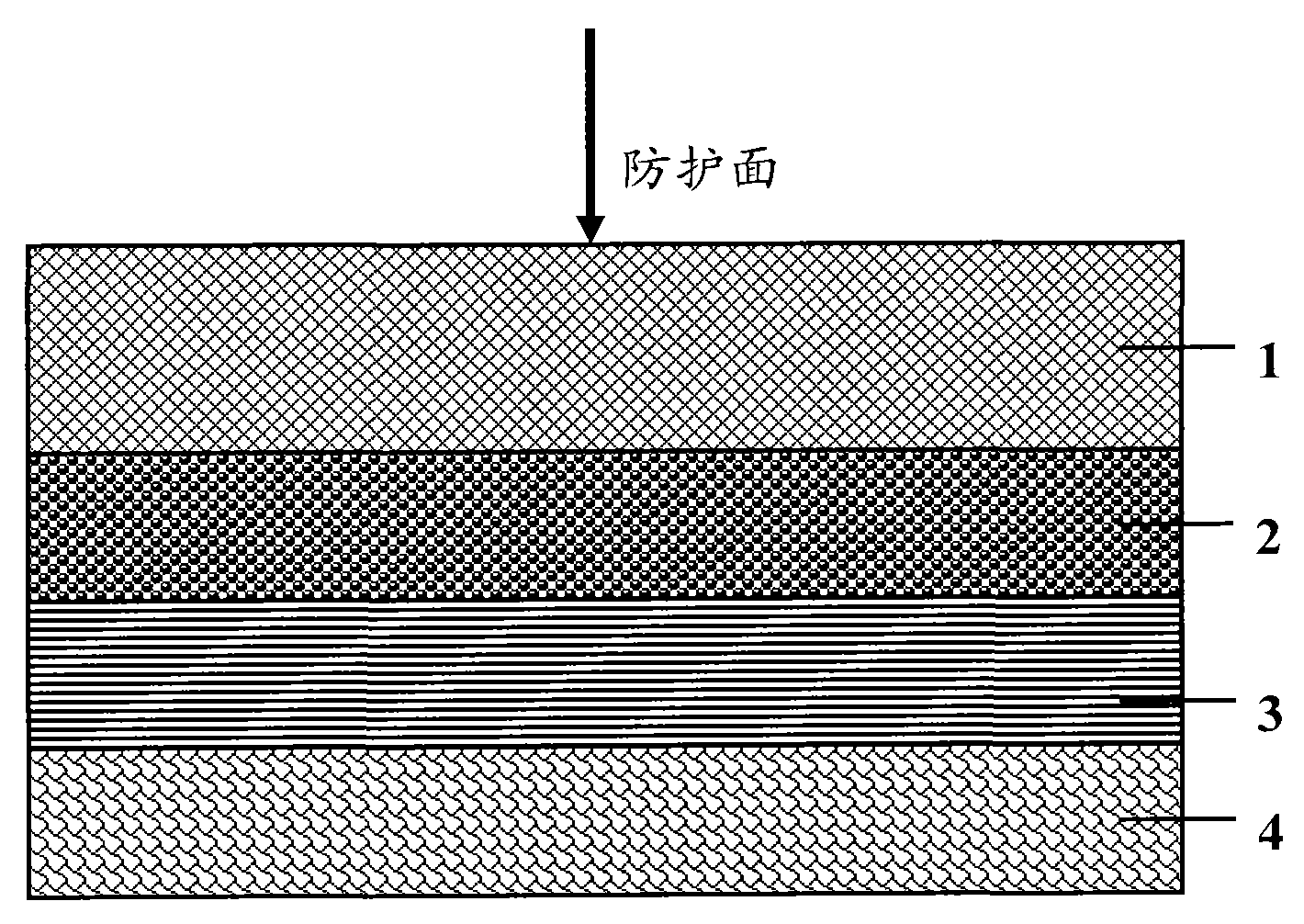

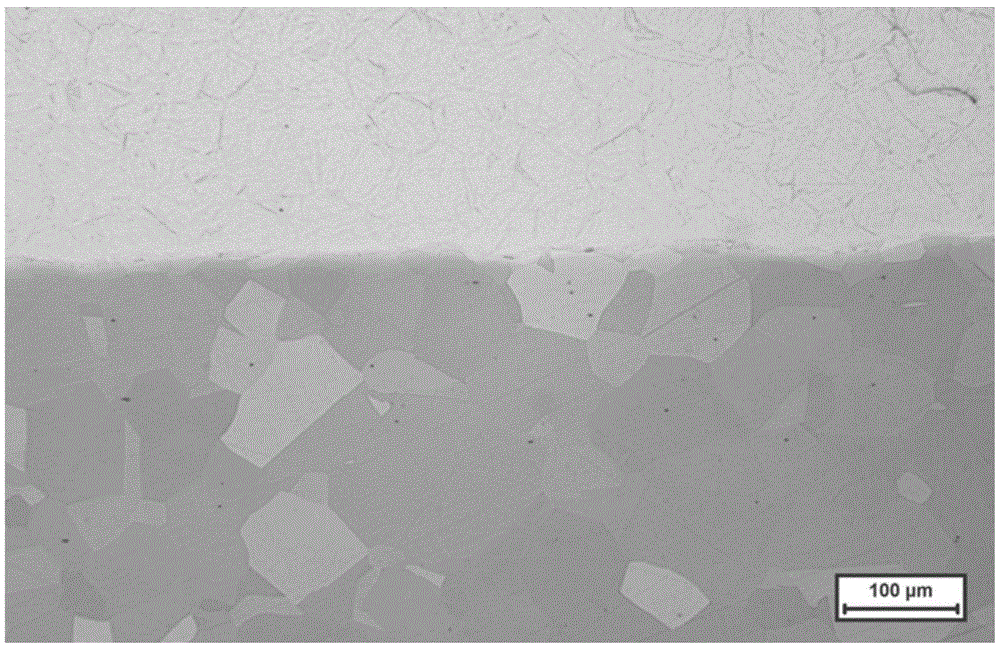

ActiveCN105543649AMeet bulletproof requirementsGood bulletproofMetal layered productsSheet steelSurface layer

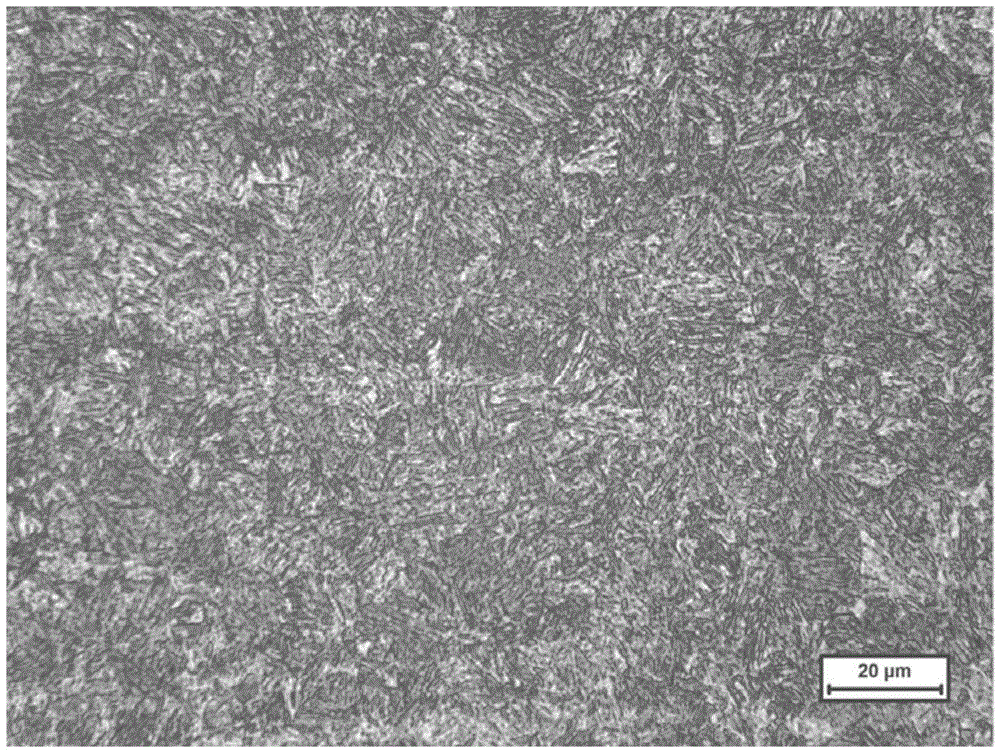

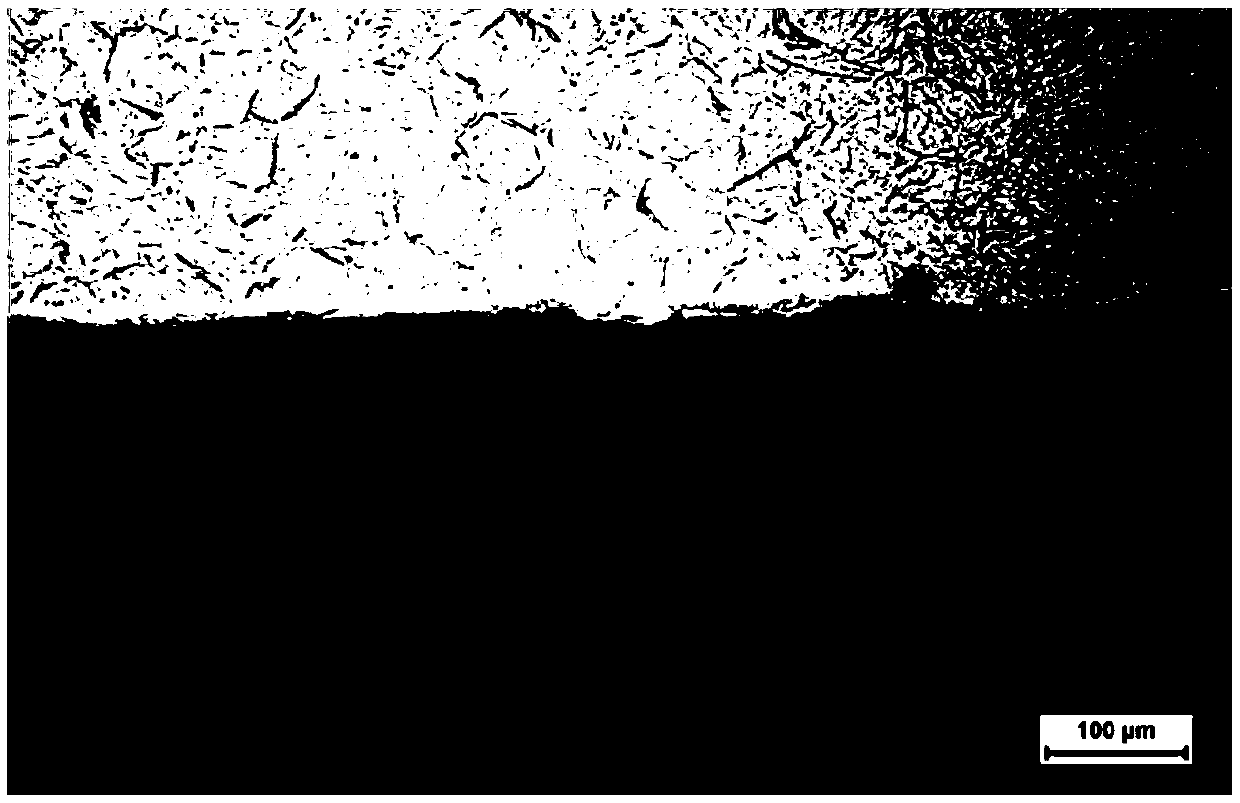

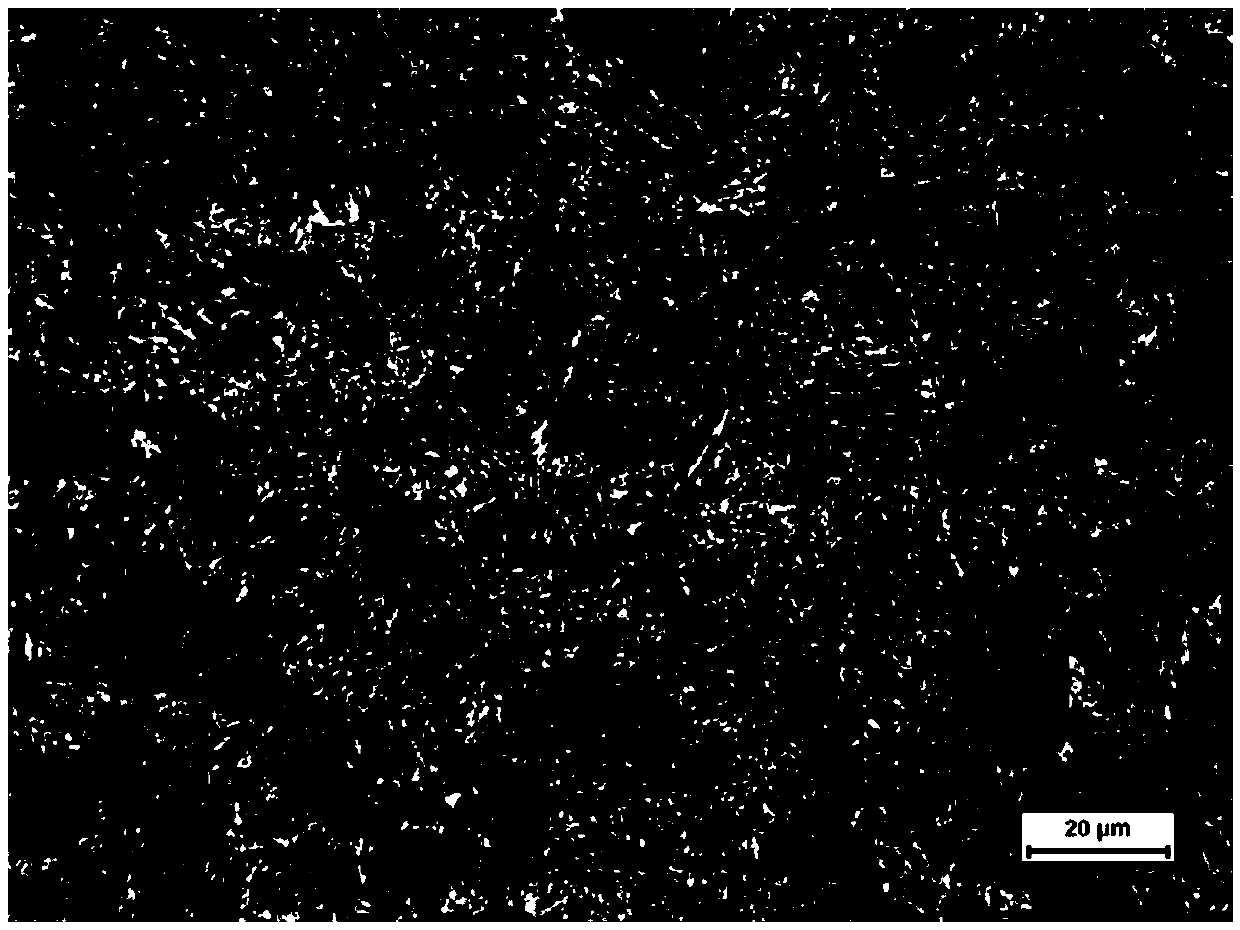

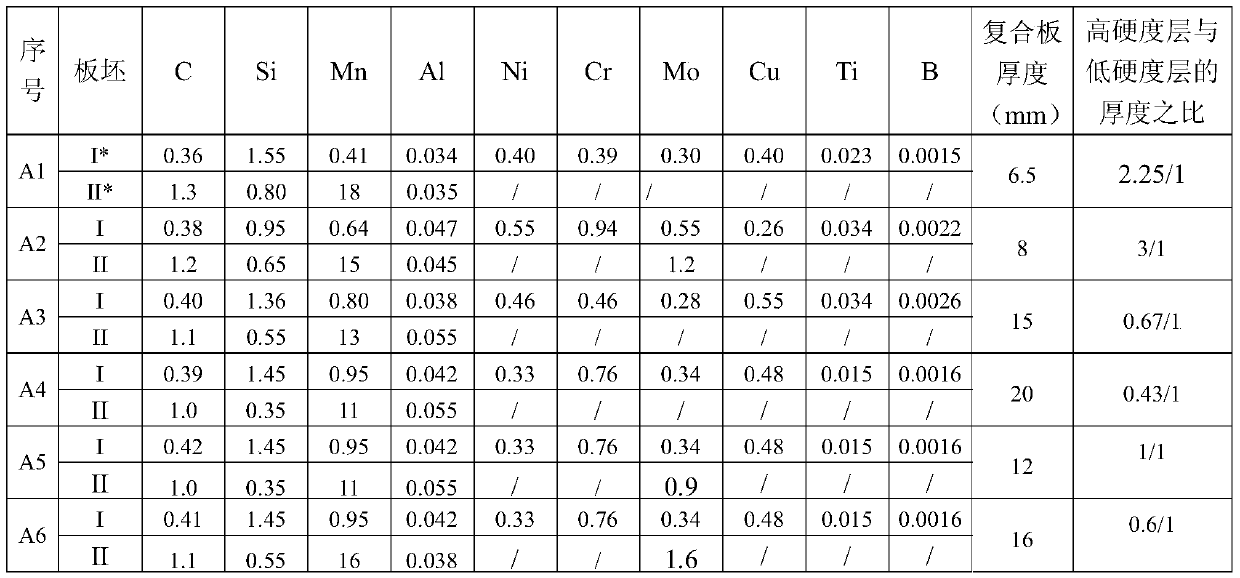

The invention discloses a three-layer composite steel plate. The three-layer composite steel plate is provided with a low-hardness layer serving as a middle base layer and a high-hardness layer serving as a surface layer; and the high-hardness layer and the low-hardness layer achieve atom combination through roll cladding, wherein the low-hardness layer is Mn13 steel, the Brinell hardness of the high-hardness layer is larger than 600, and the Brinell hardness of the low-hardness layer is lower than 250. The invention further discloses a manufacturing method for the three-layer composite steel plate. The manufacturing method comprises the steps that (1), a high-hardness layer slab and a low-hardness layer slab are prepared; (2), assembling is carried out, wherein the slab combination face is pretreated, the slab binding face is subject to peripheral welding seal, and the composite slab obtained after welding seal is subject to vacuumizing treatment; (3), heating is carried out; (4), composite rolling is carried out; (5), cooling is carried out; and (6), heat treatment is carried out, wherein the heating temperature of heat treatment ranges from 1050 DEG C to 1100 DEG C, the heating time ranges from 2 min / mm*slab thickness to 3 min / mm*slab thickness, the heated composite plate is subject to water cooling, and the water temperature is smaller than 40 DEG C; and the composite steel plate has the different hardness characteristics.

Owner:BAOSHAN IRON & STEEL CO LTD

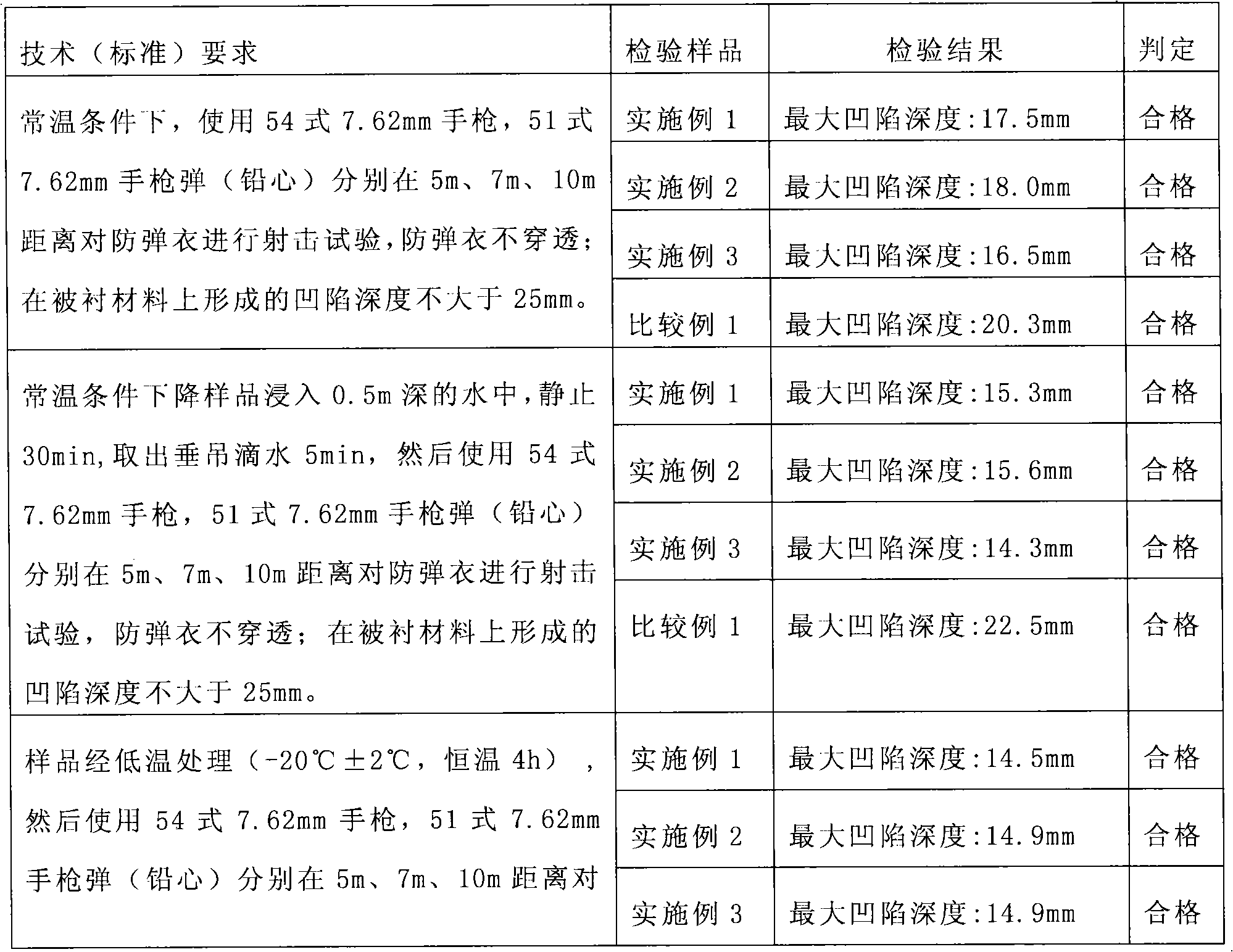

Composite bulletproof flashboard and preparation method and application thereof

ActiveCN103017609ANo fragmentationImprove bulletproof survivabilitySynthetic resin layered productsPersonal protection gearNanotechnologyCoating

The invention discloses a bulletproof flashboard and a preparation method and an application thereof. The preparation method of the bulletproof flashboard comprises the following steps of: bonding a protective layer, a ceramic layer, a middle layer, a supporting layer and a buffer layer which are coated with bonding agents in sequence; coating an outermost layer with a coating layer which is coated with a bonding agent; and molding under the negative pressure and curing. Due to the adoption of a novel structural design for the bulletproof flashboard, the entire bulletproof flashboard can effective resist the impact of bullets continuously shot by a light weapon without being broken. Moreover, the bulletproof flashboard has the characteristics of light weight, high bullet resistance, easiness in processing and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

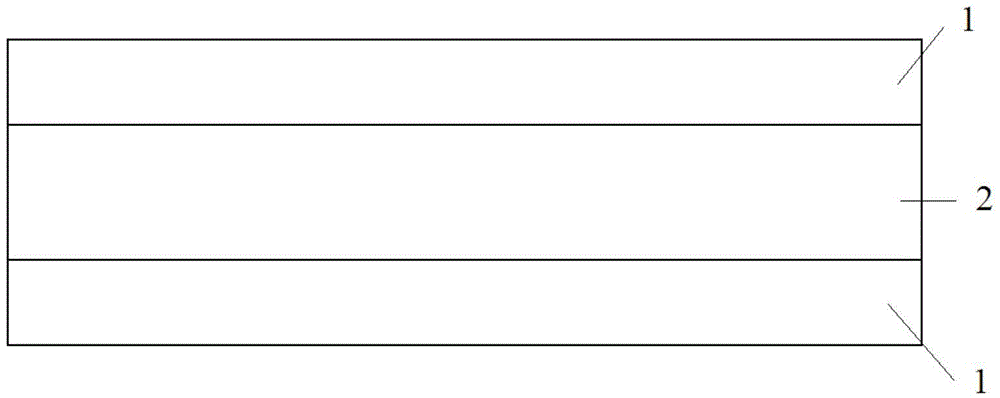

Dual-hardness clad steel plate and production method thereof

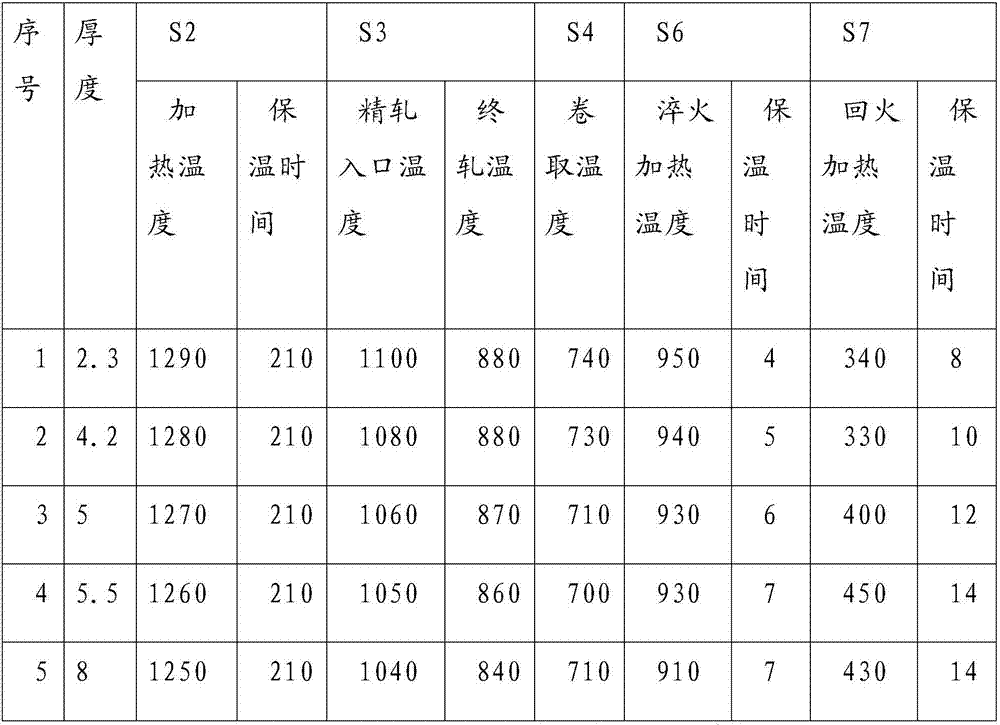

InactiveCN105499269AEasy to controlDifferent hardness characteristicsArmourTemperature control deviceHeating timeSheet steel

The invention discloses a dual-hardness clad steel plate. One surface of the steel plate is a high-hardness layer, the other surface of the steel plate is a low-hardness layer, and atom combination is achieved between the high-hardness layer and the low-hardness layer by rolling bonding, wherein Mn13 steel is adopted for the low-hardness layer, and the Brinell hardness of the high-hardness layer is greater than 600. The invention further discloses a production method of the dual-hardness clad steel plate, comprising the following steps: 1. respectively preparing a high-hardness layer slab and a low-hardness layer slab; 2. assembly: preprocessing the combined surface of the slabs, carrying out spherical welded sealing on the binding faces of the slabs, and carrying out vacuumizing treatment on a composite slab after welded sealing; 3. heating; 4. carrying out composite rolling; 5. cooling; and 6. carrying out thermal treatment, wherein the heating temperature is 1050-1100 DEG C, the heating time is 2-3min / mmx thickness, water cooling is performed on the heating slab, and the water temperature is lower than 40 DEG C. The steel plate has different hardness characteristics and good low-temperature toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

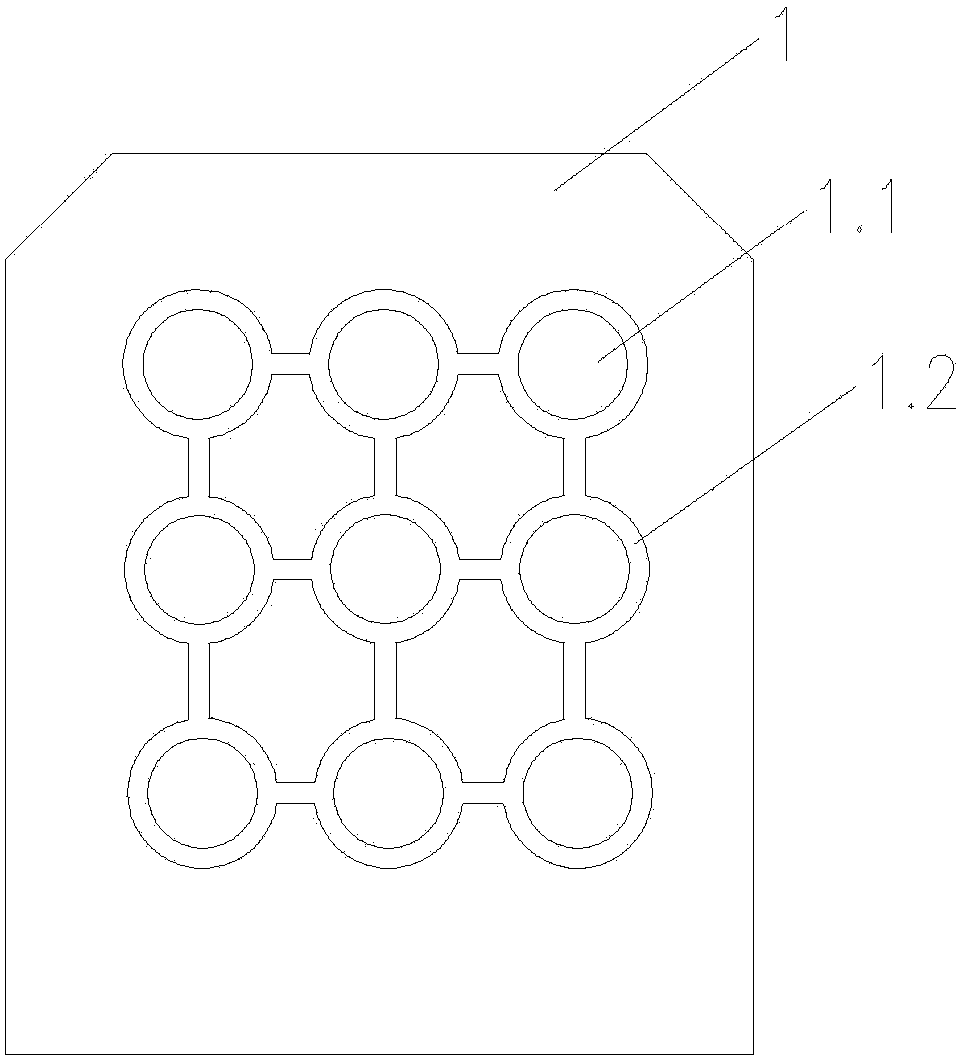

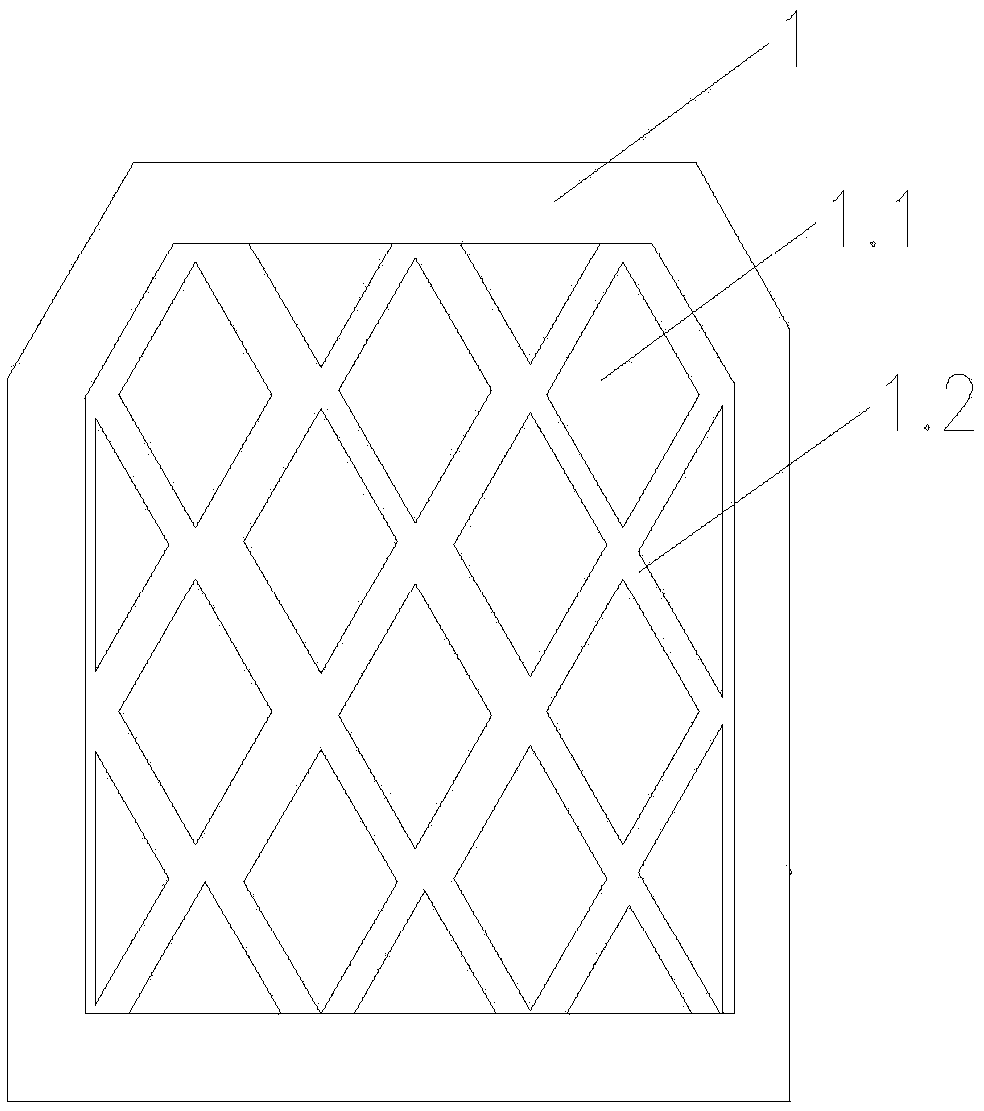

Integral type silicon carbide ceramic elasticity-proof plate and manufacturing method thereof

ActiveCN103591846AGood bulletproof effectIncrease productivityPersonal protection gearContinuous productionSilicon carbide

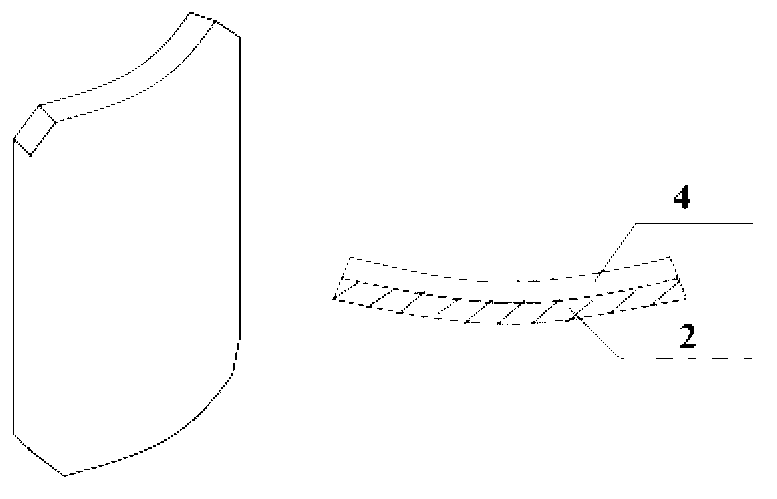

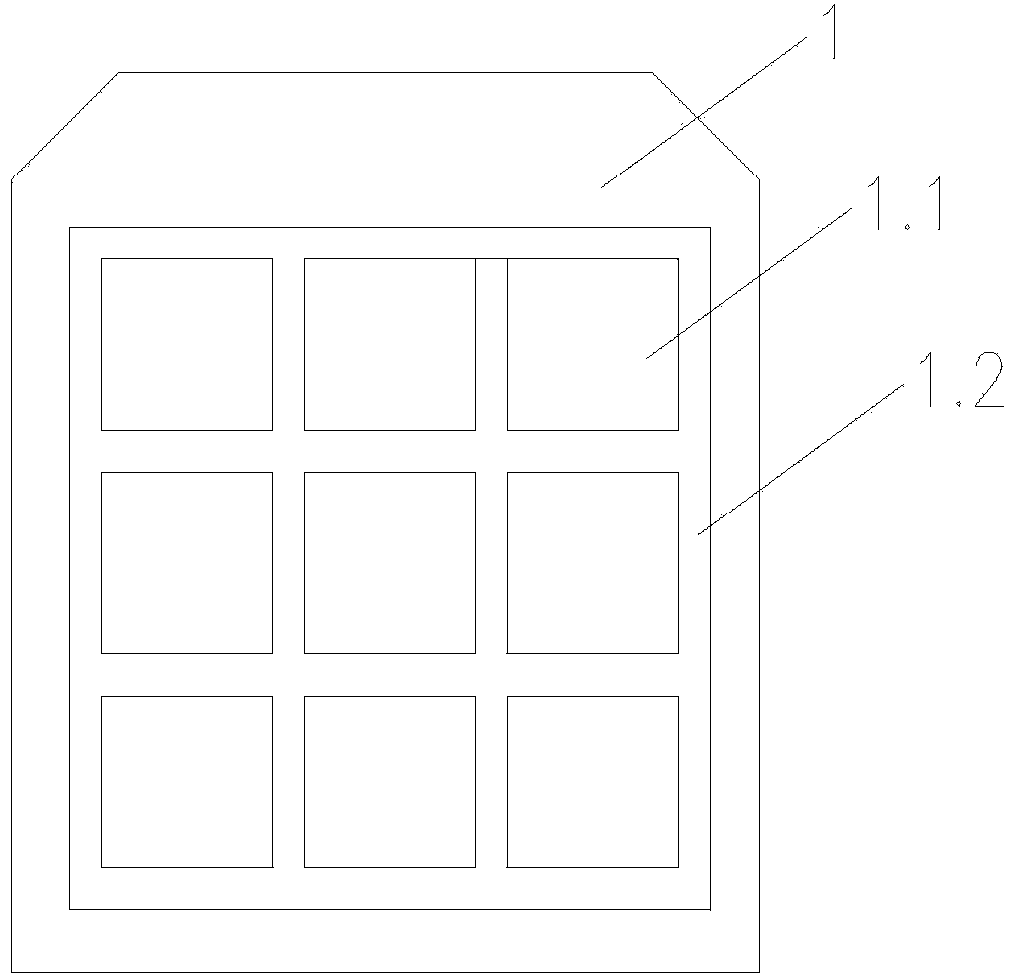

The invention discloses an integral type silicon carbide ceramic elasticity-proof plate which comprises an integral type elasticity-proof plate body (1) which can be attached to an adhesion back plate. The elasticity-proof plate body (1) is composed of a plurality of curved faces. The integral type silicon carbide ceramic elasticity-proof plate is characterized in that the outer convex arc face of the elasticity-proof plate body (1) is provided with a plurality of crack arrest grooves (1.2) which divide the elasticity-proof plate body (1) into a plurality of unit blocks (1.1). The integral type silicon carbide ceramic elasticity-proof plate has the elasticity-proof effect of both the integral type elasticity-proof plate and small block elasticity-proof plates, and is relatively low in cost under the condition of the same thickness. The invention further discloses a manufacturing method of the integral type silicon carbide ceramic elasticity-proof plate. According to the method, continuous production is achieved, repeatability is good, production efficiency is high, deformation is small in plate drying process and sintering process after molding, and the elasticity-proof performance is good.

Owner:NINGBO VULCAN TECH CO LTD

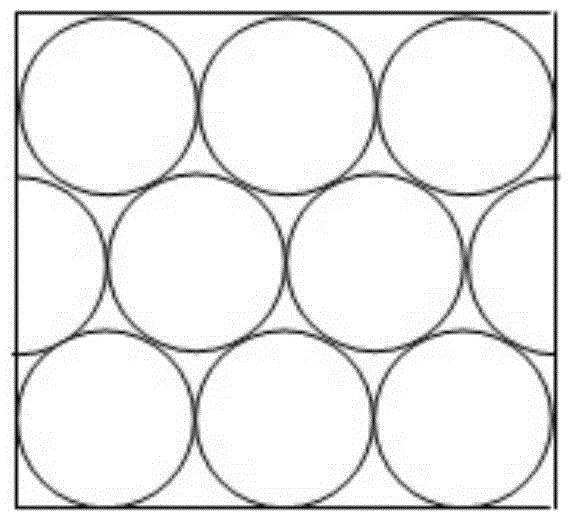

Aluminum-silicon carbide composite ceramic materials and preparation method and application thereof

ActiveCN105039912AImproves wetting and bindingImprove material performanceVacuum evaporation coatingSputtering coatingCeramic particleAluminium

The invention relates to aluminum-silicon carbide composite ceramic materials and a preparation method and application thereof. The aluminum-silicon carbide composite ceramic materials are prepared through the following steps that (1) silicon carbide ceramics are dispersed and buried in metal titanium powder, heated to 1000-1100 DEG C in a vacuum environment, kept at the temperature for 1-3h, and then cooled, so that ceramic particles with surfaces plated with metal titanium layers in an evaporation mode are obtained; (2) the ceramic particles with the surfaces plated with the metal titanium layers in the evaporation mode are put into a container, arranged tightly to form a ceramic array, heated and then put into a compression casting machine, and metal aluminum melt is cast into the ceramic array; and (3) after mold release, the surfaces of the ceramics are cleaned, and the aluminum-silicon carbide composite ceramic materials are obtained and can be used for manufacturing bulletproof plates. Compared with the prior art, the composite ceramic materials have the characteristics of being compact in combination, simple in preparation method, suitable for industrial enlargement and the like.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

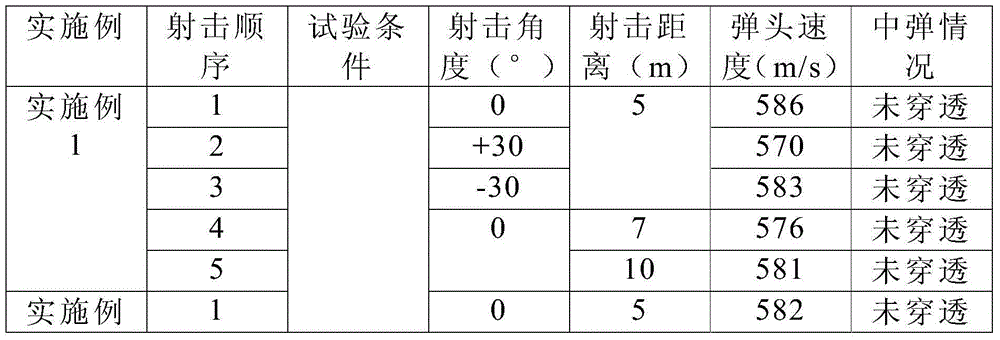

Preparation method and application of resin composition for thermosetting aramid bulletproof composite material

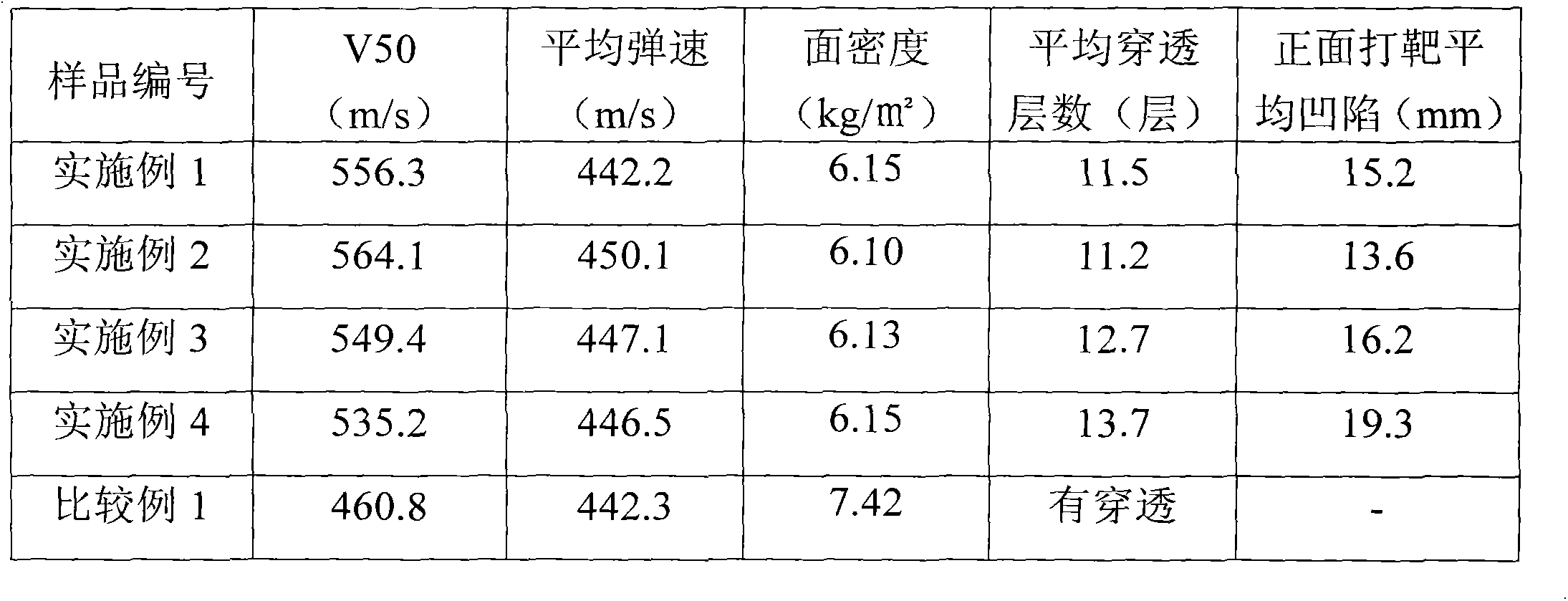

The invention provides a preparation method of a resin composition for a thermosetting aramid bulletproof composite material, and relates to the field of resin modification. The resin composition comprises 25-50% of phenolic resin, 30-60% of polyvinyl butyral solution, 10-25% of a flexibilizer and 8-12% of a reinforcer. In addition, a silicane coupling agent with an addition rate of 2-5% is adopted to improve the compatibility of the resin and fabrics, and improve the adhesion between the resin and the fabrics. Phosphoric acid is used as a thermal stabilizer to improve the weathering resistance of the resin, and is added at an amount of 1-5%. The components are mixed proportionally to prepare a modified phenolic resin system. The modified phenolic resin thus prepared has the advantages of high toughness, moderate bonding strength, excellent anti-aging property and good stability. According to shooting tests, the aramid bulletproof composite material prepared from the resin composition has the characteristics of high bulletproof performance and large margin of safety, and can significantly improve the safety and reliability of fighters.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

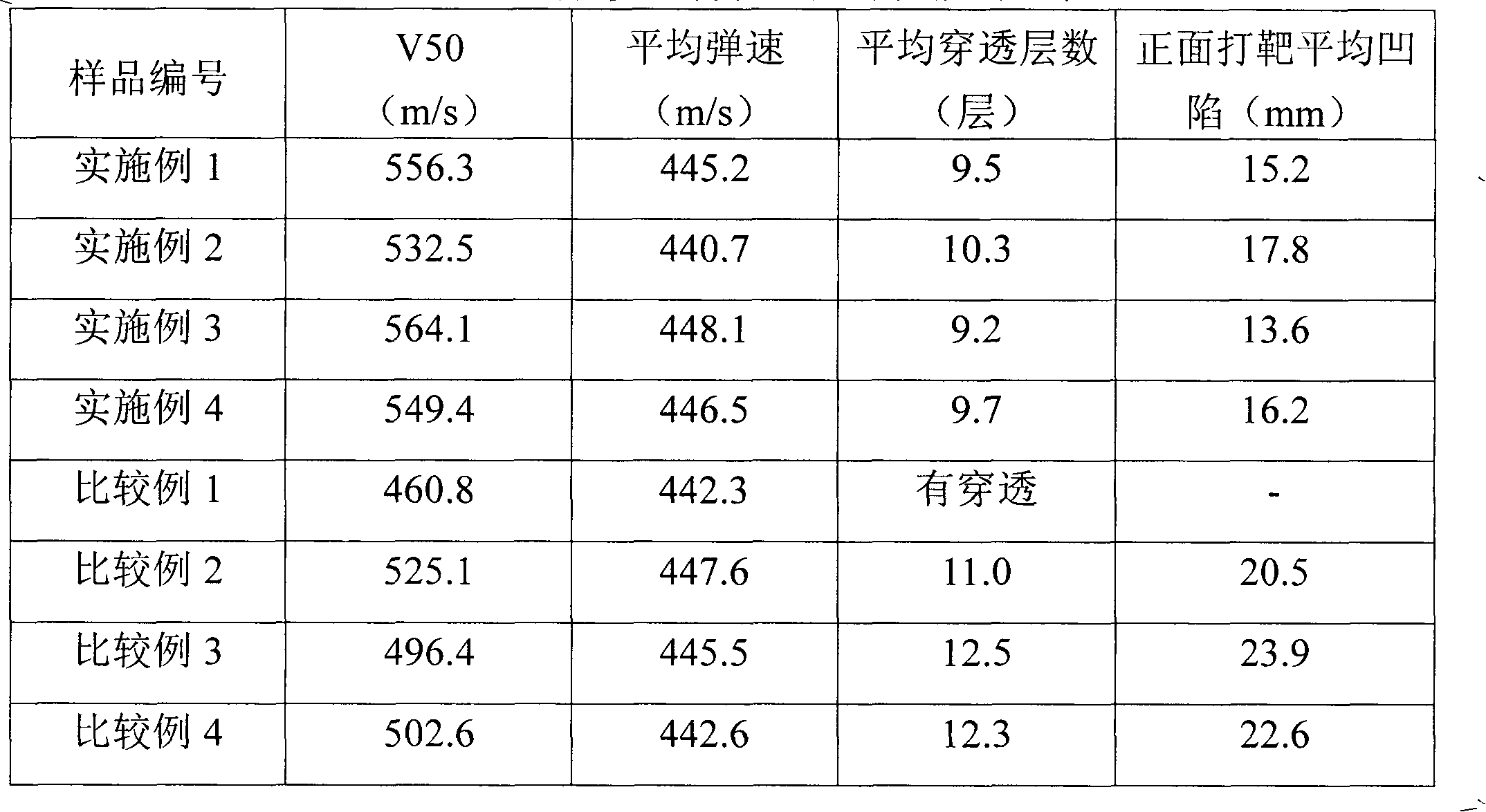

Ultra-soft temperature-resistant bulletproof optical cable and production method thereof

ActiveCN107422435AIngenious structural designImprove flexibilityFibre mechanical structuresThermal insulationPliability

The invention relates to an ultra-soft temperature-resistant bulletproof optical cable and a production method thereof. The optical cable comprises a cable core, a plastic foaming layer, a bulletproof armored layer and an outer sheath layer, the surface of the cable core is provided with the plastic foaming layer, the outside of the plastic foaming layer is provided with the bulletproof armored layer, the outside of the bulletproof armored layer is provided with the outer sheath layer, the cable core comprises optical fiber units and a central reinforcing element which are twisted in an SZ twisting manner, each optical fiber unit comprises coated optical fibers and a buffer tube, the external parts of the coated optical fibers are wrapped by the buffer tube, the central reinforcing element comprises flexible reinforcing members and a PE sheath layer wrapping the external parts of the flexible reinforcing members, and the outer sheath layer is a bellows sheath. According to the optical cable, good thermal insulation performance is achieved by employing the plastic foaming layer structure, the impact force of the exterior on the optical cable can be effectively buffered, the optical fiber has good flexibility and good bulletproof performance by employing the bulletproof armored layer, the overall bending resistance of the optical fiber can be effectively improved by employing the bellows outer sheath, and the bending recovery toughness can be improved.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Composite material for bulletproof helmet and preparation method thereof

InactiveCN103600536AGood bulletproofLight in massSynthetic resin layered productsLaminationPolyresinHot pressing

The invention relates to a composite material for a bulletproof helmet and a preparation method thereof and belongs to the technical field of articles for body protection. The composite material is prepared by alternatively stacking an aramid weftless cloth layer and a resin layer and carrying out mold pressing; the composite material comprises the following materials in percentage by weight: 70-90% of aramid weftless cloth layer and 10-30% of resin layer. The disclosed preparation method of the composite material comprises the following steps: cutting the aramid weftless cloth according to the shape and size of the needed helmet; alternatively stacking the aramid weftless cloth layer and the resin layer, putting the obtained product into a common hot-pressing preforming mold and carrying out thermosetting mold pressing so as to soften the resin layer for alternative bonding with the aramid weftless cloth layer, thereby preparing a composite material blank for the bulletproof helmet; taking out the blank from the hot-pressing preforming mold, and then putting the blank into a cold-pressing preforming mold for cold-setting mold pressing, thereby obtaining the composite material for the bulletproof helmet. The bulletproof helmet prepared by the composite material is good in bulletproof performance and light in weight.

Owner:浙江帅孚安全科技有限公司

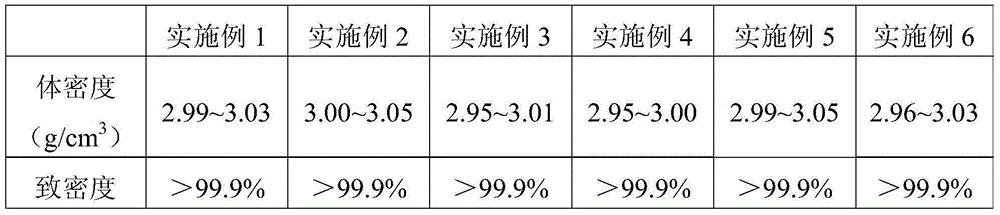

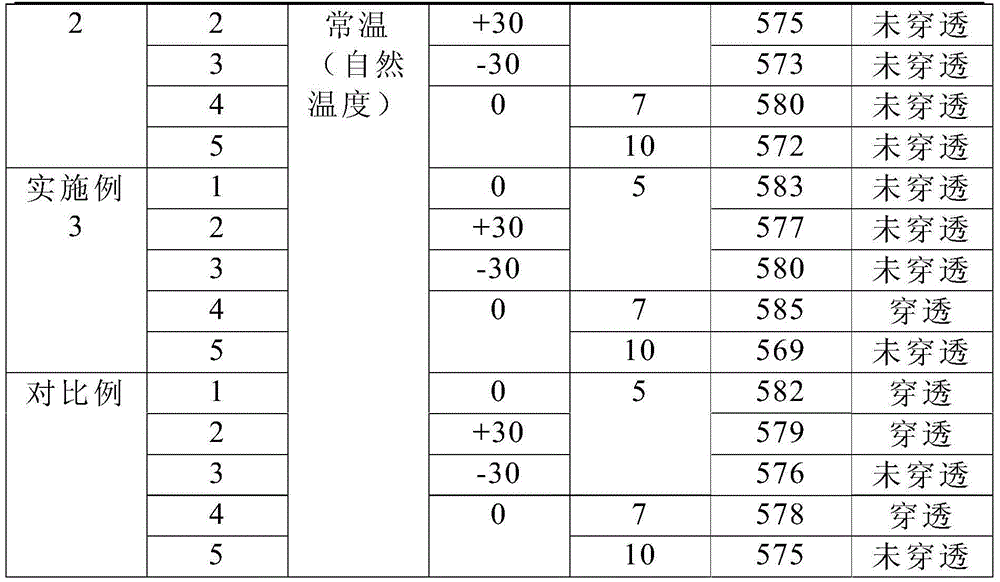

Low-cost light-weight highly-bulletproof B4C/SiC composite ceramic bulletproof plate and preparation method thereof

The invention relates to a low-cost light-weight highly-bulletproof B4C / SiC composite ceramic bulletproof plate and a preparation method thereof. The bulletproof plate is made from silicon carbide granulated powder by pressing, drying, debinding and sintering. The silicon carbide granulated powder is composed of, by weight, 60%-73% of silicon carbide micropowder, 6%-8% of phenolic resin, 0.5%-2% of carbon black, 0.5%-2% of graphite, 5%-16% of boron carbide and 10%-12% of polyvinyl alcohol. By adoption of the silicon carbide granulated powder as a raw material for preparation and adoption of a hydraulic forming machine for pressing, drying, debinding and sintering, the low-cost light-weight highly-bulletproof B4C / SiC composite ceramic bulletproof plate prepared according to the method is high in production efficiency, low in production cost and available for continuous production.

Owner:山东宝纳新材料有限公司

Bulletproof composite board and preparation method thereof

InactiveCN106767171AGood bulletproofImprove anti-fragmentation performanceLayered product treatmentProtective equipmentFibrous compositesMetallic materials

The invention discloses a bulletproof composite board and a preparation method thereof. The bulletproof composite board comprises a bullet-ward face, an interface and a backing face, wherein the bullet-ward face is a bulletproof metal material layer, the backing face is a high-performance fiber composite material layer, and the bulletproof metal material layer and the high-performance fiber composite material layer are glued together through the interface. The bulletproof metal material layer is made of a bulletproof metal plate or a bulletproof titanium alloy material. The high-performance fiber composite material layer is selectively formed by laminating one or more layers made of one or more of an ultra high molecular weight polyethylene non-woven cloth laminated board, an aramid fiber non-woven cloth laminated board and an aramid fiber woven cloth laminated board. The finished bulletproof composite board has excellent bulletproof performance, and compared with metal boards on the same bulletproof level, the weight of the bulletproof composite board is reduced by 30% or over, and meanwhile, breakage resistance is improved; and compared with high-performance fiber composite boards, the cost is reduced by about 50%, and meanwhile, the depths of bullet pits are decreased.

Owner:江苏安卡新材料科技有限公司

Bullet-proof and stab-resistant clothes and preparation method thereof

InactiveCN102435102AImproving the comprehensive performance of bulletproof and stabproofExcellent bulletproof and anti-stab comprehensive performanceSynthetic resin layered productsPersonal protection gearTextileFiber

The invention provides bullet-proof and stab-resistant clothes and a preparation method thereof. The bullet-proof and stab-resistant clothes sequentially comprises a first composite layer, a middle layer and a second composite layer from outside to inside, wherein the middle layer is a layer of titanium alloy sheet; both the first composite layer and the second composite layer sequentially comprise 18 layers of laid fabric with surface density of 135g / cm<2> and 1 layer of titanium alloy sheet from outside to inside; and fibers in the adjacent laid fabric layers are arranged in 0 to 20 degrees. The first composite layer and the second composite layer in the bullet-proof and stab-resistant clothes have higher cutting resistance and impact resistance, and the titanium alloy sheet of the inner layer is used for further improving the bullet-proof performance, so that the bullet-proof and stab-resistant clothes formed after the first composite layer, the middle titanium alloy sheet and the second composite layer are compounded are enough to resist attack of multiple times. Proved by test, the bullet-proof and stab-resistant clothes have excellent bullet-proof and stab-resistant comprehensive performance, accord with the standards of police bullet-proof clothes and stab-resistant clothes, are light in weight, and do not hinder the action of a wearer.

Owner:杨珍芬

Preparation method of novel composite bulletproof inserting plate

InactiveCN109115037AImprove ballistic performanceImprove anti-wear performancePersonal protection gearAlloyOxidation resistant

The invention discloses a preparation method of a novel composite bulletproof inserting plate. The preparation method comprises the steps that 1, a titanium alloy plate or a titanium plate is stampedinto a multi-curved plate to serve as a bullet-facing panel, and the titanium plate is stamped into the multi-curved plate to serve as a back plate; 2, aramid fiber cloth is cut into aramid fiber cloth pieces; 3, ultra-high molecular weight polyethylene prepreg is pressed into a polyethylene plate; 4, the aramid fiber cloth pieces are adhered to the convex surface of the polyethylene plate to forman aramid fiber cloth piece transition layer, ceramic is adhered to the aramid fiber cloth piece transition layer, then the aramid fiber cloth pieces are taken and adhered to the ceramic to form an aramid fiber cloth piece anti-cracking layer, and the polyethylene plate is solidified to obtain an inner core; and 5, the inner core is placed in the back plate, and the bullet-facing panel is sealedon the back plate, vacuumizing, welding and sealing are conducted, and then the bullet-proof inserting plate is obtained. According to the preparation method, the bullet-facing panel and the back plate are vacuumized and sealed, a waterproof, ultraviolet-proof, corrosion-resistant and oxidation-resistant enclosed protective space is formed around the inner core, erosion of sunlight and a humid environment to the aramid fiber, the ceramic and the ultra-high molecular weight polyethylene material of the inner core are avoided, and the service life of the bulletproof inserting plate is greatly prolonged.

Owner:XIAN KANGBEN MATERIAL

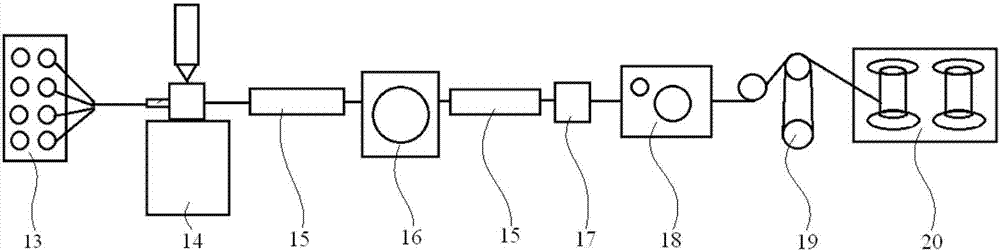

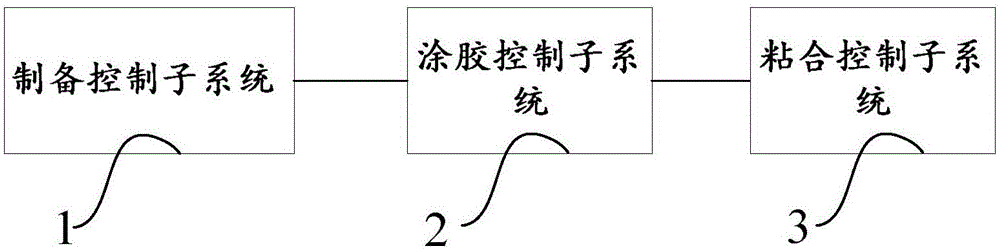

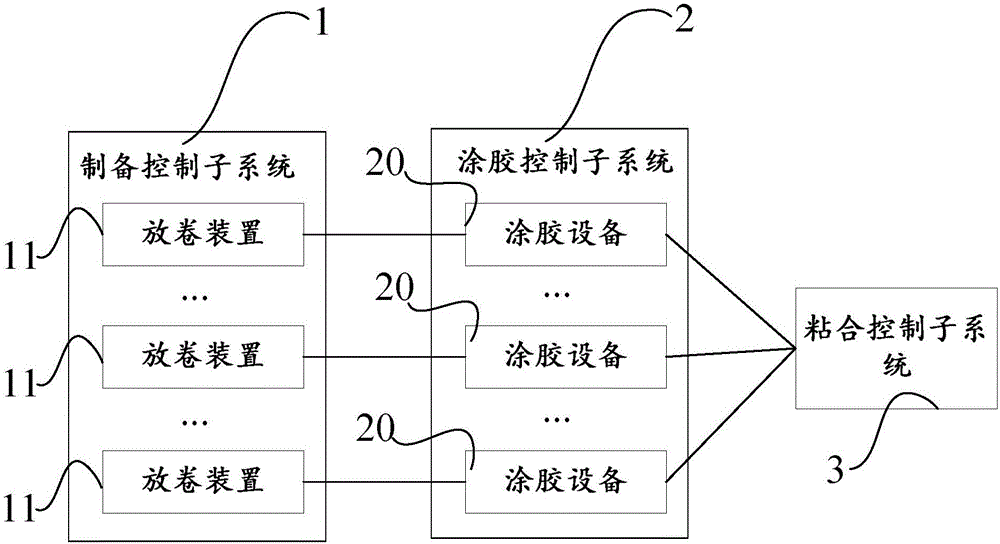

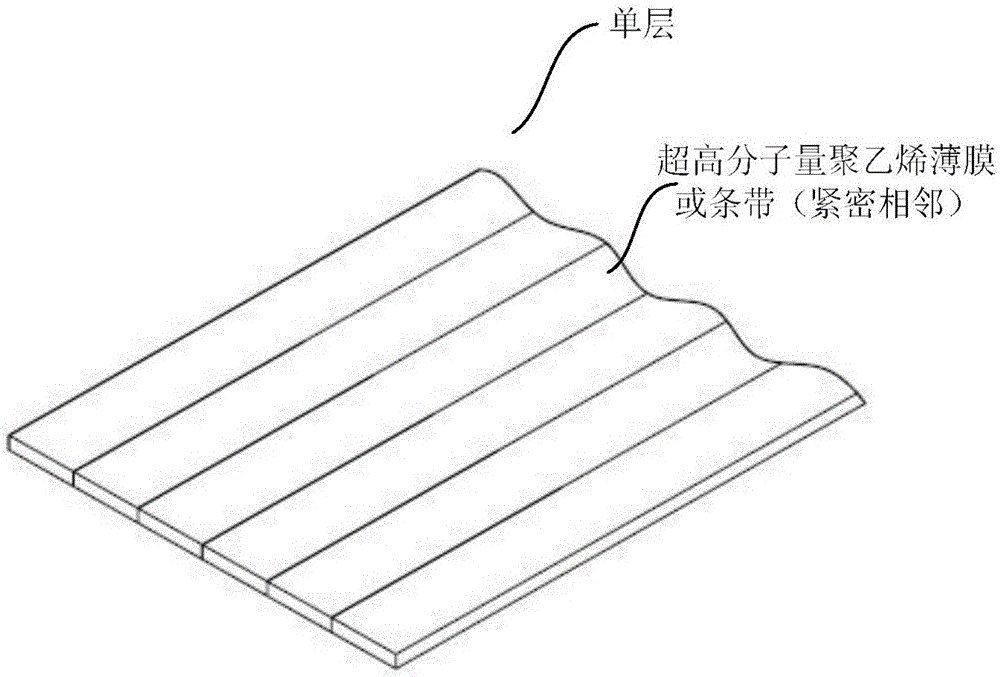

Unidirectional laminate and preparation method thereof as well as system, non-woven fabric and protective product

ActiveCN105620008AImprove integrityImprove rigidityLamination ancillary operationsProtective equipmentWoven fabricEngineering

The invention discloses a unidirectional laminate and a preparation method thereof as well as a system, a non-woven fabric and a protective product. The system comprises a preparation control subsystem, an adhesive-coating control subsystem and an adhesion control subsystem, wherein the preparation control subsystem is used for preparing a plurality of single layers, any one single layer is prepared in a way of continuously spreading a plurality of ultra-high molecular weight polyethylene films or strips, and the adjacent position of the every two continuously-spread ultra-high molecular weight polyethylene films or strips is an adjacent area; the adhesive-coating control subsystem is used for coating at least one surface of at least one single layer with an adhesive; the adhesion control subsystem is used for adhering the single layers into the unidirectional laminate through taking at least one surface coated with the adhesive as an adjacent surface under the conditions that the adjacent areas of one single layer are mutually staggered with the adjacent areas of the adjacent single layer, the single layers are parallel, and any two adjacent single layers are at least locally superposed. The preparation method is simple, easy to implement and high in efficiency; the unidirectional laminate, the non-woven fabric and the protective product have the advantages of being light in weight, good in rigidity and protection performance, and the like, and is wide in application.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

Method for making bulletproof composite materials through aramid fiber non-woven cloth

InactiveCN103526453AGood bulletproofIncreased safety marginFibre typesNon-woven fabricsChemistryEmulsion

The invention provides a method for making bulletproof composite materials through aramid fiber non-woven cloth, and relates to the field of resin modification. A resin composition comprises an acrylate adhesive water solution, ethylene-vinyl acetate copolymer emulsion, cross-linking agents and emulsifying agents. All the components are mixed according to a proper proportion to make a modification adhesive system, and a bulletproof composite plate can be directly made through compression without carrying out secondary adhesive coating on the aramid fiber non-woven cloth prepared through adhesives. Shooting tests indicate that the bulletproof plate made through the aramid fiber non-woven cloth is good in bullet proofing property, high in safety margin, low in weight and capable of obviously improving safety of war fighters.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

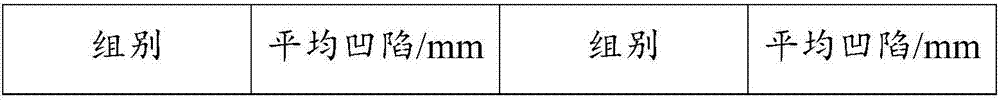

Anti-deformation material and preparation method and application thereof

ActiveCN107059404AImprove deformation resistanceIncrease softnessCarbon fibresBatch productionPenetrating wounds

The invention provides an anti-deformation material and a preparation method and application thereof; the anti-deformation material is anti-deformation UD (unidirectional) structure or fabric structure material prepared by compositing UD structure or fabric structure high-performance fiber and thermosetting resin; the anti-deformation material may give the advantages of fiber to maximum play; by using the thermosetting resin to manufacture UD structure or fabric structure, it is possible to apply the advantages of the thermosetting resin to the anti-deformation material, and the anti-deformation capacity of the anti-deformation material is improved; as fabric structure or UD structure itself is soft and light and thin, the softness of the anti-deformation material is improved. A bulletproof product made with this material has good bulletproof property, and can decrease non-penetrating trauma in human body and provide improved comfort; the preparation method of the anti-deformation material has the advantages of good convenience, good simplicity, good operational simplicity and the like, and is suitable for large-scale batch production and wide range of application.

Owner:BEIJING PROTECH NEW MATERIAL SCI CO LTD

Bulletproof safety tire

InactiveCN101966800AGood bulletproofEasy to useWith separate inflatable insertsTyresVulcanizationDynamic balance

The invention relates to a bulletproof safety tire which comprises a tire body, the inner surface of the tire body is covered by a self-sealing layer, and the outer surface of the sealing layer is covered by an auxiliary shaping layer, wherein the self-sealing layer stays in a half-vulcanization state, and the auxiliary shaping layer stays in a complete vulcanization state. The invention provides a safety tire with good bulletproof performance. The self-sealing layer of the tire has bulletproof performance, and the entire tire body of the tire has bulletproof and puncture-proof functions. When the damage diameter of the tire body is below than 8 mm, the tire body can be free from repairing, and the normal use of the tire can not be influenced. When the damage diameter of the tire body exceeds the range, the tire body can be continuously used after normal repairing. Under the action of the auxiliary shaping layer, the performance of the tire body can also meet dynamic balance in a travelling state of the tire.

Owner:杭州绿奇科技有限公司

Modified phenolic resin semi-impregnation aramid fiber prepreg

ActiveCN102909920AGood flexibilityEasy to useSynthetic resin layered productsPorosityUltimate tensile strength

The invention belongs to the technical field of armor protection materials, relates to a human protection material technology, and in particular relates to a composite material for a bulletproof helmet. According to the modified phenolic resin semi-impregnation aramid fiber prepreg, the bonding strength and toughness of the phenolic resin are adjusted through a modifier, and the matrix resin part is impregnated with aramid fiber. The modified phenolic resin semi-impregnation aramid fiber prepreg consists of a modified phenolic resin and an aramid fiber fabric, wherein the matrix resin part is impregnated with aramid fiber; the impregnation rate is between 5 and 20 percent; and the mass percentage of the resin is between 8 and 18 percent. The prepreg has high glue content uniformity and high flexibility and is convenient to use, and a bulletproof aramid composite material product prepared by the prepreg is low in porosity, light in weight, high in structural strength and excellent in bulletproof performance and is applied to the field of human protection and armor protection.

Owner:SHANDONG NON METALLIC MATERIAL RES INST +1

High-wave-transparent light honeycomb sandwich bulletproof radome

PendingCN110416724AIncrease the relative molecular massThe main chain is well combinedRadiating element housingsFiber layerWave transmission

The invention discloses a high-wave-transparent light honeycomb sandwich bulletproof radome which comprises a radome main body. A concave cover body is in the radome main body, an inner core of the radome main body is a honeycomb layer for supporting, and an ultrahigh molecular weight polyethylene fiber layer for ballistic protection with a matched shape is outside the honeycomb layer. The radomemain body is cylindrical and comprises a side surface portion as a side surface and a bottom surface portion as a bottom surface, the side surface portion has an arc shape which is contracted at two ends of a middle ridge, the bottom surface portion is planar, the bottom surface portion and the side surface portion are connected by arc bending unit, the angle between the bottom surface portion andthe side surface portion is larger than or equal to 90 degrees and smaller than 120 degrees, and the bulletproof radome is made of ultrahigh molecular weight polyethylene as a raw material and has high wave transmission performance and bulletproof performance.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP +1

Composite bulletproof unit material and production method thereof

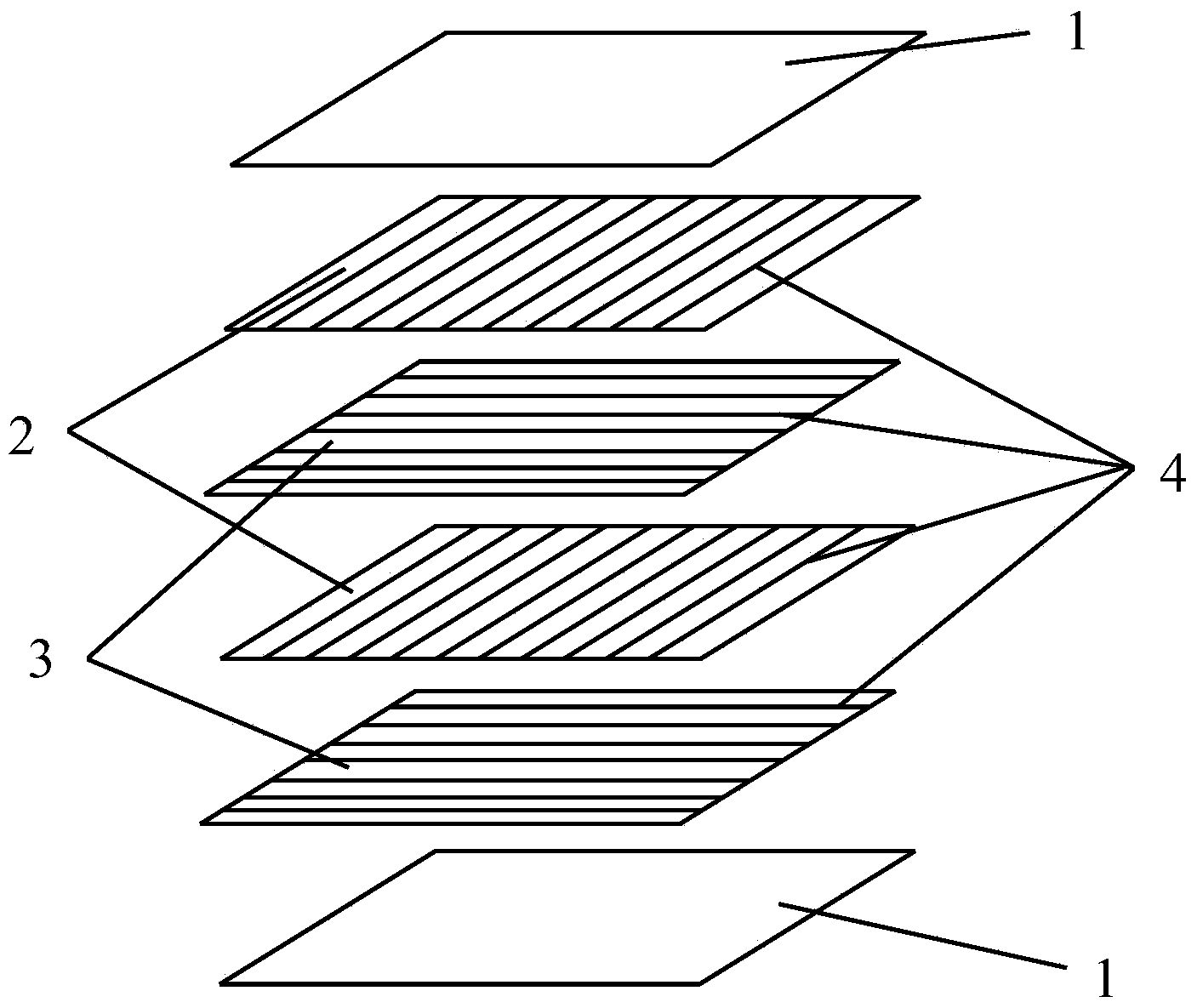

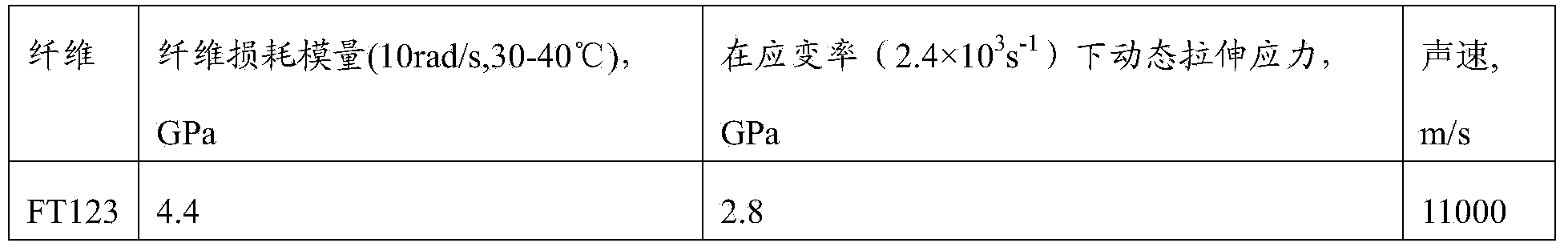

ActiveCN103884238AGood bulletproofProtective equipmentSynthetic resin layered productsOrganic filmFiber

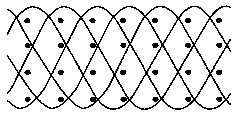

Composite bulletproof unit material is composed of N two-layer unit layers in a crossing manner; N is not smaller than 1 and not larger than 8. Organic films are attached to two sides of the unit layers. The crossing angle of each two adjacent layers is 45-90 degrees. The first layer is made of bulletproof fiber unidirectional tapes wrapped in first resin adhesive; the second layer is made of bulletproof fiber unidirectional tapes wrapped in second resin adhesive; tensile modulus of the first resin adhesive is lower than 6MPa, and the tensile modulus of the second resin adhesive is higher than 6MPa; loss modulus of the first and second resin adhesives is equal to that of bulletproof fiber at 30-40 DEG C under the same test frequency and strain value. When strain sensitivity of the bulletproof fiber is 2.4*10<3>s<-1>, dynamic tensile stress is at least 2.4GPa, and acoustic wave conduction speed is at least 1000mm / s. Two resin adhesives are applied to the adjacent layers, a bulletproof product of the composite bulletproof unit material has moderate softness and hardness and excellent bulletproof property.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

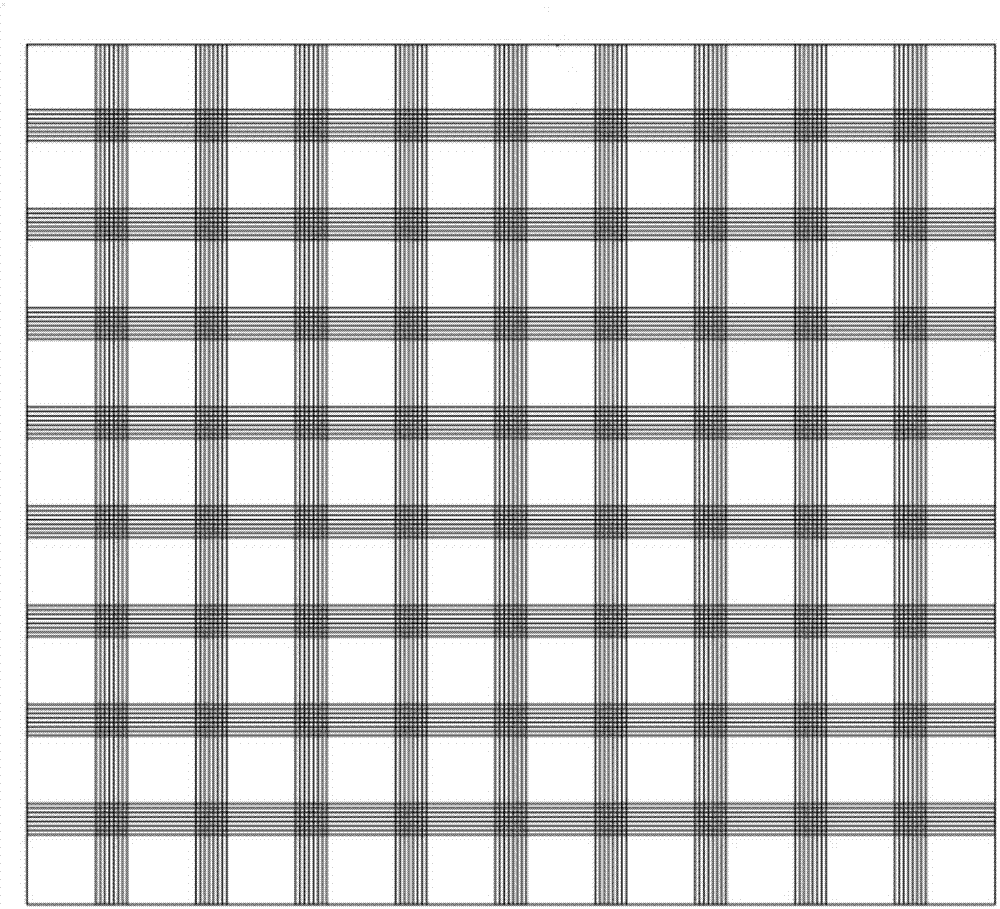

Bulletproof fabric and method for producing the same

ActiveCN103764898AAvoid harmDoes not affect the sense of wearingArmourFibre treatmentPolyvinyl acetateAramides

Disclosed are a bulletproof fabric and a method for producing the same that exhibit improved anti-traumaproperty and minimize deterioration in bulletproofness even after use under harsh conditions for a long period of time. The bulletproof fabric includes a fabric comprising at least one high-strength fiber selected from the group consisting of a high molecular weight polyethylene fiber, an aramid fiber, and a polybenzoxazole fiber, and a water repellent layer disposed on the high-strength fiber, wherein the water repellent layer is formed by treating the fabric with a water-repellent agent comprising fluorocarbon and a hardness-enhancing resin, and the hardness-enhancing resin is a polyvinyl acetate resin, a polyester resin, a polyacrylate resin, a melamine resin, or a mixture of two or more thereof.

Owner:KOLON IND INC

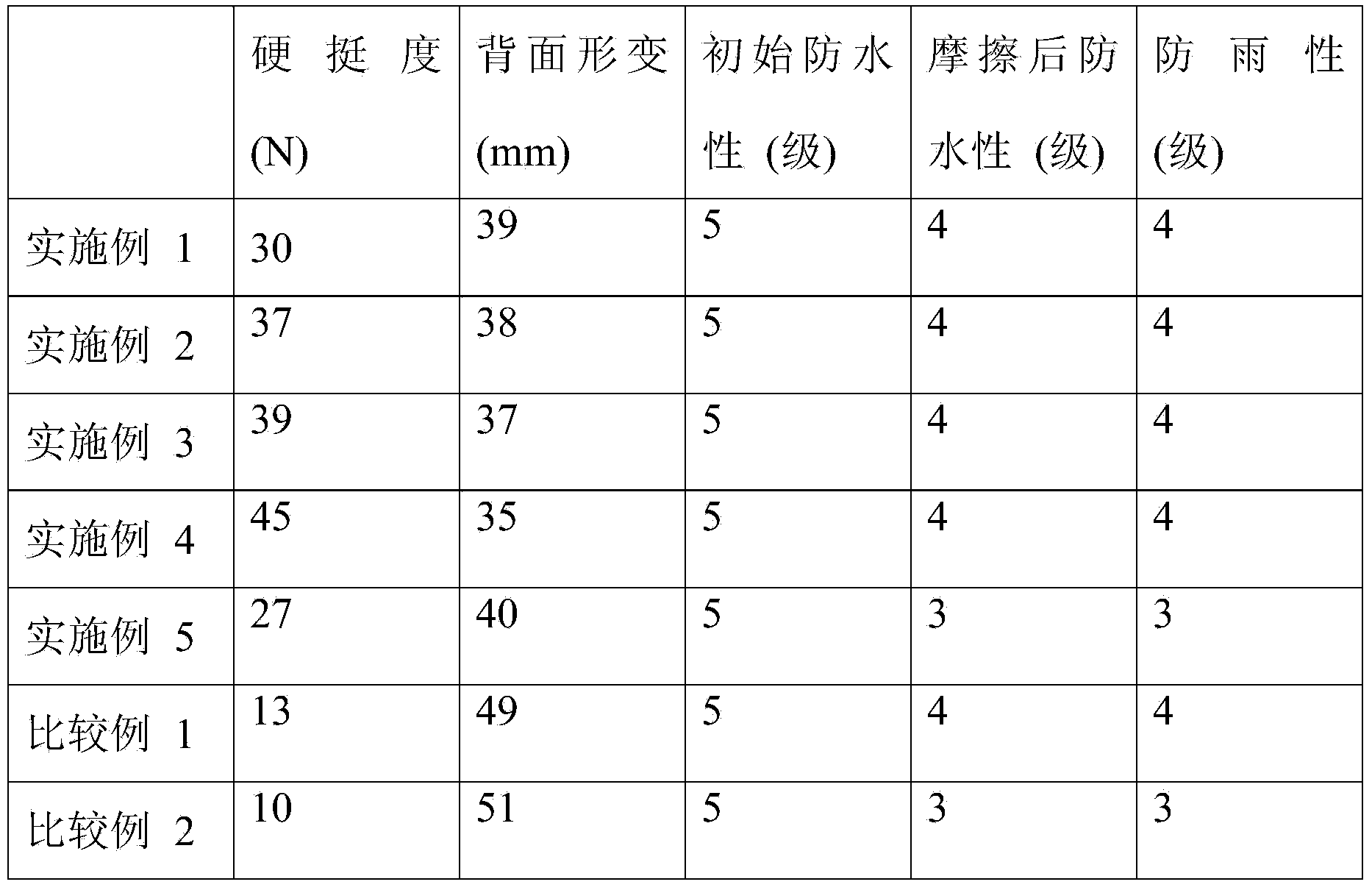

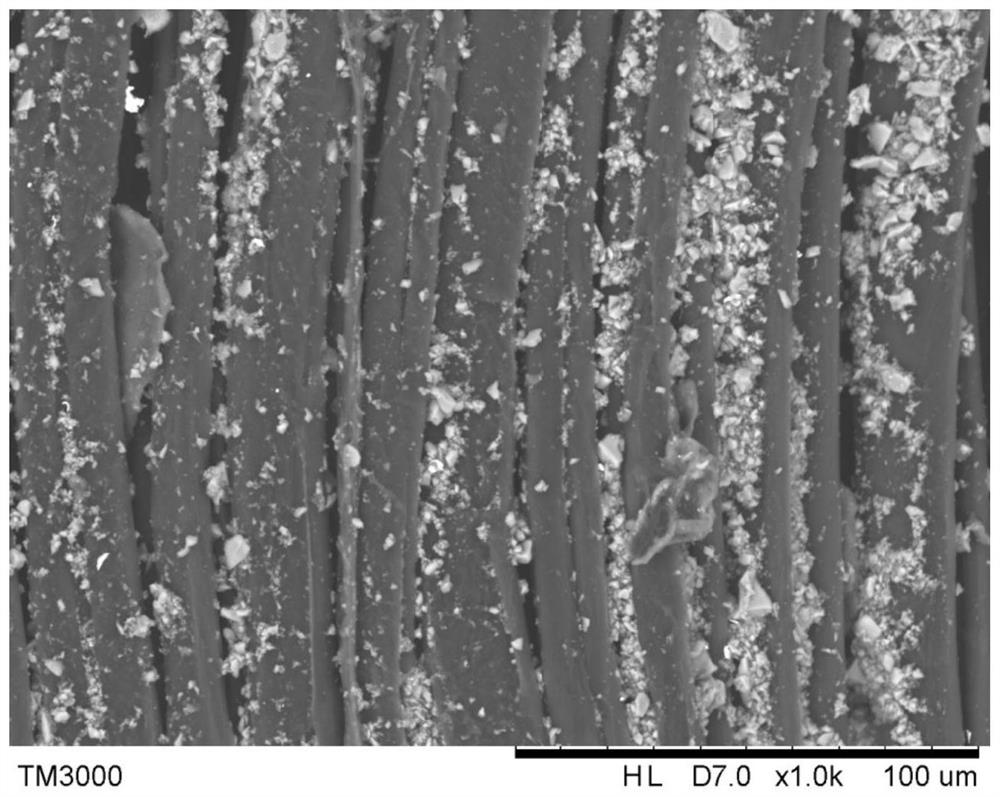

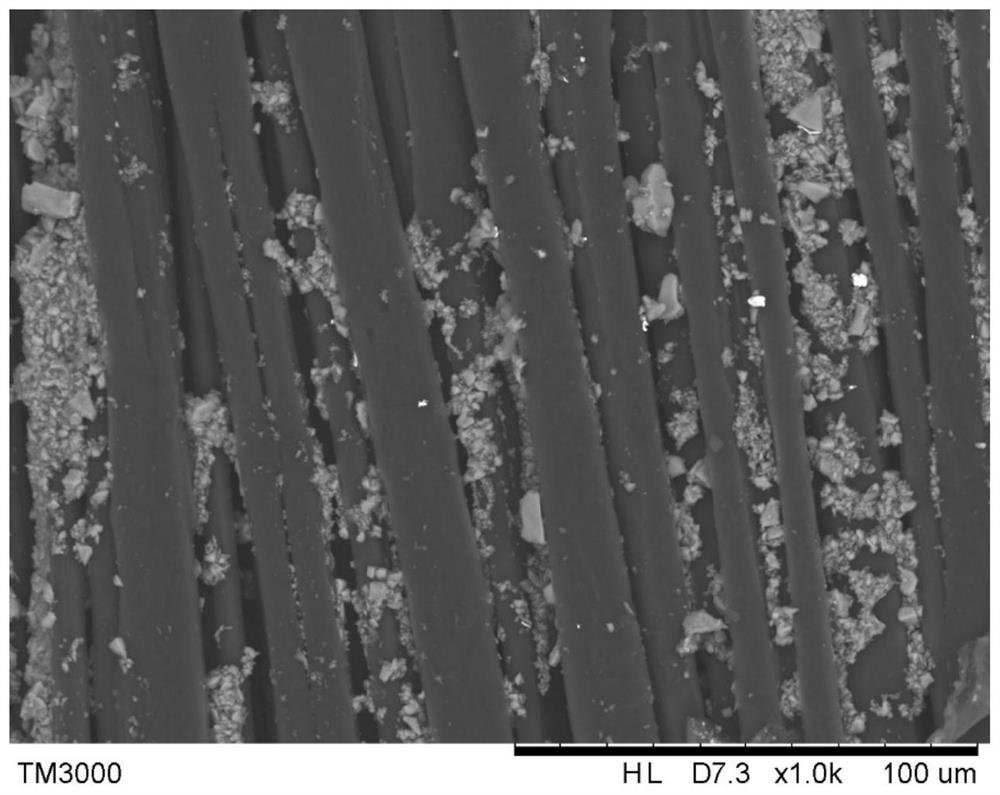

Flexible protective composite material and manufacturing method thereof

InactiveCN112900105AWith bulletproof and sharp edgeIncreased interfacial shear strengthDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentUHMWPE polyethylenePlasma treatment

The invention relates to the technical field of composite materials, and particularly discloses a flexible protective composite material. The flexible protective composite material is obtained by adopting an ultra-high molecular weight polyethylene fabric subjected to plasma treatment as a matrix and uniformly adhering a shear thickening liquid to the matrix. According to the flexible protective composite material provided by the invention, the ultra-high molecular weight polyethylene fabric is treated with the plasma treatment technology, so that the surface performance of the ultra-high molecular weight polyethylene fabric can be effectively improved, the adhesive force and the bonding performance of a dispersion in the shear thickening liquid on the surface of the ultra-high molecular weight polyethylene fabric are improved, and under the condition that the layer number and the weight of the ultra-high molecular weight polyethylene fabric are not increased, the protection performance and the flexibility of the protective composite material are effectively improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

UHMWPE fiber reinforced resin-based soft bulletproof material

PendingCN111267429AGood bulletproofBack convex depth is smallProtective equipmentSynthetic resin layered productsFiberPolymer science

The invention provides a UHMWPE fiber reinforced resin-based soft bulletproof material, and relates to the technical field of protective equipment. The soft bulletproof material comprises a middle layer, a bullet facing surface layer overlaid on the surface of one side of the middle layer, and a bullet backing surface layer overlaid on the surface of the other side of the middle layer. The woven composite material is used as a bullet-facing surface layer material and a bullet-backing surface layer material of the soft bulletproof material, and the woven composite material is formed by making UHMWPE fibers into plain cloth or twill cloth and then hot-pressing and compounding the plain cloth or twill cloth and a hot-melt resin adhesive film. A plurality of UD sheets are used as middle layermaterials, each UD sheet is formed by hot-pressing and compounding a plurality of layers of UD single sheets, every two adjacent layers of UD single sheets are orthogonally arranged, and each UD single sheet is prepared from UHMWPE fibers and thermoplastic resin according to a UD cloth forming method. The soft bulletproof material is light in weight and has excellent bulletproof performance.

Owner:NANTONG UNIVERSITY

Armor plate for C-level securicar and preparation method thereof

InactiveCN106148824AGuaranteed mechanical propertiesGuaranteed mechanical properties, i.e. strengthChemical compositionMetallurgy

The invention belongs to the technical field of armor plate production and particularly relates to an armor plate for a C-level securicar and a preparation method thereof. In the armor plate for the C-level securicar, the armor plate smelting chemical composition comprises the following components in percentage by weight: 0.22-0.24% of C, 0.12-0.20% of Si, 1.02-1.20% of Mn, less than or equal to 0.007% of P, less than or equal to 0.003% of S, 0.020-0.030% of Alt, 0.25-0.35% of Cr, 0.10-0.15% of Mo, 0.015-0.025% of Ti, less than or equal to 10ppm of [O], less than equal to 12ppm of [N], less than or equal to 2ppm of [H] and the balance of Fe and unavoidable impurities. The armor plate has excellent bulletproof property, relatively high purity and good shape and facilitates welding.

Owner:SHANDONG IRON & STEEL CO LTD

Preparation method of ultra-high molecular weight polyethylene three-dimensional fabric

The invention provides a preparation method of an ultra-high molecular weight polyethylene three-dimensional fabric. The method comprises the steps of fiber preparation, fiber bundling, beaming, knitting, taking-down and edge finishing so as to weave the ultra-high molecular weight polyethylene three-dimensional fabric, wherein the ultra-high molecular weight polyethylene three-dimensional fabricis a prefabricated member, the good anti-elastic performance is achieved after a composite material is manufactured, when the ultra-high molecular weight polyethylene three-dimensional fabric is subjected to impact of external force, the good connection between fiber structure is achieved, the impact force is dispersed, penetration of bullets and shrapnel can be effectively avoided, and the fabrichas the good bulletproof performance for the human body or armored cars.

Owner:长青藤高性能纤维材料有限公司

Aramid fiber bulletproof shield manufacturing method

InactiveCN103837041AGood bulletproofIncreased safety marginLaminationLamination apparatusSizingSafety margin

The invention provides an aramid fiber bulletproof shield manufacturing method and relates to the field of individual protection. In the aramid fiber bulletproof shield manufacturing, an aramid fiber non-weft fabric, the manufacturing method, a bulletproof shield manufacturing process and the like are adopted. Aramid fiber are subjected to fiber expanding, sizing and drying and then directly pressed to manufacture a bulletproof shield. A target practice test proves that the bulletproof shield manufactured by adopting the method is excellent in performance, high in safety margin and light in weight and can obviously improve the fighting efficiency of fighters.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

Preparation method of cold-forming titanium alloy bulletproof helmet

The invention discloses a preparation method of a cold-forming titanium alloy bulletproof helmet. The preparation method comprises the steps of 1, coating the surface of a TB5 or TB8 titanium alloy plate with an anti-oxidation coating, then, conducting solution treatment above the phase transformation point, and putting the TB5 or TB8 titanium alloy plate on an asbestos pad for air cooling after delivering the TB5 or TB8 titanium alloy plate out of a furnace; 2, cutting the TB5 or TB8 titanium alloy plate obtained after air cooling into a round plate, then, applying a lubricating agent, and then, conducting two passes of cold drawing forming, so that a bulletproof helmet shell blank is obtained; and 3, after edge cutting of the bulletproof helmet shell blank is completed, conducting agingtreatment and air cooling, so that the bulletproof helmet is obtained. According to the preparation method, the high-strength TB5 titanium alloy plate or TB8 titanium alloy plate serves as a raw material; solution treatment above the phase transformation point, the two passes of cold drawing forming and aging treatment are sequentially adopted, so that the cold forming titanium alloy bulletproof helmet is obtained; the yield of the helmet is increased, and strength and hardness of the helmet are improved; and on the basis that the protection effect of the bulletproof helmet is guaranteed, themachining flow is shortened and simplified, and the machining cost is lowered.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Application of carbon nanotube aggregates to preparation of bulletproof composite and preparation method of bulletproof composite

ActiveCN107024146ALow densityImprove impact resistanceSynthetic resin layered productsPersonal protection gearWeather resistanceCarbon nanotube

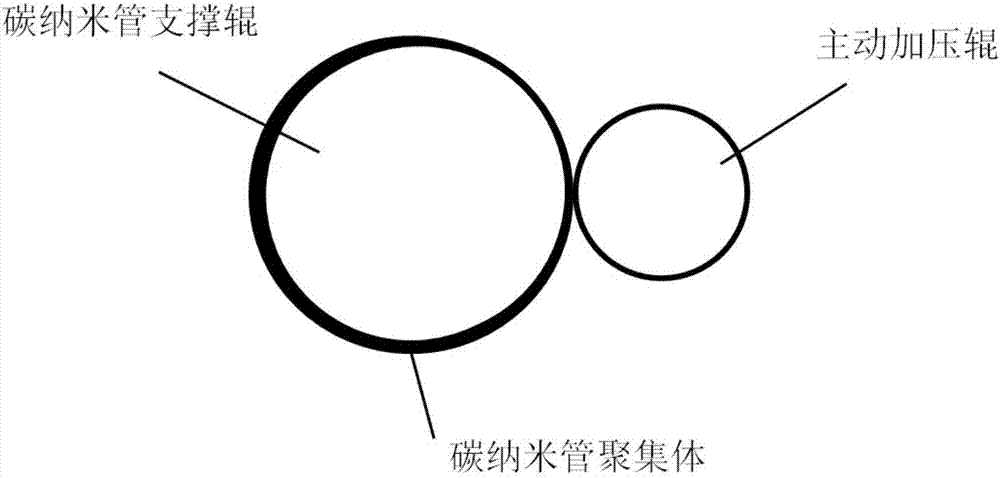

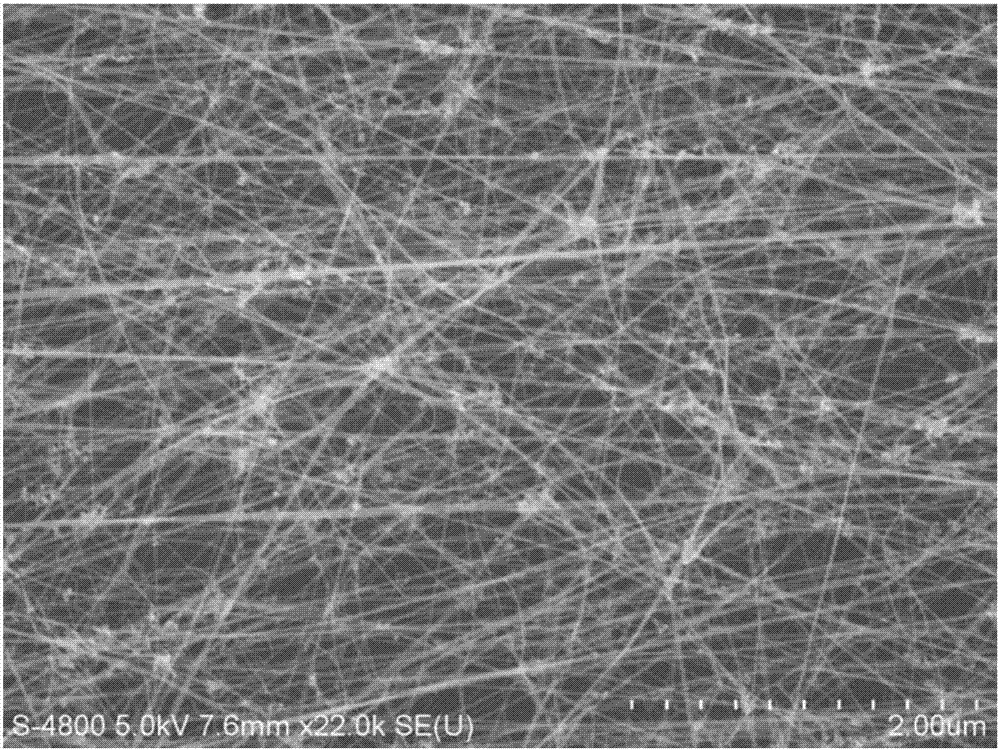

The invention discloses application of carbon nanotube aggregates to preparation of a bulletproof composite. The bulletproof composite comprises at least one carbon nanotube aggregate and fabric, wherein each carbon nanotube aggregate is provided with a macroscopic two-dimensional planar structure formed by densely gathering multiple carbon nanotubes, and the surface of at least one side of the fabric is covered with at lease one carbon nanotube aggregate. Each carbon nanotube aggregate comprises multiple oriented foundation units densely distributed in a continuous plane, wherein each foundation unit is provided with a three-dimensional planar structure formed by interweaving the carbon nanotubes, and each carbon nanotube aggregate is in the macroscopic ordered and microcosmic unordered state. The invention further discloses a preparation method of the bulletproof composite. The bulletproof composite has the beneficial effects of being light, thin, good in environment weather resistance, excellent in bulletproof performance, suitable for batched preparation, good in flexibility, capable of being attached to the human body at any curved surface and the like.

Owner:深圳前海量子翼纳米碳科技有限公司

Preparation method of light high-strength composite splinter-proof plate

InactiveCN106891012AGood mechanical propertiesGood impact resistanceCeramic shaping apparatusArmour platesWood splinterSilicon nitride

The invention discloses a preparation method of a light high-strength composite splinter-proof plate. The preparation method comprises the following steps that Al-Si alloy powder and titanium hydride powder are weighed, mixed and stirred for 8-20 h, and mixed powder is prepared; two parts of 3003Al alloy powder are weighed; silicon nitride powder with the granularity being 200 meshes is weighed; a mold is assembled and filled with silicon nitride / aluminum oxide / magnesium oxide mixed powder, sintering is carried out, and a silicon nitride layer material is prepared; the mold is sequentially filled with the alloy powder, the mixed powder and the alloy powder and then placed into a hot press to be subjected to hot pressing treatment, and a laminboard preformed part is obtained; the laminboard preformed part is placed into a well-heated heating furnace to be heated and foamed, and a foam aluminum laminboard is obtained; and the prepared silicon nitride layer material and foam aluminum laminboard are bonded through epoxy resin adhesive, and the light high-strength composite splinter-proof plate is prepared. The light high-strength composite splinter-proof plate is good in splinter-proof performance and excellent in mechanical performance.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

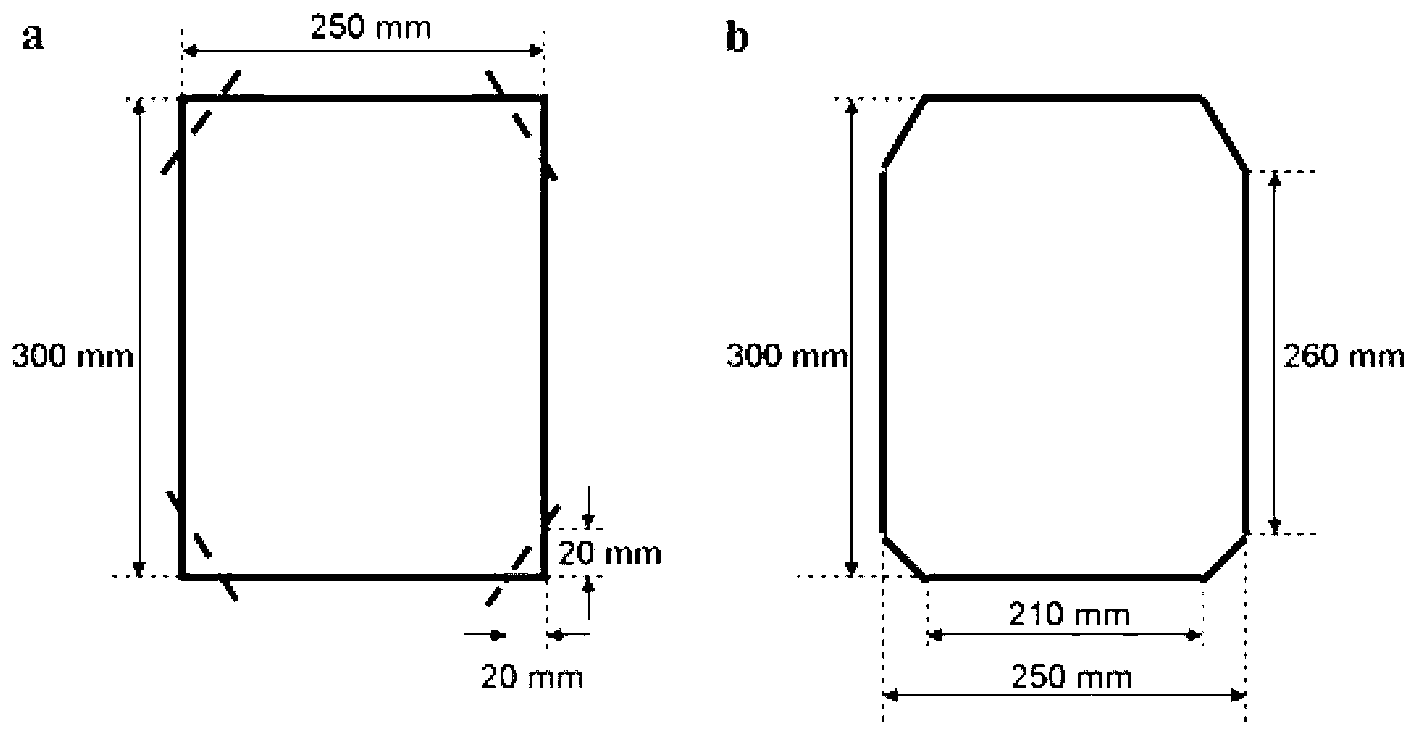

Steel plate for shield and preparation method thereof

The invention discloses a steel plate for a shield and a preparation method thereof and belongs to the technical field of steel plate production. The steel plate comprises the chemical components of, by weight, 0.35-0.43% of C, 0.20-0.40% of Si, 1.2-1.5% of Mn, 0.02-0.04% of Ti, 0.01-0.06% of Al, 0-0.4% of Ni, 0-0.5% of Cr, 0.01% of P or the less, 0.004% of S or the less, 0.008% of N or the less, 0.0010-0.0030% of B and the balance Fe and inevitable impurities. According to the steel plate for the shield and the preparation method thereof, the strength grade of the steel plate reaches 1500 MPa, good cold forming performance and excellent bulletproof performance are achieved, and the steel plate and the preparation method thereof are suitable for production of the shield.

Owner:SHOUGANG CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com