Preparation method and application of resin composition for thermosetting aramid bulletproof composite material

A technology of bulletproof composite material and resin composition, which is applied in the field of modified phenolic resin composition and its preparation, which can solve the problems of brittle fracture, unfavorable bullet ability, and fiber cloth binding of products, and improve flexibility and bonding high safety margin and excellent bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, weigh 110g polyvinyl butyral resin and 890g ethanol respectively, slowly add polyvinyl butyral resin to the ethanol solution and keep stirring, after the polyvinyl butyral resin is completely dissolved, weigh the total amount of the solution Weight, calculate the difference between the two total weights, and continue to add the ethanol weight of the two differences to the solution, mix well, and make 11% polyvinyl butyral resin solution for subsequent use.

[0031] Weigh 250g of phenolic resin, 500g of the above-mentioned polyvinyl butyral solution resin solution, 100g of dioctyl phthalate, 100g of epoxy resin, 30g of silane coupling agent and 20g of phosphoric acid, add them into a beaker and mix well to get the modified Resin solution.

[0032] Apply the above-mentioned modified resin solution evenly on the surface of the aramid fabric. After the resin is dried, cut the prepreg into a square of 300mm×300mm, stack 17 layers of fabric samples, and laminate them o...

Embodiment 2

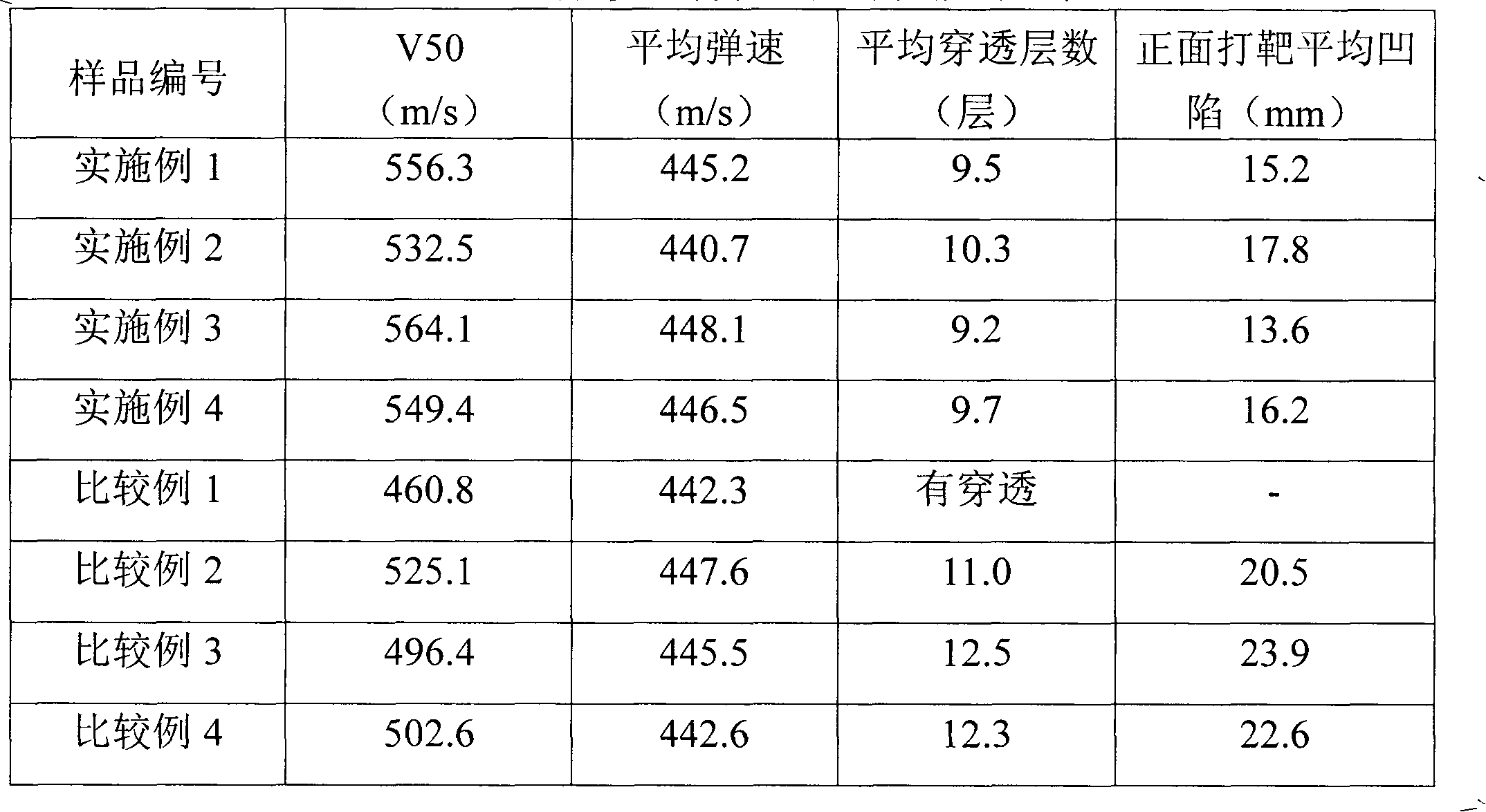

[0034] The phenolic resin in embodiment 1 is changed into 500g, polyvinyl butyral solution resin solution is changed into 300g, all the other conditions are identical with embodiment 1. Use a uzi submachine gun and 9mm Pakistani bullet (lead core bullet) to test according to the NIJ0101.04 standard of the US Department of Justice. The ballistic performance test was carried out, and the results are shown in Table 1.

Embodiment 3

[0036] Change phenolic resin into 300g in embodiment 1, change polyvinyl butyral solution resin solution into 420g, change dioctyl phthalate into 150g, change epoxy resin into 80g, all the other conditions are identical with embodiment 1. Use a uzi submachine gun and 9mm Pakistani bullet (lead core bullet) to test according to the NIJ0101.04 standard of the US Department of Justice. The ballistic performance test was carried out, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com