Anti-deformation material and preparation method and application thereof

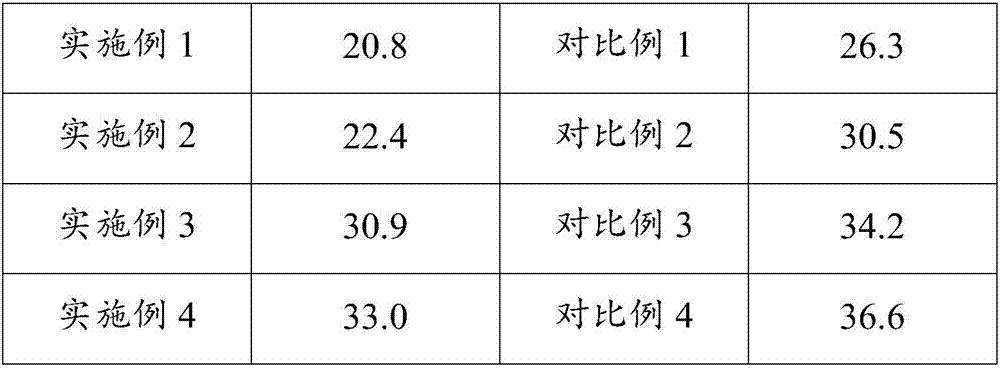

A technology of anti-deformation and high-performance fibers, which is applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve the problems of soft materials and small dent depths, and bulletproof materials can not be taken into account, so as to improve the anti-deformation ability and reduce non-destructive Penetrating injuries, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

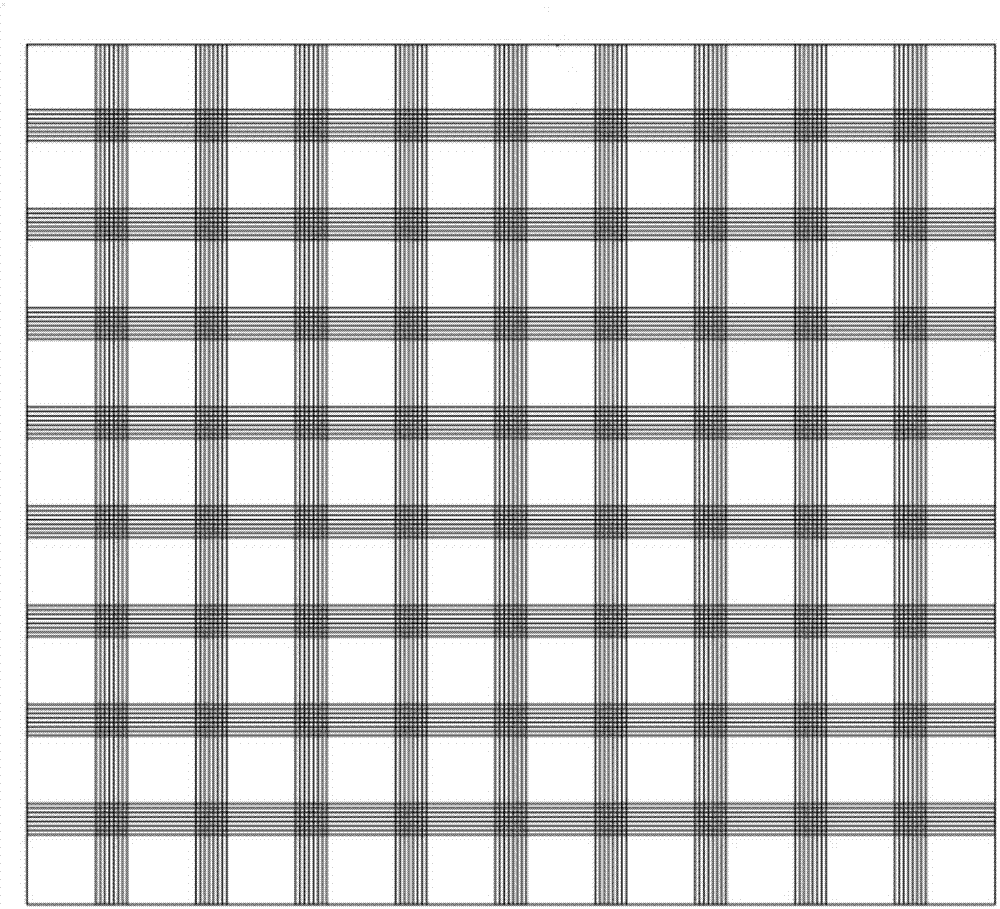

[0056] The preparation method of the anti-deformation material includes the following steps: spreading one or more high-performance fibers into a UD structure or weaving a fiber cloth with a fabric structure according to the arrangement of the grid structure, and then by solution impregnation method, the The thermosetting resin is combined with the fiber cloth to obtain a deformation-resistant UD structure or fabric structure material with a grid structure.

[0057] The application of the anti-deformation material in protective armors such as soft bulletproof vests, bulletproof chest plates, bulletproof helmets, and bulletproof vehicles.

Embodiment 1

[0059] The carbon fiber is used as the grid structure material, and the aramid fiber is prepared into a fiber cloth with a UD structure, and then the epoxy resin is combined with the fiber cloth by a solution impregnation method to obtain an aramid-carbon fiber-ring structure with a grid structure. Oxygen resin anti-deformation UD material.

Embodiment 2

[0061] The carbon fiber is used as the grid structure material, and the aramid fiber is prepared into a fiber cloth with a fabric structure, and then the epoxy resin is combined with the fiber cloth by a solution impregnation method to obtain an aramid-carbon fiber-ring with a grid structure. Oxygen resin anti-deformation fabric material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com