Flexible protective composite material and manufacturing method thereof

A composite material and flexible protection technology, applied in the direction of protective equipment, dry-cleaning fiber products, personnel protection equipment, etc., can solve the problems that affect the application effect of composite materials, low surface energy of high-performance fibers, and failure to achieve protective effects, etc., to achieve good Protective effect, improved wetting performance, effect of increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] To make a flexible protective composite:

[0031] 1. Prepare a shear thickening solution with a mass fraction of 70%

[0032] Use a balance to weigh SiO with an average particle size of 650nm 2 70g of nanoparticles, 30g of polyethylene glycol (PEG200) with a molecular weight of 200.

[0033] In order to quickly and efficiently disperse uniformly, a high-speed disperser is used to disperse at a rate of 2800r / min, and the temperature is room temperature. 2 Nanoparticles were added to PEG200 several times in small amounts, and added again when dispersed until there was no obvious precipitation or particles. When SiO 2 When the mass concentration of nanoparticles reaches 35%, use an electric stirrer for dispersion treatment, the dispersion rate is 800r / min, and the temperature is room temperature until all of them are added. Then alternately carry out ultrasonic oscillation and stirring treatment, the frequency of each ultrasonic oscillation is 40kHz, the time is 30min, ...

Embodiment 2

[0046] 1. For the flexible protective composite material obtained in Example 1, calculate SiO 2 Attachment of nanoparticles.

[0047] SiO 2 Adhesion amount of nanoparticles=(weight of flexible protective composite material-fabric weight after plasma treatment) / fabric weight after plasma treatment×100%.

[0048] After measurement and calculation, SiO in the obtained flexible protective composite 2 The attachment amount of nanoparticles reached 44.74%, compared with the SiO 2 The attachment amount of nanoparticles (27.68%) increased by 61.2%.

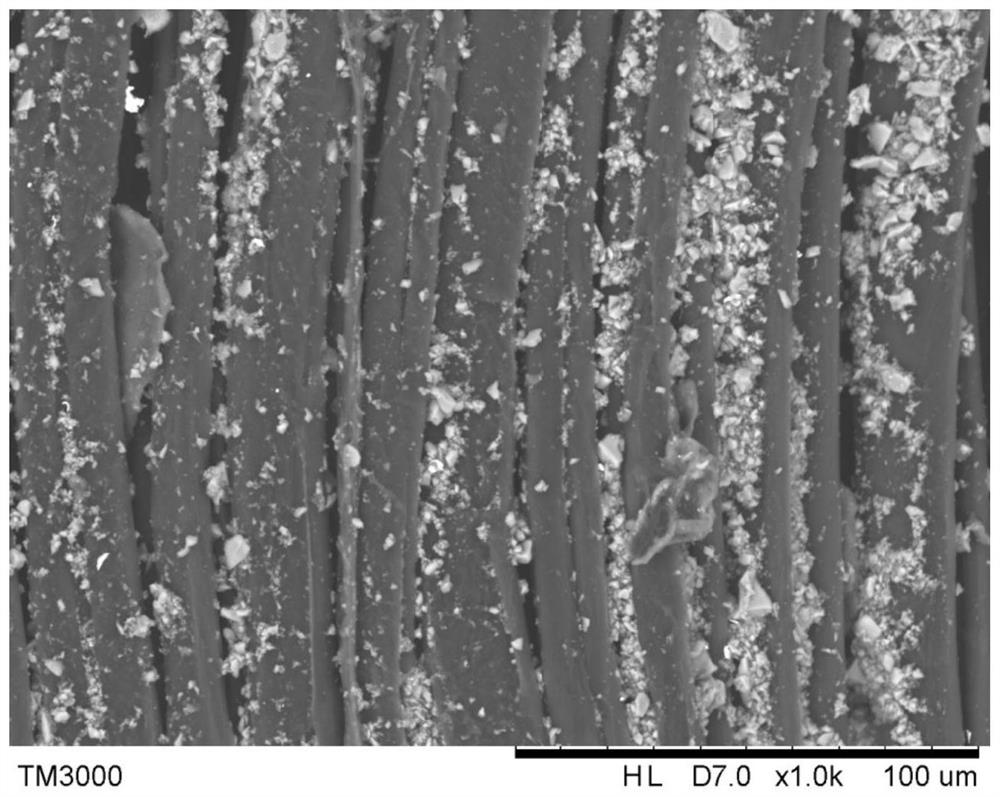

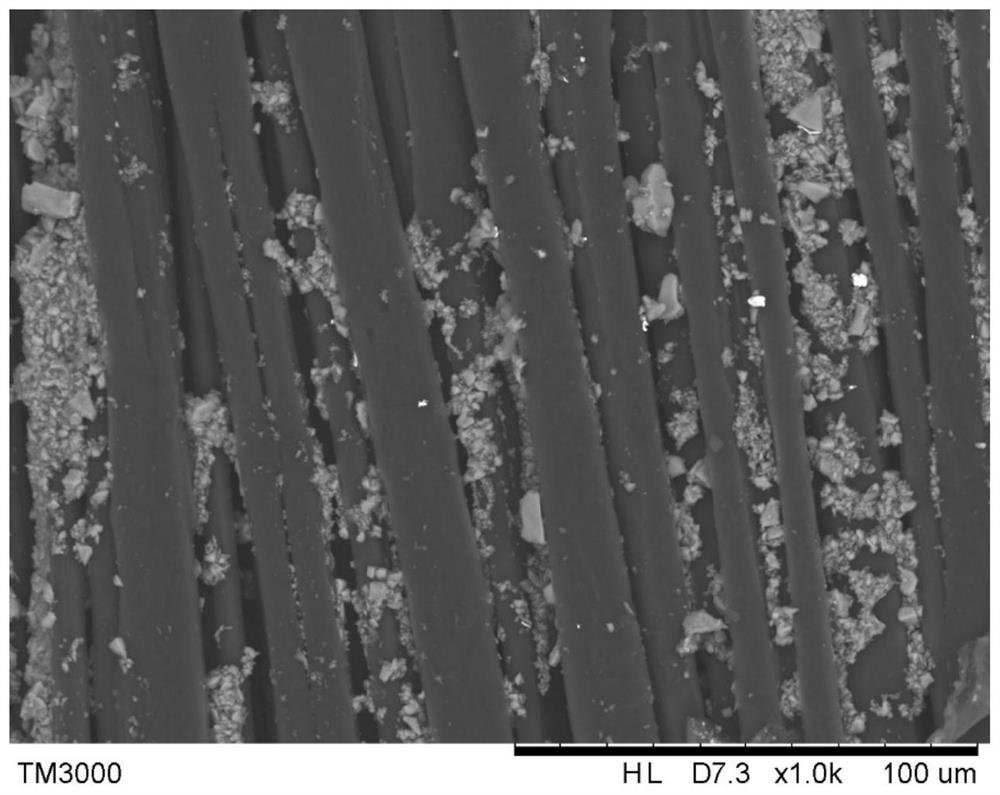

[0049] The obtained flexible protective composite material is subjected to scanning electron microscope observation, and the obtained scanning electron microscope picture is as follows: figure 1 shown. The scanning electron microscope image of the composite material obtained from the ultra-high molecular weight polyethylene fabric without plasma treatment is as follows figure 2 shown

[0050] 2. Drop hammer impact test

[0051] ...

Embodiment 3

[0056] To make a flexible protective composite:

[0057] 1. Prepare a shear thickening solution with a mass fraction of 65%

[0058] Use a balance to weigh SiO with an average particle size of 600nm 2 65g of nanoparticles, 35g of polyethylene glycol (PEG200) with a molecular weight of 200.

[0059] In order to quickly and efficiently disperse uniformly, a high-speed disperser is used to disperse at a rate of 2500r / min, and the temperature is room temperature. 2 Nanoparticles were added to PEG200 several times in small amounts, and added again when dispersed until there was no obvious precipitation or particles. When SiO 2 When the mass concentration of nanoparticles reaches 35%, use an electric stirrer for dispersion treatment, the dispersion rate is 600r / min, and the temperature is room temperature until all of them are added. Then alternately carry out ultrasonic oscillation and stirring treatment, the frequency of each ultrasonic oscillation is 35kHz, the time is 25min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com