Preparation method of ultra-high molecular weight polyethylene three-dimensional fabric

An ultra-high molecular weight, three-dimensional fabric technology, applied in the field of preparation of ultra-high molecular weight polyethylene three-dimensional fabrics, can solve the problems of insufficient fiber sheet connectivity, insufficient impact resistance, poor ballistic resistance, etc., so as to improve the interlayer performance and Effect of damage tolerance, good overall formability, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0033] This example provides a method for preparing an ultra-high molecular weight polyethylene three-dimensional fabric, with a breaking strength of 32 cN / dtex, a breaking modulus of 1200 cN / dtex, an elongation at break of 2.78%, and a linear density of 3200D.

[0034] (2) Add 90 twists to the ultra-high molecular weight polyethylene fiber, and separate 80 small rolls, each small roll is 0.5kg;

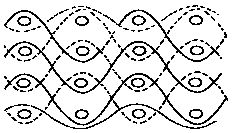

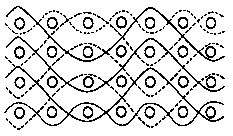

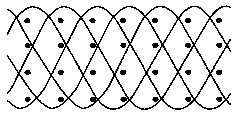

[0035] (3) Arrange the small rolls on both sides of the wire frame in a 10×4 pattern; and wind them on the guide rollers through the wire mesh, layered frame, heald frame, and heald reed.

[0036] (4) Start the computer, turn on the weaving system, input the deep cross-link pattern, set the weft d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com