Aluminum-silicon carbide composite ceramic materials and preparation method and application thereof

A technology of silicon carbide ceramics and composite ceramics, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of poor bulletproof ability of composite bulletproof boards and reduced weight of bulletproof boards, and achieve excellent bulletproof performance , to ensure the mobility requirements, and the effect of excellent bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

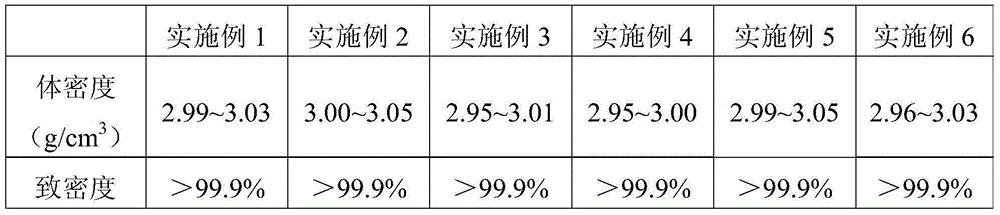

Examples

Embodiment 1

[0029] A method for preparing an aluminum-silicon carbide composite ceramic material, comprising the following steps:

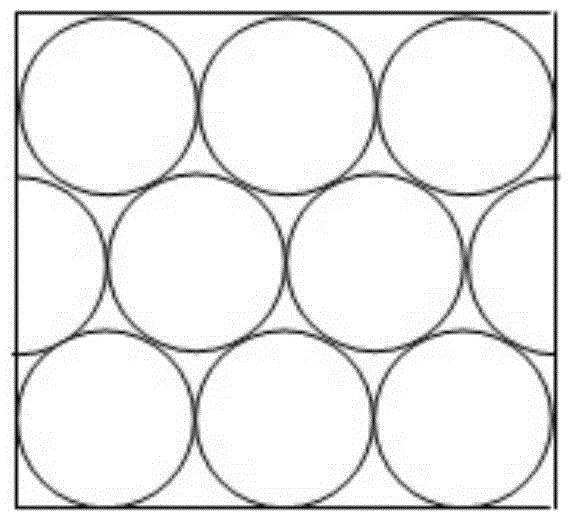

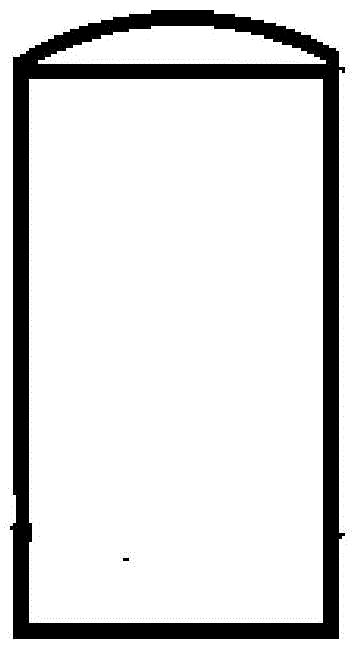

[0030] (1) 90g of titanium metal powder with a purity of 99% and a particle size of 20-60 μm and 210 g of TiO with a purity of 99.5% and a particle size of 40-100 μm 2 Mix the powder evenly, put it into a graphite container, and then disperse and embed 8 cylindrical pressureless sintered silicon carbide and 2 semi-cylindrical pressureless sintered silicon carbide into the mixed powder. The outer dimension of each silicon carbide is columnar Type, the main body size is Φ8mm×12mm, one end of the cylinder is a plane, the other end is a spherical crown with a diameter of 25mm and a height of 2mm, its structure is as follows figure 2 shown;

[0031] (2) Put the above mixture together into a vacuum furnace and keep the vacuum degree to 2×10 -3 Pa or above, heat up to 1000°C for 2 hours, and after cooling in the furnace, take out and clean the surface of the cera...

Embodiment 2

[0036] A method for preparing an aluminum-silicon carbide composite ceramic material, comprising the following steps:

[0037] (1) Mix 120g of titanium metal powder with a purity of 99% and a particle size of 20 to 60 μm with 180 g of TiO with a purity of 99.5% and a particle size of 40 to 100 μm 2 Mix the powder evenly and put it into a graphite container; then disperse and embed 8 cylindrical reaction-sintered silicon carbide and 2 semi-cylindrical reaction-sintered silicon carbide into the mixed powder. The outer dimension of each silicon carbide is columnar, The main body size is Φ12mm×10mm, one end of the cylinder is a plane, and the other end is a spherical crown with a diameter of 28mm and a height of 3mm;

[0038] (2) Put the above mixture together into a vacuum furnace and keep the vacuum degree to 2×10 -3 Pa or above, heat up to 1100°C for 1 hour, and after cooling with the furnace, take out and clean the surface of the ceramic particles to obtain silicon carbide ce...

Embodiment 3

[0043] An aluminum-silicon carbide composite ceramic material, including 13 closely arranged silicon carbide ceramics, the surface of the silicon carbide ceramics is coated with a 1 μm metal titanium layer, aluminum alloy melt is poured between each silicon carbide ceramics and combined into a whole, aluminum alloy -Silicon carbide composite ceramic material is prepared by the following steps:

[0044] (1) 240g of pure titanium powder with a particle size of 20μm and 60g of TiO with a particle size of 40μm 2 Mix the powder evenly, put it into a ceramic crucible to obtain a mixed powder, then disperse and embed 11 reaction-sintered cylindrical silicon carbide ceramics and 2 reaction-sintered semi-cylindrical silicon carbide ceramics into the mixed powder to obtain The main body size of the mixture, cylindrical silicon carbide ceramics and semi-cylindrical silicon carbide ceramics is Φ5mm×8mm, one end of the cylindrical silicon carbide ceramics is a plane, the other end is a spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com