Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Give full play to the catalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam metal hydrogenating catalyst and its preparing method and use

ActiveCN1781595ALow densityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPorosityChemical plating

The present invention discloses hydrogenating catalyst of foam metal and its preparation process and application. The hydrogenating catalyst includes foamed metal carrier and active noble metal component in effective amount supported onto the carrier, the carrier is prepared through powder metallurgical process, and the active component is supported via chemical plating process and distributed homogeneously on the port surfaces of the foamed carrier. The catalyst has the advantages of high catalytic activity, firm combination between the active component and the carrier, high stability, simple preparation process, high porosity of the carrier, great specific surface area, etc. in addition, the catalyst provides sufficient gas-liquid contact area, is favorable to mass transfer between gas phase and liquid phase, may be used in catalytic rectification and possesses both reaction and separation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

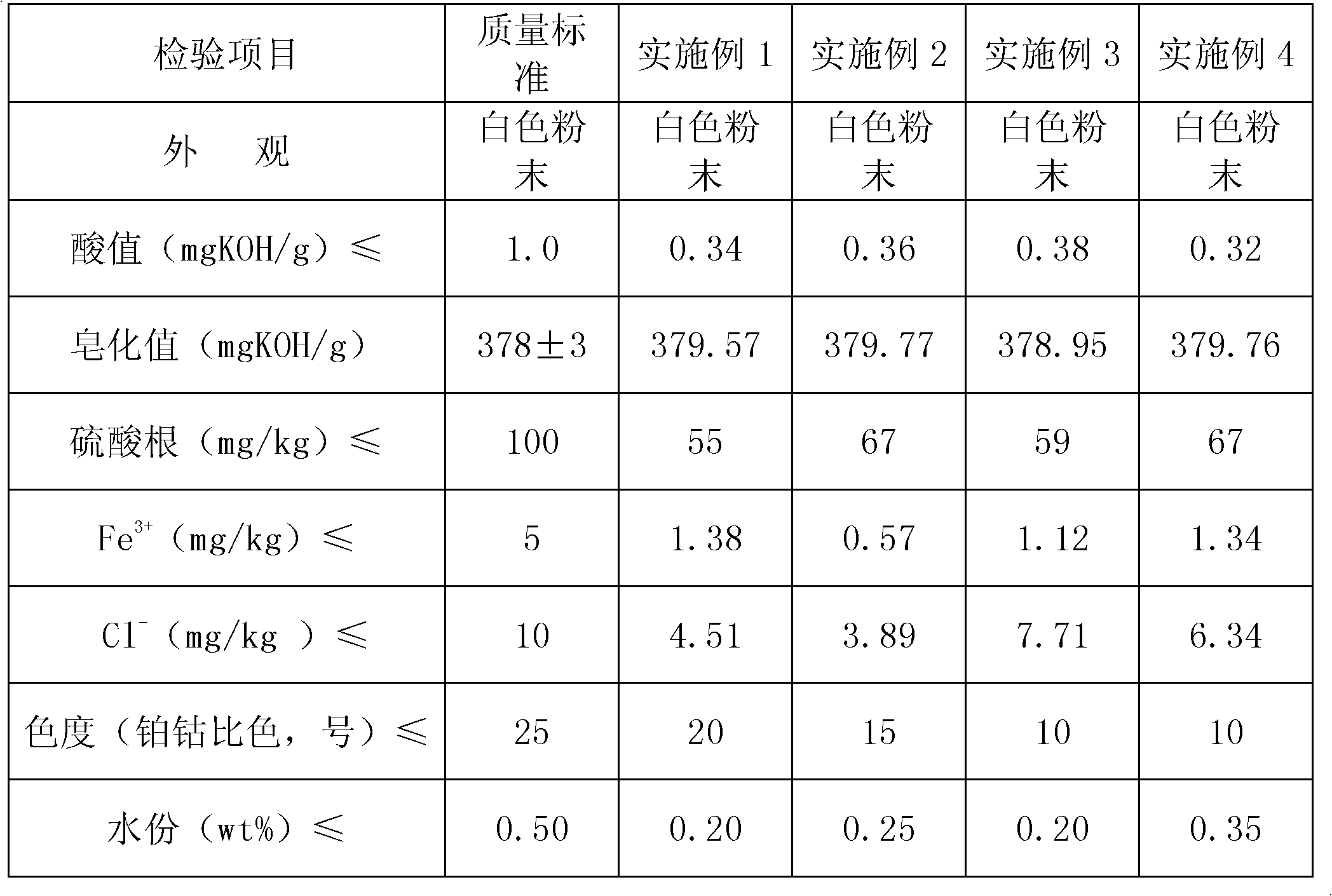

Method for synthesizing dimethyl isophthalate-5-sodium sulfonate

ActiveCN102633693AReduce usageImprove conversion rateSulfonic acids salts preparationSulfonateCadmium sulfate

The invention discloses a method for synthesizing dimethyl isophthalate-5-sodium sulfonate. Dimethyl isophthalate-5-sodium sulfonate is prepared by steps of sulfonation reaction, esterification, neutralization reaction and aftertreatment with isophthalic acid and fuming sulfuric acid serving as raw materials, wherein the sulfonation reaction is completed in three reaction temperature zones, different catalysts are used in different reaction temperature zones, cadmium sulfate is used as the catalyst at the temperature ranging from 150 DEG C to 159 DEG C, SiO2 is used as the catalyst at the temperature ranging from 160 DEG C to 169 DEG C, and mercuric sulfate is used as the catalyst temperature ranging from 170 DEG C to 181 DEG C. By the method, sulfonation reaction effect is improved, conversion rate of isophthalic acid is increased, sulfonation reaction temperature is lowered while sulfonation reaction time is shortened, reaction by-products including disulfonate, polymer and sulfone compounds are greatly reduced, product purity is improved while product yield is increased, and further, usage of fuming sulfuric acid and usage of sodium carbonate in a subsequent neutralization procedure are reduced, so that production cost is reduced.

Owner:WEIFANG WORLD CHEM

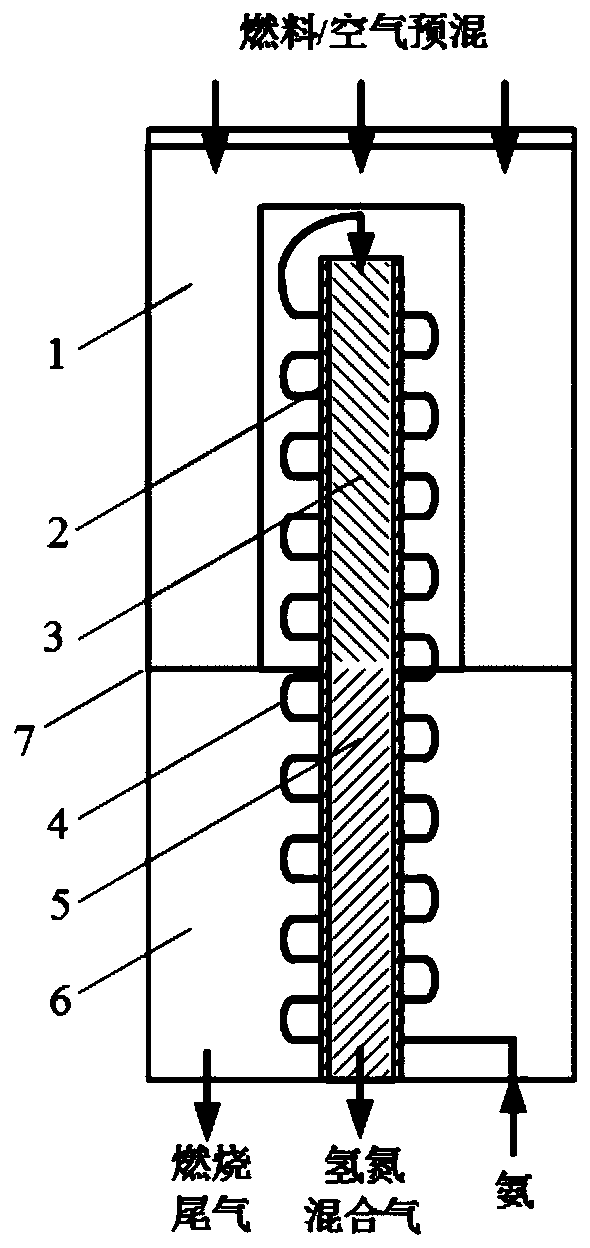

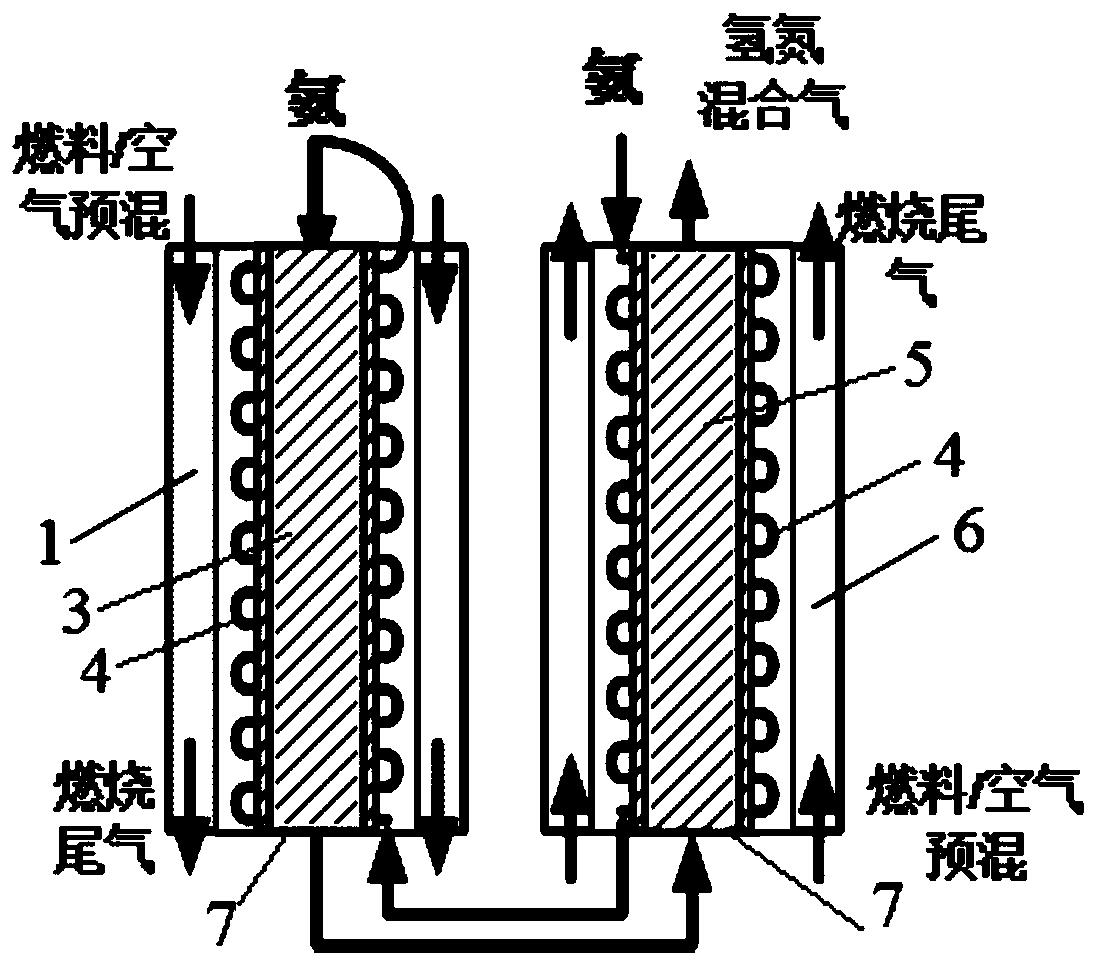

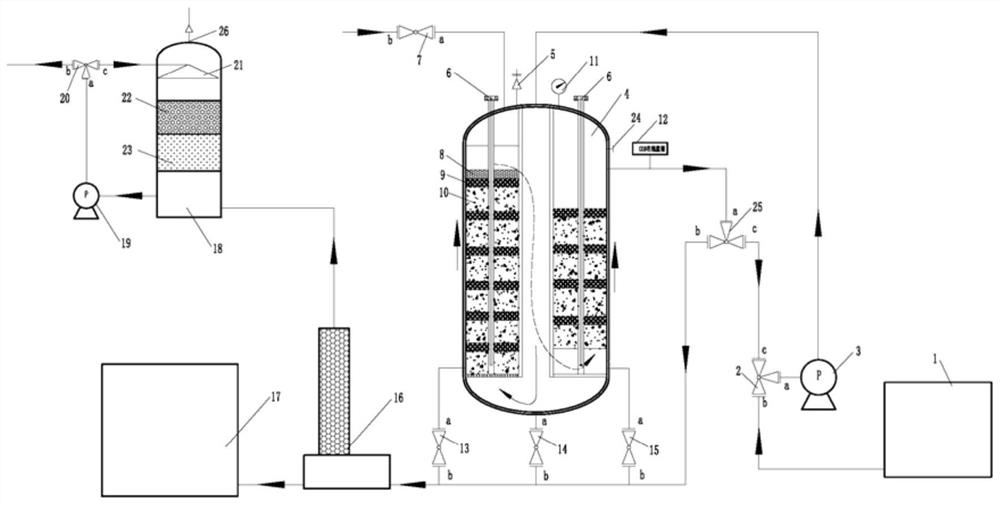

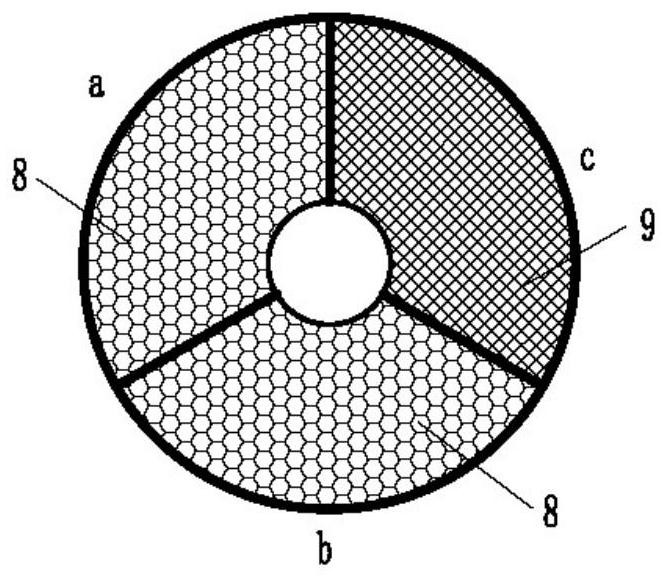

Ammonia decomposition device, ammonia decomposition system and hydrogen production method

ActiveCN110203882ADecompose thoroughlyImprove decomposition efficiencyGas treatmentHydrogen separation using solid contactDecompositionNitrogen

The invention belongs to the technical field of hydrogen production, and concretely relates to an ammonia decomposition device, an ammonia decomposition system and a hydrogen production method. The ammonia decomposition device comprises a shell, a heating zone, a heat exchange zone, a reaction section and a heat exchange coil. The heat exchange coil is spirally wound around the outer wall of the reaction section to sufficiently heat ammonia gas, so the heating efficiency of ammonia gas is increased; a first reaction section and a second reaction section which are sequentially communicated arearranged in the reaction section to ensure that the ammonia gas is decomposed after entering the first reaction section in order to generate a nitrogen and hydrogen mixture, so the decomposition efficiency of the ammonia gas is increased; and the second reaction section can perform secondary decomposition on the residual ammonia gas in the nitrogen and hydrogen mixture produced in the first reaction section, so the residual amount of ammonia gas in the nitrogen and hydrogen mixture in the second reaction section is reduced, thereby the ammonia gas is decomposed more thoroughly. The device makes the conversion rate of ammonia gas reach 99.9% or more and the residual amount of ammonia gas in the nitrogen and hydrogen mixture less than 1000 ppm.

Owner:福大紫金氢能科技股份有限公司

Fischer-Tropsch synthesis method

ActiveCN101570462ALow selectivityHigh selectivityHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionLarge poreFischer–Tropsch process

The invention relates to a Fischer-Tropsch synthesis method, which comprises that: hydrogen and carbon monoxide contact with each other under the condition of Fischer-Tropsch synthesis and in the presence of a Fischer-Tropsch synthesis catalyst, wherein the Fischer-Tropsch synthesis catalyst comprises a first Fischer-Tropsch synthesis catalyst and a second Fischer-Tropsch synthesis catalyst; the pore volume of the first Fischer-Tropsch synthesis catalyst is less than that of the second Fischer-Tropsch synthesis catalyst; and the hydrogen and the carbon monoxide contact with the first Fischer-Tropsch synthesis catalyst first and then contact with the second Fischer-Tropsch synthesis catalyst. By making the hydrogen and the carbon monoxide contact with the first Fischer-Tropsch synthesis catalyst with small pore volume first and then contact with the second Fischer-Tropsch synthesis catalyst with large pore volume, the method can give full play to the catalysis of the catalyst, reduce the selectivity of CH4 products, improve the selectivity of a Fischer-Tropsch synthesis liquid C5+ hydrocarbon, and simultaneously improve the conversion rate of raw materials CO.

Owner:CHINA PETROLEUM & CHEM CORP +1

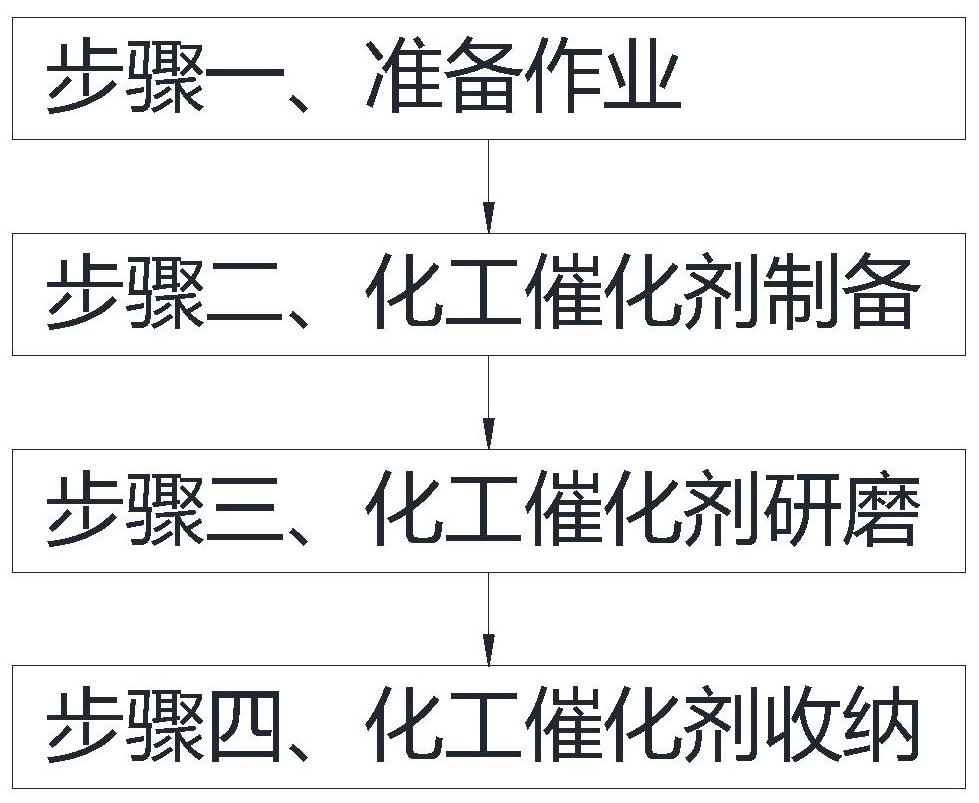

Chemical catalyst production preparation method

InactiveCN112138775AImprove grinding effectReduce sizeGrain treatmentsProcess engineeringManufacturing engineering

The invention relates to a chemical catalyst production preparation method, and chemical catalyst production preparation equipment is used in the method. The chemical catalyst production preparation equipment comprises a base and a grinding device, and the grinding device is arranged on the upper surface of the base. The chemical catalyst production preparation method can solve the following problems that at present, when a chemical catalyst is ground and smashed, the amount of the chemical catalyst ground by an existing chemical catalyst grinding device at a time needs to be manually controlled, the grinding device is difficult to automatically adjust and control during grinding, and only one grinding process exists in the chemical catalyst grinding process. And filtering treatment does not exist, so that the particle size of the ground chemical catalyst is difficult to give into full play to the catalytic action of the chemical catalyst in a chemical reaction.

Owner:合肥谷口化工科技有限公司

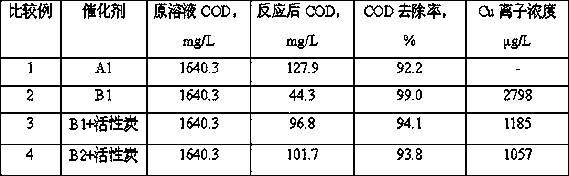

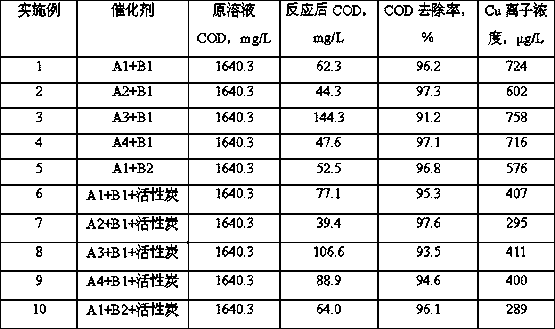

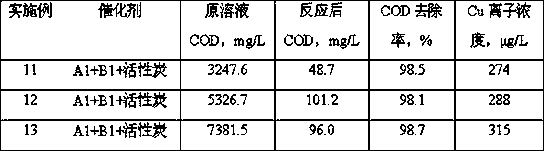

Catalytic wet oxidation treatment method of organic wastewater

PendingCN108069495AGive full play to the catalytic effectEasy to handleWater treatment parameter controlMolecular sieve catalystsOxidative treatmentOxidizing agent

The invention relates to the technical field of wastewater treatment and particularly discloses a catalytic wet oxidation treatment method of organic wastewater. The treatment method comprises steps as follows: the organic wastewater and an oxidizing agent enter a reactor for a reaction, and the reactor is sequentially filled with a catalyst A and a catalyst B according to the contact sequence with the organic wastewater. The method adopts a simple process, is good in stability and high in COD removal capability and can solve the problem about metal loss.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

High-heat-resistant amorphous polyester preparation method

The invention provides a high-heat-resistant amorphous polyester preparation method, which comprises: using terephthalic acid and ethylene glycol as main reaction raw materials, adding modified monomers 1,4-cyclohexane dimethanol and spiro diol, and carrying out direct esterification by using a tin / phosphorus / antimony composite catalyst to prepare the high-heat-resistant amorphous polyester. According to the present invention, the tin compound is added as the esterification catalyst at the esterification stage, the phosphorus compound is added to passivate the tin catalyst after the esterification is completed, and the antimony-based catalyst is added as the condensation polymerization catalyst, such that the catalysis effect of the tin compound to the esterification reaction can be ensured, and the problems that the tin catalyst as the condensation polymerization catalyst can yellow the polyester to cause the poor thermal stability of the product can be avoided.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Low-temperature reversible hydrogen storage magnesium based composite material

InactiveCN1570175AImprove mechanical propertiesHigh activityHydrogen separation using liquid contactFuel cellsMagnesium matrix composite

The invention discloses a magnesium-based composite material. The material comprises (by weight) 0.5% to 5.0% of nano TiO#-[2], 1.0% to 3.0% of Cr, 5.0% to 15.0% of Ni, and the balancing Mg. The magnesium-based composite material has high hydrogen storage capacity, good activation property and good hydrogen adsorbing-releasing dynamics performance.

Owner:ZHEJIANG UNIV

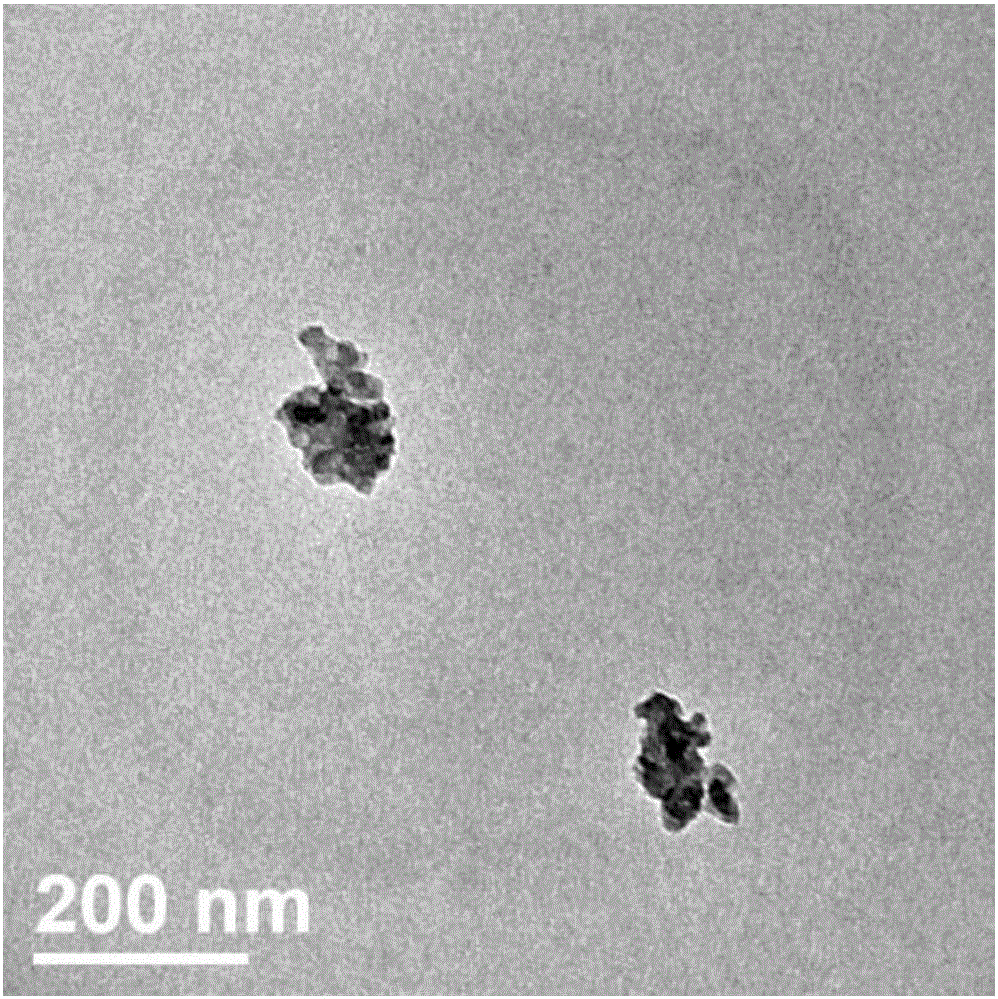

Organic-inorganic hybrid material, and preparation method thereof

The invention discloses a preparation method of an organic-inorganic hybrid material. The preparation method comprises following steps: (1) a natural inorganic layered silicate material is mixed with a metal nitrate aqueous solution, and an obtained mixture is stirred to be uniform; (2) a sodium hydroxide aqueous solution is added into the mixture obtained in step 1, and an obtained mixed material is stirred to be uniform; (3) the mixed material obtained in step 2 is subjected to filtering, drying, and calcination; and (4) a modified material obtained in step 3 is delivered into a chemical vapor deposition furnace, an inert gas is used for purging furnace tubes, hydrogen is added, temperature is increased to 450 to 550 DEG C, a mixed gas of ethylene and hydrogen is used for replacing hydrogen, temperature is increased to 600 to 1200 DEG C, and constant temperature is maintained for 1 to 5h. The carbon nano tube-inorganic layered silicate hybrid material is suitable for improving modified polyester high elastomer; the synthesis method is simple; application period is long; and it is beneficial for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

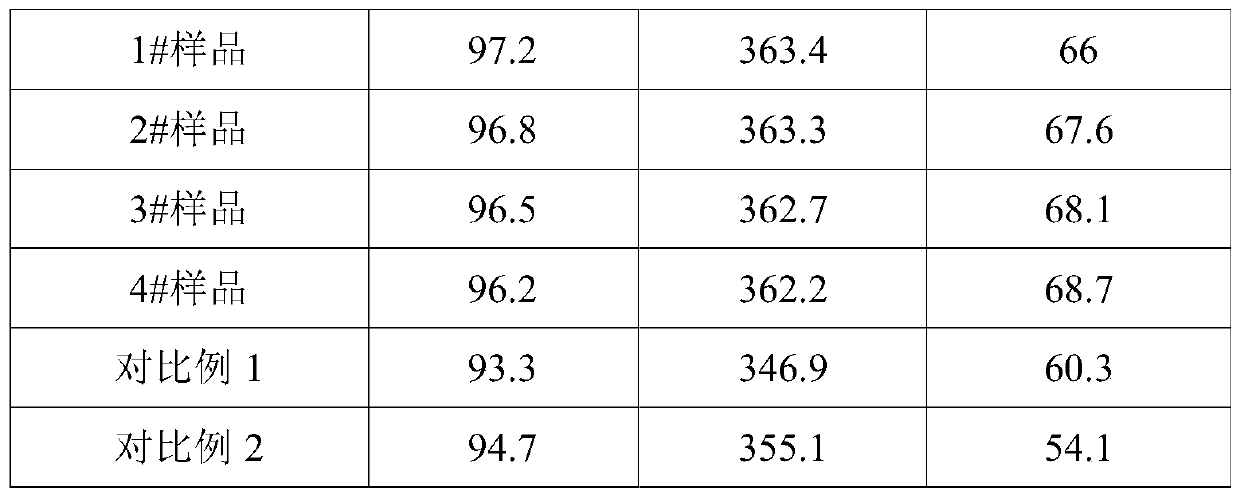

High-capacity fast-charging type microcrystal graphite negative electrode material and preparation method thereof

ActiveCN110416497ASignificant increase in capacityGood catalytic uniformityCarbon compoundsCell electrodesDegaussingLithium electrode

The invention discloses a preparation method of a high-capacity fast-charging type lithium ion battery negative electrode material. The preparation method comprises the following steps of mixing a silicon-based catalyst with a pore-forming agent to prepare a catalyst / pore-forming agent compound, and then mixing microcrystalline graphite with the catalyst / pore-forming agent compound and a binder uniformly, and next, carrying out isostatic pressing treatment to obtain isostatic pressing blocks; carbonizing the isostatic pressing blocks to obtain carbon blocks containing micron-scale pores; and carrying out catalytic graphitization on the carbon blocks containing the micron-scale pores, and then performing crushing, shaping, grading, degaussing and screening to obtain the high-capacity fast-charging type lithium ion battery negative electrode material. According to the method, the graphitization degree of the microcrystalline graphite is improved to 96% or above, and the reversible capacity is improved to 360 mAh / g or above, and the charging capacity ratio at 6C / 1C is higher than 65%.

Owner:HUNAN SHINZOOM TECH

Expanded halogen-free flame-retardant EVA-based composite material and preparation method thereof

ActiveCN106397963AReduce manufacturing costImprove flame retardant performancePhosphoric acidChemistry

The invention discloses an expanded halogen-free flame-retardant EVA-based composite material and a preparation method thereof. The preparation method is characterized in that a synergistic flame retardant, namely Zirconate-Amino Trimethylene Phosphonic Acid (Zr-ATMP) is synthesized under hydrothermal conditions by taking nitrogen-based trimethylene phosphoric acid and zirconium oxychloride as raw materials; the flame-retardant composite material is prepared from EVA, a char-forming agent (starch), a flame retardant and the synergistic flame retardant in manners of extrusion and dicing; the mass percentage ratio of the EVA to the char-forming agent to the flame retardant to the synergistic flame retardant is 50:12.5:(35.5-32.5):(2-5). The composite material has the advantages that the raw materials are poisonless and harmless, the preparation way is simple and safe, a role in obviously improving the flame retardance and the mechanical property of the EVA is played, particularly, a role in obviously promoting char forming is played during combustion, and the molten drop phenomenon is eliminated.

Owner:NANJING UNIV OF SCI & TECH

Method for catalytic conversion of biomass

ActiveCN105062518AGive full play to the catalytic effectLow costBiofuelsSolid fuelsFiltrationReaction temperature

The invention discloses a method for catalytic conversion of biomass. The method comprises steps as follows: (1), collected bean curd swill is naturally fermented, and biomass is naturally air-dried and then broken; (2), the fermented bean curd swill and the broken biomass are mixed in the mass ratio being (1:1)-(10:1) and sent to a reaction kettle; (3), the reaction kettle filled with a mixture of the bean curd swill and the biomass is heated for carbonization, and after the reaction ends, and solid products are obtained through cooling, collection, filtration and separation and can be taken as fuel or chemical raw materials. The fermented bean curd swill is taken as a solvent, biomass is subjected to hydrothermal conversion, and the catalytic action of rich lactic acid and succinic acid contained in the bean curd swill is sufficiently exerted. The hydrothermal conversion technology is controlled at the two-stage reaction temperatures, the lactic acid and the succinic acid in the fermented bean curd swill are dissolved in water and can be sufficiently spread into the biomass, and the catalytic effect of the bean curd swill is improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

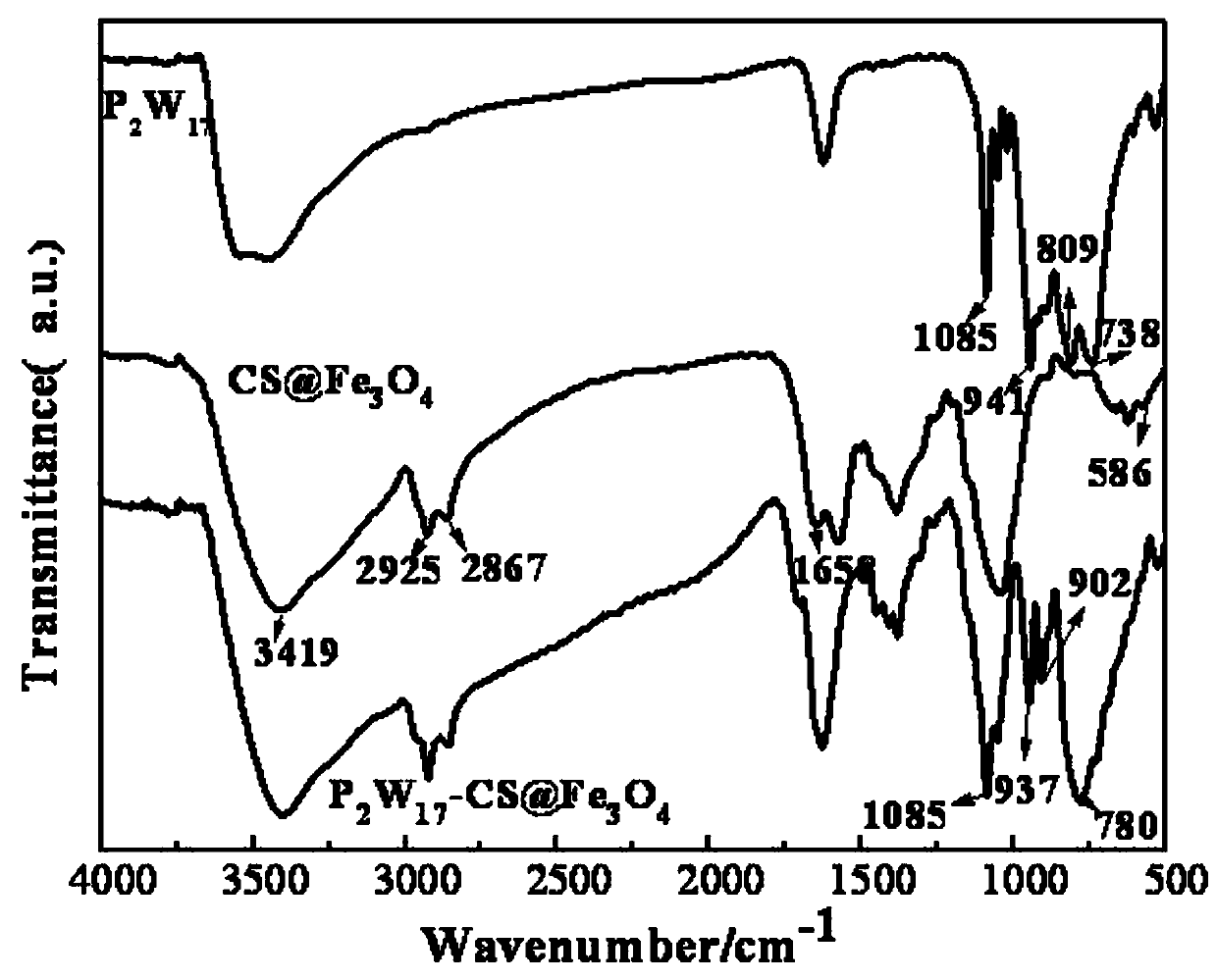

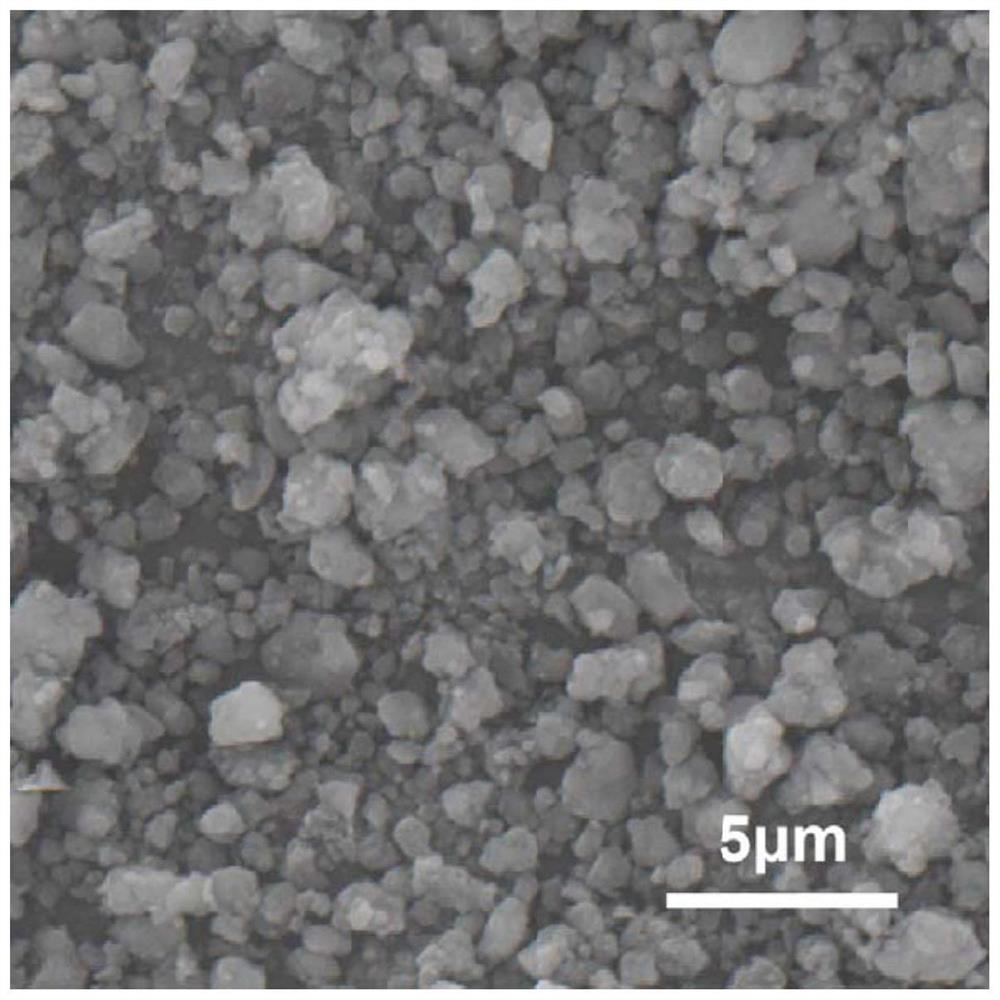

High-dispersion polyoxometallate magnetic microsphere catalyst, and preparation method and application thereof

InactiveCN110586186AGood dispersionReduce dosageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDispersityMicrosphere

The invention belongs to the technical field of loaded polyoxometallate catalysts, and provides a high-dispersion polyoxometallate magnetic microsphere catalyst, and a preparation method and application thereof so as to overcome the defects that polyoxometallate used as a catalyst is small in specific surface area, few in reaction activity sites, prone to aggregation, soluble in water, difficult to separate and recycle and the like. Dawson type phosphotungstate is loaded onto a CS@Fe3O4 microsphere by a covalent bonding method, and a covalent loaded Dawson type phosphotungstate magnetic microsphere P2W17-CS@Fe3O4-1 is obtained; or, Keggin type phosphotungstate and the Dawson type phosphotungstate are respectively loaded to an organic modified magnetic Fe3O4 microsphere by an electrostaticbonding method, and loaded Keggin type phosphotungstate and loaded Dawson type phosphotungstate are obtained. The dispersity and the specific surface area of the polyoxometallate are improved, the catalytic oxidation activity of the polyoxometallate and the oxidation efficiency of tetrahydrothiophene are improved, and a magnetic carrier provides favorable conditions for catalyst separation and recycling.

Owner:ZHONGBEI UNIV

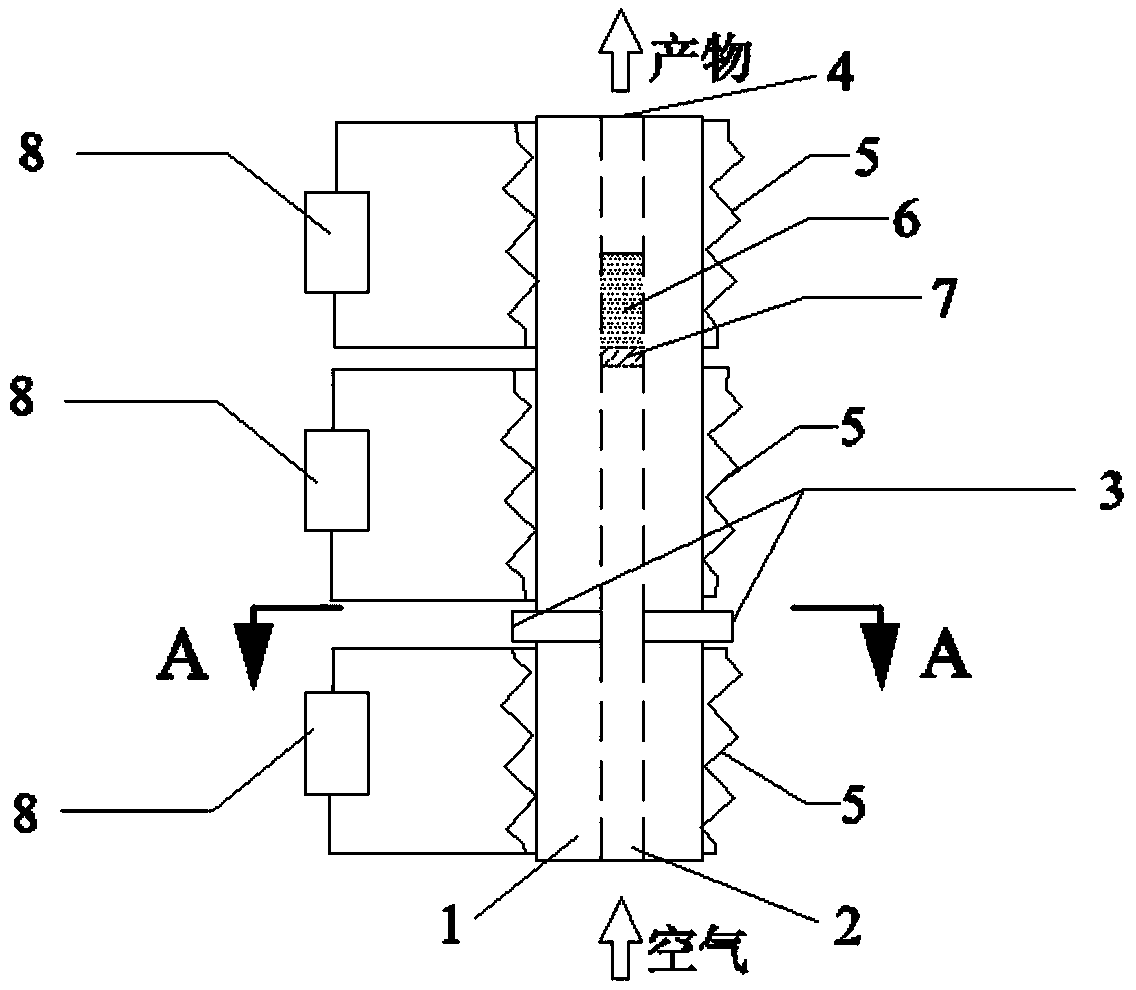

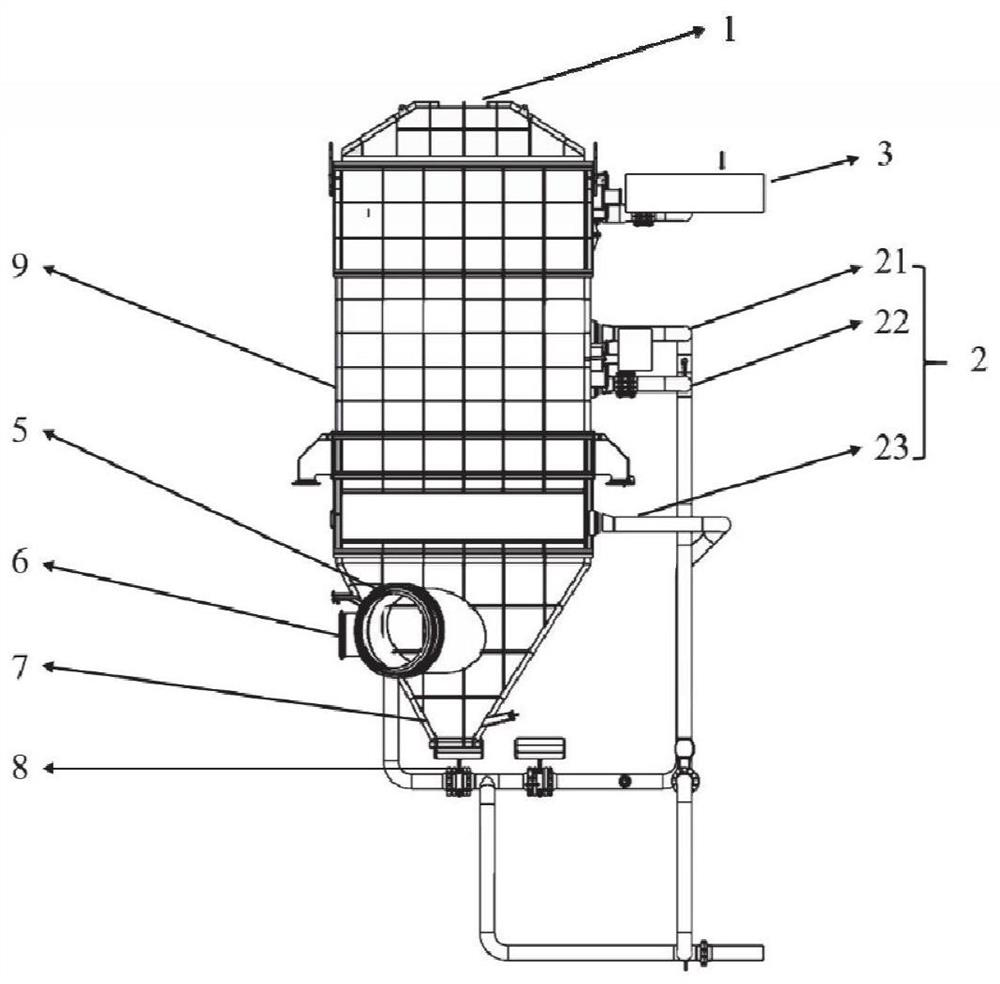

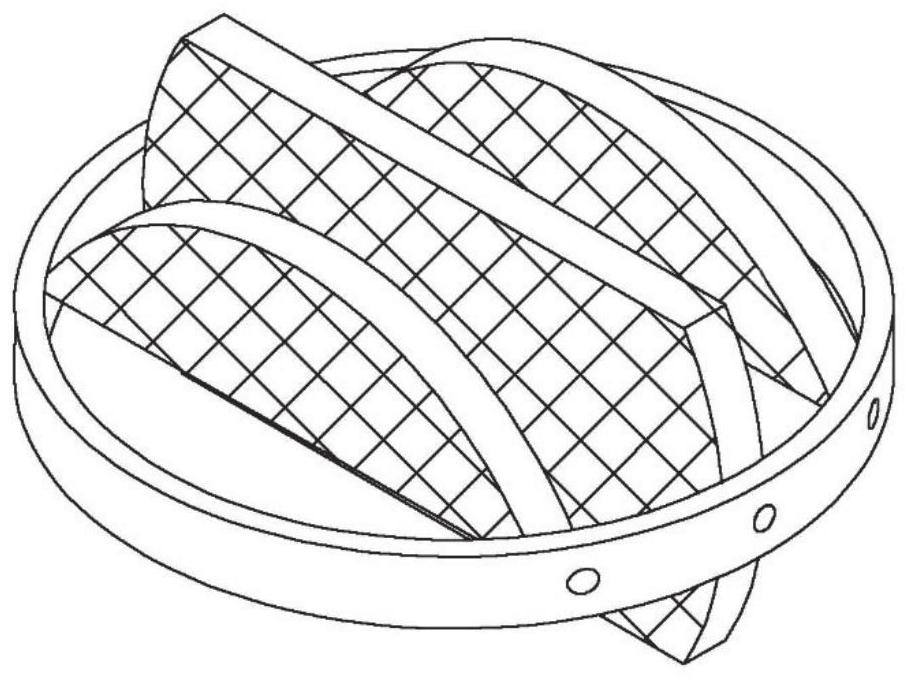

Fluidized bed reactor for preparing ammonia by virtue of pyrolysis of urea

The invention discloses a fluidized bed reactor for preparing ammonia by virtue of pyrolysis of urea. The fluidized bed reactor comprises a reactor body, wherein an air inlet for introducing air or smoke is formed in the lower part of the reactor body; a reaction product outlet is formed in the upper part of the reactor body; a plurality of solution inlets for introducing a urea solution into the reactor body are formed in the side surface of the reactor body; the outer side of the reactor body is coated with a plurality of groups of resistive heaters from top to bottom, and each group of resistive heaters are respectively connected with corresponding temperature control devices. By forming the solution inlets for introducing the urea solution in the side surface of the reactor body and arranging the resistive heaters for heating the reactor on the outer side of the reactor body, the urea can be pyrolyzed and transformed in the reactor, therefore the fluidized bed reactor disclosed by the invention is low in cost, simple to control and free of secondary pollution.

Owner:XI AN JIAOTONG UNIV

Load type platinum-based catalyst and preparation method thereof

ActiveCN106622226AHigh catalytic activityImprove catalytic stabilityCatalystsHydrocarbon preparation catalystsEvaluation resultReduction treatment

The invention provides a load type platinum-based catalyst and a preparation method thereof. The preparation method comprises the steps of firstly preparing mesoporous aluminum oxide with certain porous structure parameters, and reacting SnCl2.2H2O with the prepared mesoporous aluminum oxide in aqueous alkali to prepare an Sn-Al LDHs / Al2O3 composite with certain morphology; then dipping the prepared Sn-Al LDHs / Al2O3 into solution containing platinic acid to achieve in-situ reduction of platinum metal between laminates of Sn-Al LDHs, extruding and moulding into strips, and then performing drying and activating treatment, thus converting the Sn-Al LDHs / Al2O3 composite into an SnO2-Al2O3 composite oxide with certain morphology; finally preparing the Pt / Sno2-Al2O3 catalyst through hydrogen reduction treatment, wherein the Pt / Sno2-Al2O3 catalyst can be applied to catalytic reaction of preparing propylene through propane dehydrogenation. The reaction performance evaluation results of the catalyst show that the catalyst prepared through the preparation method has high thermal stability and catalytic activity, is long in service, and shows good application prospect.

Owner:SOUTHEAST UNIV

Low-temperature reversible hydrogen storage magnesium based composite material

InactiveCN1256456CImprove mechanical propertiesHigh activityHydrogen separation using liquid contactFuel cellsMagnesium matrix composite

Owner:ZHEJIANG UNIV

Preparation method of vinyl phenyl silicone oil

The invention provides a preparation method of vinyl phenyl silicone oil, which comprises the following steps: (1) sequentially adding deionized water, solid acid and divinyl tetramethyl disiloxane into a reaction kettle, stirring, mixing, heating to 40-100 DEG C, and dropwisely adding phenyltriethoxysilane into the reaction kettle after the temperature of the reaction kettle is stable; (2) afterdropwise addition of the phenyltriethoxysilane is finished, stirring and reacting for 1-3 hours at 40-100 DEG C, cooling to room temperature, discharging to obtain a reaction solution, and filtering the reaction solution to obtain a filtrate; and (3) washing the filtrate obtained in the step (2) with water until the filtrate is neutral, putting the filtrate into another clean reaction kettle, introducing nitrogen, continuously heating to 60-100 DEG C while stirring, vacuumizing, and carrying out reduced pressure distillation to remove low-boiling-point substances, thereby obtaining the vinyl phenyl silicone oil. The vinyl phenyl silicone oil prepared by the preparation method disclosed by the invention has relatively high refractive index and light transmittance and relatively low viscosity.

Owner:新纳奇材料科技江苏有限公司

Catalyst for catalyzing butadiene cyclization trimerization and application method thereof

InactiveCN102688775AEasily hydrolyzedAvoid hydrolysisOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPolymer sciencePtru catalyst

The invention relates to a catalyst for catalyzing butadiene cyclization trimerization and an application method thereof. The components of the catalyst include titanium naphthenate and AlRyZ3-y, wherein Z is a halogeno group, R is an alkyl group, and Y is more than 0 and less than or equal to 3; and the catalyst also includes a small amount of zirconium naphthenate. When the catalyst is used for catalyzing the butadiene cyclization trimerization, methylbenzene, the zirconium naphthenate, the AlRyZ3-y, the butadiene and the titanium naphthenate are added into a reaction kettle in sequence and then mixed; the mixture is reacted for 20-40 hours at the temperature of 30-90 DEG C to obtain a reaction product; and sedimentation, distillation and purification treatments are carried out on the reaction product to obtain a butadiene trimer. Through measuring, the conversion of the butadiene is 90-95%, and the content of trans, trans, cis-1,5,9-cyclododecatriene in the trimer is 99.99-100%.

Owner:WUDI SINORANCE CHEM

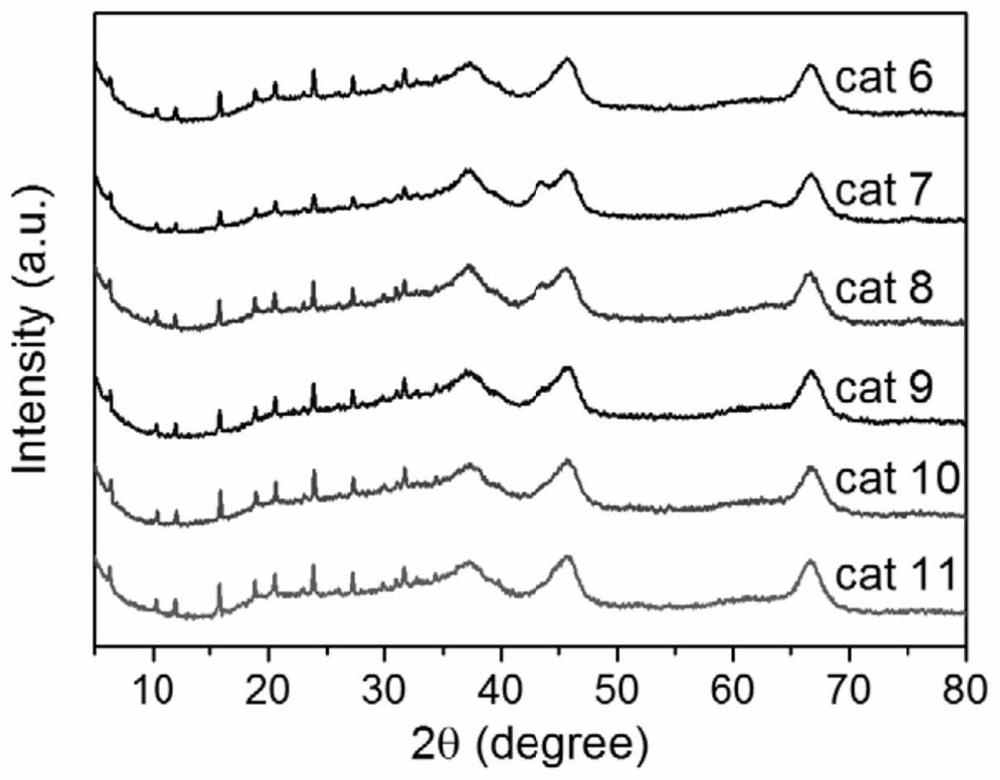

Hydrocracking isomerization catalyst as well as preparation method and application thereof

ActiveCN111701623AIncrease mass transfer rateHigh selectivityCatalyst carriersMolecular sieve catalystsAlkaneMolecular sieve

The invention relates to a composite carrier of an alumina-coated molecular sieve, a hydrocracking isomerization catalyst, and a preparation method and application thereof. Firstly, a molecular sieveis subjected to an amino acid pore broadening treatment; then the molecular sieve is sulfonated, the sulfonated molecular sieve is added into an alcohol-water solution containing hexadecyl trimethyl ammonium bromide, an aluminum source and urea are added, and then crystallizing, washing, drying, and roasting are performed to obtain the composite carrier, which has abundant pores and abundant acidic sites, thereby enhancing the hydro-isomerization performance. Pt, Pd, Ni and Co are used as main active metals; Na, K, Be, Mg, Ca, Sr, Cr, Mn, Fe, Cu and Zn are used as auxiliary metals; and the auxiliary metals can enhance the dispersity of the active metals, can selectively cover and inhibit the acidic sites of the molecular sieve, play a key role in hydrogenation activity, and have higher activity in the aspect of preparation of biofuel from long-chain alkane through hydro-isomerization.

Owner:NANKAI UNIV

Refuse incinerator system and method for catalytic removal of waste incineration flue gas purification furnace chamber

ActiveCN112902193BBoth fire-resistant and thermal insulation propertiesGuaranteed selective removalIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

The invention discloses a garbage incinerator system and a method for catalytic removal of garbage incinerator flue gas purification furnace, comprising a garbage incinerator, the flue gas outlet of the garbage incinerator is connected to a flue, the flue gas outlet of the garbage incinerator is provided with a heat exchange device, and the garbage incinerator The garbage input port of the furnace is equipped with a mixing device, which is connected to the garbage source and the chlorine inhibitor source. The furnace wall of the boiling section of the garbage incinerator furnace is equipped with an insulating high-temperature catalyst layer, and the furnace wall of the suspension section of the garbage incinerator furnace wall and the inner wall of the flue are provided with insulation Medium-temperature catalyst layer and heat storage ball layer are laid on the surface of the heat exchange device; chlorine inhibitor is formed by compounding sulfur-containing carbon and calcium oxide; heat-insulating high-temperature catalyst is formed by compounding refractory material and high-temperature catalyst; heat-insulating medium-temperature catalyst is formed by compounding refractory material and medium-temperature catalyst Formation; heat storage balls contain catalytically active components. The invention can effectively reduce the cost of the out-of-furnace treatment of flue gas and fly ash, effectively realize the inhibition in the process of dioxin formation and the decomposition of incineration products.

Owner:SHANDONG UNIV

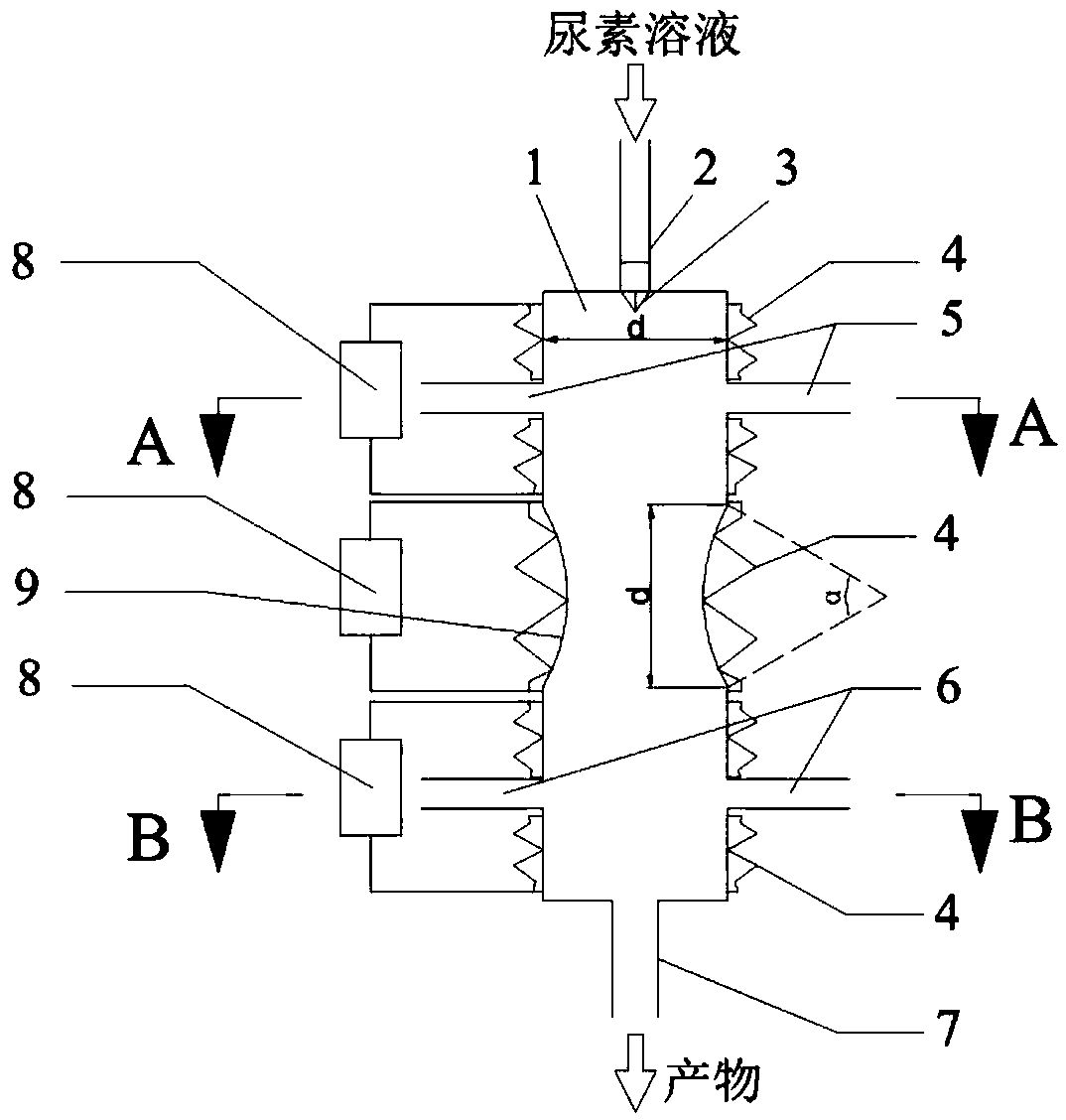

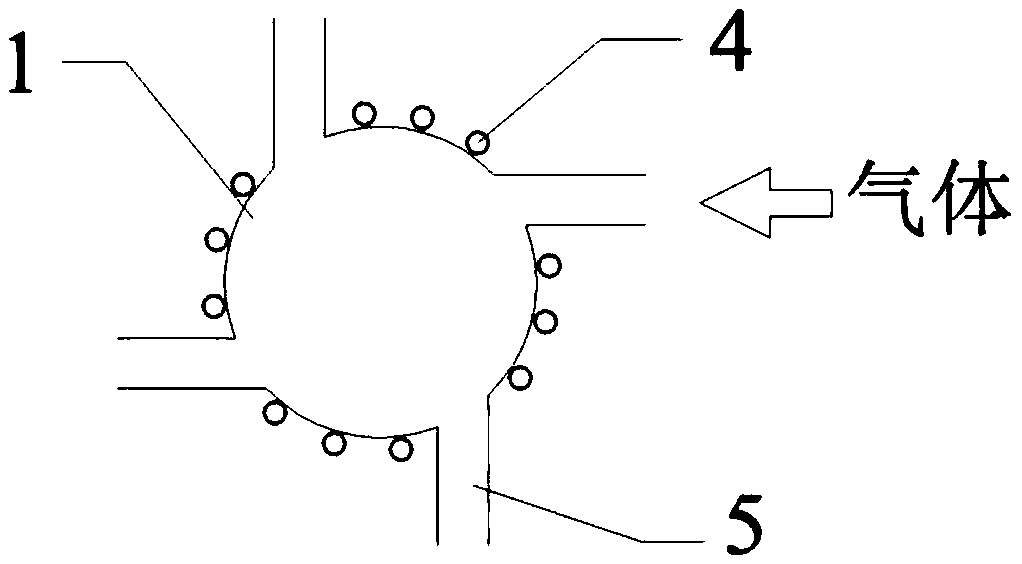

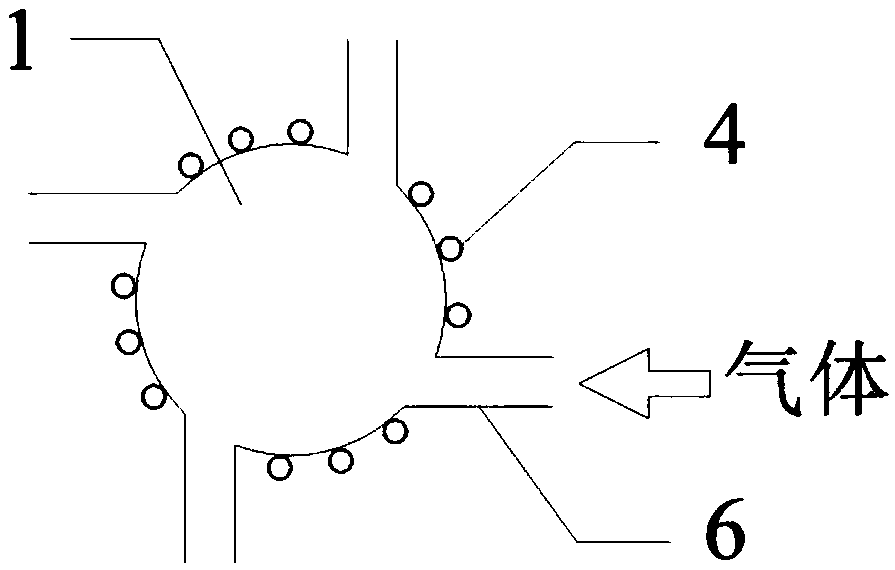

Bitangent circle reactor applied to urea pyrolysis to produce ammonia

PendingCN108675318AImprove catalytic effectAvoid spin wash actionAmmonia preparation/separationChemistryDecomposition

The invention discloses a bitangent circle reactor applied to urea pyrolysis to produce ammonia. The bitangent circle reactor comprises a urea solution inlet and a decomposition product outlet, wherein the urea solution inlet and the decomposition product outlet are respectively formed in the upper part and the lower part of the reactor body, two groups of gas inlets for introducing air or smoke are formed in a lateral side of the reactor body, the two groups of the gas inlets of the reactor body are respectively distributed along an upper lateral wall and a lower lateral wall of the reactor body according to a rotational flow tangent circle, the tangent circle directions of the upper gas inlets and the lower gas inlets are opposite to each other, a zooming section is arranged in the middle section of the reactor body, an inner wall of the zooming section is of an annular corrugated structure, the outer side of the reactor body is wrapped by a plurality of groups of heating electric resistance wires from top to bottom, each group of heating electric resistance wires are respectively connected with a corresponding temperature control device, the reactor body is an aluminum cylinder,the zooming section is arranged between the solution inlet and the product outlet, and the inner wall of the zooming section of the reactor is of the annular corrugated structure. The bitangent circle reactor disclosed by the invention can effectively improve the ammonia producing efficiency through urea pyrolysis, reduce pyrolysis energy consumption and achieve both low cost and high efficiency.

Owner:XI AN JIAOTONG UNIV

Catalyst and application of catalyst in catalyzing butadiene cyclization trimerization

InactiveCN102688781ABreak interactionHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsDistillationCyclododecatriene

The invention relates to a catalyst and application of the catalyst in catalyzing butadiene cyclization trimerization. The components of the catalyst include TiX4 and AlRyZ3-y, wherein X and Z are halogeno groups; R is alkyl; Y is more than 0 and less than or equal to 3; the catalyst is characterized by also includin CP2ZrC12. When the catalyst is used for catalyzing the butadiene cyclization trimerization, toluene, CP2ZrC12, AlRyZ3-y, butadiene and TiX4 are added to a reaction kettle in sequence and then mixed; the mixture reacts for 20-40 hours at 30-90 DEG C to obtain a reaction product; and sedimentatin, distillation and purification treatments are carried out on the reaction product to obtain a butadiene trimer. Through measuring, the conversion rate of the butadiene is 90-95%; and the content of trans, trans, cis-1, 5, 9-cyclododecatriene in the trimer is 99.99-100%.

Owner:WUDI SINORANCE CHEM

Methanol carbonyl oxidation synthesis of dimethyl carbonate device

ActiveCN104415711BAvoid local depositionPromote circulationOrganic compound preparationPreparation from carbon monoxide and oxygenGas liquid reactionPtru catalyst

The invention relates to a device for synthesis of dimethyl carbonate by methanol carbonyl oxidization, the device includes a tubular reaction segment, the upper end of the tubular reaction segment is a reactor gas-liquid separation section, the upper part of the tubular reaction segment is provided with a methanol feeding port, the lower part of the tubular reaction segment is provided with a CO and O2 mixed gas feed port, and also provided with an external circulating pipeline extending from the bottom of the tubular reaction segment to the methanol feeding port at the upper part of the tubular reaction segment, the external circulating pipeline is provided with a centrifugal pump, and the centrifugal pump can forcibly delivery a gas-liquid reaction raw material on the bottom of the tubular reaction segment to the top of the tubular reaction segment. The device for synthesis of the dimethyl carbonate by methanol carbonyl oxidization replaces a reflux vice reaction tube by the circular pipeline with the centrifugal pump, can effectively prevent the local deposition of a catalyst in a reactor, strengthens cycle of the catalyst in the device, significantly increases the contact area, and gives full play to the catalytic effect of the catalyst.

Owner:黄志忠

Perovskite type composite photocatalyst and preparation method thereof, and special system and method

ActiveCN113663679ALarge specific surface areaImprove adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsCharge carrierPhysical chemistry

The invention discloses a perovskite type composite photocatalyst and a preparation method thereof, and a special system and method, wherein the perovskite type composite photocatalyst is LaNi[x]Co[1-x]O[3] / CeO[2], and x is 0.9-0.98. LaNi[x]Co[1-x]O[3] is obtained through modification by doping Co in LaNiO3 under the condition that anion and cation surfactants with different molar ratios are mixed, then LaNi[x]Co[1-x]O[3] and CeO2 are compounded under ultrasonic assistance, separation of charge carriers is effectively promoted, the specific surface area is increased, and the perovskite type composite photocatalyst which is environmentally friendly and high in photocatalytic capacity and adsorption performance is obtained. The integrated wastewater and tail gas treatment system is totally closed by adopting special equipment, semiconductor organic wastewater is efficiently treated by utilizing a perovskite type composite photocatalyst LaNi[x]Co[1-x]O[3] / CeO[2], and the system is automatic, intelligent, high in mass transfer efficiency, capable of fully utilizing visible light, environment-friendly and free of secondary pollution.

Owner:SOUTHEAST UNIV

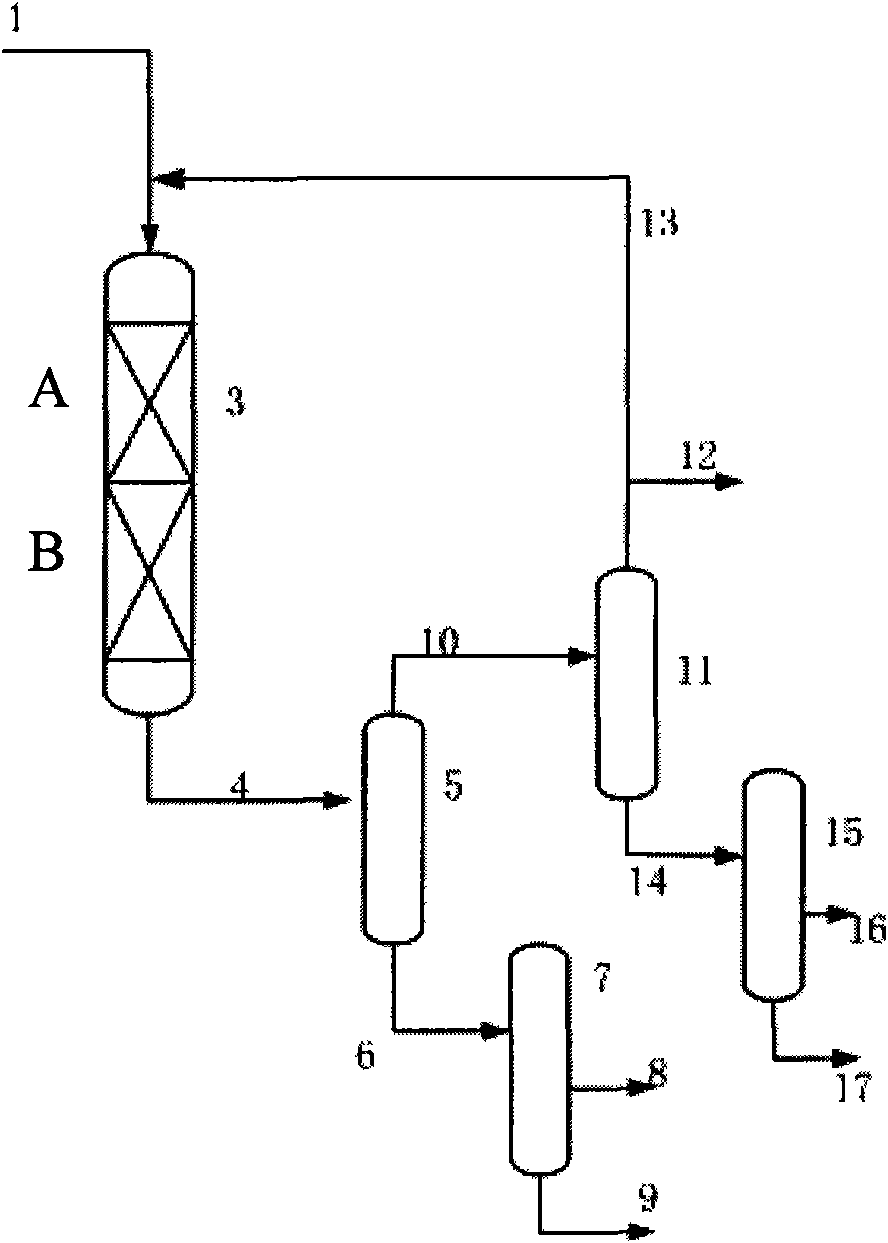

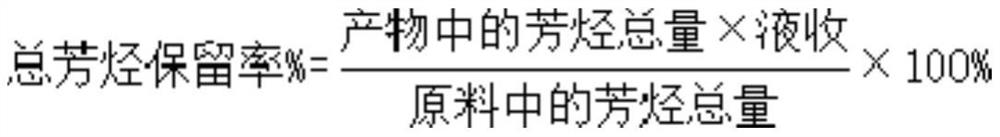

Method and system for preparing light aromatic hydrocarbon

ActiveCN112574782AHigh retention rateReduce nitrogen contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaAromatic hydrocarbon

The invention relates to a hydrocracking method and system for producing high-quality light aromatic hydrocarbon. The method mainly solves the problem of low arene purity when arene is used as a target product in the prior art. A catalytic diesel oil flow is subjected to hydrofining, impurity separation and deep denitrification, and then a hydrocracking reaction is carried out. After the reaction,fractions including light hydrocarbons, heavy naphtha rich in light aromatic hydrocarbons, and heavy tail oil are obtained through separation. The method can be used for producing heavy naphtha containing high-quality light aromatic hydrocarbons from catalytic diesel oil, solves the problem of low purity of aromatic hydrocarbons in a hydrocracking product of catalytic diesel oil, and achieves a good technical effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

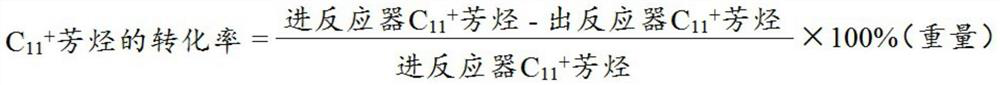

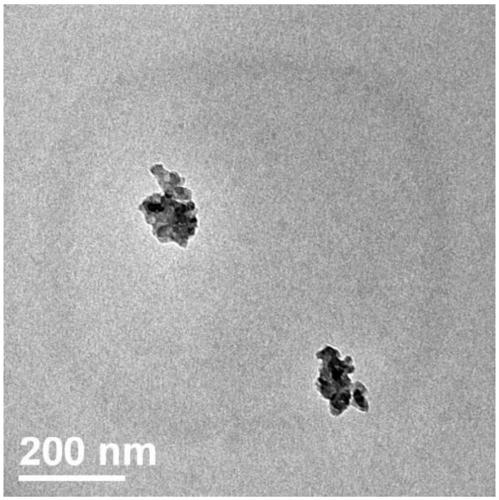

Metal and carbon-based material electrode surface carbon nano tube coating and preparation method thereof

ActiveCN111545437AGive full play to the adsorptionGive full play to the catalytic effectCarbon compoundsPretreated surfacesMetal frameworkCarbon nanotube

The invention discloses a metal and carbon-based material electrode surface carbon nano tube coating and a preparation method thereof and belongs to the technical field of semiconductor coatings. Thecarbon nano tube coating comprises a carbon nano tube and a metal framework. A carbon nano tube coating precursor comprises a metal salt solution, a surface functionalized carbon nano tube and an organic solvent. The metal and carbon-based material electrode surface carbon nano tube coating is generated after a reaction through a thermal-decomposition idea. The preparation method of the metal andcarbon-based material electrode surface carbon nano tube coating includes the following steps that the surface functionalized carbon nano tube is dispersed in the organic solvent for ultrasonic treatment, and a stable dispersed system is formed; and the metal salt solution and carbon nano tube dispersion liquid are mixed uniformly and then applied to the surface of an electrode, drying is performed in a drying box, a thermal decomposition reaction is performed in a tube furnace, and thus the carbon nano tube coating on the surface of the electrode is prepared. The specific surface area of thecoating prepared through the method is large, a catalytic action of the carbon nano tube is fully utilized, the preparation method and process are simple, and the industrialized production is facilitated.

Owner:上海金铎禹辰水环境工程有限公司

Garbage incinerator system and garbage incineration flue gas purification hearth catalytic removal method

ActiveCN112902193ABoth fire-resistant and thermal insulation propertiesGuaranteed selective removalIncinerator apparatusChimneysThermodynamicsPtru catalyst

The invention discloses a garbage incinerator system and a garbage incineration flue gas purification hearth catalytic removal method. The garbage incinerator system comprises a garbage incinerator; a flue gas outlet of the garbage incinerator is connected with a flue; a heat exchange device is arranged at the flue gas outlet of the garbage incinerator; a garbage throwing opening of the garbage incinerator is provided with a mixing device; the mixing device is connected with a garbage source and a chlorine inhibitor source; a heat-preservation high-temperature catalyst layer is arranged on the furnace wall of a boiling section of a hearth of the garbage incinerator; heat-preservation medium-temperature catalyst layers are arranged on the furnace wall of a suspension section of the hearth of the garbage incinerator and the inner wall of the flue; a heat storage ball layer is laid on the surface of the heat exchange device; the chlorine inhibitor is formed by compounding sulfur-containing carbon and calcium oxide; the heat preservation high-temperature catalyst is formed by compounding a refractory material and a high-temperature catalyst; the heat-preservation medium-temperature catalyst is formed by compounding a refractory material and a medium-temperature catalyst; and catalytic active components are contained in the heat storage balls. According to the garbage incinerator system and the garbage incineration flue gas purification hearth catalytic removal method, the external treatment cost of the flue gas and the fly ash can be effectively reduced, and inhibition of dioxin during generation and decomposition of products obtained after incineration are effectively achieved.

Owner:SHANDONG UNIV

Preparation method of formaldehyde decomposition type heating radiator coating material with high absorption rate

PendingCN110079186AOptimized areaImprove structural performanceGas treatmentOther chemical processesHigh absorptionDecomposition

The invention relates to a preparation method of a formaldehyde decomposition type heating radiator coating material with a high absorption rate and belongs to the technical field of coatings. According to the technical scheme, 18-crown ether-6 is taken as a template agent, a hexagonal crystal EMT molecular sieve is successfully prepared with a steam crystallization technology and supported on thesurface of an aerogel material packet, a potassium chloride solution is supported, and potassium elements are more uniformly distributed in the molecular sieve. Meanwhile, cations in the prepared molecular sieve are in different positions, have different steric hindrance and have different energy, so that the cations are stable in molecular sieve channels, and the functions of regulating the surface characteristics and the pore structures of the molecular sieve are realized; the molecular sieve has a large specific surface area and pore volume, more adsorption sites can be provided, and the oxygen adsorption of the molecular sieve is increased; besides, the composite aerogel material has excellent specific surface area and structure performance, the bonding strength and the adsorption performance of the material are further improved, and the composite material has excellent adsorption performance.

Owner:谢治高

A method for catalytic conversion of biomass

ActiveCN105062518BGive full play to the catalytic effectLow costBiofuelsSolid fuelsFiltrationReaction temperature

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of intumescent halogen-free flame-retardant EVA-based composite material and preparation method thereof

ActiveCN106397963BReduce manufacturing costMeet environmental protection requirementsPhosphoric acidZirconate

The invention discloses an expanded halogen-free flame-retardant EVA-based composite material and a preparation method thereof. The preparation method is characterized in that a synergistic flame retardant, namely Zirconate-Amino Trimethylene Phosphonic Acid (Zr-ATMP) is synthesized under hydrothermal conditions by taking nitrogen-based trimethylene phosphoric acid and zirconium oxychloride as raw materials; the flame-retardant composite material is prepared from EVA, a char-forming agent (starch), a flame retardant and the synergistic flame retardant in manners of extrusion and dicing; the mass percentage ratio of the EVA to the char-forming agent to the flame retardant to the synergistic flame retardant is 50:12.5:(35.5-32.5):(2-5). The composite material has the advantages that the raw materials are poisonless and harmless, the preparation way is simple and safe, a role in obviously improving the flame retardance and the mechanical property of the EVA is played, particularly, a role in obviously promoting char forming is played during combustion, and the molten drop phenomenon is eliminated.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com