Metal and carbon-based material electrode surface carbon nano tube coating and preparation method thereof

A carbon nanotube and electrode surface technology, which is applied in the coating process of metal materials, devices for coating liquid on the surface, coatings, etc., to achieve the effect of large specific surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

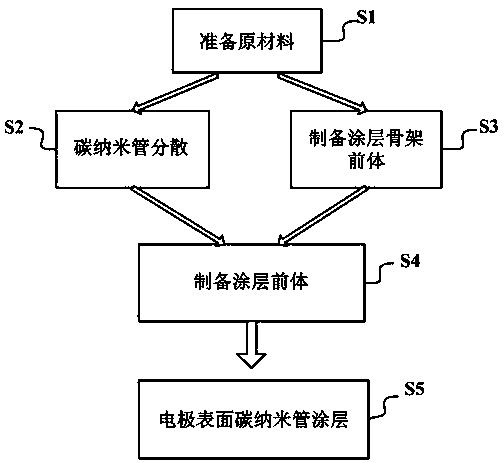

[0031] The preparation method comprises the following steps: S1: providing nano-surface functionalized carbon nanotubes, metal salt solution, organic solvent, polyvinyl alcohol, deionized water and target electrodes. Wherein the metal salt solution includes any of metal salts such as tetrabutyl titanate, chloroplatinic acid, aluminum isopropoxide and zinc acetate or contains any one of them, and the carbon nanotubes are functional after plasma treatment Carbonized carbon nanotubes, the organic solvent is any one of organic alcohols such as ethanol, isopropanol, n-butanol and butanol or contains any one of them, and the target carrier is a metal and carbon-based material electrode; S2: The carbon nanotubes are uniformly dispersed in an organic solvent, and ultrasonic treatment is performed to further disperse the carbon nanotubes in the solution. Wherein the mass fraction of carbon nanotubes in the carbon nanotube dispersion is 20% to 45%; S3: mix the metal salt solution with d...

Embodiment 1

[0037]Disperse 2.0 g of carbon nanotubes evenly in 10 g of absolute ethanol, and ultrasonicate for 30 min; mix 5.35 g of tetrabutyl titanate, 12.25 g of isopropanol and 0.45 g of deionized water, and slowly add 2.23 g of polyvinyl alcohol , stirred at room temperature for 2 h to obtain the coating skeleton precursor; uniformly mixed the dispersed graphene dispersion and the coating skeleton precursor at a mass ratio of 1:1, stirred at room temperature for about 1 h, and obtained the carbon nanotube coating precursor The precursor solution is coated on the surface of the target electrode, dried in an oven at 100°C for about 1 h, taken out, and placed in a tube furnace at 430°C for about 3 h to obtain the surface of the electrode. carbon nanotube coating.

Embodiment 2

[0039] Evenly disperse 3.0 g of carbon nanotubes in 10 g of absolute ethanol, and ultrasonicate for 30 min; mix 8.14 g of chloroplatinic acid, 12.25 g of isopropanol and 0.45 g of deionized water, slowly add 4.51 g of polyvinyl alcohol, and Stir for 4 h to obtain the coating skeleton precursor; uniformly mix the dispersed graphene dispersion and the coating skeleton precursor at a mass ratio of 3:1, and stir at room temperature for about 1 h to obtain the carbon nanotube coating precursor; Coat the precursor solution on the surface of the target electrode, dry it in an oven at 100°C for about 2 hours, take it out, and put it in a tube furnace at 500°C for a thermal decomposition reaction for about 3 hours to obtain carbon nanotubes on the electrode surface coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com