Hybridization film for FCC gasoline desulfurize and method of preparing the same

A hybrid membrane and gasoline technology, applied in chemical instruments and methods, membrane technology, petroleum industry, etc., can solve the problems of short service life, low sulfur capacity of adsorbent, etc., and achieve simple method, high adsorption rate and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

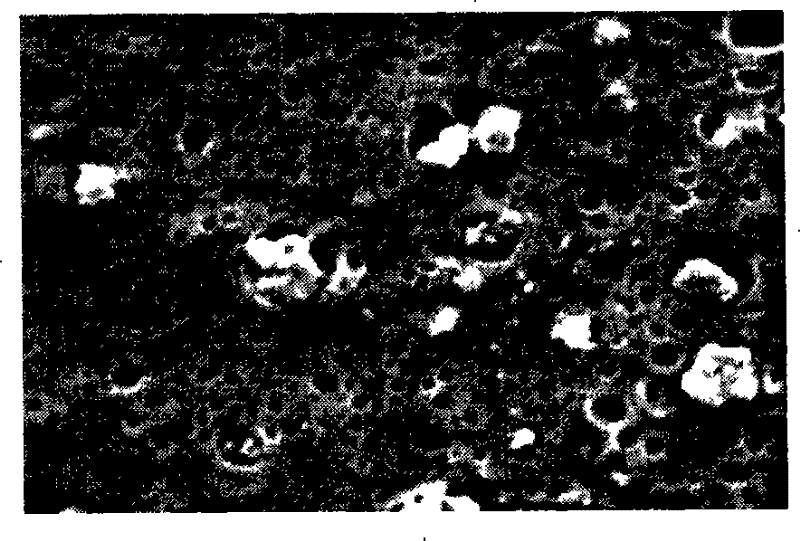

Image

Examples

Embodiment approach

[0044] The present invention simultaneously designs the preparation method of described hybrid film, and it comprises the following steps:

[0045] 1. Preparation of casting solution: According to the mass fraction requirements of the hybrid membrane formula of the present invention, fully mix the various components described, stir at 70-80°C for 4-12 hours, and let stand for degassing for 24 hours. After ~48 hours, a uniformly mixed casting solution was prepared.

[0046] 2. Membrane making: at 20-80°C, scrape-coat the prepared casting solution on a flat plate or non-woven fabric to form a flat film, and then soak it in a coagulation bath with a temperature of 20-80°C for 48-48°C. 72 hours, so that the membrane is completely solidified and formed, and the residual solvent and additives are removed, so that the desulfurization membrane with adsorption function can be prepared.

[0047] The flat plate includes a flat glass plate and a stainless steel plate; the scraping method...

Embodiment 1

[0053] The mass percent formulation of the hybrid membrane is designed as follows: 15 wt parts of polyethersulfone [BASF production]; 6.4 wt parts of CeY powder (PES / CeY=70 / 30), with an average particle size of 6.16 μm; 16 wt parts of polyethylene glycol-400; 4 parts by weight of polyvinylpyrrolidone and 58.6 parts by weight of N-methylpyrrolidone.

[0054] The process of manufacturing the hybrid membrane is as follows: first add 15g of polyethersulfone to 58.6g of NMP and stir at 70-80°C for more than 4 hours. After the dissolution is complete, add 16g of PEG-400 and 4g of PVP. After the solid is completely dissolved, add 6.4 gCeY, in order to ensure that the CeY powder is completely dispersed in the polymer, let stand for degassing for 24 hours, and prepare a casting solution; manually scrape the casting solution at a temperature of 40°C on a glass plate to form a flat film with a thickness of 0.25mm Afterwards, it is solidified and formed in a water coagulation bath at 60° ...

Embodiment 2

[0056] The mass percentage formula of the hybrid membrane is designed as follows: 15 wt parts of polyethersulfone [BASF production]; 22.5 wt parts of CeY powder (PES / CeY=40 / 60), with an average particle size of 6.16 μm; 16 wt parts of polyethylene glycol-400; 8 parts by weight of polyvinylpyrrolidone and 42.5 parts by weight of N-methylpyrrolidone.

[0057] The process of manufacturing the hybrid membrane is as follows: first add 15g of polyethersulfone to 42.5g of NMP and stir at 70-80°C for more than 4 hours. After the dissolution is complete, add 16g of PEG-400 and 4g of PVP. After the solid is completely dissolved, add 22.5 gCeY, in order to ensure that the CeY powder is completely dispersed in the polymer, let stand for degassing for 24 hours, and prepare a casting solution; manually scrape the casting solution at a temperature of 40°C on a glass plate to form a flat film with a thickness of 0.25mm Afterwards, solidify and shape in a water coagulation bath at 60°C; then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com