Fischer-Tropsch synthesis method

A Fischer-Tropsch synthesis and carbon monoxide technology, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the production of hydrocarbons from carbon oxides. The effect of increasing the conversion rate and increasing the selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

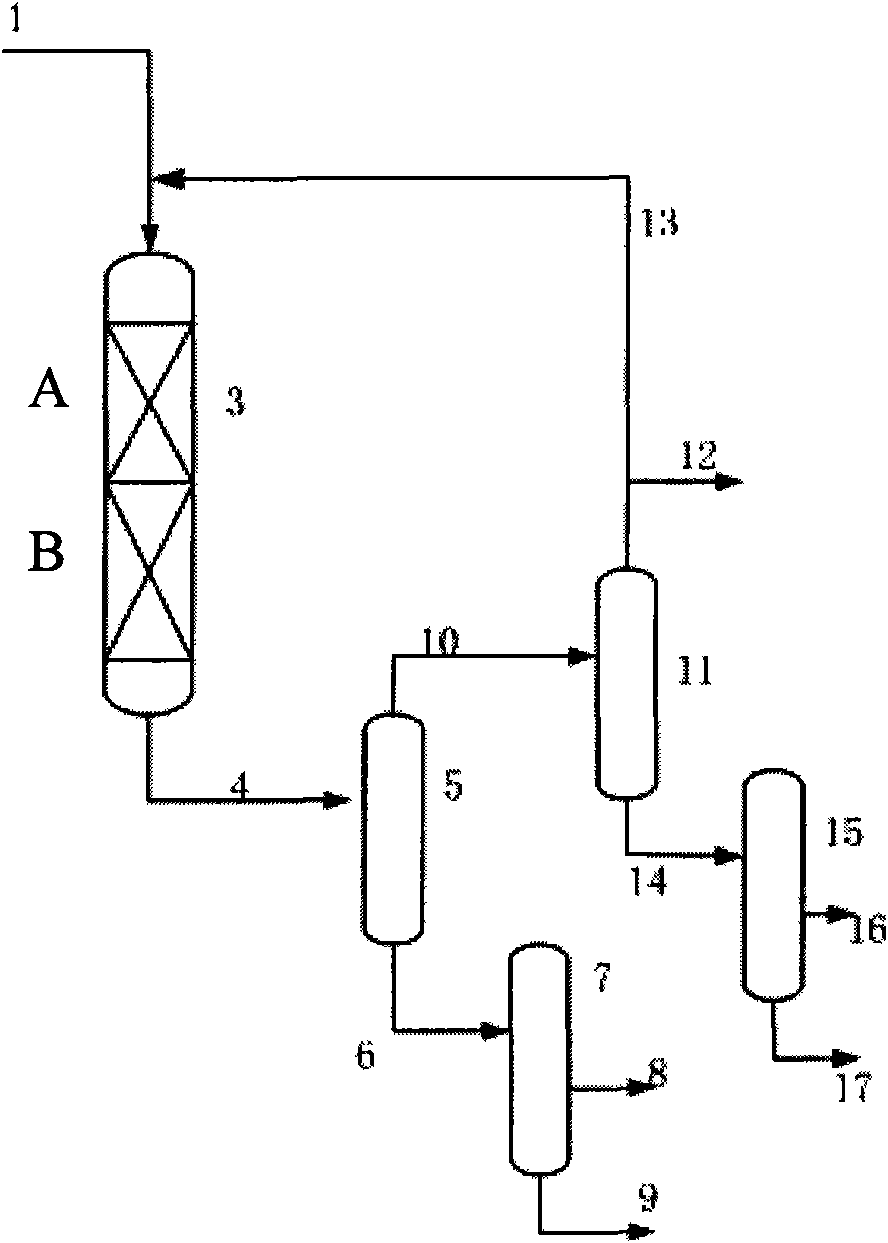

[0027] like figure 1 In the device shown, the first Fischer-Tropsch synthesis catalyst is loaded in the first reaction zone A of the reactor, and the second Fischer-Tropsch synthesis catalyst is loaded in the second reaction zone B. Wherein, the pore volume of the first Fischer-Tropsch synthesis catalyst is 0.4 ml / g (the carrier roasting temperature is 950° C., the catalyst roasting temperature is 400° C.), and the total weight of the first catalyst is used as the benchmark, and the content of cobalt oxide is 14% by weight. For alumina, the specific surface area is 200 square meters / g. The pore volume of the second Fischer-Tropsch synthesis catalyst is 0.6 ml / g (the calcination temperature of the carrier is 900°C, and the calcination temperature of the catalyst is 400°C). Based on the total weight of the second catalyst, the content of cobalt oxide is 14% by w...

Embodiment 2

[0029] This example is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

[0030] According to the same method as in Example 1, the difference is that the pore volume of the first Fischer-Tropsch synthesis catalyst is 0.2 ml / g (the carrier calcination temperature is 1050°C, the catalyst calcination temperature is 400°C), and the pore volume of the second Fischer-Tropsch synthesis catalyst is It is 0.9 ml / g (the carrier calcination temperature is 700°C, the catalyst calcination temperature is 400°C), and the volume ratio of the first catalyst and the second catalyst is 7:3.

Embodiment 3

[0032] This example is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

[0033] According to the same method as in Example 1, the difference is that the pore volume of the first Fischer-Tropsch synthesis catalyst is 0.3 ml / g (the carrier calcination temperature is 980°C, the catalyst calcination temperature is 400°C), and the pore volume of the second Fischer-Tropsch synthesis catalyst is It is 0.7 ml / g (the carrier calcination temperature is 800°C, the catalyst calcination temperature is 400°C), and the volume ratio of the first catalyst and the second catalyst is 3:7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com