High-dispersion polyoxometallate magnetic microsphere catalyst, and preparation method and application thereof

A technology of polyoxometalates and magnetic microspheres, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve difficult recovery, difficult separation, active Limited space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

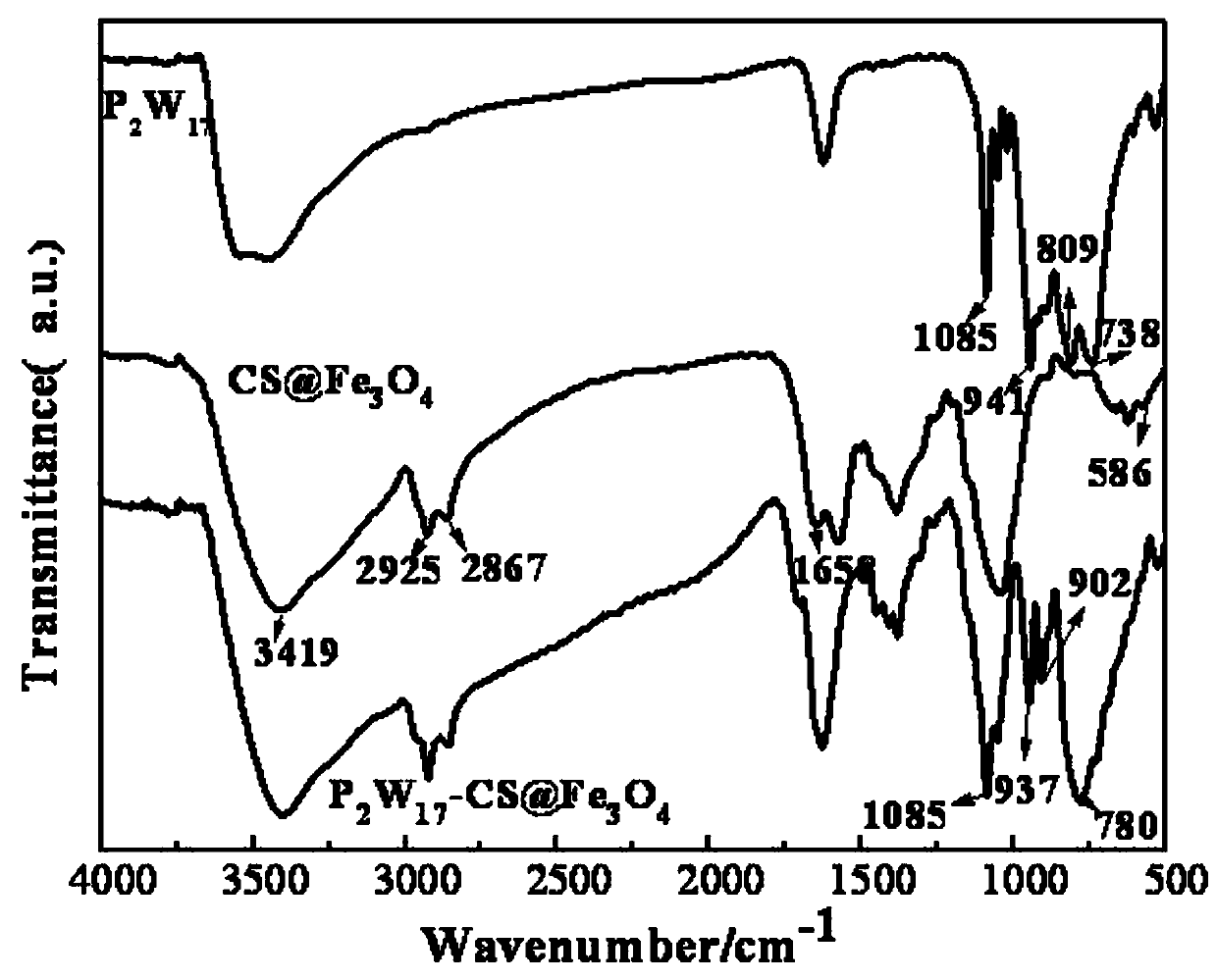

Image

Examples

Embodiment 1

[0023] Embodiment 1: the Fc of chitosan modification 3 o 4 Covalent loading of P on magnetic microspheres 2 W 17 Composite catalyst P 2 W 17 -CS@Fe 3 o 4 -1 preparation: the steps are as follows: 156 mg KH-560 and 1.0 g P 2 W 17 Add it to a mixed solution of 30 mL of acetonitrile and water ((V / V)=1:2), adjust the pH of the solution to 2, react at room temperature for 6 h, and then pour the reaction solution into a beaker. Then containing 0.84 gNBu 4 Add 5 mL of Br aqueous solution to the above reaction solution, the solution turns white, and viscous precipitates form at the bottom, filter, wash with ethanol and water in sequence, and dry with ether to obtain a white solid powder, which is epoxy-modified tungsten phospholipid Salt P 2 W 17 -EPO; then 0.3 g CS@Fe 3 o 4 Microspheres were added to 30 mL of DMF, N 2 Under protection, add 0.1 g NaOH solid and 0.3 gP 2 W 17 -EPO,N 2 Under protection, raise the temperature to 60 °C, react for 24 h, cool to room temper...

Embodiment 2

[0024] Embodiment 2: the Fc of chitosan modification 3 o 4 Covalent loading of P on magnetic microspheres 2 W 17 Composite catalyst P 2 W 17 -CS@Fe 3 o 4 -1 preparation: the steps are as follows: 256 mg KH-560 and 2.0 g P 2 W 17 Add it to a mixed solution of 40 mL of acetonitrile and water ((V / V)=2:2), adjust the pH of the solution to 3, react at room temperature for 8 h, and then pour the reaction solution into a beaker. Then containing 0.84 gNBu 4 Add 7 mL of Br aqueous solution to the above reaction solution, the solution turns white, and a viscous precipitate forms at the bottom. Then, filter, wash with ethanol and water in sequence, and dry with ether to obtain a white solid powder, which is epoxy-modified Phosphotungstate P 2 W 17 -EPO; then 0.4 g CS@Fe 3 o 4 Microspheres were added to 40 mL of DMF, N 2 Under protection, add 0.2 g Na 2 CO 3 solid and 0.4 g P 2 W 17 -EPO,N 2 Under protection, the temperature was raised to 70 °C, reacted for 25 h, cooled...

Embodiment 3

[0025] Embodiment 3: the Fc of chitosan modification 3o 4 Covalent loading of P on magnetic microspheres 2 W 17 Composite catalyst P 2 W 17 -CS@Fe 3 o 4 -1 preparation: the steps are as follows: 356 mg KH-560 and 3.0 g P 2 W 17 Add it to a mixed solution of 50 mL of acetonitrile and water ((V / V)=2:3), adjust the pH of the solution to 4, react at room temperature for 9 h, and then pour the reaction solution into a beaker. Then containing 0.84 gNBu 4 9 mL of aqueous solution of Br was added to the above reaction solution, the solution turned white, and a viscous precipitate formed at the bottom. Then, it was filtered, washed with ethanol and water in sequence, and dried with ether to obtain a white solid powder, which was epoxy-modified Phosphotungstate P 2 W 17 -EPO. Then 0.5 g CS@Fe 3 o 4 Microspheres were added to 50 mL of DMF, N 2 Under protection, add 0.3 g NaHCO 3 Solid and 0.5 g epoxy-modified phosphotungstate P 2 W 17 -EPO,N 2 Under protection, raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com