Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Eliminate scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-plastic composite mobile phone shell and forming method thereof

InactiveCN103722668AUniform wall thicknessBeautiful surfaceDomestic articlesCoatingsConvex structureUltimate tensile strength

The invention provides a metal-plastic composite mobile phone shell and a forming method thereof. The provided mobile phone shell has a metal surface and a plastic structure feature, wherein the external surface of the mobile phone shell is made of a sheet metal and is small in wall thickness, high in strength and beautiful in appearance; a convex structure feature of the internal surface of the mobile phone shell is made of plastics, so that the formation of a complex installation structure is facilitated, and the functional requirements on assembling and shock absorption and the like are satisfied. According to the forming method, structure features of the sheet metal and the plastic are firmly combined together and form an integral structure. Meanwhile, according to the forming method, the combination strength of plastics and metals is high, so that the mobile phone shell satisfies the assembling and application requirements of mobile phones, and also can be applied to the shell production fields of household appliances, computers and other industrial products.

Owner:ZHEJIANG NORMAL UNIVERSITY

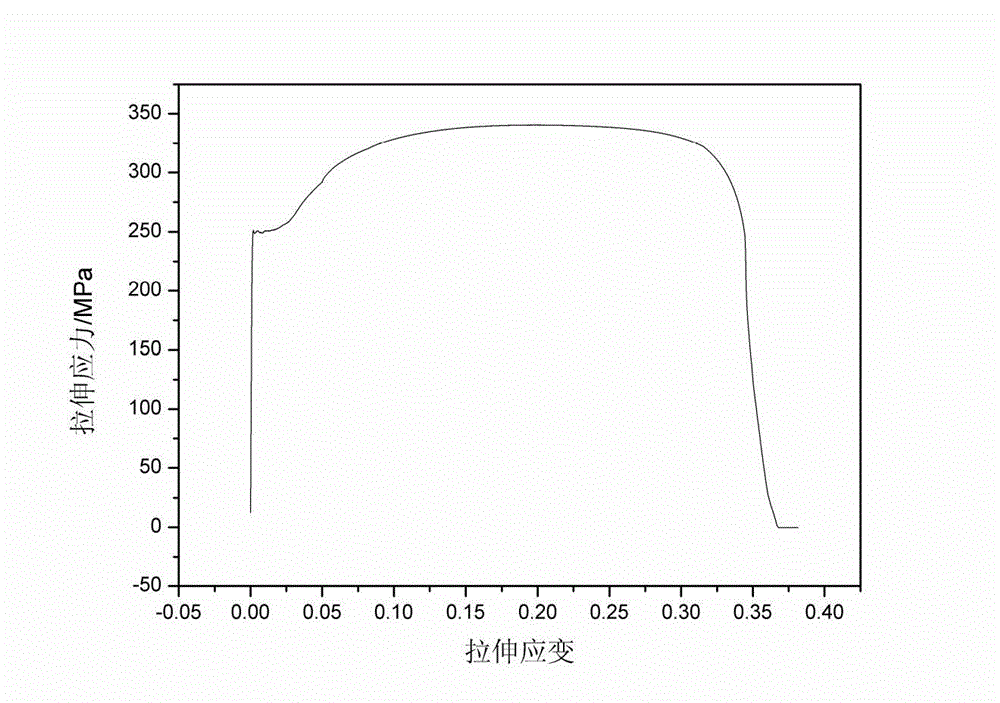

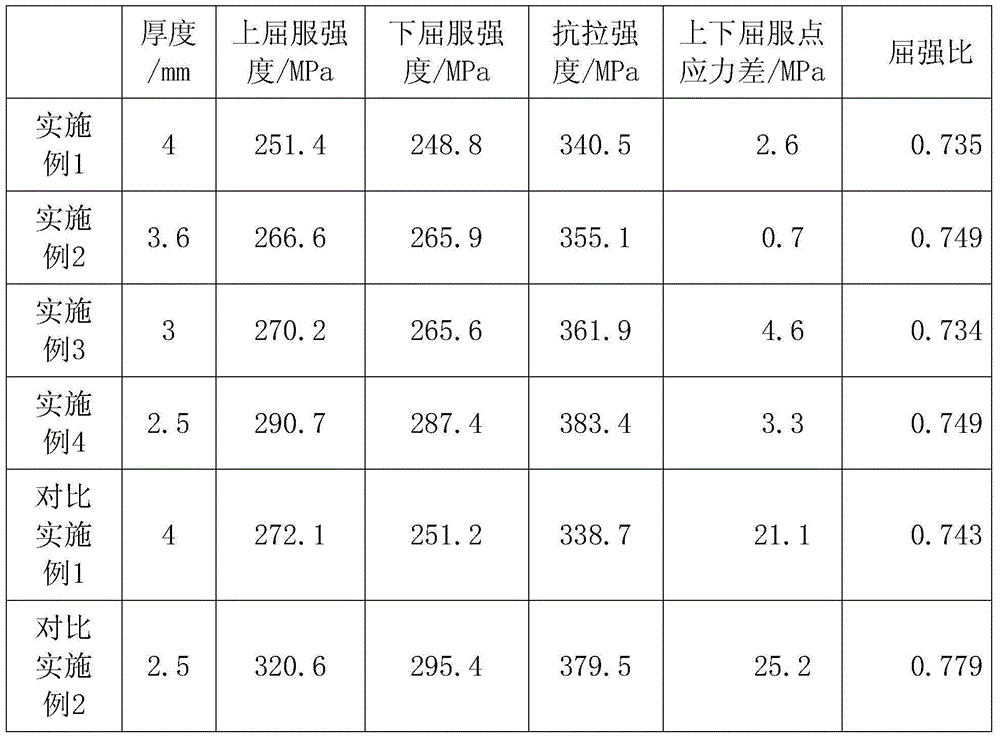

Hot-rolled pickled plate and production method thereof

The invention discloses a hot-rolled pickled plate and a production method thereof. According to the hot-rolled pickled plate, based on a common low carbon steel component system, by reasonably adding microalloy elements B and Ti and combining insulation of a coilbox before finish rolling and relaxation and cooling after finish rolling, the effects of controlling structures and a precipitated phase as well as reducing KESHI gas mass in the low carbon steel are achieved, so that the stress difference of upper and lower yield points of a hot rolled strip is reduced to below 5MPa and the defect of surface cross breaks of the hot rolled strip in a pickling, uncoiling and straightening process is eliminated. Not only is the defect of surface cross breaks of the hot rolled strip solved, but also the conventional production process of eliminating cross breaks by temper rolling is further avoided, thereby shortening the time and lowering the cost for actual production of a steel mill. The production method is an economical and effective production method of the hot-rolled pickled plate. The hot-rolled pickled plate disclosed by the invention can be widely applied to industries of household appliances, automobiles and hardware mechanical and electrical products.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD

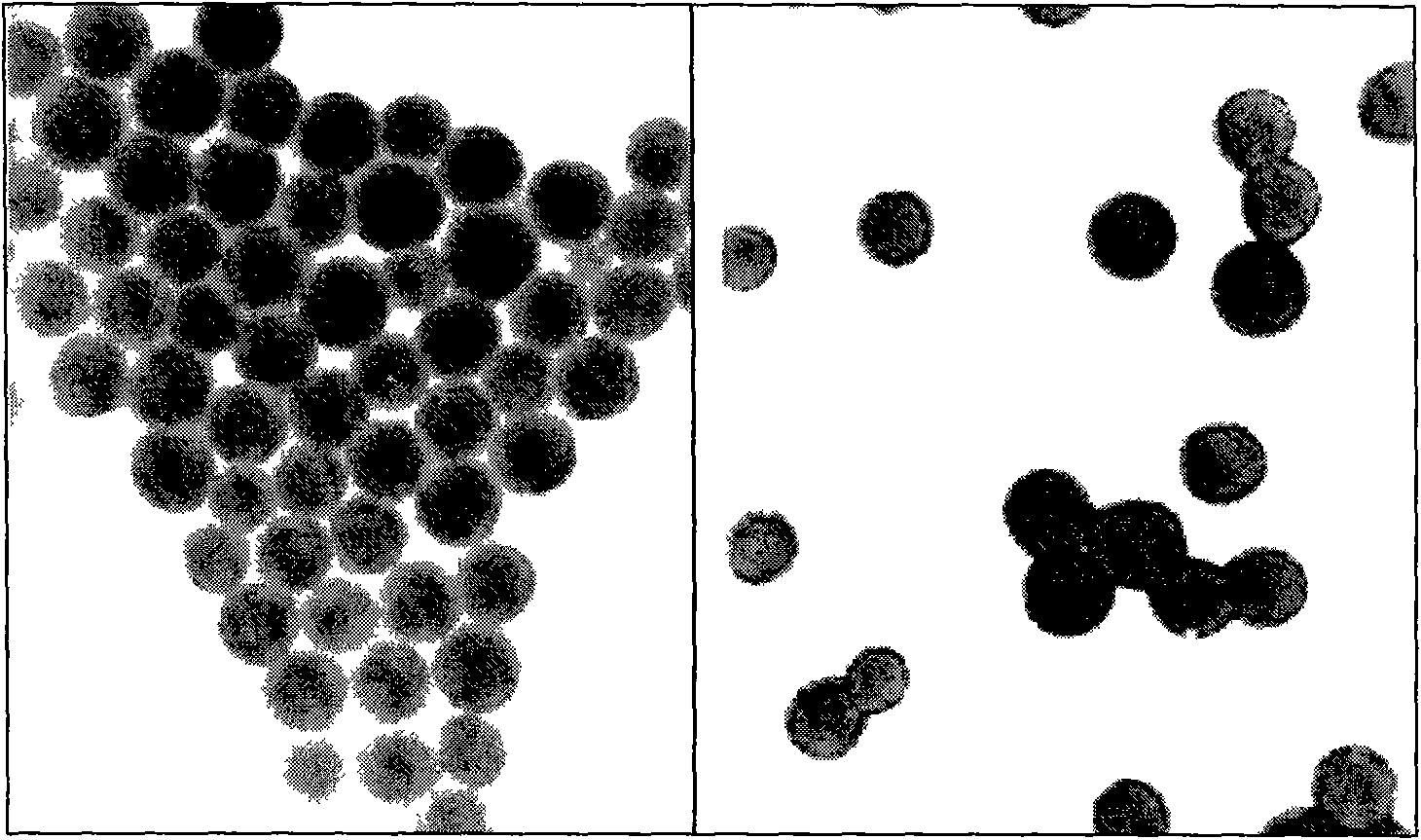

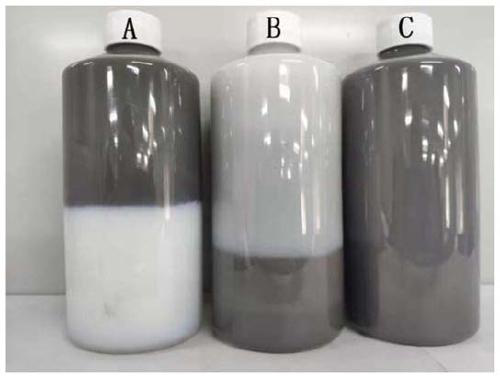

Method for preparing silica/ceria composite abrasive grains

ActiveCN101671538AGood removal effectHigh selectivityOther chemical processesSemiconductor/solid-state device manufacturingVery large scale integrated circuitsCerium

The invention relates to a method for preparing silica / ceria composite abrasive grains, which comprises the following steps: 1) adding organic additives to silicon sol, stirring until the organic additives dissolve, and then, adding trivalent or tetravalent cerium salts, so as to obtain a dispersion liquid; 2) placing the dispersion liquid in an autoclave provided with a PTFE (polytetrafluoroethylene) lining, sealing the autoclave and conducting a heating reaction; and 3) centrifugating, purifying and stoving after the reaction, and finally obtaining the silica / ceria composite abrasive grains.The silica / ceria nuclear-shell composite abrasive grains prepared by the invention contain no homogeneous-nucleation ceria grains; and the composite abrasive grains have the advantages that the polishing removal rate and the selectivity thereof can be effectively increased, the surface roughness thereof can be reduced and the defects, such as scratches, can be eliminated. Therefore, the compositeabrasive grains are applicable to the chemical mechanical polishing (CMP) of very-large-scale integrated circuits (VLSIC) and glass.

Owner:浙江新创纳电子科技有限公司

Semiconductor material polishing method and polishing solution for polishing gallium antimonide substrate

PendingCN112701037AImprove surface roughnessGuaranteed stabilitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGallium antimonideOrganic acid

In order to overcome the defects that when a soft semiconductor material such as gallium antimonide is polished by adopting a CMP (Chemical Mechanical Polishing) process in the prior art, metal ions and the like contained in a polishing abrasive and a polishing solution are easily attached to the surface of a polished object, scratches are generated on the surface of the polished object, and the service life of the polishing solution is short, the invention provides a semiconductor material polishing method and a polishing solution for polishing a gallium antimonide substrate. According to the method, a semiconductor material with the Mohs hardness of 1.5-6 is polished. A first step is rough polishing, and a polishing solution containing a hard abrasive is adopted to conduct mechanical polishing on a semiconductor material substrate slice. A second step is medium polishing, and a medium polishing solution comprises a soft polishing abrasive, a weak acid oxidizing agent, organic acid, a hydrophilic nonionic surfactant and deionized water. A third step is fine polishing, and a fine polishing solution comprises a weak acid oxidizing agent, organic acid and deionized water. When the polishing method is adopted for polishing a semiconductor material, corrosion pits and scratches are eliminated, pits are reduced, and a material with good surface roughness is obtained.

Owner:SUZHOU KUNYUAN OPTOELECTRONICS CO LTD

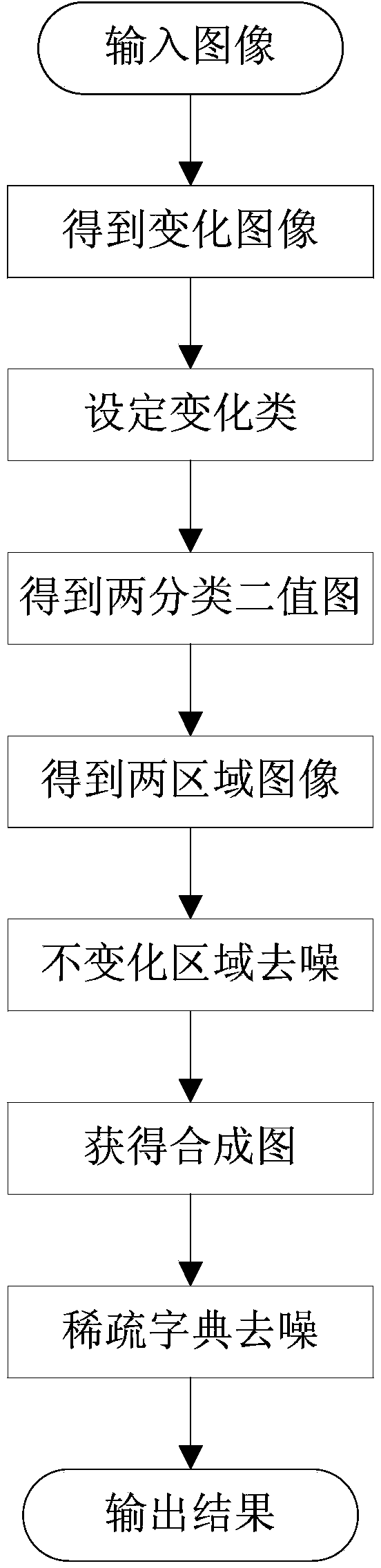

SAR image sparsing denoising method based on change detection

InactiveCN103473755AImprove consistencyOvercoming the problem of introducing false informationImage enhancementPattern recognitionChange detection

The invention discloses an SAR image sparsing denoising method based on change detection. The SAR image sparsing denoising method includes the steps of firstly, inputting an image; secondly, obtaining a changed area image; thirdly, setting a change classification; fourthly, obtaining a two-classification binary image; fifthly, obtaining a two-area image; sixthly, conducting denoising on unchanged areas; seventhly, estimating noise standard deviation; eighthly, obtaining a synthetic image; ninthly, conducting sparsing dictionary denoising; tenthly, outputting a result. The denoising preprocessing is conducted for the SAR image change detection, and the SAR image sparsing denoising method has the advantages that the consistency of a changed area is kept well, the noise of an unchanged area can be well restrained, meanwhile, the texture detail information, outline detail information and edge detail information of an SAR image, especially of the changed area which has great influence on change detection at later period are reserved, scratches produced after denoising is conducted on the image are eliminated, the pseudo information produced when noise is restrained is reduced, and the accuracy of the change detection is improved.

Owner:XIDIAN UNIV

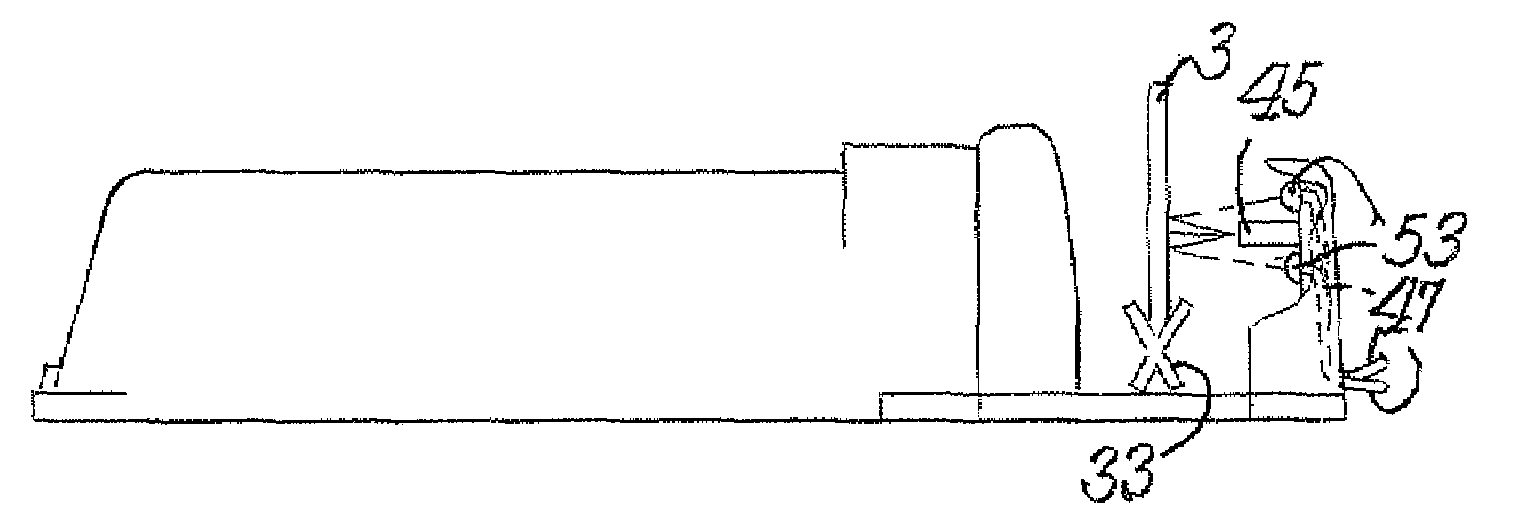

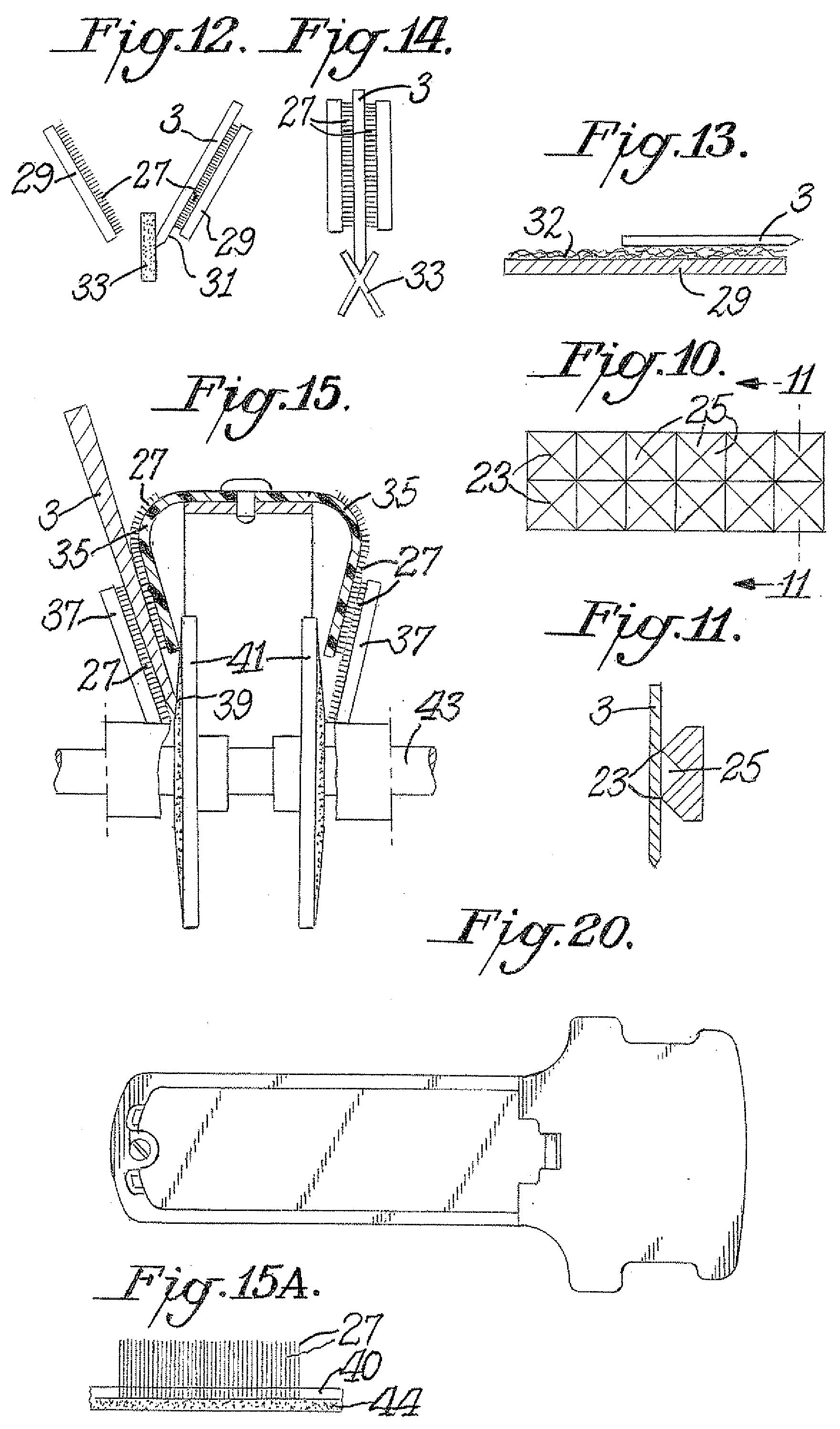

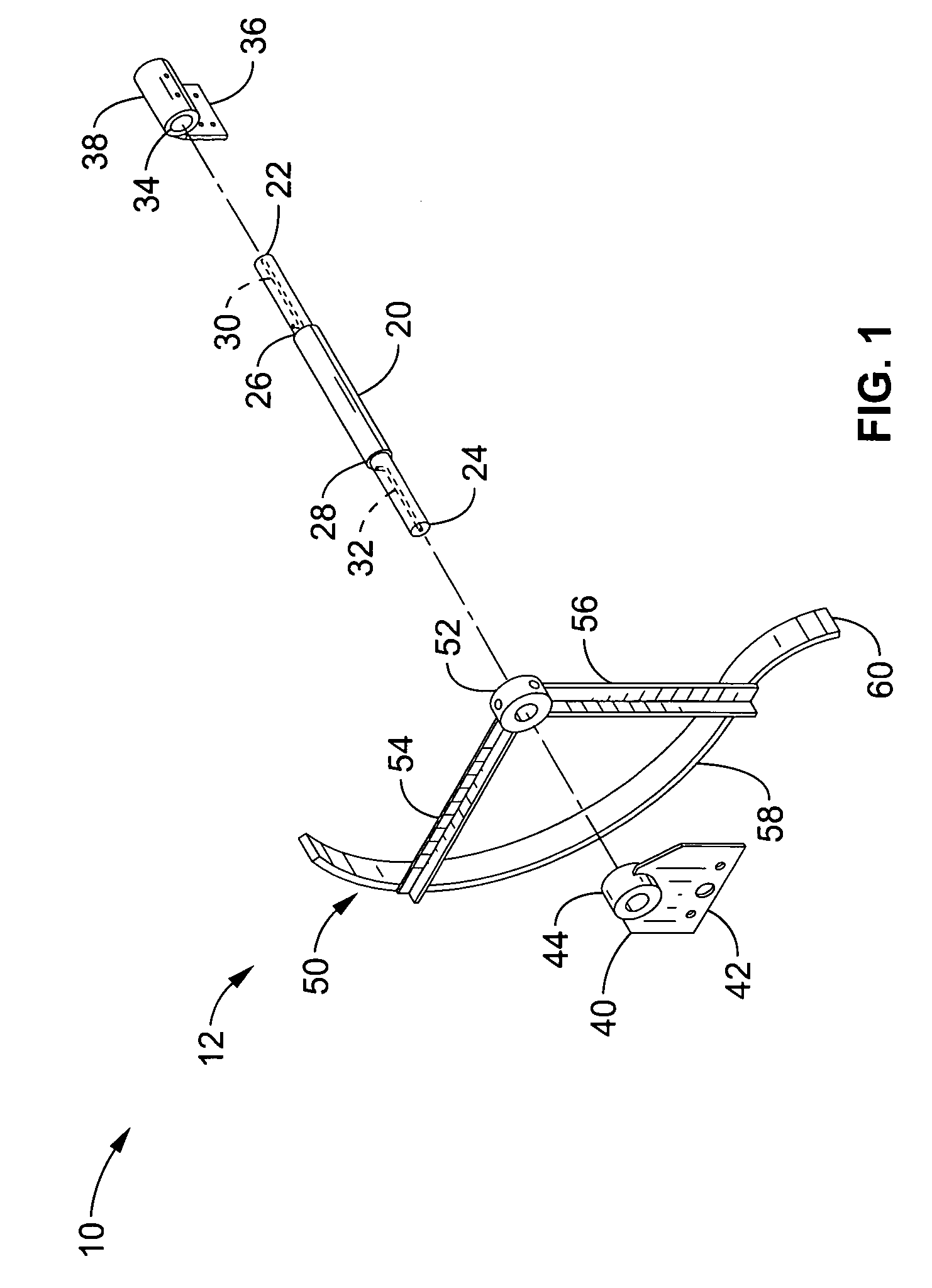

Knife sharpener with improved knife guides

ActiveUS20070197148A1Eliminate burnishingEliminate scratchesEdge grinding machinesRevolution surface grinding machinesKnife sharpenerKnife blades

Owner:EDGECRAFT

Optical disc apparatus

InactiveUS20080235715A1Eliminate scratchesSolid reliabilityRecord information storageRecord carrier contruction detailsControl signalActuator

To eliminate scratches on a disc surface of an optical disc in an emergency eject operation, there is provided an optical disc apparatus including: an emergency eject detector for detecting an emergency eject instruction; a rotation speed detector for producing a signal corresponding to the rotation speed of the optical disc; and a logical circuit unit which is operated by a first signal from the emergency eject detector and a second signal from the rotation speed detector, and when the second output signal is not more than a reference level, produces a third signal so as to input a control signal for instructing stop of the actuator control into an actuator controller. After detection of the emergency eject instruction, the apparatus performs the actuator control without producing the third signal until the rotation speed is not more than a predetermined value. Thus the objective lens is made in a focus control state or in a saving state in which the objective lens is separated from the disc surface.

Owner:HITACHI-LG DATA STORAGE

High-precision efficient automatic grinding and detecting production line and high-precision efficient automatic grinding and detecting production method

ActiveCN105728851ARealize automatic detection functionRealize fully automatic processingMetal sawing tool makingMeasurement/indication equipmentsProduction lineThree degrees of freedom

The invention discloses a high-precision efficient automatic grinding and detecting production line which comprises a manipulator mechanism (s) with three degrees of freedom, a cleaning mechanism (q), a turnover mechanism (f), a detecting mechanism (j), a working table (g), a material table (w) and two grinding machines (m). The two grinding machines (w) are respectively arranged at two ends of the working table (g); the manipulator mechanism (s) with the three degrees of freedom is used for loading and unloading materials; the working table (g) is used for mounting the manipulator mechanism (s) with the three degrees of freedom, the cleaning mechanism (q), the turnover mechanism (f), the detecting mechanism (j) and the material table (w); the material table (w) is used for arranging workpieces. The invention further provides a high-precision efficient automatic grinding and detecting production method. The high-precision efficient automatic grinding and detecting production line and the high-precision efficient automatic grinding and detecting production method have the advantages that the high-precision efficient automatic grinding and detecting production line is compact in structure, material grabbing, workpiece cleaning, workpiece turnover and workpiece detecting and mounting can be carried out on the same working table, the two grinding machines can be in simultaneous working states under various actions of manipulators, and accordingly the work efficiency can be greatly improved.

Owner:LINQING XINGHE HONGXIN MACHINE

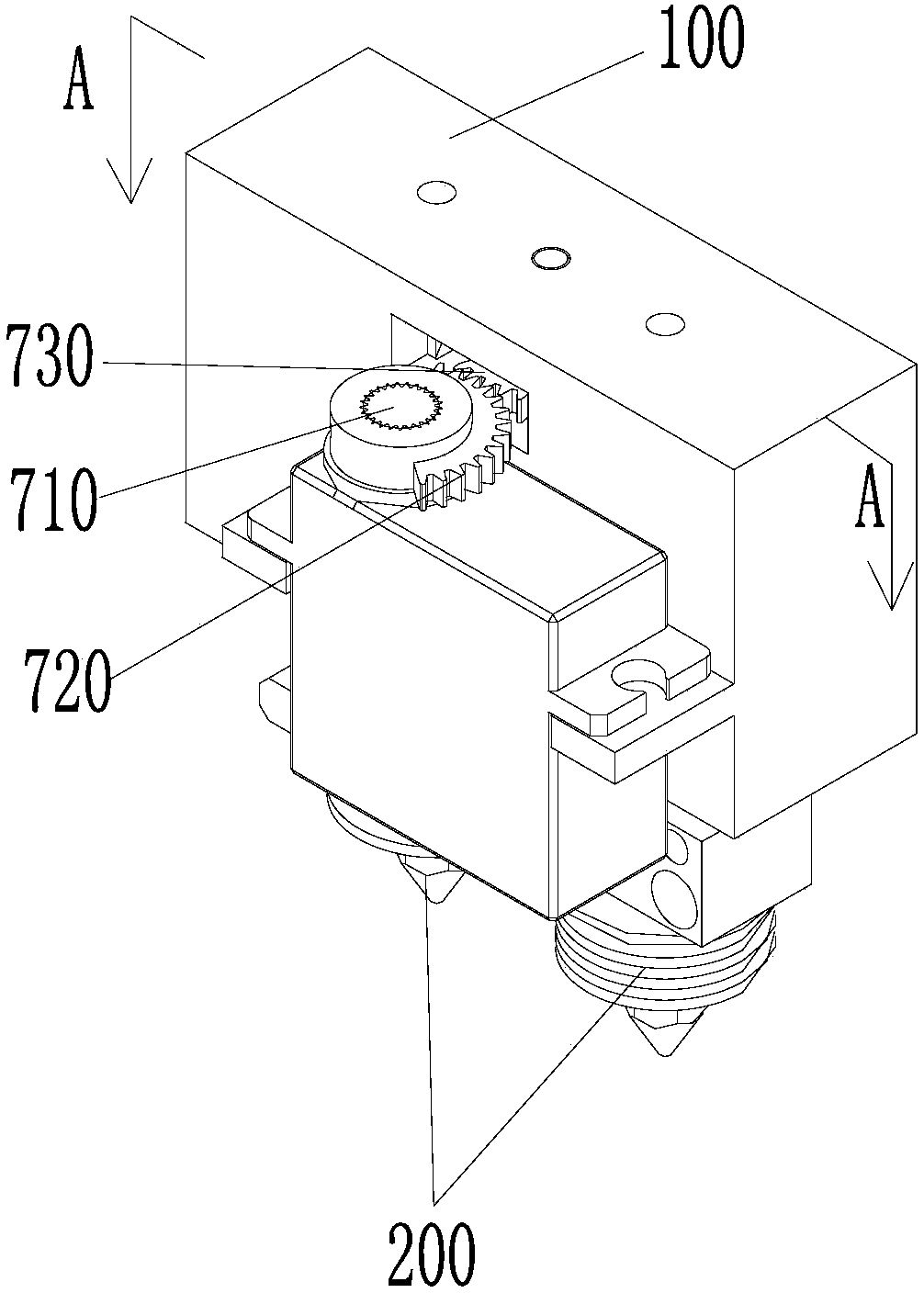

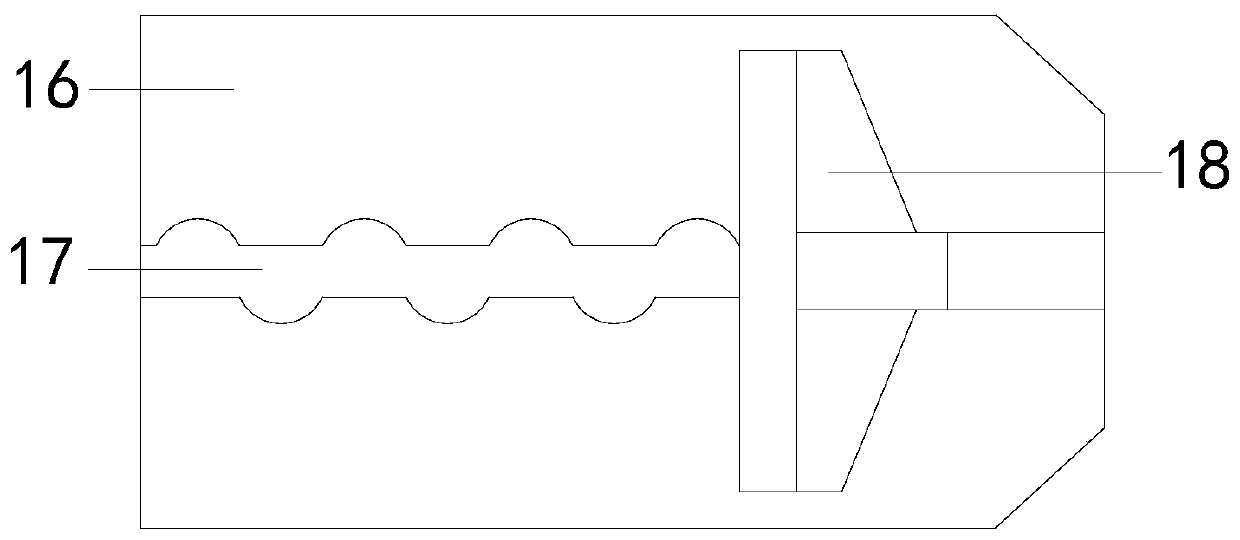

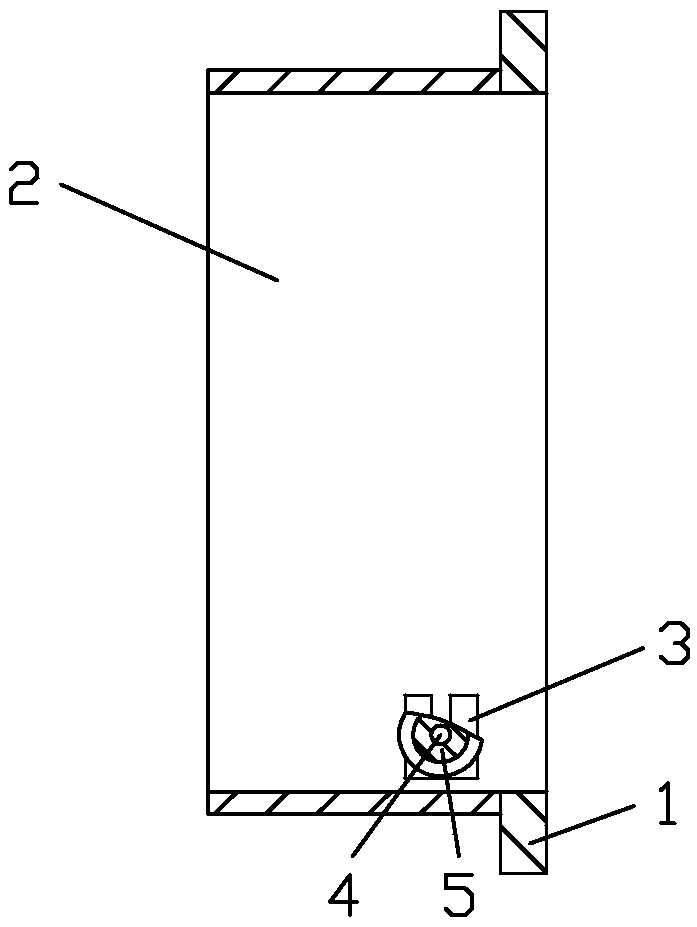

Double-sprayer switching device for 3D printer

PendingCN107599393AEliminate scratchesHigh positioning accuracyManufacturing driving meansApplying layer means3d printPressure transmission

The invention provides a double-sprayer switching device for a 3D printer. The double-sprayer switching device for the 3D printer comprises two switch blocks of a mutual mirror structure, a rotation piece and two elastic pieces. The two switch blocks are installed on two sprayer devices. Each switch block is provided with a pressure bearing portion. Each pressure bearing portion comprises a downward pressing station stopping portion, a pressure transferring portion and a return station stopping portion, wherein the pressing station stopping portion, the pressure transferring portion and the return station stopping portion are sequentially connected. The rotation piece is connected with a machine shell. Two pressing pieces are arranged on the rotating piece. The two elastic pieces are arranged on the two sprayer devices in a sleeving manner. The elastic pieces support the switch blocks. The rotating pieces can rotate in a reciprocating manner. The rotating piece drives the pressing pieces to move on the pressure bearing portions. When the pressing pieces move from the return station stopping portions to the downward pressing station stopping portions, the pressing pieces push the pressure transferring portions to move downwards. When the pressing pieces move on the downward pressing station stopping portions or the return station stopping portions, the pressure bearing portionskeep the stopped state. The double-sprayer switching device for the 3D printer can eliminate the phenomenon that in the 3D print process, the double sprayer devices scratch each other, and the sprayerdevices have high locating precision and high repeated locating precision in the movement process.

Owner:SHANGHAI FUSION TECH CO LTD

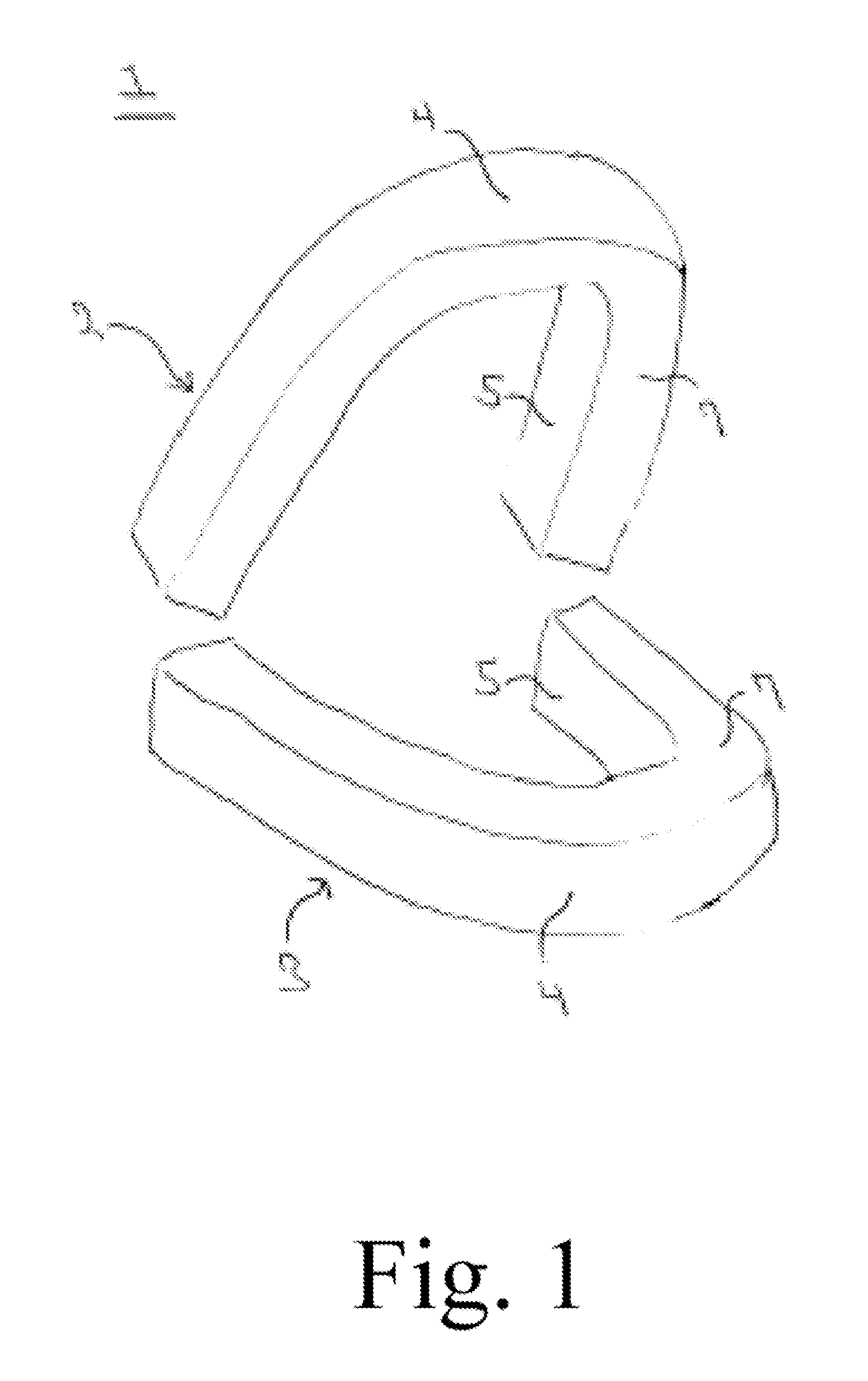

Oral device

InactiveUS8037883B2Eliminating abrasionEliminate scratchesOperating chairsTeeth fillingPenisClitoris

The present invention is an oral device comprised of two main components, a U-shaped lower bite plate and a U-shaped upper bite plate, which are molded to fit the front teeth of a wearer with a soft flexible contact surface. The oral device of the present invention comprises an upper bite plate and a lower bite plate each having a generally U-shaped appearance. The upper bite plate removably fits over the upper teeth of a person and the lower bite plate removably fits over the lower teeth of a person. Each bite plate includes a U-shaped buccal side and a U-shaped lingual side connected by a U-shaped top portion. The U-shaped top portion is further comprised of an exposed surface and an attaching surface where the exposed surface is the surface that contacts a penis, clitoris, or other body part while the attaching surface contacts the wearer's teeth.

Owner:ENGEL HARRY

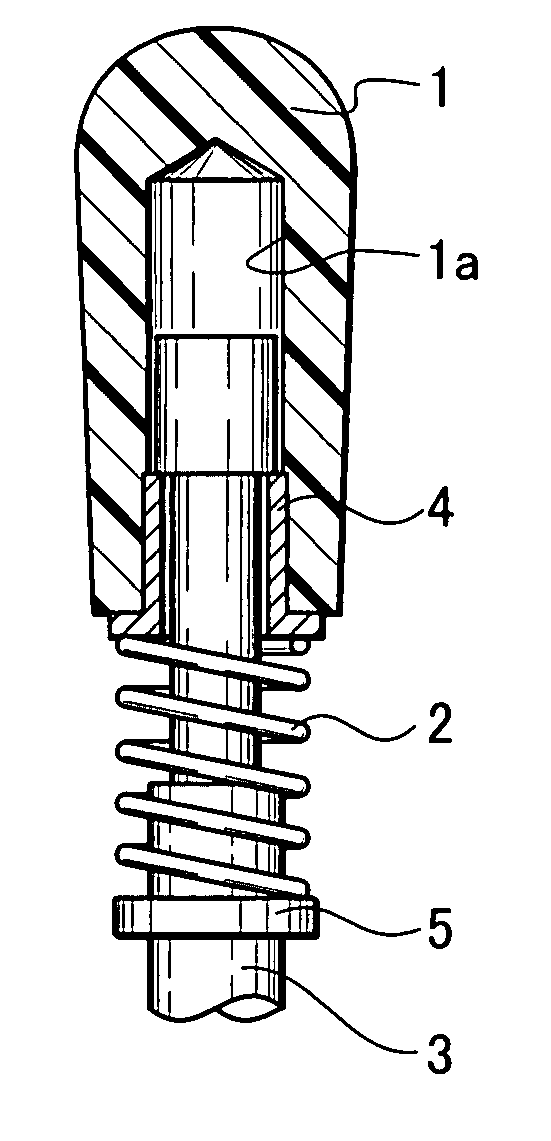

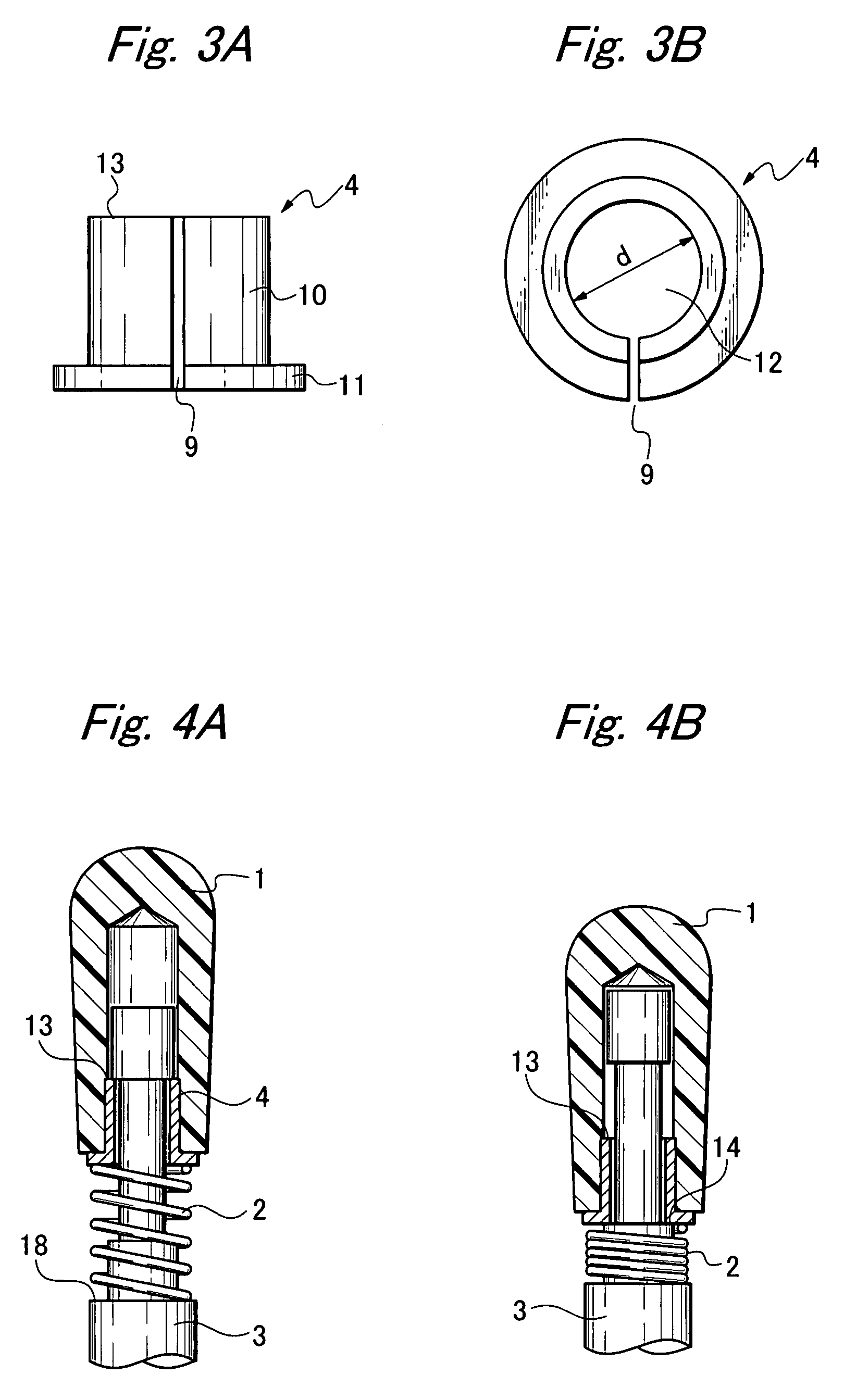

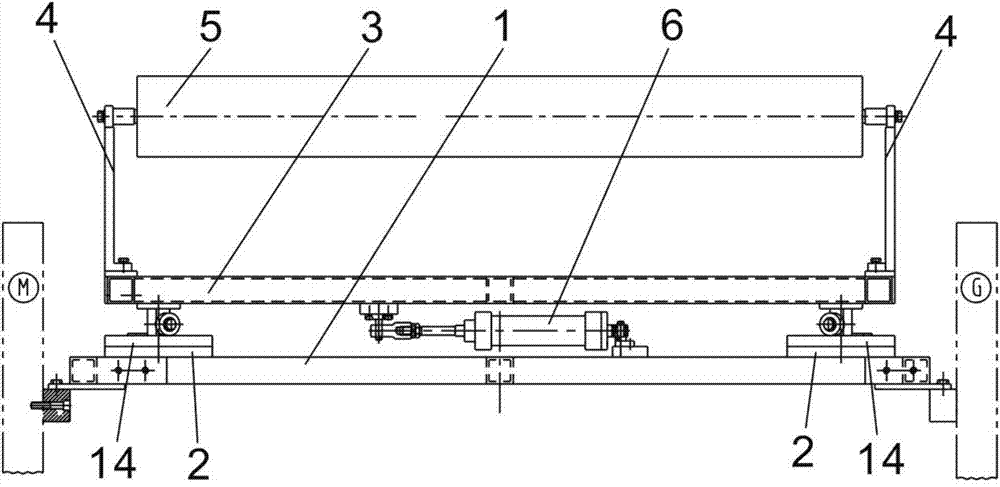

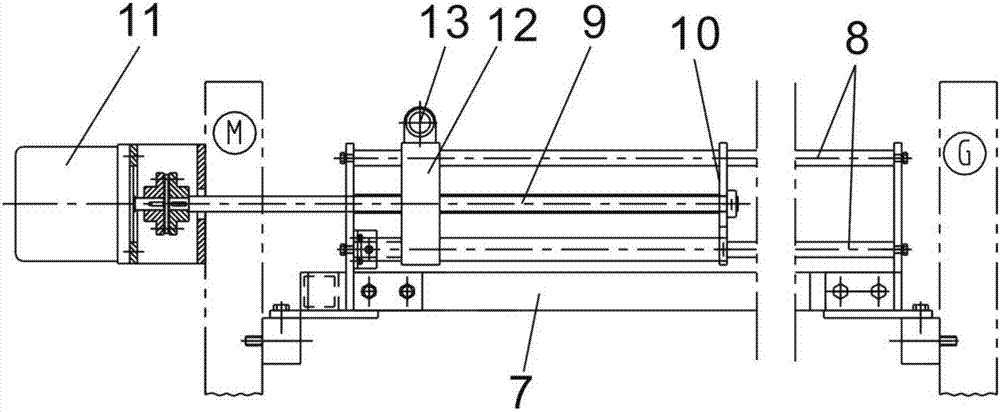

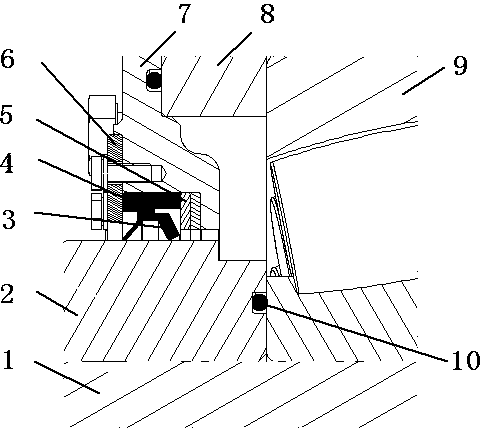

Pin tip attachment structure of conveyor chain for can making

To provide a pin tip attachment structure that can engage a container with a bottom, such as a can or bottle, and convey the container without scratching it, a small diameter portion having a predetermined length is formed at a front end portion of a pin. A bushing is fitted in a lower end portion of a cylindrical hole of a pin tip having the cylindrical hole opened at a lower end side, and the bushing is vertically movably inserted onto the small diameter portion of the pin. A stopper portion for retaining the bushing is provided at a front end of the small diameter portion. A spring receiver portion is provided below the small diameter portion, and a coil spring is provided in a compressible manner between the spring receiver portion and the bushing or the lower end of the pin tip.

Owner:DAIDO KOGYO CO LTD

Single-roller rectification device during proceeding

The invention discloses a single-roller rectification device during proceeding. The single-roller rectification device comprises a movable track mechanism and a film detecting mechanism, wherein connecting plates are fixedly connected to two ends of the upper surface of a lower fixed bracket of the movable track mechanism respectively, and are connected with an upper movable bracket through deflection mechanisms; guide roller brackets are fixedly connected to two ends of the upper movable bracket, and a rectification guide roller is arranged between the guide roller brackets; a pusher is mounted between the lower fixed bracket and the upper movable bracket; the film detecting mechanism comprises a fixed detection frame, guide plain shafts are mounted on the detecting fixed frame, a screw rod is arranged between the guide plain shafts, a bar-shaped support frame is fixedly connected to one end of the screw rod, two ends of the support frame are nested on the guide plain shafts, and the other end of the screw rod is connected with a synchronous motor; the guide plain shafts are further sleeved with a sliding block which is in threaded connection with the screw rod; and a detecting head is mounted on the sliding block. According to the single-roller rectification device, the film can be rectified to a suitable position precisely in a high-speed proceeding process, and is not prone to wrinkling or scrapping.

Owner:SHAANXI BEIREN PRINTING MACHINERY

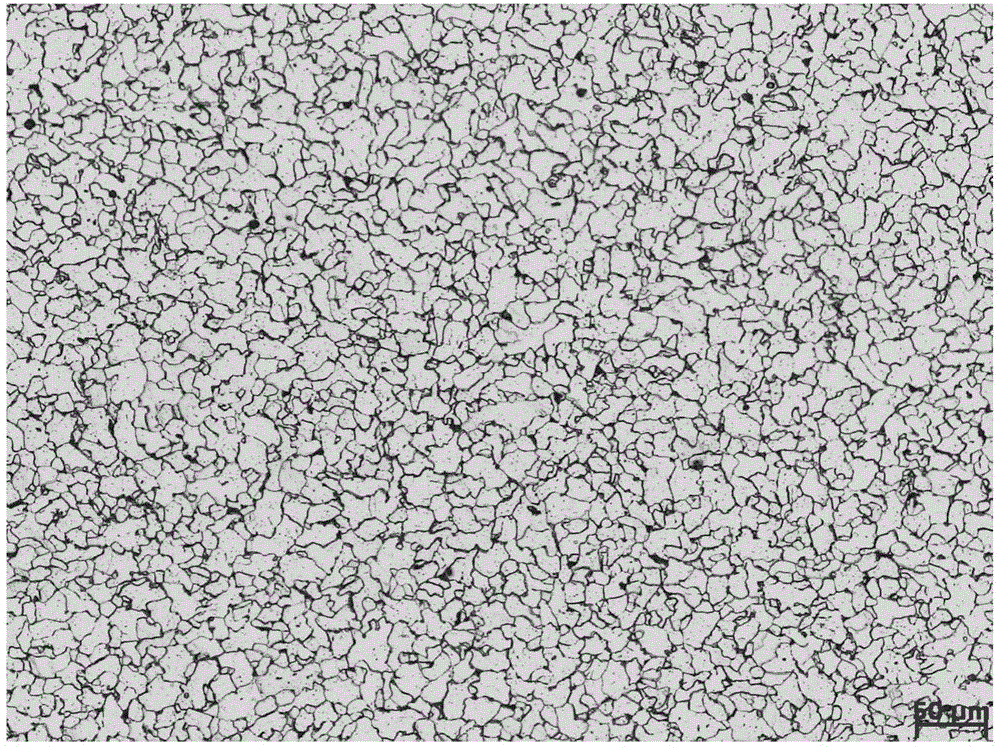

Preparation method of aluminium alloy metallographic sample

InactiveCN104198257AShort manufacturing timeImprove Surface DefinitionPreparing sample for investigationMetallurgyAluminium alloy

The invention provides a preparation method of an aluminium alloy metallographic sample. The preparation method disclosed by the invention comprises the following steps of sampling, coarsely grinding, finely grinding, coarsely polishing, finely polishing for the first time, electrolyzing, finely polishing for the second time, performing acid pickling on the surface and corroding. Compared with related technologies, the preparation method of the aluminium alloy metallographic sample disclosed by the invention has the benefits that the preparation time of the aluminium alloy metallographic sample is shortened; the preparation efficiency is increased; scratches are effectively eliminated; the surface definition of the aluminium alloy metallographic sample is increased; the problem that a part of phases is corroded, lost or raised is effectively solved; false observation is effectively avoided; and the accuracy for metallographic analysis is high.

Owner:中山市江润金属压铸有限公司

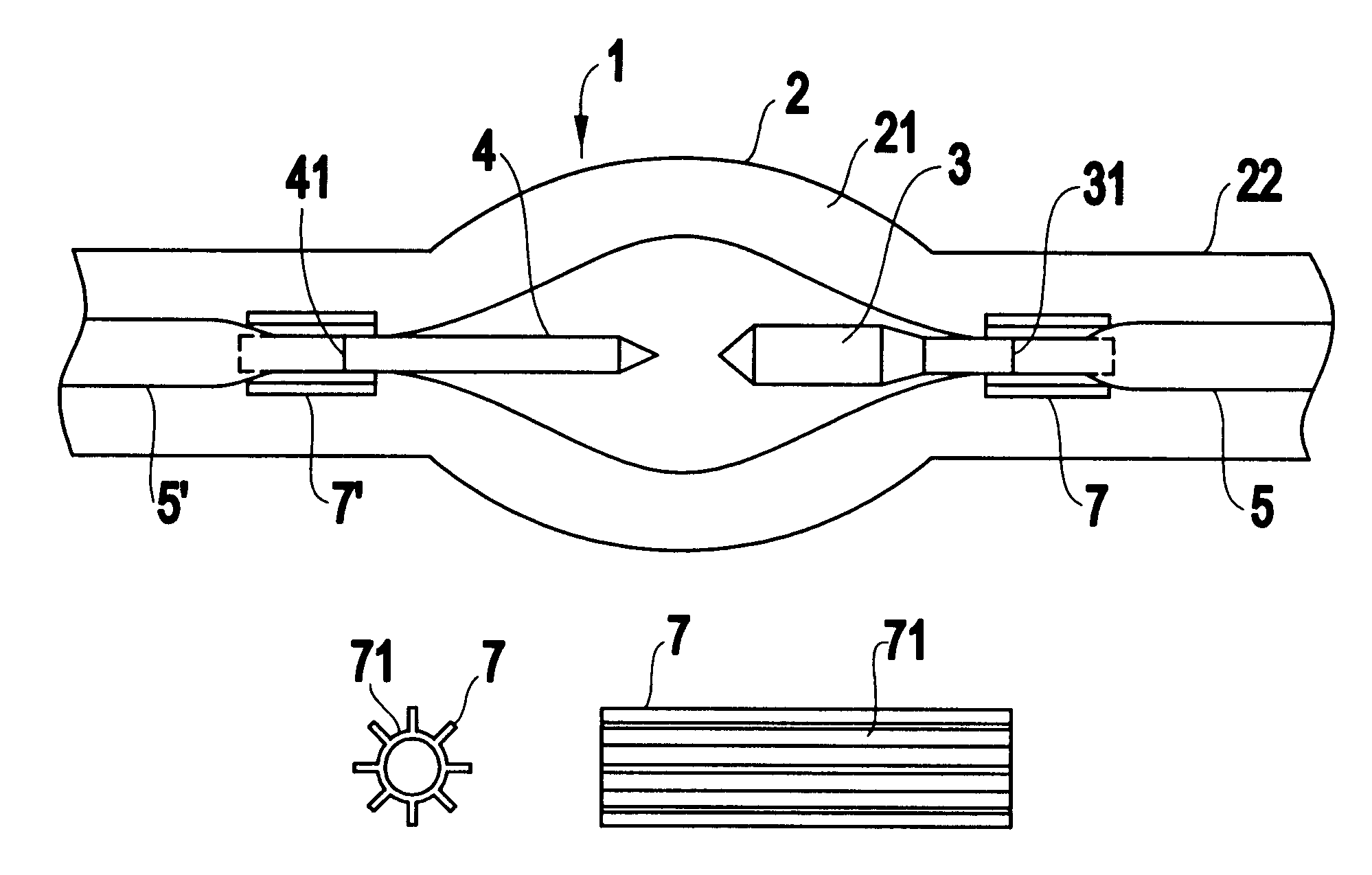

High-voltage discharge lamp with cylindrical member to mitigate thermal stress

InactiveUS6426592B2Eliminate scratchesReduce thermal stressVacuum tube vessel sealsVacuum tube leading-in conductor sealsGas-discharge lampHigh pressure

A high-voltage discharge lamp has a bulb made of quartz glass, a pair of electrodes and molybdenum foils, wherein the pair of electrodes are arranged so as to oppose each other and are joined to respective ones of the molybdenum foils, and the bulb and molybdenum foils are hermetically sealed at seal portions of the bulb. The joints between the pair of electrodes and the respective molybdenum foils are covered by cylindrical members having slits on an outer surface and / or an inner surface thereof.

Owner:USHIO DENKI KK

Large composite material skinned die and manufacturing method thereof

InactiveCN102166597AEliminate scratchesNot easy to scratchShaping toolsSynthetic resin layered productsVarnishMaterials science

The invention discloses a large composite material skinned die and a manufacturing method thereof. The die comprises a combined welding supporting base, a combined welding supporting frame, a glass steel layer and an epoxy resin layer which is stuck on the glass steel layer, wherein a layer of fluorinated polyurethane lusterless porcelain varnish is coated on the surface of the epoxy resin layer. Pits on the surface of epoxy resin are completely filled through the fluorinated polyurethane lusterless porcelain varnish, which can be tightly combined with the epoxy resin and has high permeability; the defect that micro air vents are formed on the surface of the epoxy resin of the large composite material skinned die is overcome substantially; and the surface quality and the air tightness reliability of the large composite material skinned die are obviously improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

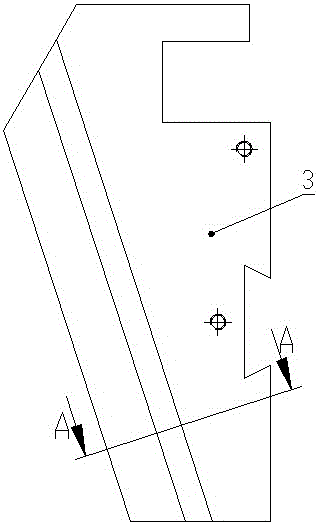

Tensile clamp for self-lubricating wedge jaw testing machine

InactiveCN105890990AImprove frictionImprove fixture performance and service lifeMaterial strength using tensile/compressive forcesLubricationWear resistant

The invention discloses a tensile clamp for a self-lubricating wedge jaw testing machine. A clamping base is provided with a U-shaped cavity with a narrow opening and a wider bottom. A clamping block is connected with one side face of a sliding block. The other side face of the sliding block corresponds to the side wall face of the U-shaped cavity of the clamping base. The side face, matched with the side wall face of the U-shaped cavity of the clamping base, of the sliding block is coated with a wear-resistant material or provided with a friction plate in an embedded mode, and a pair of sliding friction faces are formed. The friction faces do not need to be lubricated by an oil film, friction force between the sliding block and the clamping base can be lowered, the servo performance of the sliding block can be greatly improved, eccentricity of a jaw during a tensile test is overcome, a working face of the clamping base is protected forcefully, and scratches of the friction faces of the clamping base are eliminated; the phenomenon that a test curve fluctuates due to the fact the a clamp is clamped is avoided, the experimental data accuracy can be improved, the service life of the clamp can be prolonged, and the tensile clamp can work for a long time on the oil-free lubrication condition. After the clamp is used for a long time, only the friction plate needs to be replaced, and the sliding block or the clamping base does not need to be replaced.

Owner:济南天辰试验机制造有限公司

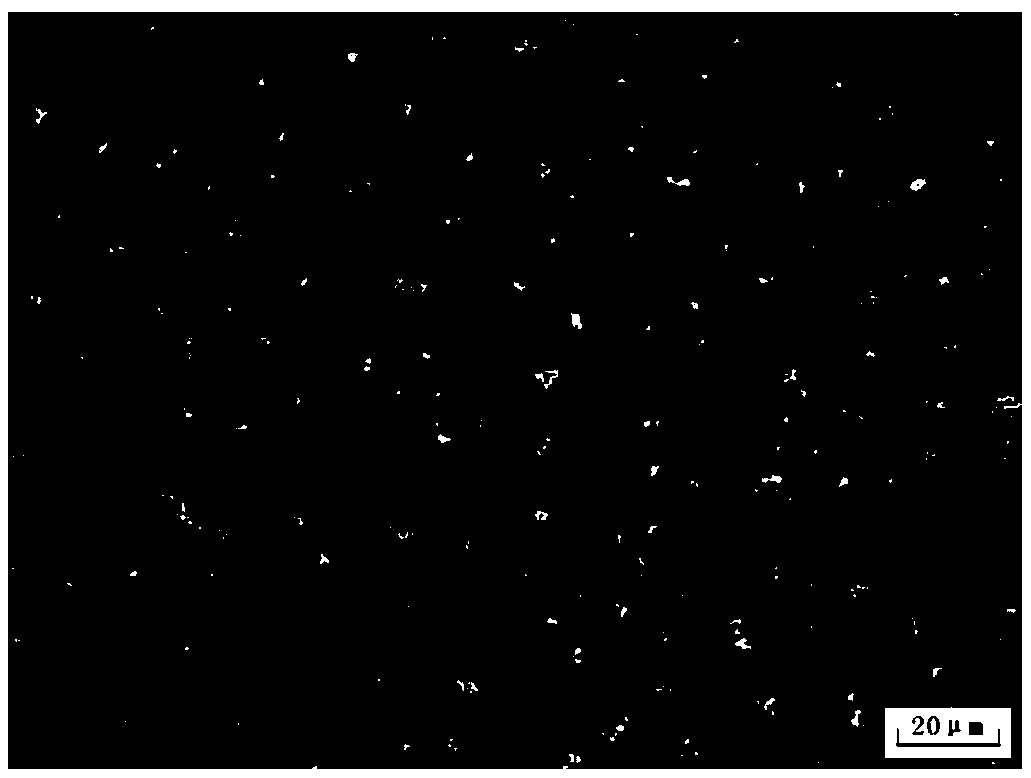

Method for preparing SUS304 weld metallographic phase and quantitatively analyzing ferrite intensity

InactiveCN109187125AReduce the interference of human factorsEliminate scratchesPreparing sample for investigationMaterial analysis by optical meansImaging processingInterference factor

The invention discloses a method for preparing an SUS304 weld metallographic phase and quantitatively analyzing ferrite intensity. The method for preparing the SUS304 weld metallographic phase comprises the following steps: sampling, inlaying, coarse grinding, fine grinding, polishing, corroding, cleaning, observing and the like. The method for quantitatively analyzing ferrite intensity of the SUS304 weld metallographic phase comprises the following steps: (1) performing gray-scale processing; (2) Gaussian smoothing; (3) performing threshold segmentation; (4) blocking; (5) calculating the white area proportion of each block; and (6) solving the variance of the white area proportion of each block. By adjusting the grinding method and time, selecting the types of polishing agents and corrosive liquid and adjusting the ratio and storage manner of the polishing agents and corrosive liquid, the scratch can be eliminated, so that the tissues completely and clearly appear, the operation is simple and feasible, and the human interference factor of corrosive tissues is small; and the image processing algorithm is high in precision, the portability is high, and the ferrite intensity in the metallographic phase is conveniently and accurately quantified.

Owner:GUANGDONG UNIV OF TECH

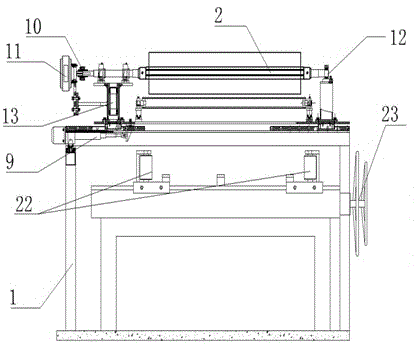

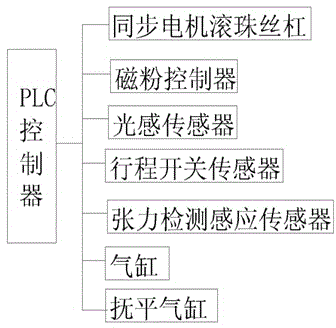

Paint scratch prevention device for longitudinal shearing production line of purline workshop

InactiveCN104670974ASimple structureEasy to useArticle deliveryWebs handlingTectorial membraneProduction line

The invention relates to equipment for longitudinal shearing production and splitting of a color-coated steel plate, and particularly discloses a paint scratch prevention device for a longitudinal shearing production line of a purline workshop. The device comprises the longitudinal shearing production line, and is characterized in that a laminating machine is arranged on the front part of the longitudinal shearing production line, and comprises a bracket, and protective film air expanding shafts, protective films, a tension detection device, a spiral guide roller, film pressing leather rollers, color steel deviation rectification regulation device, plate surface smoothing rollers, an optical sensor, a PLC (Programmable Logic Controller) and the like, which are arranged on the bracket. The device has the beneficial effects that the device is simple in structure and convenient to use, and can be well jointed with a conventional longitudinal shearing production line for operation; when the device is used, an electric system is adopted for control after the loading (protective film) of an operator, so that time, power and labor are saved, the quality of a product is improved, and the phenomenon of paint scratches is eliminated.

Owner:山东万事达建筑钢品股份有限公司

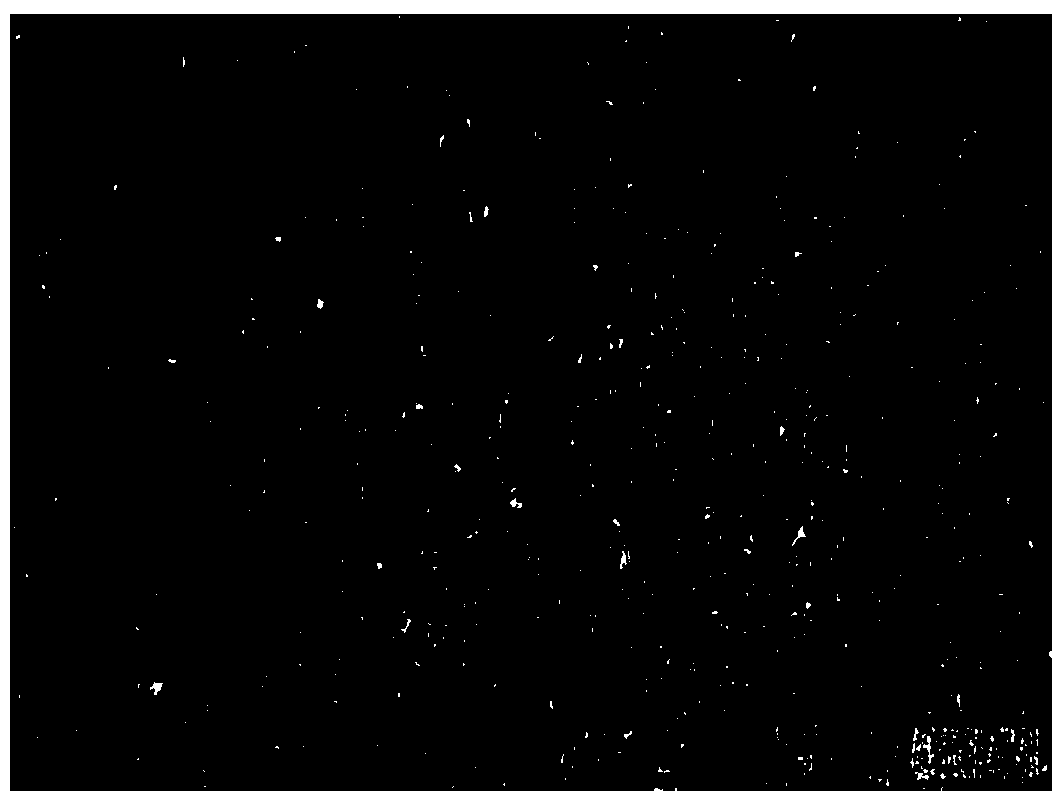

Method for detecting distribution and content of residual austenite in low alloy structure steel

ActiveCN109142010AThe overall image is beautifulGood for metallographic observationPreparing sample for investigationMaterial analysis by optical meansAlloySolvent

The invention discloses a method for detecting distribution and the content of residual austenite in low alloy structure steel. Water is used as cooling liquid, metallographic waterproof abrasive paper is used for rough grinding and fine grinding of a test surface of a sample, the sample subjected to fine grinding is polished, sodium metabisulfite, picric acid, sodium hydroxide, distilled water, hydrochloric acid and absolute ethyl alcohol are mixed, stirred and heated to prepare a corrosion reagent, the polished sample is subjected to electrolytic polishing treatment, the sample subjected toelectrolytic polishing treatment is placed into prepared corrosion solvents to remove interference phases, and distribution and the content of the residual austenite of the sample are detected by metallographic observation and representation. The method is simple in operation and short in polishing corrosion time. After the low alloy structure steel is corroded, a residual austenite structure in the low alloy structure steel can be clearly displayed. Characteristic parameters such as the content, the size, the shape and distribution of the residual austenite can be rapidly, accurately and quantitatively analyzed by metallographic software.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rubber and plastic granulator

InactiveCN110877362AResolve issues where shape is affectedTroubleshoot issues where particle shape is affectedMetal working apparatusBlade plateStructural engineering

The invention discloses a rubber and plastic granulator. The granulator structure comprises a driving case, a granulating mechanism, a conveying plate and a rack, the side edge of the driving case isconnected to the granulating mechanism, a conveying plate is arranged at the bottom of the granulating mechanism and communicates with the granulating mechanism, and the rack is arranged on the bottomend surface of the driving case. The granulator has the beneficial effects that: a knife groove of a unique folding knife holder can accommodate a knife edge on a knife board, so that the knife boardcan descend for a certain distance again after the rubber plastic strip is cut and is prevented from being in contact with a pressure-bearing seat, the phenomenon that nicks are generated due to impact and collision between the knife edge and the pressure-bearing base is effectively eradicated, the granulator guarantees that the knife edge can have a sharp cutting state in the operation process,a unique knife sharpening shaft structure is beneficial for keeping the sharpness degree of the knife edge, and therefore it is guaranteed that the cut rubber plastic particles are standard in shape and flat in fracture.

Owner:陈牡蓉

Oral Device

ActiveUS20070295342A1Increase rangeDoubling overall stimulationOperating chairsTeeth fillingPenisClitoris

The present invention is an oral device comprised of two main components, a U-shaped lower bite plate and a U-shaped upper bite plate, which are molded to fit the front teeth of a wearer with a soft flexible contact surface. The oral device of the present invention comprises an upper bite plate and a lower bite plate each having a generally U-shaped appearance. The upper bite plate removably fits over the upper teeth of a person and the lower bite plate removably fits over the lower teeth of a person. Each bite plate includes a U-shaped buccal side and a U-shaped lingual side connected by a U-shaped top portion. The U-shaped top portion is further comprised of an exposed surface and an attaching surface where the exposed surface is the surface that contacts a penis, clitoris, or other body part while the attaching surface contacts the wearer's teeth.

Owner:ENGEL HARRY

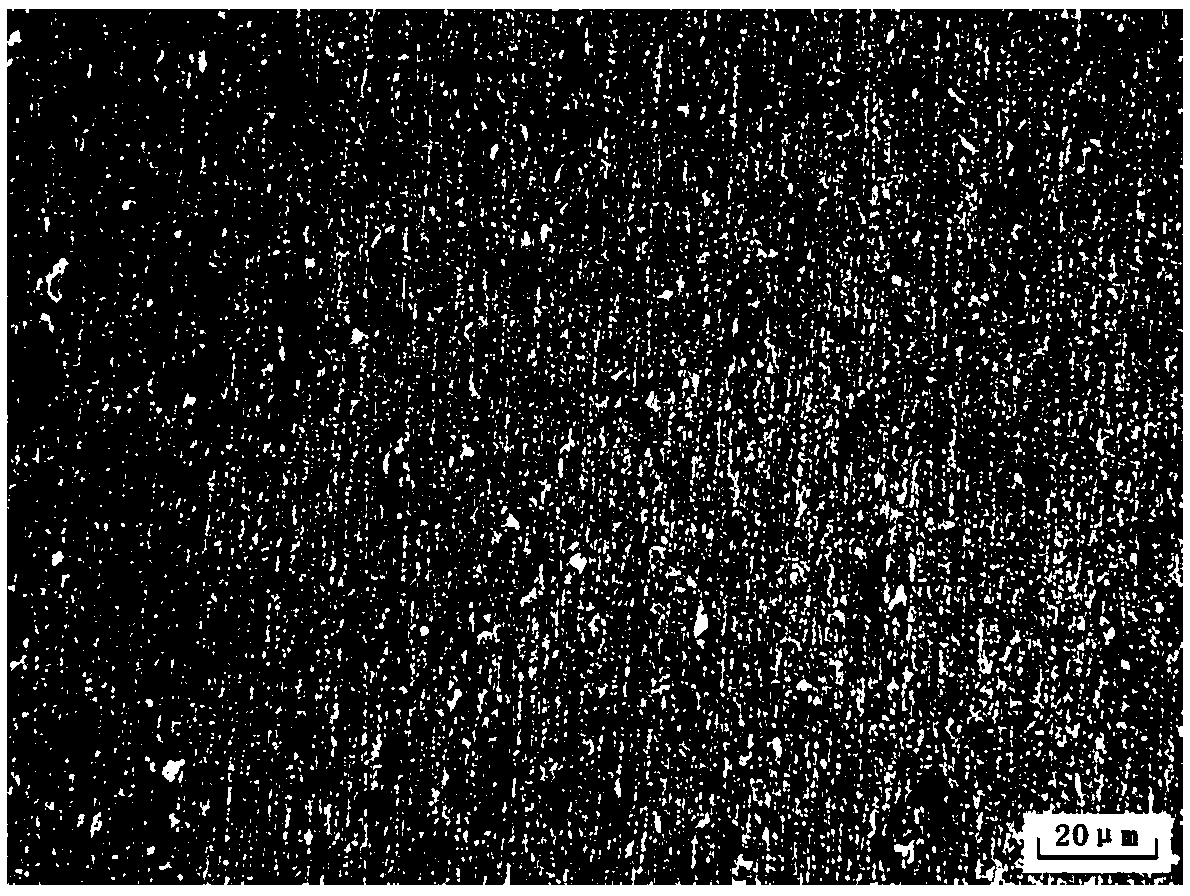

Preparation method for sample applicable to EBSD analysis of Al and Al alloy

InactiveCN108918560ALow costHigh popularityMaterial analysis using wave/particle radiationEtchingIon beam

The invention provides a preparation method of a sample applicable to EBSD analysis of Al and an Al alloy. According to the method, a metal sheet with a diameter of 3 mm and a thickness of 0.5 mm is cut from a metal block by using an electrospark wire-electrode cutting method and is then separately ground by using sand paper No. 320, sand paper No. 800 and sand paper No. 2000 so as to gradually thin the metal sheet to a thickness of 200 [mu]m; corroding the metal sheet by using a double-jet etching method until a shiny surface appears; and then placing the sample into an ion milling instrumentfor ion beam polishing so as to remove corrosives and corrosion marks on the surface of the sample, thereby preparing an Al or Al alloy sample for EBSD analysis. The method is convenient and simple to operate, low in preparation cost and large in a polishing range, can be implemented by using preparation equipment for transmissions without purchasing of extra instruments, has good versatility, and is applicable to preparation of EBSD samples from all kinds of Al and Al alloys and other metal materials.

Owner:SHANGHAI JIAO TONG UNIV

Main bearing sealing system for wind generating set

The invention provides a main bearing sealing system for a wind generating set. The main bearing sealing system comprises front and rear positioning rings of a bearing, front and rear sealing covers, a sealing and spacing piece, a framework oil seal, a V-shaped wiper scraper seal, an O-shaped ring, and a bearing end cover. The V-shaped wiper scraper seal is arranged on an atmosphere side, and the framework oil seal is arranged on a grease side. Both the V-shaped wiper scraper seal and the framework oil seal are provided with sealing lips which can freely slide on the surface of a shaft.

Owner:SUZHOU TITPWE WIND ENERGY TECH

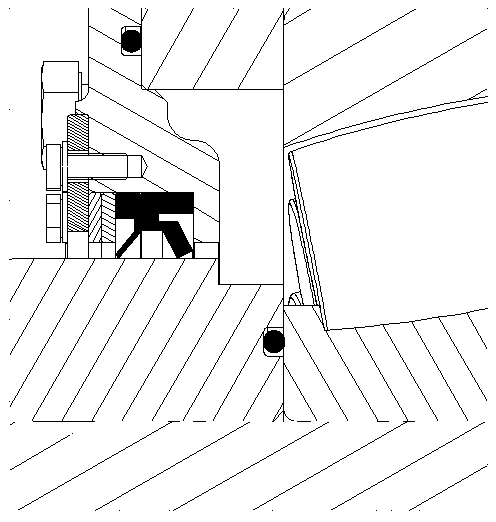

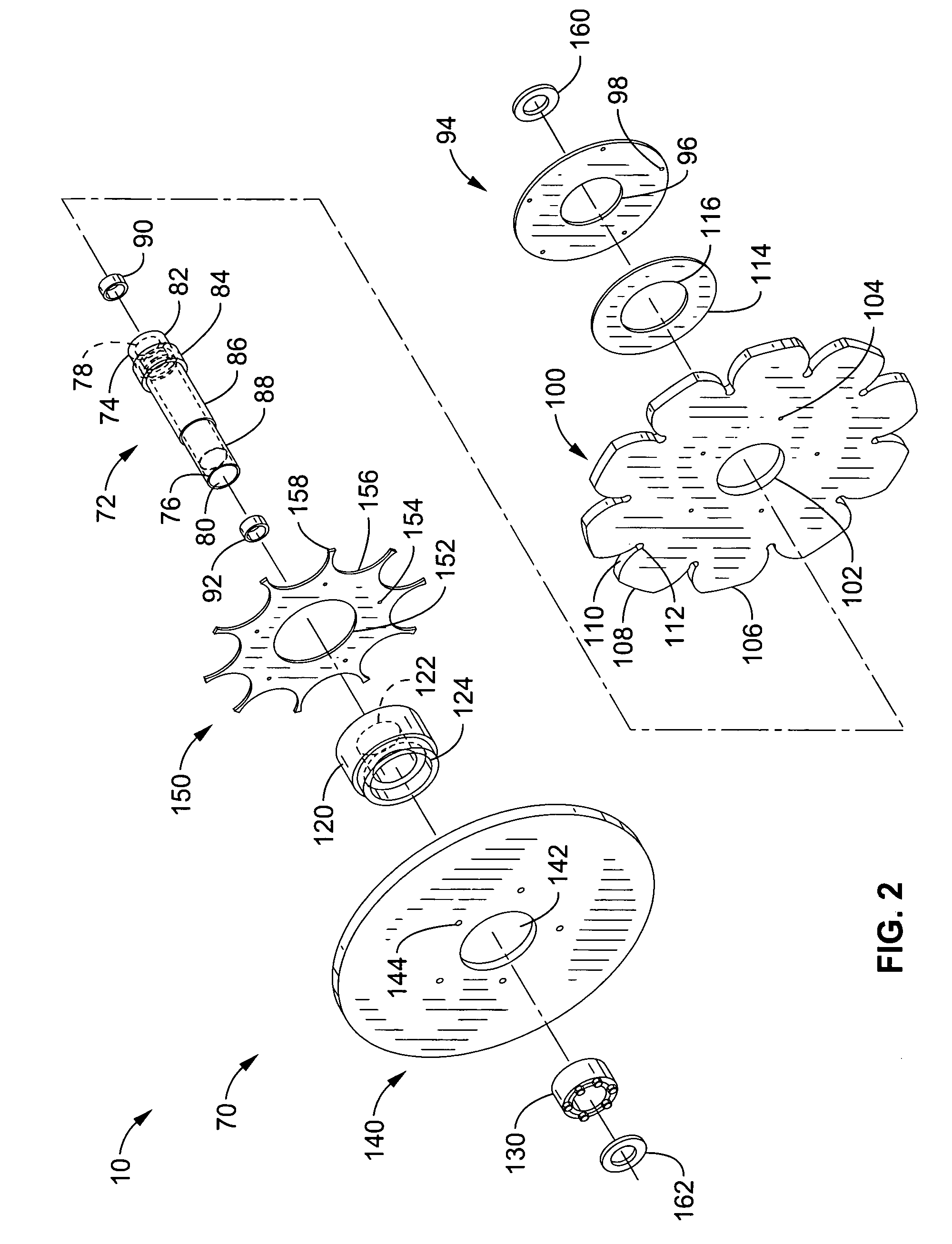

Can extractor apparatus

ActiveUS7284656B1Eliminate transferReduce scratchesFood preservationLavatory sanitoryEngineeringScratching

A can extractor for atmospheric rotary cookers and coolers has a clover wheel, a star wheel and a star wheel flange made of stainless steel. The clover wheel and star wheel are aligned and coupled to a sleeve rotating on a stationary shaft. The star wheel is coupled to the sleeve using an adjustable keyless hub / shaft locking device. The clover wheel and star wheel are spaced to accommodate bulging or deformed cans. A center discharge chute is supported on the rotating sleeve with a plastic bushing. Cans from the reel of a cooker / cooler are positioned with a can stripper between the star wheel and clover wheel while the reel rotates the clover wheel. The stainless steel components reduce scratching and eliminate transfer of rust to cans. A plastic clover wheel and a plastic star wheel flange are disclosed that do not scratch or transfer rust to the cans.

Owner:ALLIED MACHINE

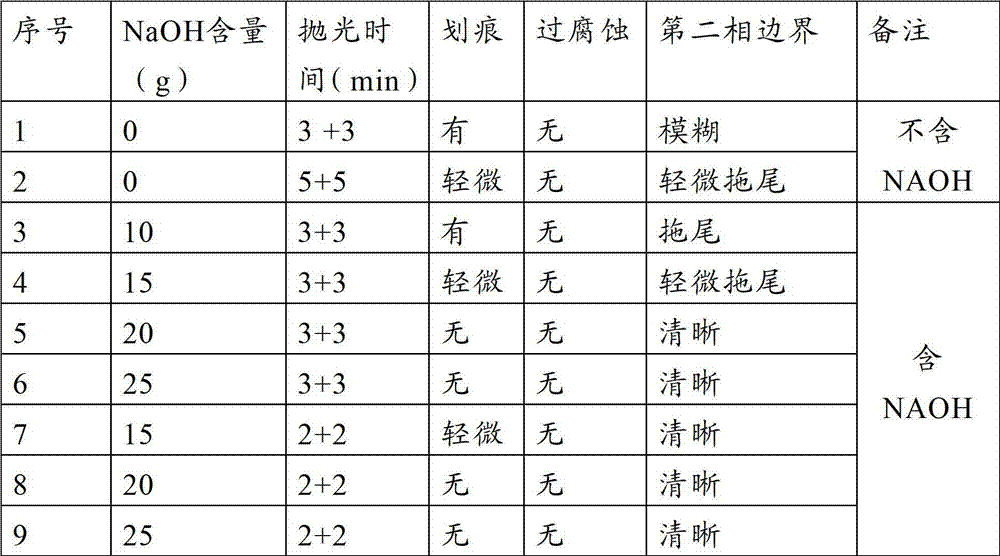

Polishing agent for precise polishing of high-alloy-aluminium metallographic sample, and precise polishing method

InactiveCN103074631AFast preparationDe-perturbation layerPreparing sample for investigationElectrolysisAlloy

The invention discloses a polishing agent for precise polishing of a high-alloy-aluminium metallographic sample. The polishing agent comprises water, corundum particles and sodium hydroxide, namely, sodium hydroxide, which is an chemical aggressive agent, is added in corundum polishing suspension formed by water and corundum powder, so that not only can the problems of disturbance layers and scratches of mechanical polishing be avoid, but also the problem of disappearance or protrusion of part of phase corrosion of electrolysis and chemical polishing can be avoid, further, the circumstance of observation illusion can be avoided; and meanwhile, the time for precise polishing can be shortened greatly, so that the purpose of preparing high-quality metallographic samples quickly can be achieved. When the agent for precise polishing of a high-alloy-aluminium metallographic sample, provided by the invention, is in use, a polisher is started first, then a reagent bottle filled with the polishing agent is shaken until the polisher runs normally so as to ensure that the polishing agent is mixed uniformly, and the reagent bottle is compressed to enable the polishing agent to be uniformly sprayed onto polishing fabric of the polisher. The invention further discloses a precise polishing method for a high-alloy-aluminium metallographic sample.

Owner:SOUTHWEST ALUMINUM GRP

Electromagnetic disc brake and traction machine provided with same

ActiveCN104140054AReduce axial sizeLow costBuilding liftsHoisting equipmentsInterference fitElectromagnetic interference

The invention relates to an electromagnetic disc brake and a traction machine provided with the electromagnetic disc brake. The electromagnetic disc brake disclosed by the invention comprises a stationary iron core and two movable iron cores through electromagnetic interaction, two brake discs fixed with a main shaft, and two brake plates which are matched with the movable iron cores and are used for clamping the brake discs, wherein the two movable iron cores are respectively positioned on the two sides of the stationary iron core, and a brake spring is arranged between each of the two movable iron core and the stationary iron core; a coil winding acting on each movable iron core is arranged on the stationary iron core; the two brake discs and the two brake plates are arranged outside the corresponding movable iron cores in sequence. The stationary iron core, the two movable iron cores and the two brake plates are fastened in a penetrating mode through a connecting sleeve, unthreaded holes penetrating through the connecting sleeve are formed in the stationary iron core, the two movable iron cores and the two brake plates, the connecting sleeve and the stationary iron core are connected through interference fit, and the connecting sleeve and the brake plates are pressed together through riveting. The electromagnetic disc brake is smaller in size, safe and convenient to use and convenient to maintain.

Owner:浙江西子富沃德电机有限公司

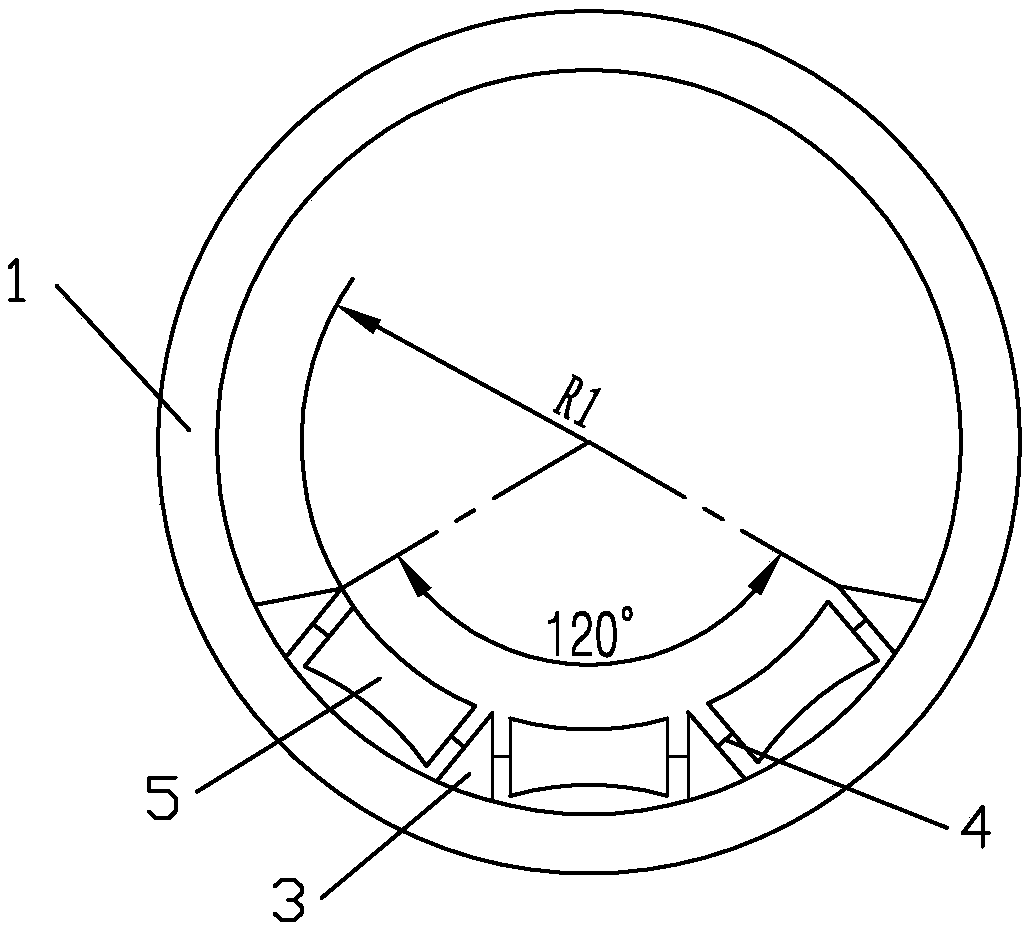

Groove roller-type cable pipe mouth sheath device

InactiveCN109616954AImprove threading efficiencyAvoid contactApparatus for laying cablesRolling resistanceBuilding construction

The invention discloses a groove roller-type cable pipe mouth sheath device. The groove roller-type cable pipe mouth sheath device comprises a pipe mouth baffle ring and a positioning short pipe, wherein the positioning short pipe is inserted into a cable protection pipe, a plurality of roller bases are arranged on an inner wall of the positioning short pipe, an arc groove roller is arranged between adjacent roller bases by a roller shaft, the groove arcs of the plurality of groove rollers are concentric with equal radius, preferably, and an angle of a fan-shaped coverage region of the plurality of groove rollers in the cable protection pipe is larger than or equal to 120 degrees. The grove roller-type cable pipe mouth sheath device has the beneficial effects of simple structure and low fabrication cost, can be repeatedly used and is convenient to carry and disassemble; sliding friction between a cable at a cable protection pipe inlet and the cable protection pipe is changed to rollingfriction, the resistance during the construction process is greatly reduced, meanwhile, direct contact of the cable and the cable protection pipe is prevented, and the risk that the cable is damagedis reduced.

Owner:CRRC CONSTR ENG CO LTD

High-temperature alloy wire preparation method capable of being used for increasing yield of high-temperature alloy rivets

The invention discloses a high-temperature alloy wire preparation method capable of being used for increasing yield of high-temperature alloy rivets, and belongs to the technical field of high-temperature alloy wire preparation. Aiming to solve the problems of scratches, peeling, dirt and the like on the surface of a drawn high-temperature alloy wire in the prior art, the high-temperature alloy wire preparation method comprises the following steps of drawing and reducing an initial wire with the diameter phi of 8.0 mm-12.0 mm to 6.5 mm + / -0.2 mm on a fixed die single drawing machine; and reducing the diameter through using a continuous drawing type roller mode wire drawing machine to phi 2.4 mm which is less than or equal to specification < phi 6.3 mm. According to the preparation method,the advantages of a fixed die single drawing machine and a roller die type wire drawing machine are combined; and meanwhile, specific solution annealing treatment procedures are designed according toinitial wires and target wires of different specifications, the surface of the prepared wire is free of quality defects, the prepared wire can serve as a raw material for high-temperature alloy rivetproduction, and the yield of the wire is increased to 90% or above from 60%.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Nano-diamond automatic repair liquid for reciprocating piston engine

The invention discloses a nano-diamond automatic repair liquid for a reciprocating piston engine. The liquid is characterized by being prepared by the following steps: (1) adding a nano-diamond into a dispersant OP-10, stirring for over 20 minutes, then standing, and after bubbles fully disappear and black precipitates appear at the bottom, pouring out a supernate, wherein the nano-diamond is a spherical particle, the grain size of which is 2-4n, and the addition proportion of OP-10 and the nano-diamond is 0.8-1.2mg of nano-diamond per L of OP-10; and (2) adding the supernate into lubricating oil, and stirring and mixing to obtain the automatic repair liquid, wherein the weight ratio of the supernate and the lubricating oil in percentage by weight is (10-30%):(90-70%). The nano-diamond in the automatic repair liquid is good in dispersing effect and stable and can be placed for a long time. The repair liquid is simple in formula, low in cost and simple in preparation method.

Owner:CHONGQING HAILIYUN TECH

Polishing solution, preparation method thereof and processing method of silicon carbide crystal

ActiveCN109988510AHigh hardnessImprove polishing efficiencySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesDefoaming AgentsPolycrystalline diamond

The invention relates to the technical field of precision machining and in particular relates to a polishing solution, a preparation method thereof and a processing method of a silicon carbide crystal. The polishing solution comprises the following components in parts by weight: 5-30 parts of polycrystalline diamond micropowder, 1000 parts of silica sol, 2-40 parts of a suspending agent,4-21 partsof a wetting agent, 2-14 parts of a defoaming agent and 2-10 parts of a pH regulator. The preparation method comprises the steps: mixing the polycrystalline diamond micropowder, the suspending agent,the wetting agent, the defoaming agent and the pH regulator, adding the mixture into water, then, adding silica sol, and carrying out uniform stirring. The polishing solution can be used for processing the silicon carbide crystal. If the polishing solution disclosed by the invention is matched with a polishing pad to polish silicon carbide, the precision polishing time can be effectively shortened, the whole grinding and polishing time can be shortened, and the surface quality of the crystal can be remarkably improved.

Owner:盘锦国瑞升科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com