Groove roller-type cable pipe mouth sheath device

A roller-type, cable protection tube technology, which is applied in the direction of cable installation devices, cable installation, cable laying equipment, etc., can solve the problems of large drag resistance and easy damage of the insulation protection layer, so as to reduce the drag resistance and improve wear resistance. The effect of setting efficiency and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

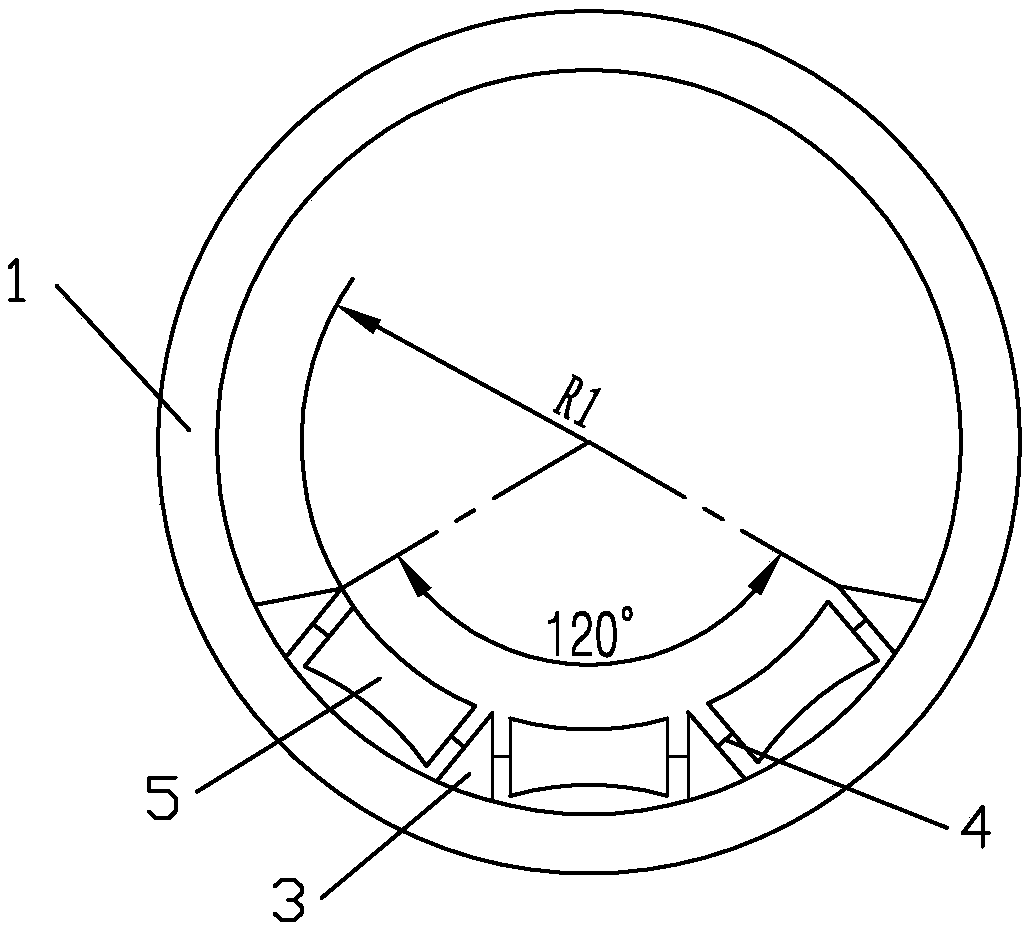

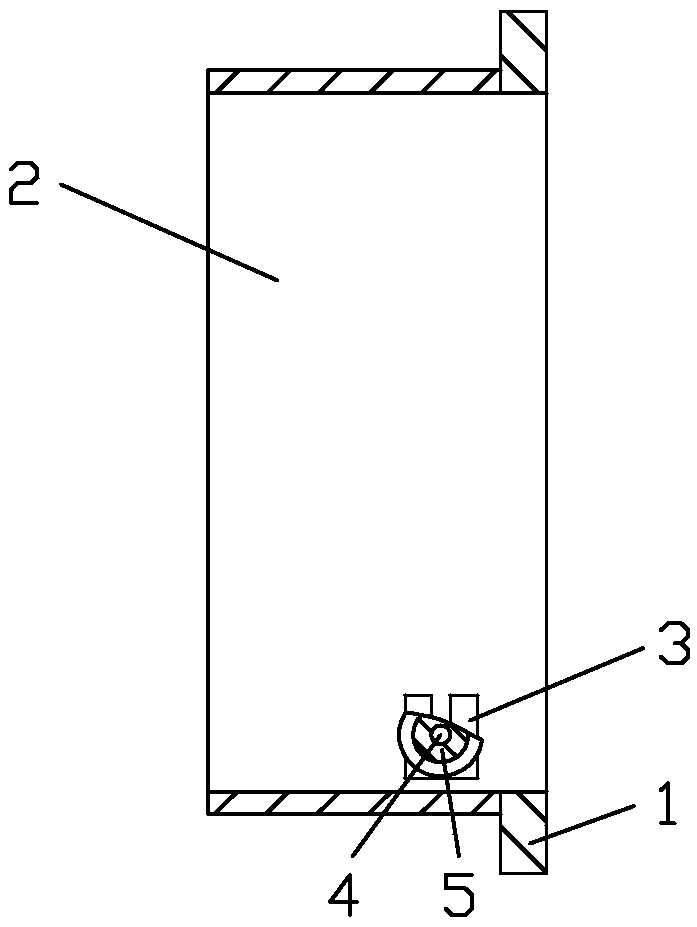

[0019] Example 1, see figure 1 , figure 2 , a grooved roller type cable nozzle sheath device, comprising a nozzle retaining ring 1 and a short positioning tube 2 for inserting into the cable protection tube, a plurality of roller bases 3 are arranged on the inner wall of the short positioning tube 2, adjacent rollers The groove rollers 5 with circular arc grooves are arranged between the bases 3 through the roller shafts 4; the groove arcs of a plurality of groove rollers 5 are concentric.

[0020] Wherein, the positioning short pipe 2 is integrally formed or welded on the nozzle retaining ring 1, the inner diameter of the nozzle retaining ring 1 is greater than or equal to the inner diameter of the positioning short pipe 2; the outer diameter of the nozzle retaining ring 1 is not less than the outer diameter of the cable protection tube ; The positioning short tube 2 is less than or equal to the inner diameter of the cable protection tube. The angle of the fan-shaped cover...

Embodiment 2

[0023] Example 2, combined with image 3 , the roller base 3 is detachably fixedly connected to the short positioning tube 2, and a plurality of the grooved rollers 5 are axially staggered.

[0024] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated hereafter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com