Paint scratch prevention device for longitudinal shearing production line of purline workshop

A technology of slitting production line and workshop, which is applied in the direction of coiling strips, transportation and packaging, and sending objects, etc., can solve the problems of inability to meet the requirements of high-quality appearance of products, high pressure on color-coated steel plates, and long service life, etc. The effect of scratching, remarkable anti-stick performance and good butt running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

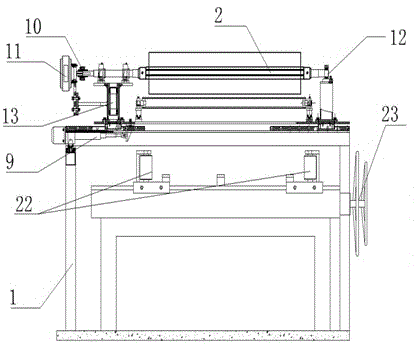

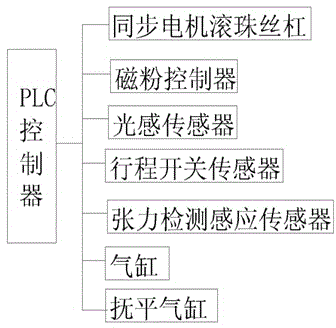

[0041] Such as figure 1 , 2 As shown, the anti-scratch paint device of the slitting production line in the purlin workshop includes a slitting production line, and a laminating machine is installed at the front of the slitting production line. The laminating machine includes a bracket 1, a protective film air shaft 2 installed on the bracket 1, and a protective film Membrane 3, tension detection device, spiral guide roller 4, membrane pressing roller 5, color steel deviation correction adjustment device, board surface smoothing roller 6; vertical linear guide rail 7 and slider 8 are laid on the bracket 1, and the slider 8 passes through The protective film air shaft 2 is installed on the platform; the linear guide rail 7 is provided with a synchronous motor ball screw 9; one end of the protective film air shaft 2 is connected to the magnetic powder controller 11 through a coupling 10; the protective film 3 is installed on the protective film air shaft 2, one end of the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com