Hot-rolled pickled plate and production method thereof

A hot-rolled pickling and production method technology, applied in the field of steel rolling, can solve the problems that low-carbon steel is difficult to obtain quasi-acicular ferrite structure, etc., to eliminate scratches and roll marks defects, reduce work hardening, and improve surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

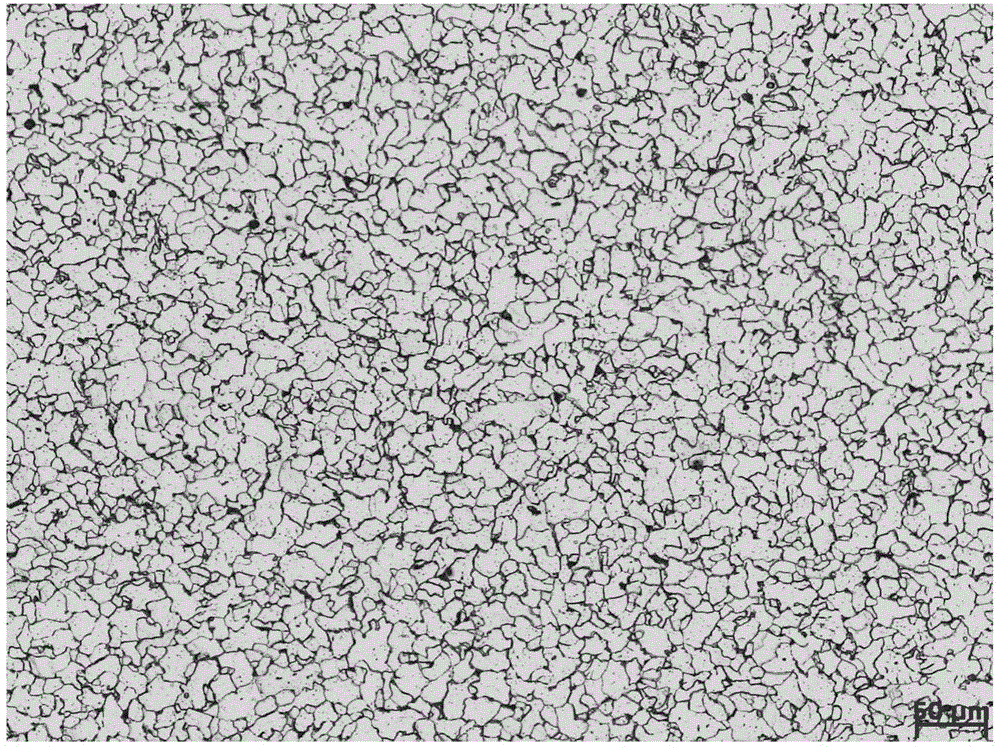

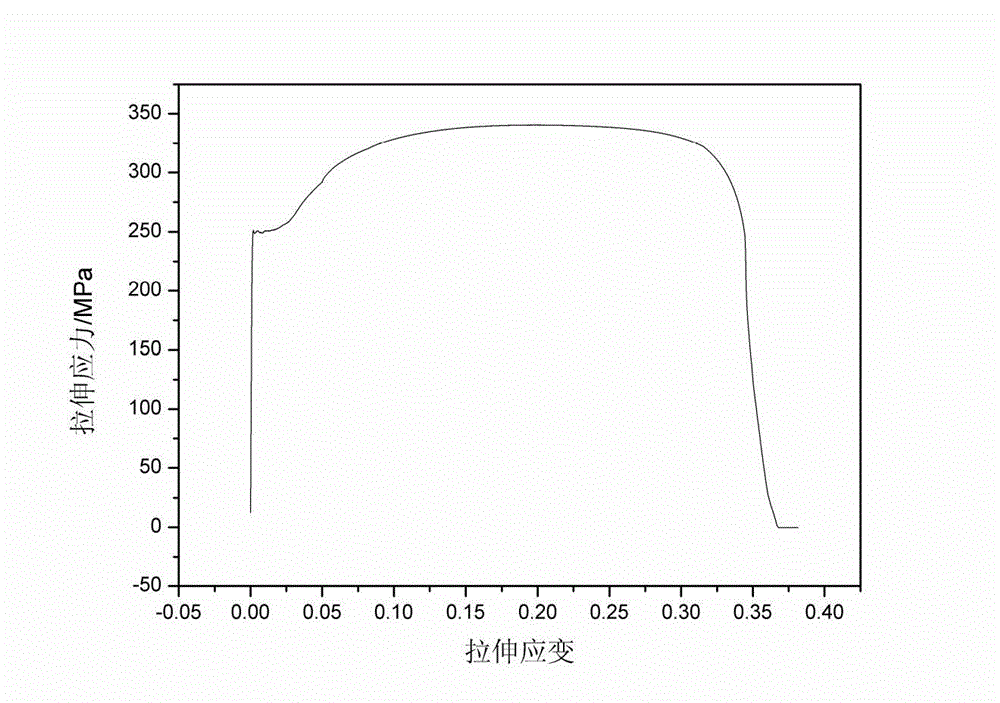

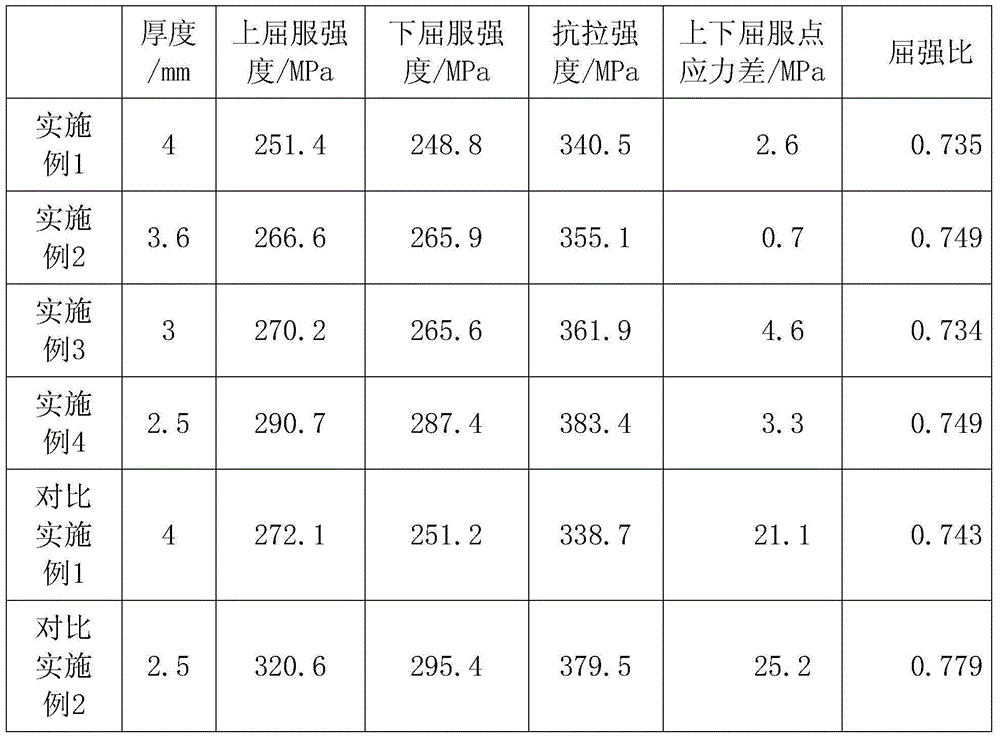

Embodiment 1

[0038] The main components of the hot-rolled pickled sheet in this example are shown in Table 1. The preparation method is as follows: heat the continuous casting slab of the composition to 1220°C, rough roll it into a 35mm intermediate slab through R1 and R2 stands, and The hot coil box is kept warm before finishing rolling. The rough rolling reduction rate is 85%, and the rough rolling exit temperature is 1050°C. Then the intermediate billet is continuously rolled into 4mm strip steel by F1~F7 seven stands. The final rolling temperature of the strip is 880°C. The strip is air-cooled at the exit of the finishing mill for 8s, and then cooled in the rear section of the laminar flow cooling section, and the coiling temperature is 668°C. The steel coils cooled to room temperature are uncoiled and straightened on the push-pull pickling production line, then pickled, rinsed and dried, and cut and oiled to the final product. The concentrations of the four acid tanks during the pi...

Embodiment 2

[0040]The main components of the hot-rolled pickled sheet in this example are shown in Table 1. The preparation method is as follows: heating the continuous casting slab of the composition to 1180°C, rough rolling it into a 35mm intermediate slab through R1 and R2 stands, and The hot coil box is kept warm before finishing rolling. The rough rolling reduction rate is 85%, and the rough rolling exit temperature is 1000°C. Then the intermediate billet is continuously rolled into 3.6mm strip steel by F1~F7 seven stands. The final rolling temperature of the strip is 870°C. The strip is air-cooled at the exit of the finishing mill for 6s, and then cooled in the latter section of the laminar flow cooling section, and the coiling temperature is 670°C. The steel coils cooled to room temperature are uncoiled and straightened on the push-pull pickling production line, then pickled, rinsed and dried, and cut and oiled to the final product. The concentrations of the four acid tanks duri...

Embodiment 3

[0042] The main components of the hot-rolled pickled sheet in this example are shown in Table 1. The preparation method is as follows: heating the continuous casting slab of the composition to 1200°C, rough rolling it into a 35mm intermediate slab by R1 and R2 stands, and The hot coil box is kept warm before finishing rolling. The rough rolling reduction rate is 85%, and the rough rolling exit temperature is 1050°C. Then the intermediate billet is continuously rolled into 3mm strip steel by F1~F7 seven stands. The final rolling temperature of the strip is 870°C. The strip is air-cooled at the exit of the finishing mill for 6s, and then cooled in the latter section of the laminar flow cooling section, and the coiling temperature is 660°C. The steel coils cooled to room temperature are uncoiled and straightened on the push-pull pickling production line, then pickled, rinsed and dried, and cut and oiled to the final product. The concentrations of the four acid tanks during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com