Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Eliminate mutation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

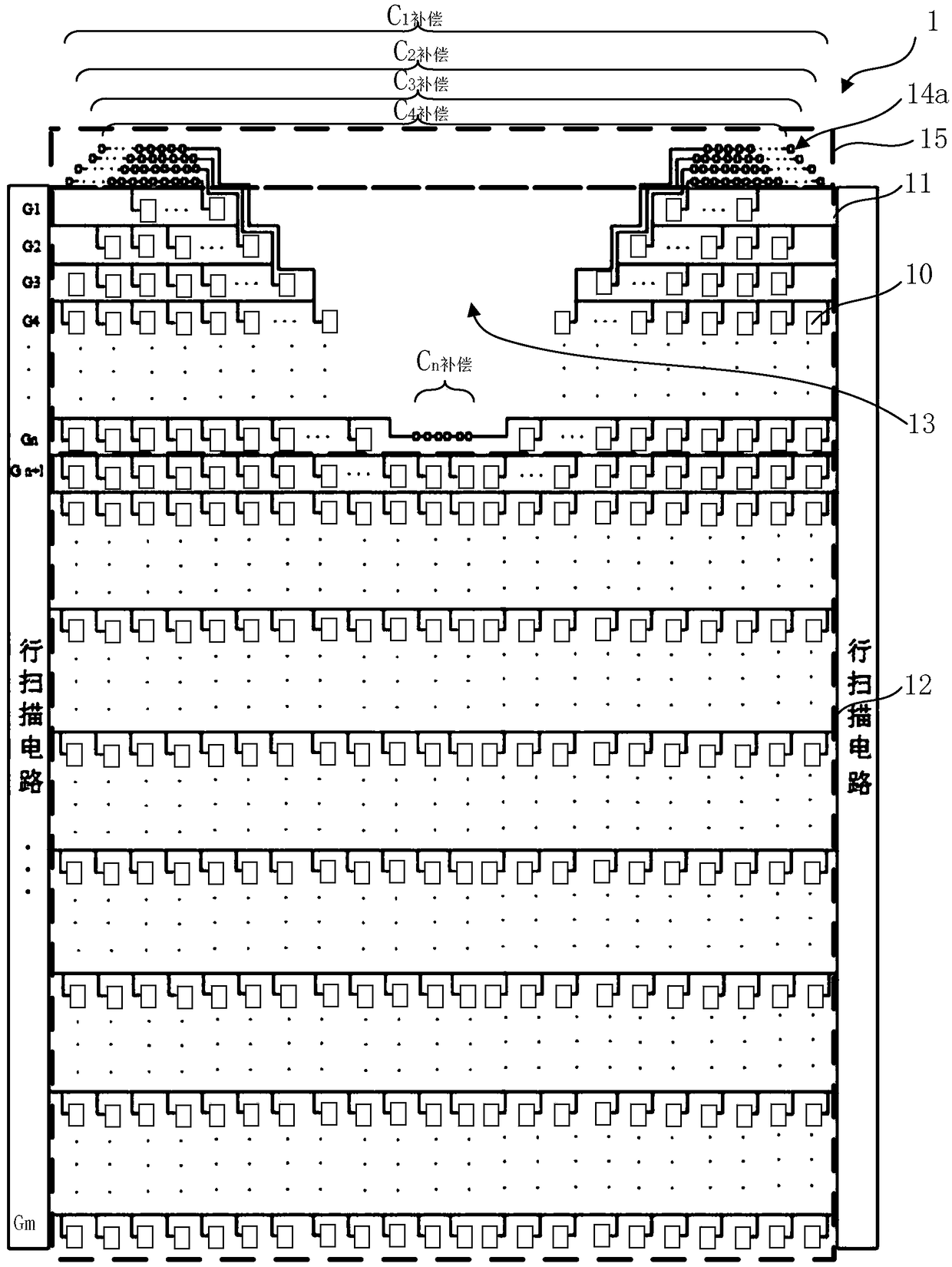

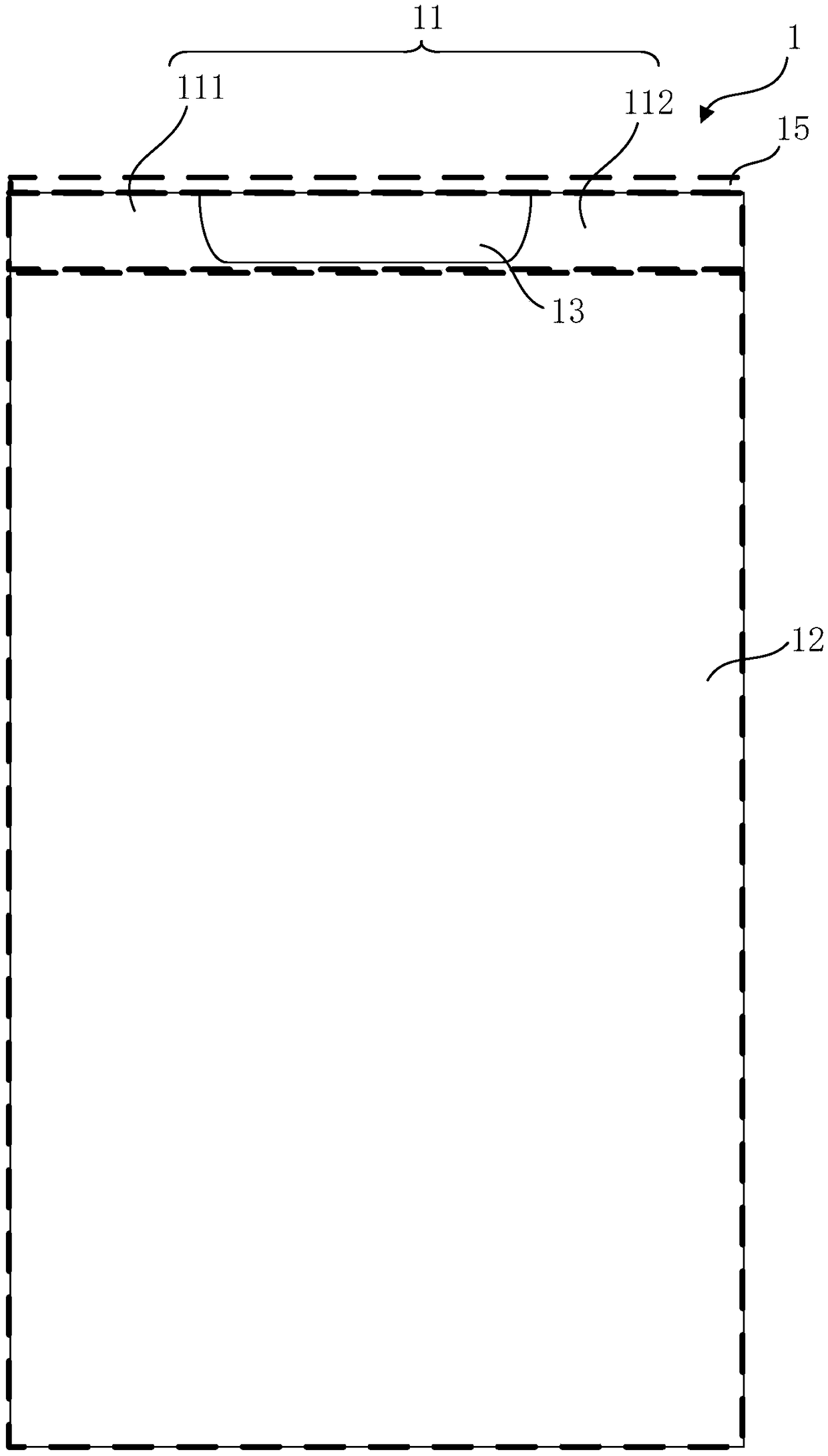

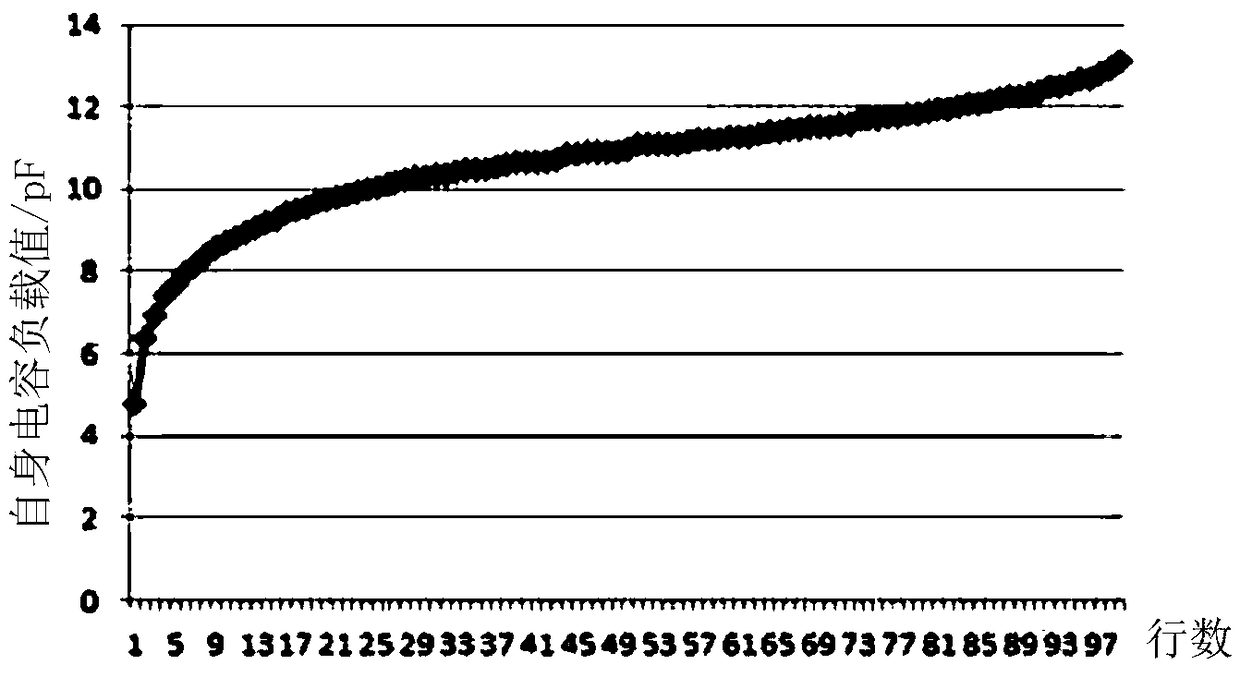

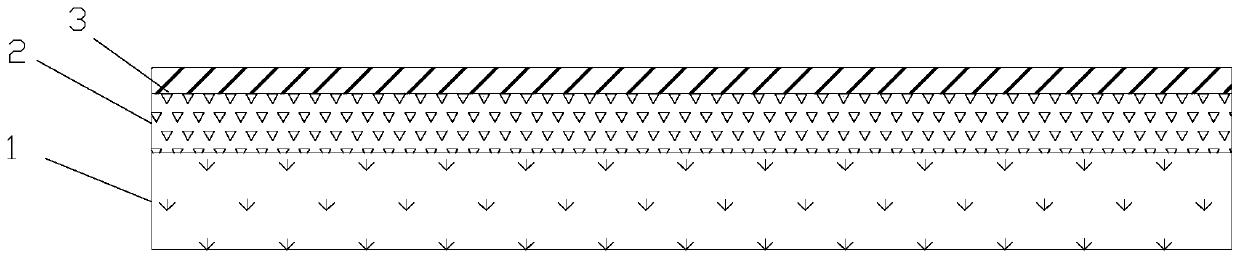

Display device and display panel

InactiveCN109061975AReduce areaIncrease the proportionStatic indicating devicesSolid-state devicesCapacitanceScan line

The invention provides a display device and a display panel. A standard of carrying out capacitor compensation on each line of scan lines of a first display area with relatively few pixel units comprises the fact that a capacitor total load value of the line of scan lines adjacent to a second display area is equal to own capacitor load value of a line of scan lines in the second display area, andthe capacitor total load value of each line of scan lines close to the second display area and the capacitor total load value of each line of scan lines away from the second display area are graduallyreduced. The display device and the display panel have the advantages that through utilization of the feature that human eyes are insensitive to gradually varied brightness variation, mutation of thecapacitor total load value of each line of compensated scan lines in the first display area and at the border of the first display area and the second display area is eliminated, so the display is uniform; and through gradual variation of the capacitor total load values in the first display area, a setting area of compensation capacitors is reduced, reduction of the area of a frame area is facilitated, a narrow frame is realized, and a screen-to-body ratio is increased.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

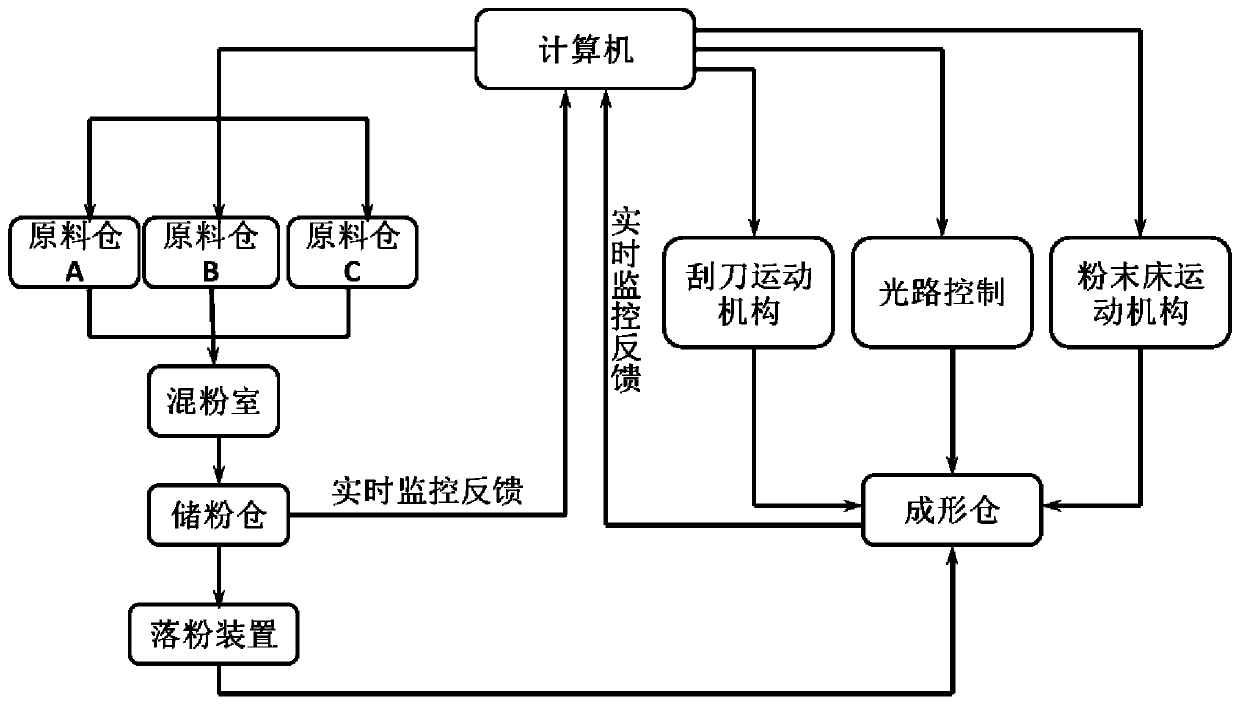

Selective laser melting device and preparation method for gradient material

InactiveCN110369715ARealize integrated manufacturingReduce the use effectAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a selective laser melting device and a preparation method for a gradient material. The device is provided with 2-5 raw material bins, and each raw material bin, a powder mixingroom, a powder storage bin, a powder dropper and a control valve define a powder feeding system with 2-5 channels, and an outlet of the powder storage bin communicates with an inlet of the powder dropper. Alloy powder needed for each slice layer is mixed in proportion, and is printed and formed through processes of raw material bin powder-feeding, mixing room powder-mixing, powder storage bin powder storage and powder dropper powder-dropping, so that preparation for the gradient material with components continuously changing in a vertical direction is realized; and the obtained formed part issmoothly transited in component and texture in macro-scale, so that component and performance mutation caused by metallurgical bonding, formed by layer-by-layer alternated printing of various powderin the prior art, of molten pool scale are eliminated, and therefore, integrated integral manufacturing of structure and function is realized. Uniform transition performance indexes in space scale canavoid the problems of discordant deformation and stress concentration, so that using performance of the formed part is favorably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

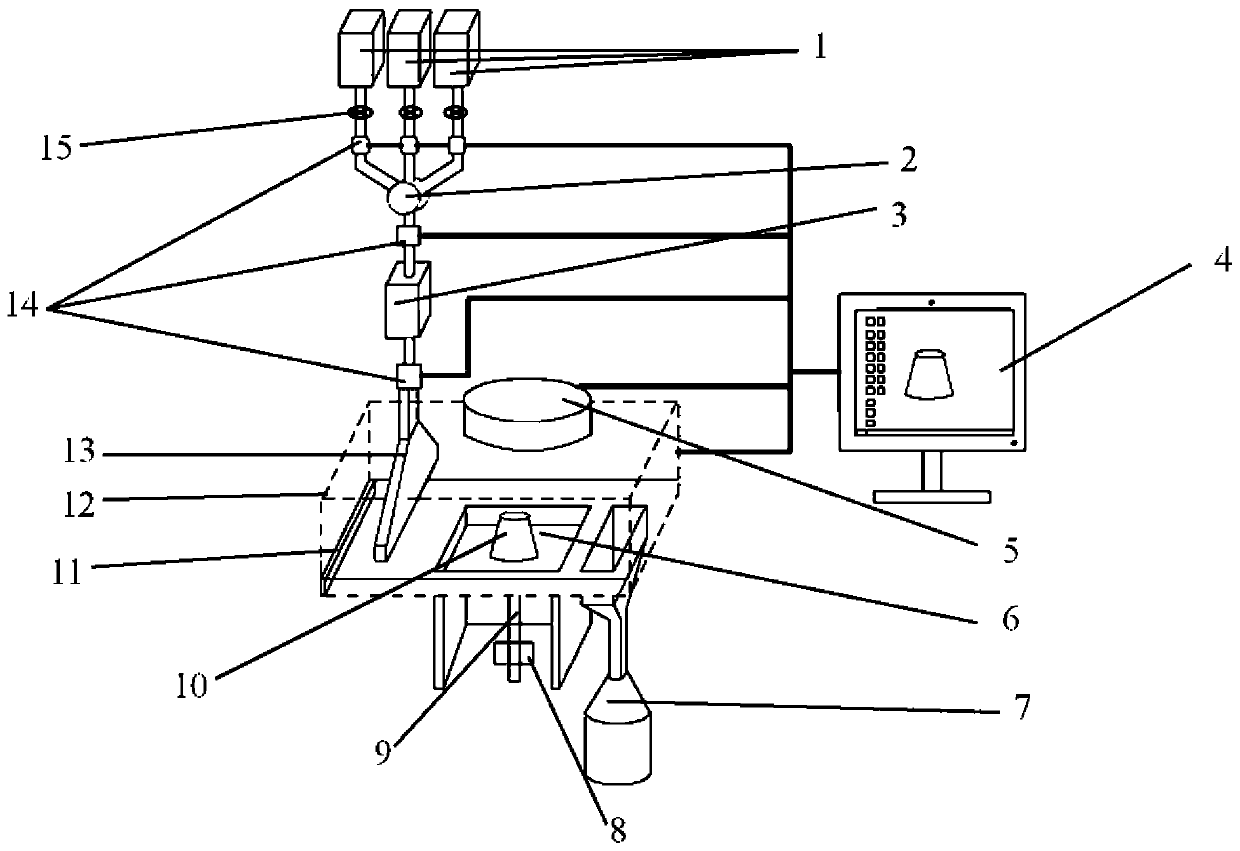

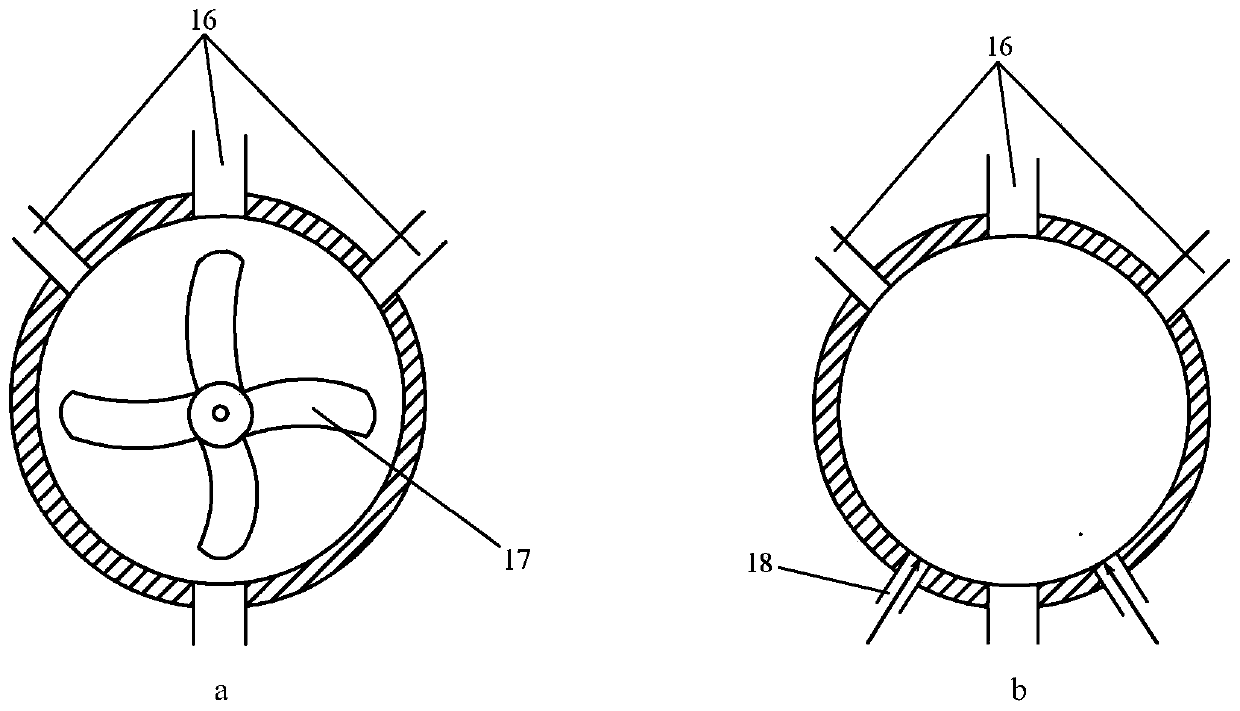

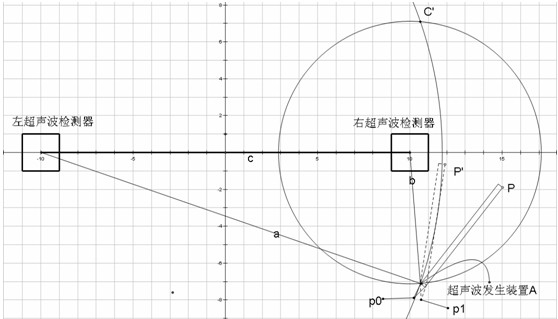

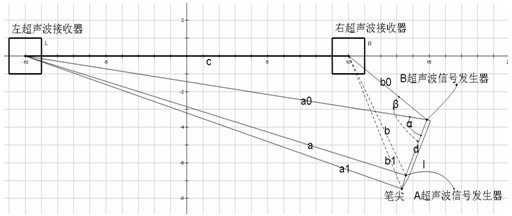

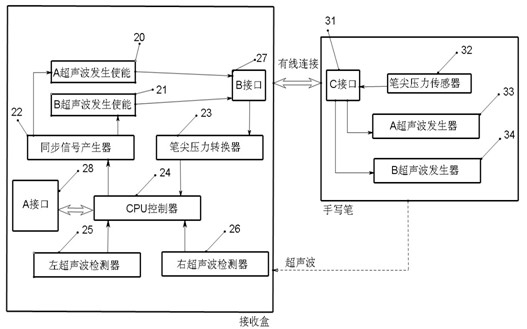

Handwriting input calibrator and calibration method thereof

InactiveCN102253769AEliminate inconsistenciesEliminate mutationInput/output processes for data processingHandwritingGraphics

The invention discloses a handwriting input calibrator, which comprises a receiving box, a handwriting pen, a pressure sensor and an ultrasonic generator, wherein the pressure sensor and the ultrasonic generator are arranged at the lower end of the handwriting pen; left-end and right-end ultrasonic receivers and a central processing unit (CPU) controller are arranged in the receiving box; one ultrasonic generator is also arranged at the upper end of the handwriting pen; ultrasonic signals which are simultaneously generated by the ultrasonic generators at two ends of the handwriting pen are received by the left-end and right-end ultrasonic receivers of the receiving box and input to the CPU controller; and the signals are converted by the CPU controller, and x and y coordinate values of displacement of a handwriting pen point are calculated. The position change of the pen point caused by different handwriting modes or habits is calculated by detecting time in which ultrasonic waves of the upper and lower ends of a pen holder arrive at the left-end and right-end ultrasonic receivers, and a displacement difference is accurately compensated according to the x and y coordinate values which are detected and calculated by the CPU controller, so the positions of lines or graphs which are written on paper by the handwriting pen completely correspond to the lines or the graphs which are displayed on a display screen of the computer, and the inconformity or variation of handwritings which are stored and displayed by the computer and the handwritings which are formed on the paper by the handwriting pen point is eliminated.

Owner:NINGBO YIFANG EDUCATION TECH DEV

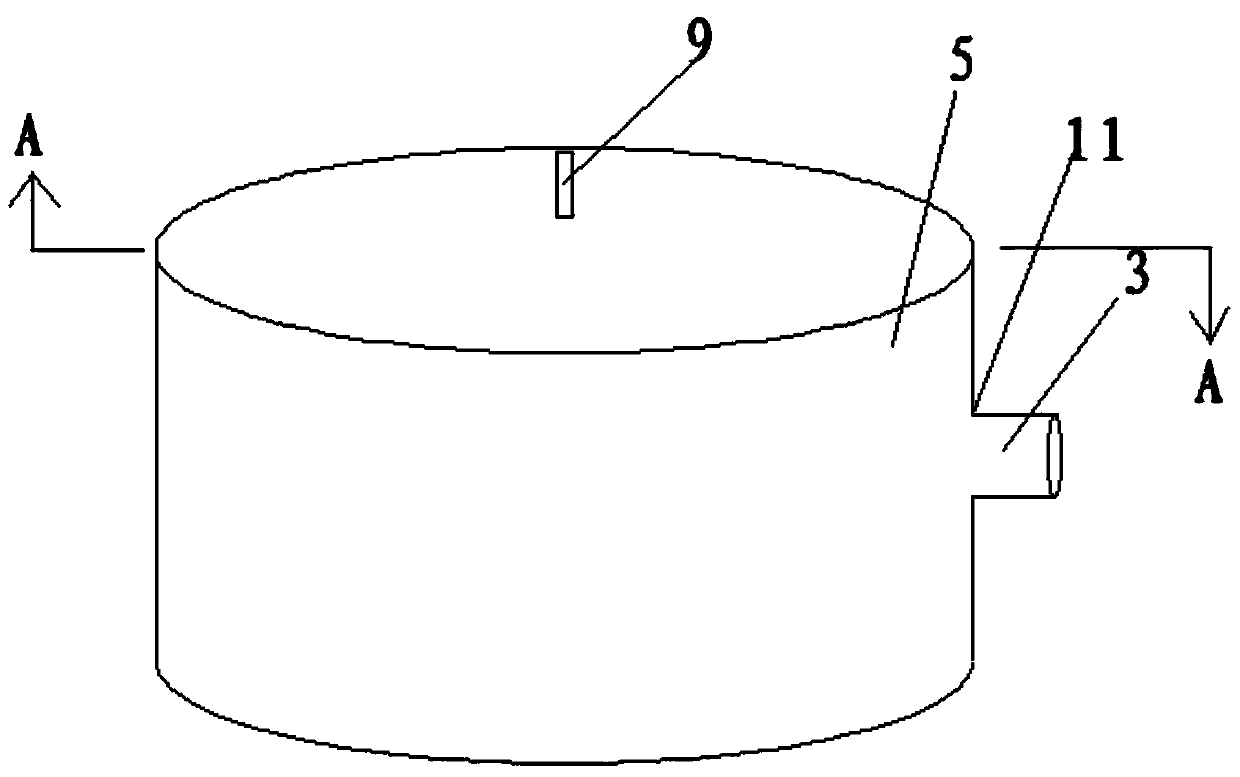

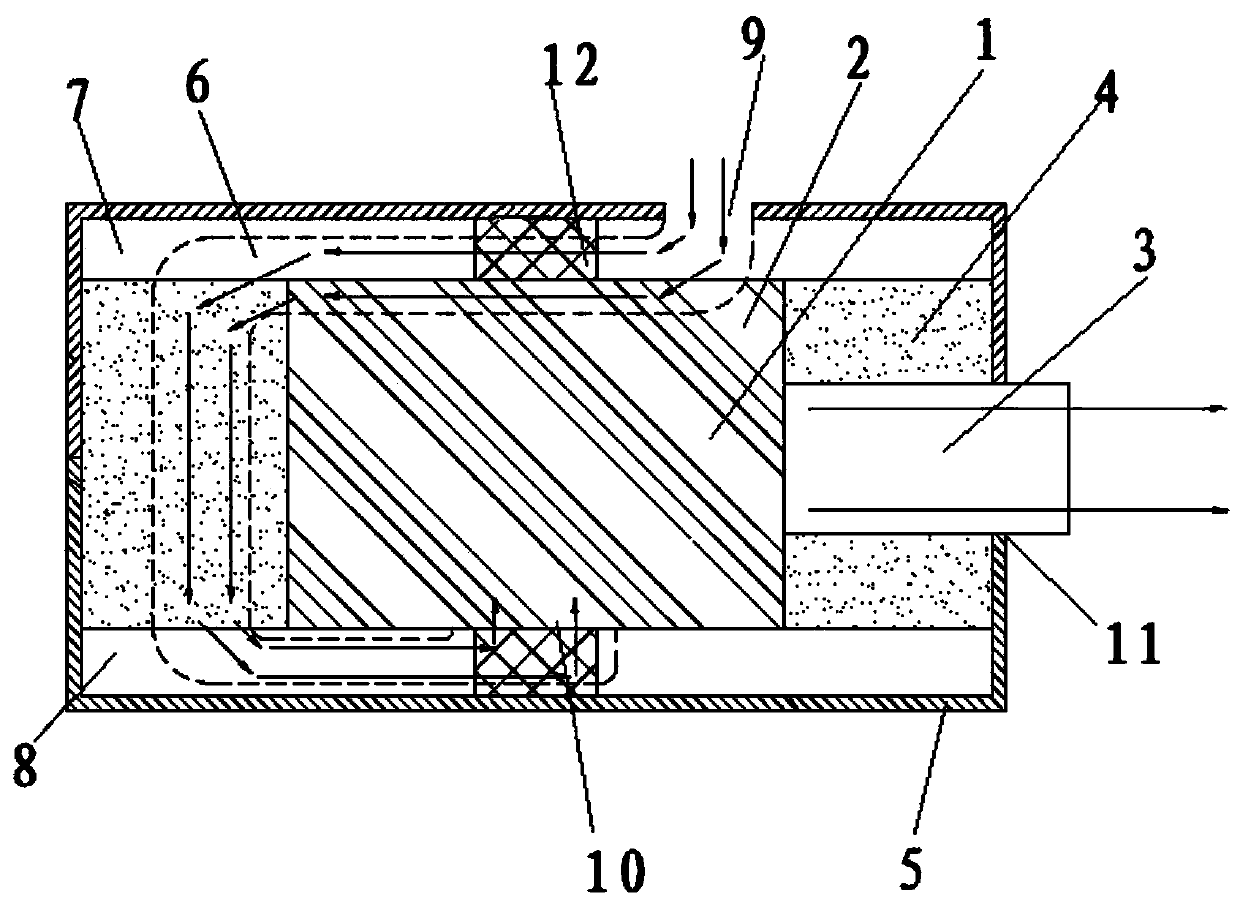

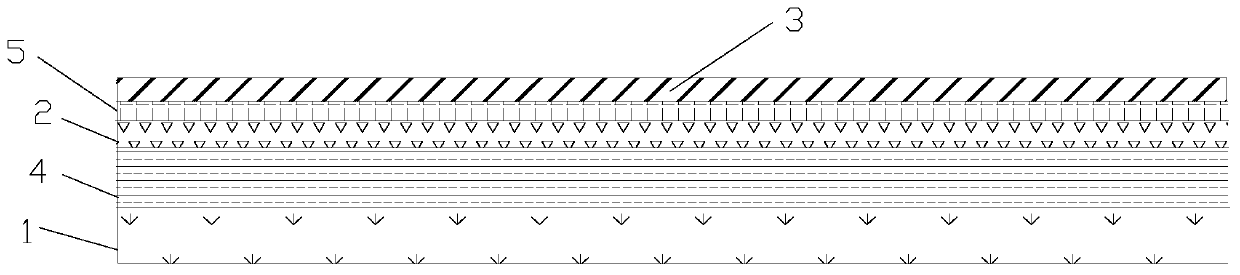

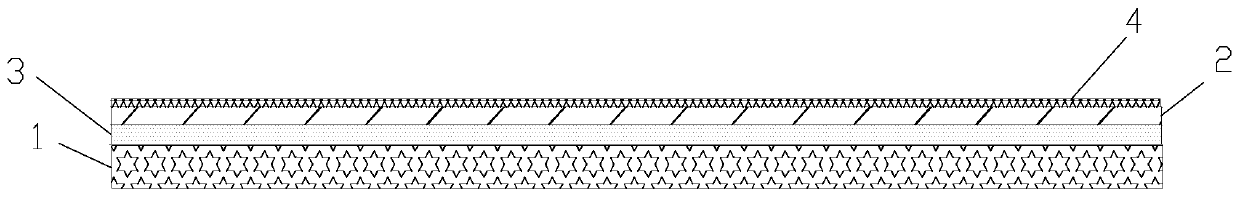

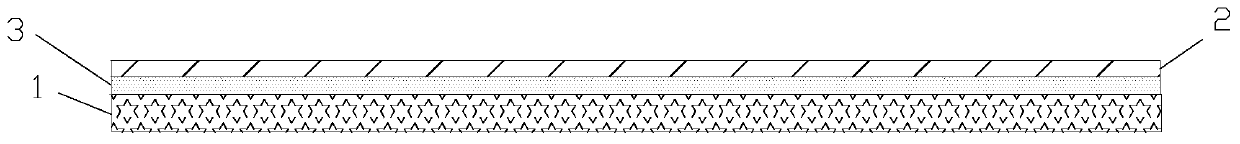

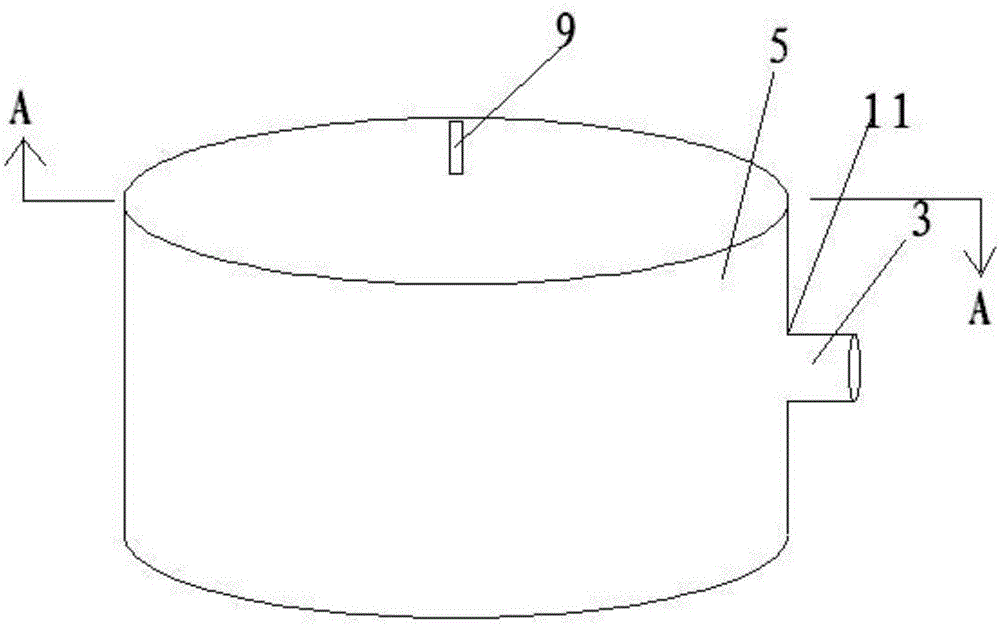

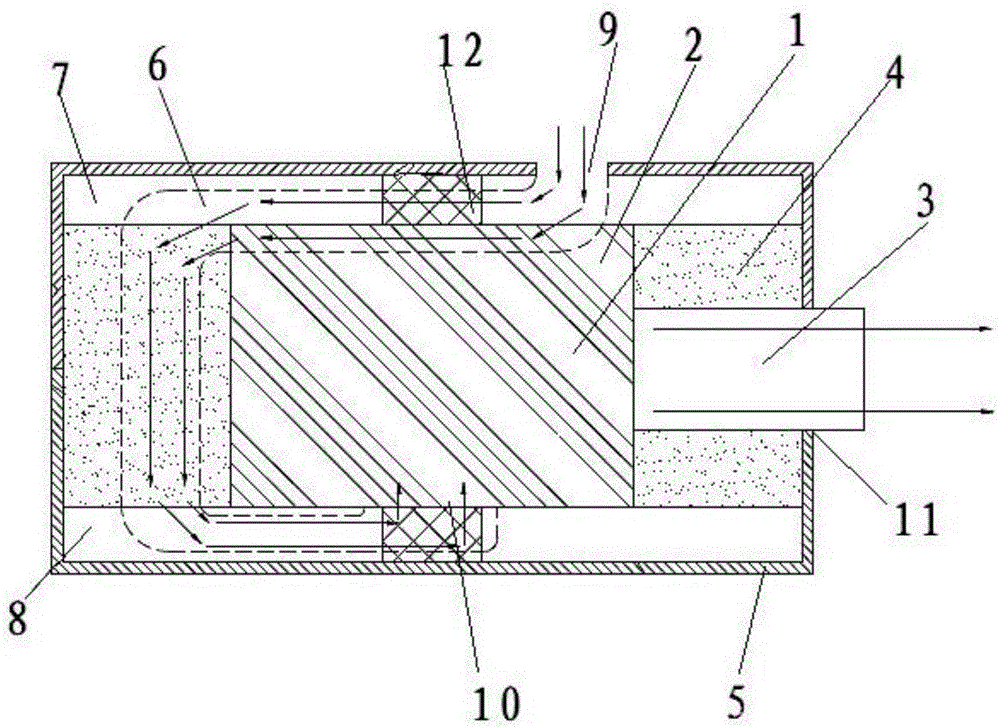

Pipeline noise reduction structure for breathing machine

ActiveCN103736186AReduce vibration and noiseReduce dynamic noiseRespiratorsPump componentsSoft layerLife quality

The invention discloses a pipeline noise reduction structure for a breathing machine. The pipeline noise reduction structure for the breathing machine comprises a draught fan (1) and is characterized in that the draught fan (1) comprises a draught fan body (2) and a compressed air output port (3), the periphery of the draught fan body (2) is tightly wrapped by a breathable soft layer (4), a sealing cabin (5) is arranged outside the breathable soft layer (4), the upper portion and the lower portion of the sealing cabin (5) are respectively provided with an air ventilation chamber (6), a first air input port (9) is formed in the upper portion of the sealing cabin (5), a second air input port (10) is formed in the lower portion of the draught fan (1), and a through hole (11) used for penetrating through the compressed air output port (3) is formed in the periphery of the sealing cabin (5). The pipeline noise reduction structure for the breathing machine is reasonable in design, simple, low in cost, safe and reliable, noise of the breathing machine is effectively reduced, it is ensured that a patient can easily fall asleep, and the sleeping quality and the living quality of the patient are improved.

Owner:KEMAI CHANGZHOU ELECTRONICS

High-quality polycrystalline diamond compact and preparation method thereof

InactiveCN110143021AImprove high temperature resistanceInhibit sheddingAdditive manufacturing apparatusIncreasing energy efficiencyPolycrystalline diamondCobalt

The invention relates to the technical field of super-hard composite materials, particularly to a high-quality polycrystalline diamond compact and a preparation method thereof. According to the invention, the high-quality polycrystalline diamond compact is manufactured by using double-beam 3D printing equipment which performs processing with high-power continuous beams and ultra-fast pulsed laserbeams alternately; and gradual transition layers are formed among layers, so bonding between a matrix and diamond and between the diamond and nickel is firm, and an interlayer interface is free of sudden changes in thermal and mechanical quantities. The polycrystalline diamond compact of the invention comprises, arranged from bottom to top, the matrix, a matrix-diamond gradual transition layer, adiamond layer, a diamond-nickel gradual transition layer, a nickel layer and a cobalt-free binder. The diamond-nickel gradual transition layer improves the heat dissipation performance of the polycrystalline diamond compact, prevents thermal stress corrosion from generating cracks on the surface of the diamond layer, and greatly improves the thermal stability of the polycrystalline diamond compact. Double-beam 3D printing technology used in the invention makes D-D bonding firm and ultra-high hardness to be obtained, so the polycrystalline diamond compact has high heat resistance, wear resistance and impact toughness, and thus has prolonged service life.

Owner:上海梁为科技发展有限公司

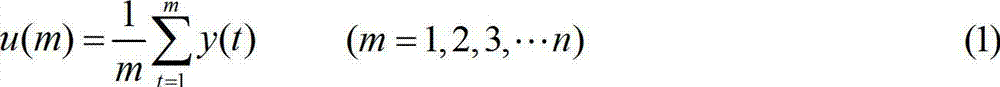

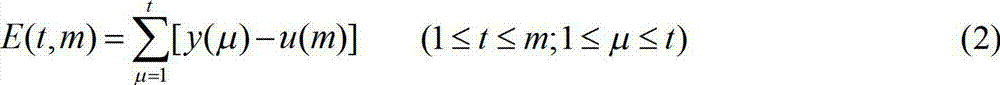

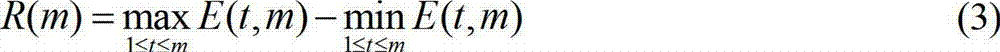

Hurst index-based slope safety evaluation method

InactiveCN103077306AEliminate mutationImprove applicabilitySpecial data processing applicationsSlope monitoringEngineering

The invention discloses a hurst index-based slope safety evaluation method, which comprises the following steps of: (1) performing safety classification; (2) preprocessing data; (3) simply prejudging the data; (4) calculating hurst indexes and related parameters; (5) determining a slope safety level; and (6) analyzing other parameters. According to the hurst index-based slope safety evaluation method provided by the invention, the integral safety of a slope is analyzed and evaluated by calculating the hurst index H of each monitoring point in a slope monitoring system and then combining all hurst indexes H; and compared with the conventional other methods, the method has the advantages of capability of eliminating the sudden change of monitoring data caused by field construction and the like and excellently high applicability.

Owner:HOHAI UNIV

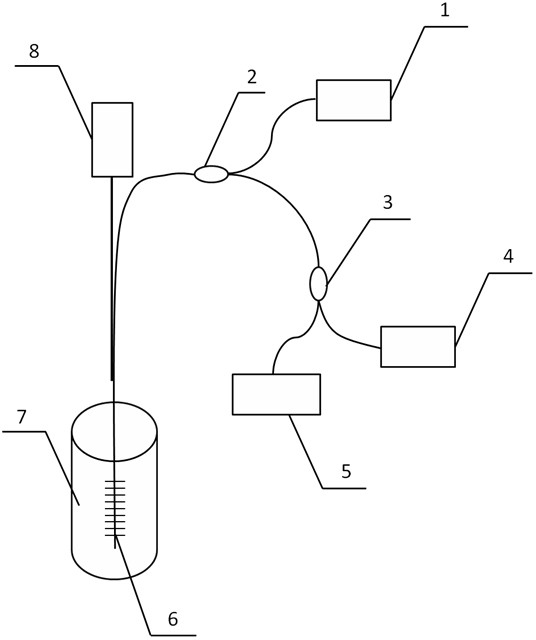

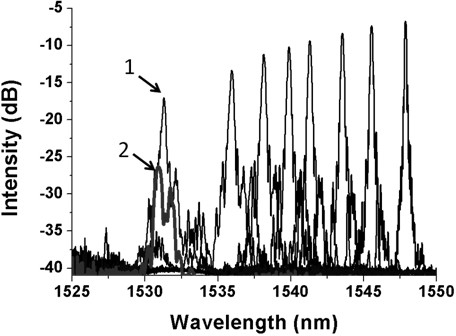

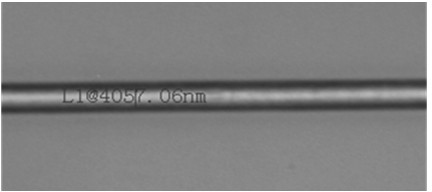

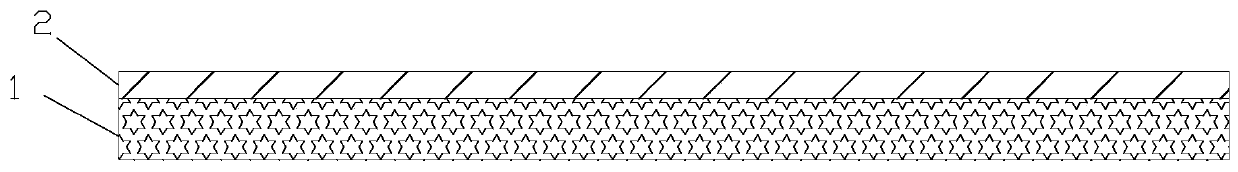

Method and device for manufacturing low-loss micro-nanometer fiber bragg grating sensor in chemical corrosion method

InactiveCN102645237AReduced gradient of refractive index changeEliminate corrosion interface mutationsPhase-affecting property measurementsConverting sensor output opticallyAutomatic controlFiber bragg grating sensor

The invention relates to a method and a device for manufacturing a low-loss micro-nanometer fiber bragg grating sensor in a chemical corrosion method. The device comprises a broad-band light source, an optical fiber circulator, a 3-dB optical fiber coupler, a spectrograph, an optical power meter, a stepping motor, an optical fiber written with a bragg grating and a polytetrafluoroethylene container containing corrosion solution. The method and the device control the speed of the optical fiber written with bragg grating in corrosion mode so as to manufacture the sensor through an automatic control technique. An optical fiber gradual-changing area can be slowly transited to a micro-nanometer fiber part by slowly lifting the optical fiber so that refractive index changing gradient of the optical fiber gradual-changing area can be reduced. The method and the device for manufacturing the low-loss micro-nanometer fiber bragg grating sensor in the chemical corrosion method has the advantages of being high in accuracy, low in cost, good in anti-interference performance, simple and practical in structure, suitable for mass production and the like.

Owner:ZHEJIANG UNIV

Method for prolonging endurance life of diamond compact and diamond compact

The invention relates to the technical field of super-hard composite materials, in particular to a method for prolonging the endurance life of a diamond compact and the diamond compact. The method forprolonging the endurance life of the diamond compact includes the steps: irradiating an interface between a substrate and a diamond layer and the surface of the diamond layer by ultra-fast pulse laser beams; polishing the surface of the diamond layer. The diamond compact is manufactured by the ultra-fast pulse laser beams, a gradient transition layer is generated between layers, so that the substrate and the diamond layer are firmly combined, and sudden change of a thermal quantity and a mechanical quantity on the interlayer interface is avoided. The surface (cold annealing) of the diamond layer is irradiated by the ultra-fast pulse laser beams, thermal stress concentration and lattice defects of the diamond layer can be eliminated, D-D bonds on the surface of the diamond layer can be firmly bonded, cobalt atoms are 'extruded' to the surface of the diamond layer, a rich cobalt layer is removed by polishing, ultra-high surface smoothness is realized, the high-temperature resistance ofthe diamond compact is improved, and the service life of the diamond compact is prolonged.

Owner:上海梁为科技发展有限公司

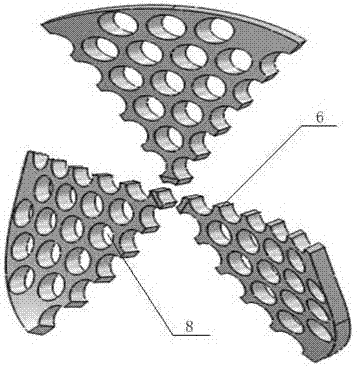

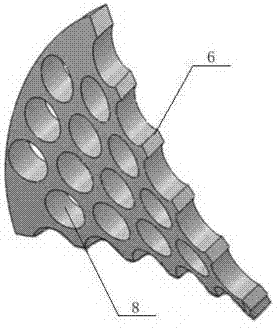

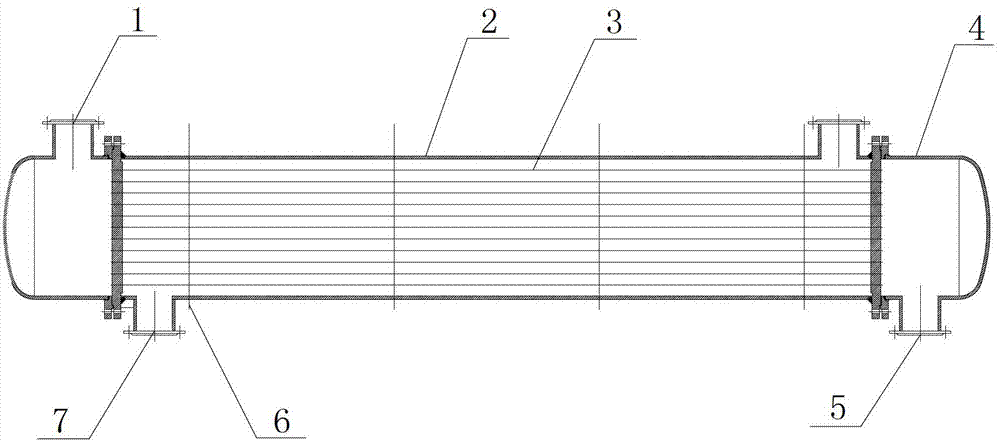

Shell-and-tube heat exchanger provided with blade type clapboards

InactiveCN102878830ANot easy to scaleImprove maintenance workloadHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a tubular heat exchanger with high heat transfer coefficient and low pressure loss, in particular relating to a shell-and-tube heat exchanger provided with blade type clapboards. The shell-and-tube heat exchanger comprises a shell (2) and heat exchange pipes (3); the shell-and-tube heat exchanger is characterized in that the two sides of the shell (2) are provided with guide cylinders (7), the two ends of the shell (2) are provided with sealing covers (4), a shell pass inlet (1) and a shell pass outlet (5) are respectively arranged on the sealing covers (4) of the two ends; every blade type clapboard (6) is arranged between the heat exchange pipes (3); a quantity of through holes (8) are arranged in the blade type clapboards (6); the heat exchange pipes (3) pass through the through holes (8) and are fixed in the shell (2). The outer diameters of the blade type clapboards (6) are same as the inner diameter of the shell (2); and gaps are formed among the through holes (8) and the heat exchange pipes (3). With the adoption of the shell-and-tube heat exchanger, enough strength disturbance is guaranteed, at the same time, the pressure loss of a shell pass fluid is effectively reduced, the heat transfer temperature difference is reduced, the total heat transfer coefficient is improved, the fluid outside the pipe is low in flowing resistance and good in heat exchange effect, and the shell-and-tube heat exchanger is convenient to produce and mount and long in service life.

Owner:山东双涵石化装备有限公司 +1

Preparation method and application of DNA polymerase accelerant

The invention discloses a preparation method and application of a DNA polymerase accelerant. The DNA polymerase accelerant is composed of three kinds of heat-stability protein which are uracil DNA glycosidase UDG, hypoxanthine DNA glycosidase AlkA and endonuclease IV respectively. UDG is in charge of cutting off dU basic groups generated in a PCR, AlkA is in charge of cutting off generated dI basic groups, and endonuclease IV is in charge of cutting off basic group removal loci. The joint action of the three kinds of protein can achieve the purposes that the inhibition effect of the dU / dI basic groups on the activity of B type DNA polymerase is released; the dU / dI basic groups are repaired and corrected, and the PCR faithfulness of the A type and B type DNA polymerase is improved. In addition, the activity of 3'-excision enzymes of endonuclease IV can provide deleted correction activity of the A type DNA polymerase. The DNA polymerase accelerant can effectively increase the PCR yield of the B type DNA polymerase by 1-3 times.

Owner:SUZHOU KUANGSHI JUNCHI BIOLOGICAL SCI & TECH

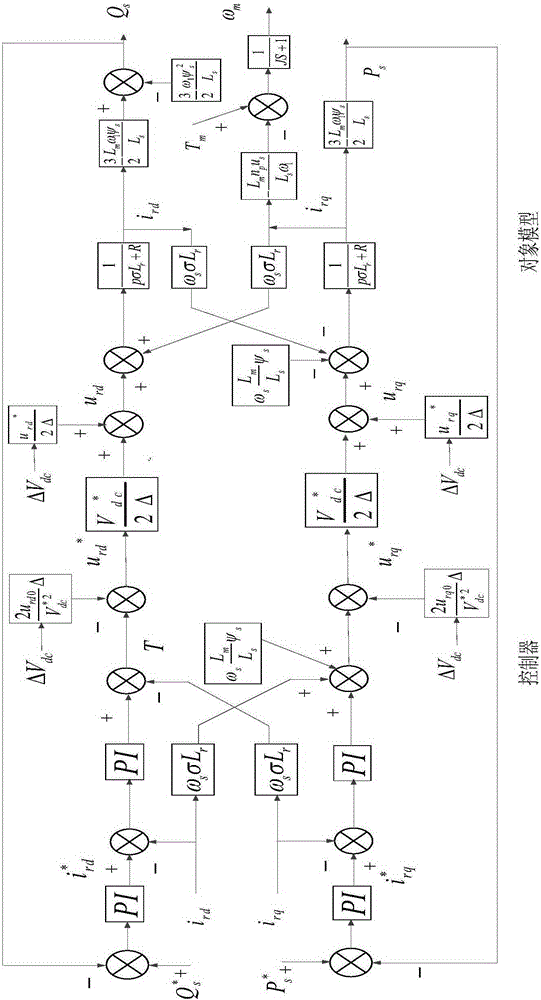

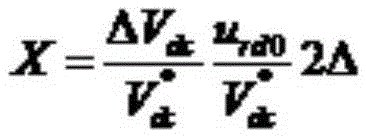

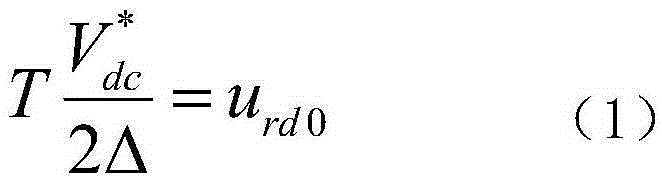

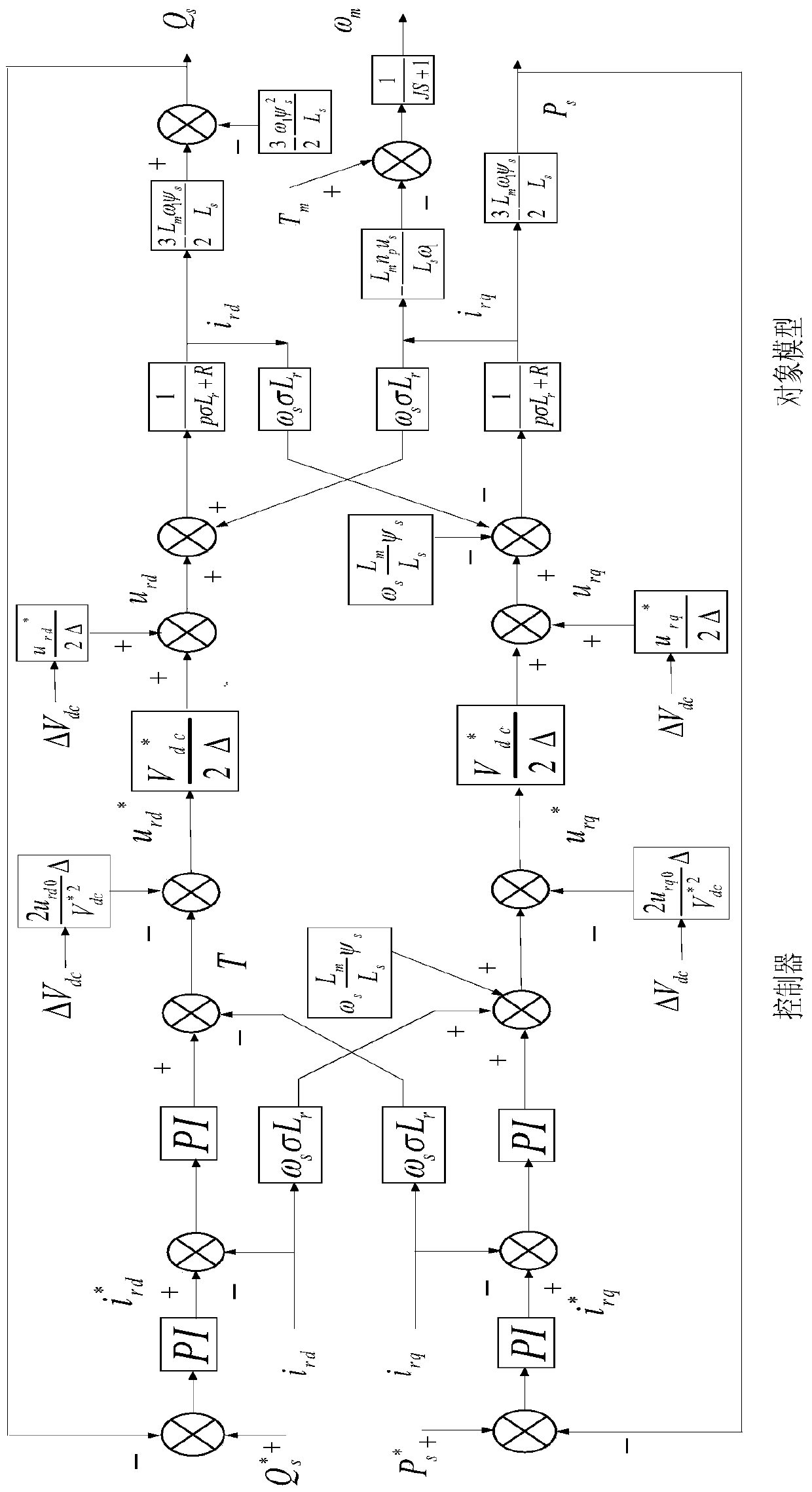

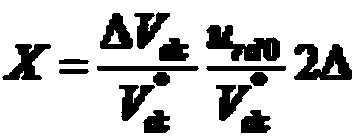

Method for controlling output power of rotor side of double-fed draught fan

The invention relates to a method for controlling the output power of the rotor side of a double-fed draught fan. Feedforward control is introduced, so that the influence of bus voltage fluctuation is eliminated, it is guaranteed that the power of an object model is stably output under the condition of bus voltage fluctuation, after improved control is applied, the capacitor capacity can be reduced, and engineering cost is reduced. A rotor side improved control strategy is high in control accuracy and high in response speed, the power fluctuation can be reduced during direct voltage fluctuation, and output is more stable.

Owner:WUHAN UNIV

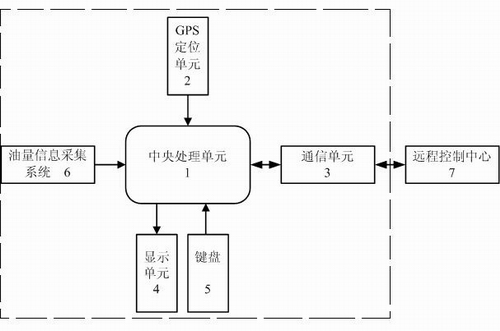

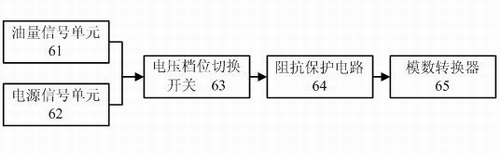

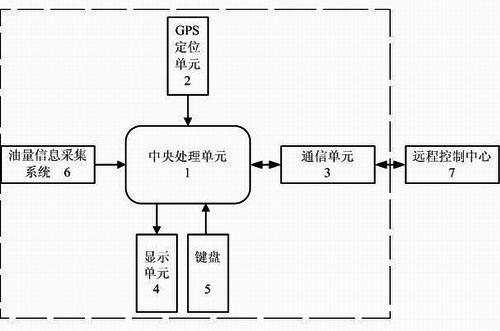

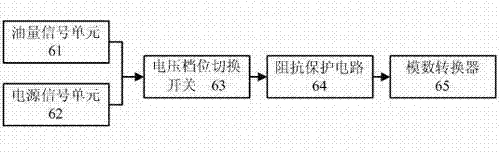

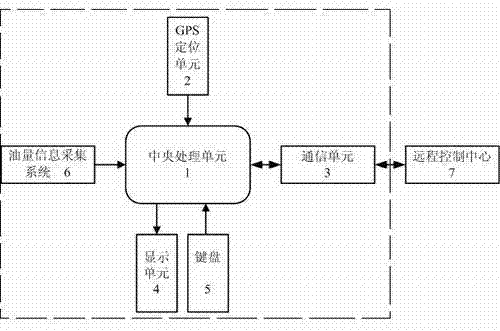

Method for oil mass signal synchronous compensation of on-vehicle positioning terminal

InactiveCN101865715AHigh Acquisition AccuracyLow costElectric signal transmission systemsCurrent/voltage measurementCommunication unitRemote control

The invention discloses a method for oil mass signal synchronous compensation of an on-vehicle positioning terminal. The on-vehicle positioning terminal employing the method comprises a central processing unit, a GPS positioning unit, a communication unit, a display unit, a keyboard and an oil mass information acquisition system, wherein the GPS positioning unit, the communication unit and the display unit are connected with the central processing unit respectively; and the keyboard and the oil mass information acquisition system are also connected with the central processing unit respectively. In the method, by synchronously acquiring power supply signals and oil mass signals, and performing operation processing on the signals by the central processing unit through an analog-digital converter, the abrupt changes of the oil mass in an oil tank are eliminated, a real oil mass value is input to a local display unit or is sent to a remote control center by the communication unit so as to realize the real-time accurate monitoring of the oil mass of the oil tank of a vehicle.

Owner:天合导航通信技术有限公司

Noise reduction structure for ventilator pipeline

ActiveCN103736186BReduce vibration and noiseReduce dynamic noiseRespiratorsPump componentsSoft layerLife quality

The invention discloses a pipeline noise reduction structure for a breathing machine. The pipeline noise reduction structure for the breathing machine comprises a draught fan (1) and is characterized in that the draught fan (1) comprises a draught fan body (2) and a compressed air output port (3), the periphery of the draught fan body (2) is tightly wrapped by a breathable soft layer (4), a sealing cabin (5) is arranged outside the breathable soft layer (4), the upper portion and the lower portion of the sealing cabin (5) are respectively provided with an air ventilation chamber (6), a first air input port (9) is formed in the upper portion of the sealing cabin (5), a second air input port (10) is formed in the lower portion of the draught fan (1), and a through hole (11) used for penetrating through the compressed air output port (3) is formed in the periphery of the sealing cabin (5). The pipeline noise reduction structure for the breathing machine is reasonable in design, simple, low in cost, safe and reliable, noise of the breathing machine is effectively reduced, it is ensured that a patient can easily fall asleep, and the sleeping quality and the living quality of the patient are improved.

Owner:KEMAI CHANGZHOU ELECTRONICS

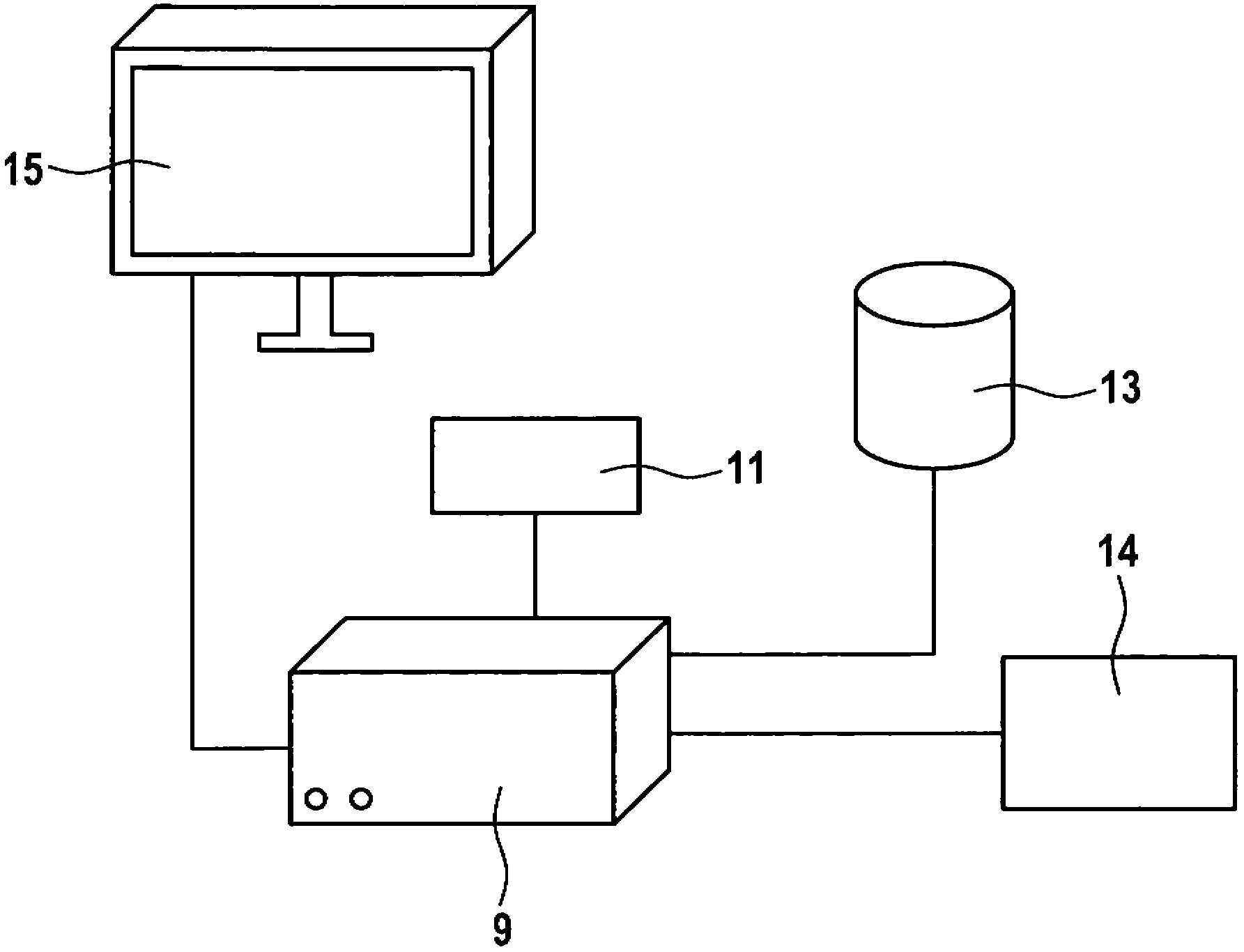

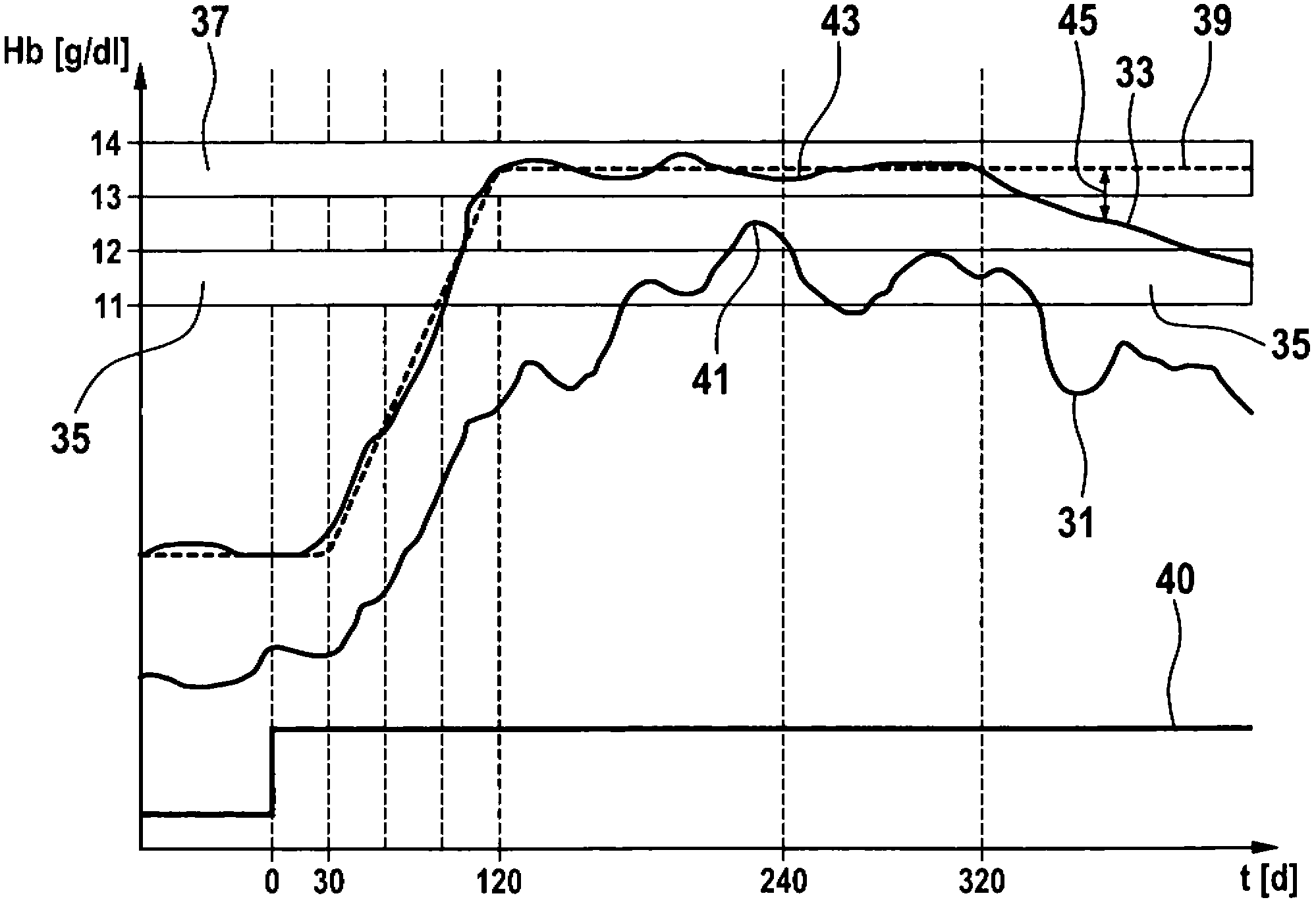

Methods and apparatuses for predicting the effects of erythropoesis stimulating agents (esa), and for determining a dose to be administered

ActiveCN103270414AEliminate Fluid State ChangesGet the target range rightDisease diagnosisBiological testingMedicineDigital storage

The present invention relates to a method for predicting the concentration or the mass of haemoglobin or an approximation thereof, respectively, in a body fluid and / or an extracorporeal sample thereof of a patient at a later, second point of time, the patient having theoretically or in reality been administered a certain dose of an erythropoesis stimulating agent at an earlier, first point of time. It relates further to a method for determining the dose of an erythropoesis stimulating agent to be administered to a patient, to a method for determining whether a patient is affected by circumstances leading to the loss of haemoglobin, to corresponding devices and to an erythropoesis stimulating medicament for use in the treatment of anemia. Finally the present invention relates to corresponding means, digital storage means, a computer program product, and a computer program.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

A Method for Controlling the Output Power of the Rotor Side of a Doubly-fed Fan

The invention relates to a method for controlling the output power of the rotor side of a double-fed draught fan. Feedforward control is introduced, so that the influence of bus voltage fluctuation is eliminated, it is guaranteed that the power of an object model is stably output under the condition of bus voltage fluctuation, after improved control is applied, the capacitor capacity can be reduced, and engineering cost is reduced. A rotor side improved control strategy is high in control accuracy and high in response speed, the power fluctuation can be reduced during direct voltage fluctuation, and output is more stable.

Owner:WUHAN UNIV

Pharmaceutical composition for preventing and treating premature ovarian failure and improving osteoporosis and preparation method thereof

PendingCN114712447ADelay agingImproves perimenopausal symptomsOrganic active ingredientsOrganic chemistryPremature agingAngelica Sinensis Root

The invention discloses a pharmaceutical composition for preventing and treating premature ovarian failure and improving osteoporosis and a preparation method of the pharmaceutical composition, relates to the technical field of traditional Chinese medicine compositions, and solves the technical problem that the purposes of resisting aging and prolonging life cannot be fundamentally achieved by only tonifying kidney or nourishing ovary when the premature ovarian failure and the osteoporosis are treated at present. The traditional Chinese medicine composition is prepared from the following raw materials: soy isoflavone, herba epimedii, glossy privet fruit, radix polygoni multiflori preparata, angelica sinensis, radix paeoniae alba, medlar, ginseng, oyster, safflower, rose, jujube, rhizoma atractylodis macrocephalae fried with bran, fructus psoraleae and Chinese yam. The pharmaceutical composition for preventing and treating premature ovarian failure and improving osteoporosis has the effects of tonifying kidney, regulating menstruation and nourishing ovary, and can regulate all links of cerebral cortex, hypothalamus-pituitary gland-adrenal gland and ovarian axis.

Owner:四川汇智启创科技服务有限公司

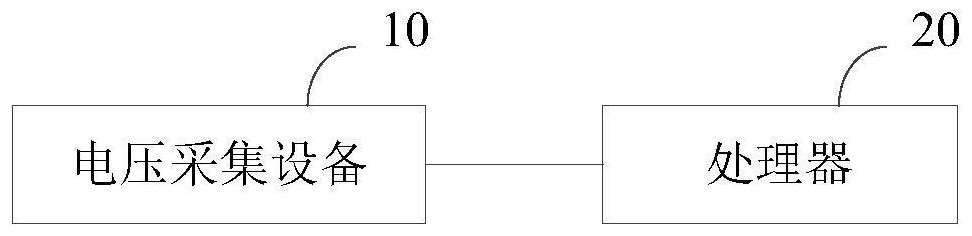

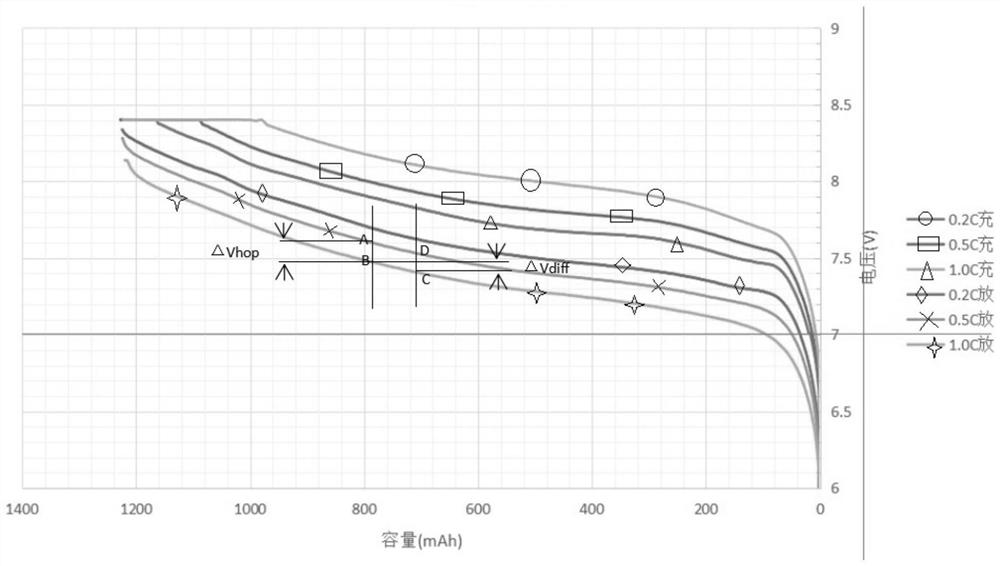

Battery electric quantity determination method and device, terminal equipment and storage medium

PendingCN114660465AEliminate mutationAccurately determineElectrical testingComputational physicsElectrical battery

The invention is suitable for the technical field of electric quantity calibration, and provides a battery electric quantity determination method and device, terminal equipment and a storage medium, and the method comprises the steps: obtaining a first calibration voltage of a battery at an (i-1) th sampling moment when it is determined that a battery voltage value before an ith sampling moment suddenly changes, the first calibration voltage is determined based on the j-n-th voltage variation of the battery in the j-n-th sampling period and the j-th voltage variation of the battery in the j-n-th sampling period, and the j-th sampling period is a sampling period in which the voltage variation is smaller than a preset threshold value for the first time after the j-n-th sampling period; obtaining a second calibration voltage based on the first calibration voltage and the jth voltage variation; determining the battery electric quantity at the ith sampling moment based on the second calibration voltage; voltage jitter is eliminated, the battery electric quantity is determined more accurately, and the battery electric quantity changes stably.

Owner:UBTECH ROBOTICS CORP LTD

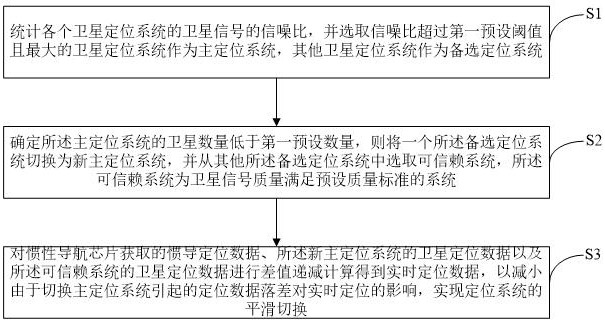

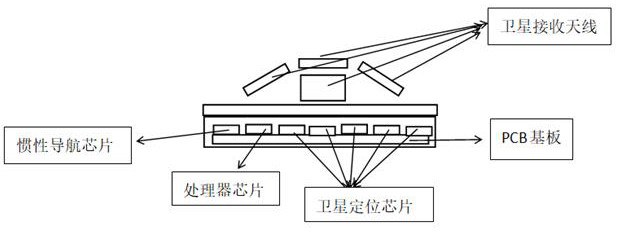

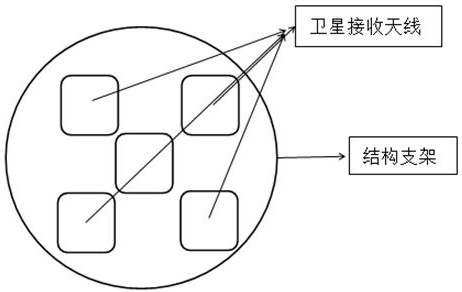

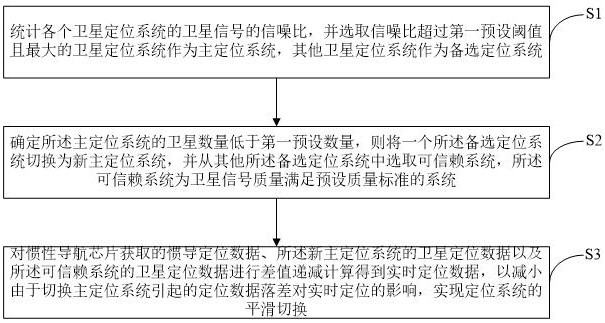

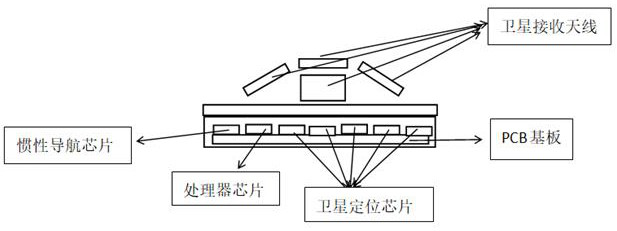

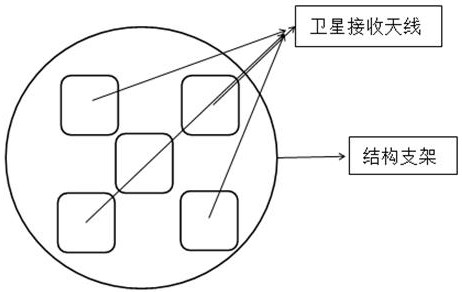

An anti-jamming satellite positioning device coupled with multiple positioning systems

ActiveCN113900134BHigh positioning accuracyImprove anti-interference abilitySatellite radio beaconingAnti jammingSatellite positioning

This application relates to an anti-jamming satellite positioning device coupled with multiple positioning systems, including an integrated processor chip, an inertial navigation chip and a satellite positioning chip on a PCB substrate. A satellite positioning chip is connected to a satellite receiving antenna to form a satellite positioning system. The processor The chip is configured to: calculate the satellite signal-to-noise ratio of each satellite positioning system, and select the satellite positioning system with the largest signal-to-noise ratio exceeding the first preset threshold as the main positioning system, and other satellite positioning systems as the alternative positioning system; determine If the number of satellites in the main positioning system is lower than the first preset number, switch an alternative positioning system to the new main positioning system, and select a reliable system from other alternative positioning systems; The system and the satellite positioning data of the reliable system are calculated by decreasing the difference to obtain real-time positioning data. The device can reduce the gap of positioning data between different systems and realize smooth switching of positioning systems.

Owner:天津仁爱学院 +1

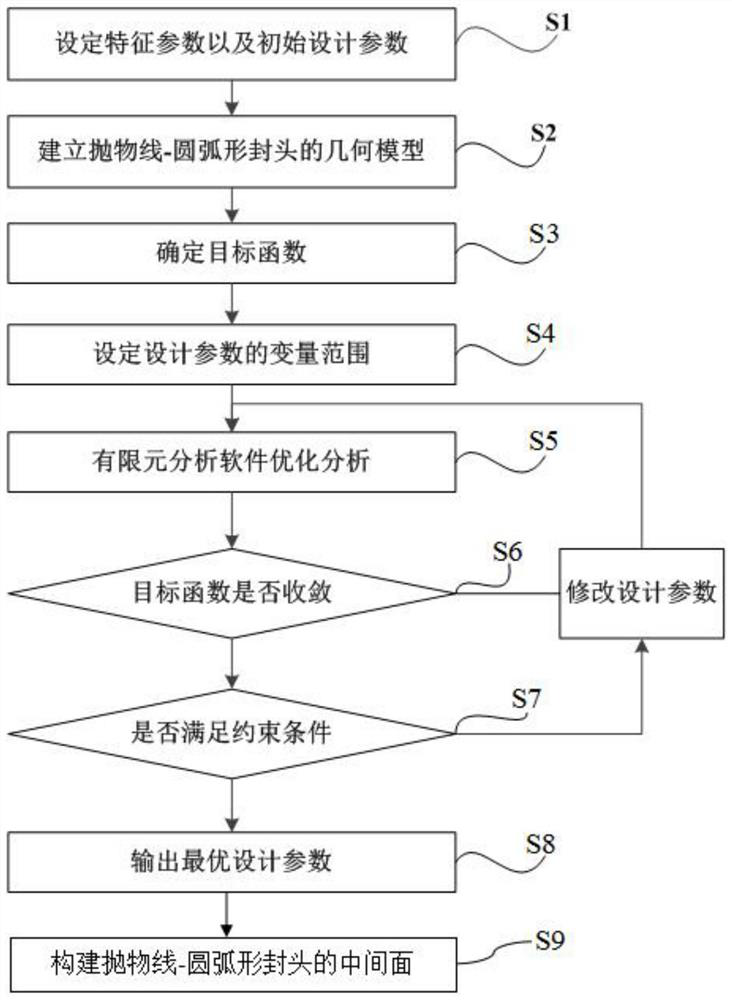

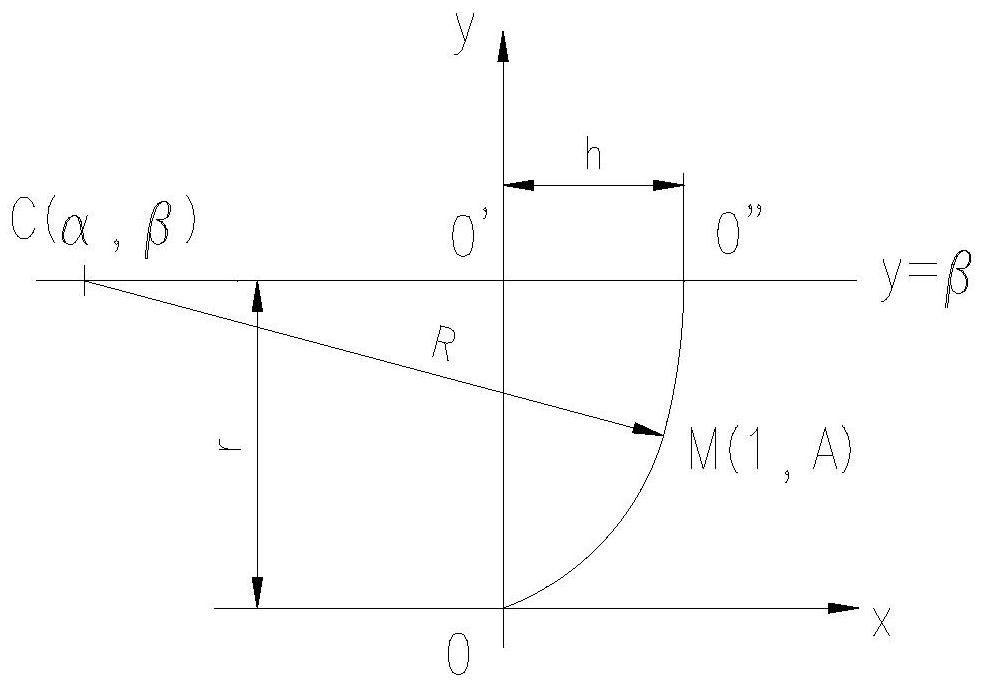

A method for optimal design of parabolic-arc-shaped head structure

ActiveCN107895098BShorten the timeSave materialGeometric CADDesign optimisation/simulation2D geometric modelFinite element analysis software

The invention provides an optimum structural design method for a parabolic-arc seal head. The method comprises the following steps: 1, setting characteristic parameters and initial design parameters of the parabolic-arc seal head; 2, establishing a two-dimensional geometric model according to the characteristic parameters and the initial design parameters; 3, determining a corresponding function at a minimal stress of the two-dimensional geometric model as an objective function; 4, setting a variable range of the initial design parameters; 5, performing optimized analysis on the initial designparameters by setting constraints and loads so as to obtain stress intensity values corresponding to the initial design parameters by using finite element analysis software; 6, substituting the stress intensity values into the objective function, judging whether the objective function is convergent and meets constraint conditions, if not, modifying the initial design parameters and returning to the step 5; and 7, obtaining the optimized design parameters when the objective function is convergent and meets the constraint conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Multi-positioning system coupled anti-interference satellite positioning equipment

ActiveCN113900134AHigh positioning accuracyImprove anti-interference abilitySatellite radio beaconingEngineeringLocation Equipment

The invention relates to multi-positioning-system coupled anti-interference satellite positioning equipment. The equipment comprises a processor chip, an inertial navigation chip and a satellite positioning chip which are integrated on a PCB substrate, and one satellite positioning chip is connected with one satellite receiving antenna to form a satellite positioning system; and the processor chip is configured to count the signal-to-noise ratio of satellite signals of each satellite positioning system, select the satellite positioning system with the maximum signal-to-noise ratio exceeding a first preset threshold value as a main positioning system, and the other satellite positioning systems as alternative positioning systems, switch one alternative positioning system into a new main positioning system and select a trustworthy system from other alternative positioning systems if it is determined that the number of satellites of the main positioning system is lower than a first preset number, and perform difference decreasing calculation on the inertial navigation positioning data and the satellite positioning data of the new main positioning system and the trustworthy system to obtain real-time positioning data. The equipment can reduce the fall of positioning data among different systems, and realizes smooth switching of the positioning systems.

Owner:天津仁爱学院 +1

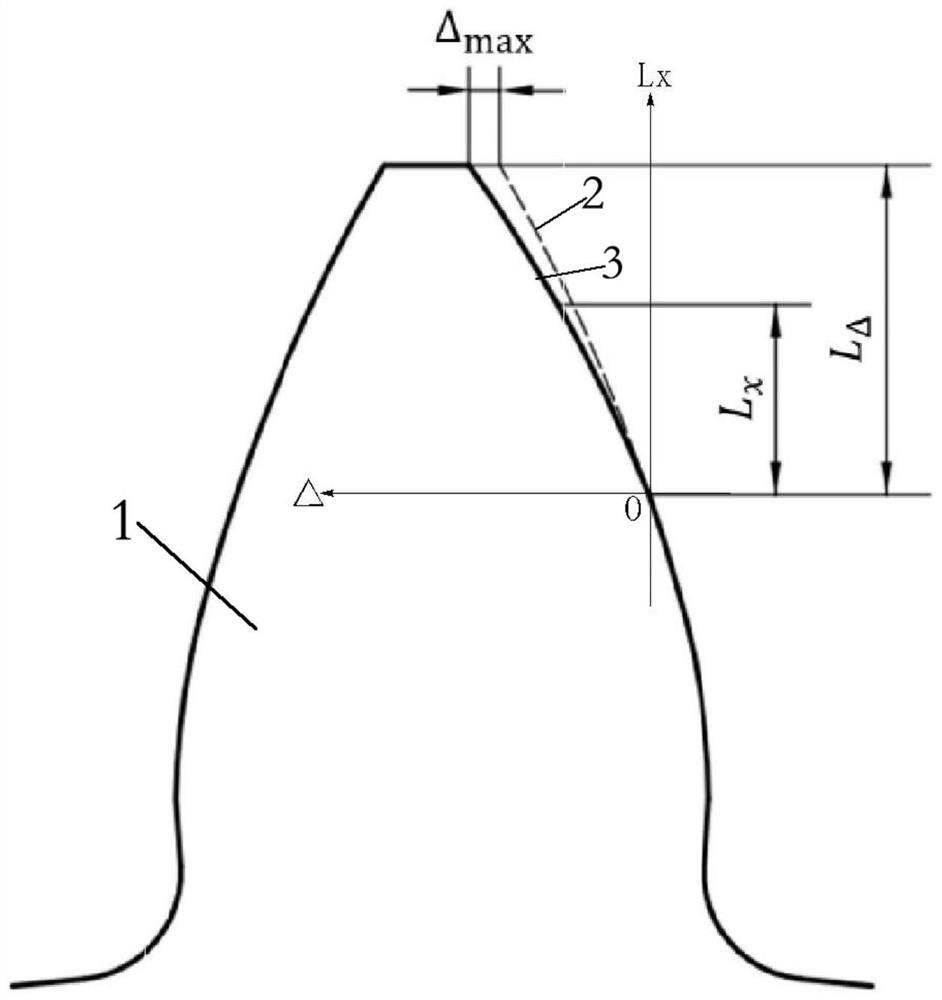

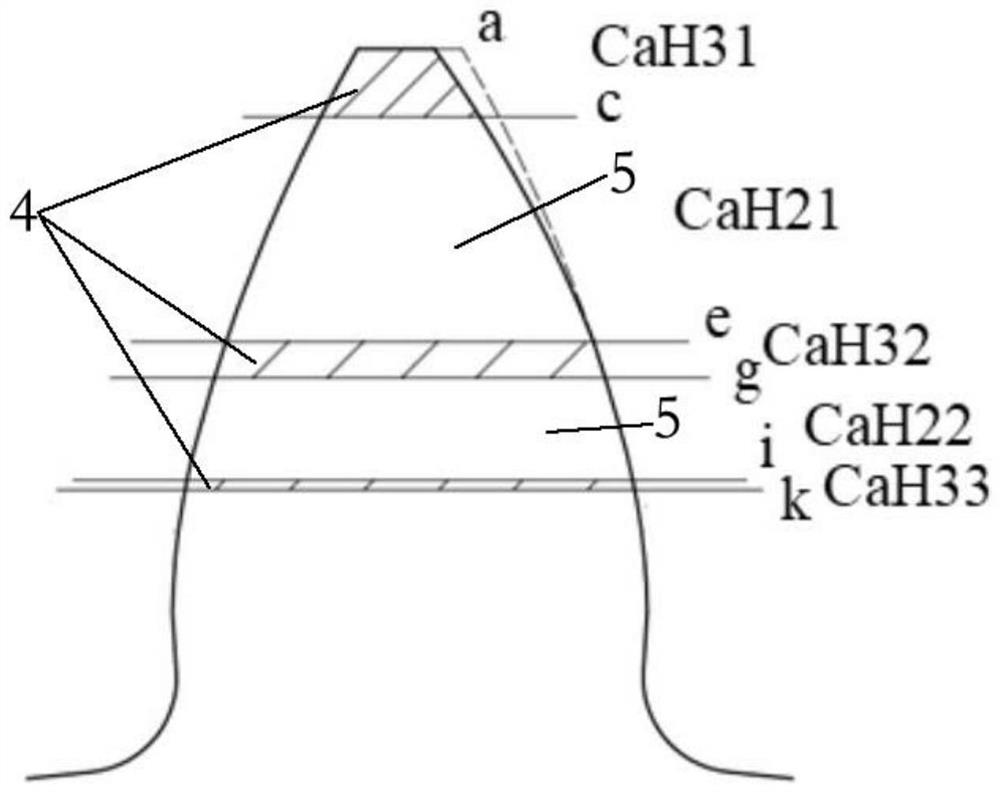

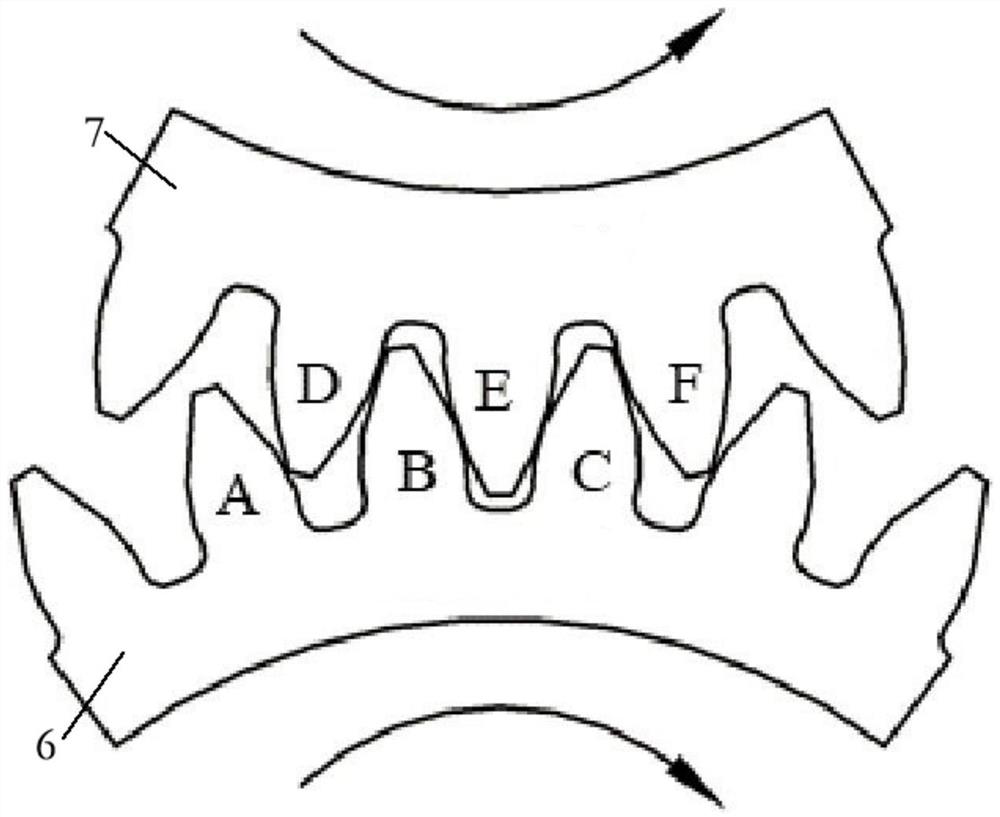

A gear modification method for reducing the contact temperature of gear tooth surfaces

ActiveCN113464624BImprove glue resistanceReduce mutationGeometric CADPortable liftingRectangular coordinatesGear wheel

The invention relates to the technical field of gear modification, in particular to a gear modification method for reducing the contact temperature of the gear tooth surface, comprising the following steps: S1: selecting the three-tooth meshing area closest to the tooth tip and the corresponding two-tooth meshing area The tooth profile of the tooth profile to be modified is used as the tooth profile to be modified; S2: The plane rectangular coordinate system (O-L X Δ), the plane Cartesian coordinate system (O-L X Δ) of the ordinate axis L X Parallel to the radial direction of the gear, the abscissa axis of the plane rectangular coordinate system is the modification amount Δ; S3: Calculate the maximum modification amount Δ of the end point relatively close to the tooth tip on the tooth profile to be modified max ; S4: Select a modification curve, the equation of the modification curve is: In the above formula, L Δ It is the ordinate of the end point relatively close to the tooth tip on the tooth profile to be modified. The invention can reduce the maximum tooth surface contact temperature when the gear teeth are meshed, and reduce or even eliminate the sudden change of the load in each meshing area of the meshing gear.

Owner:UNIV OF JINAN +1

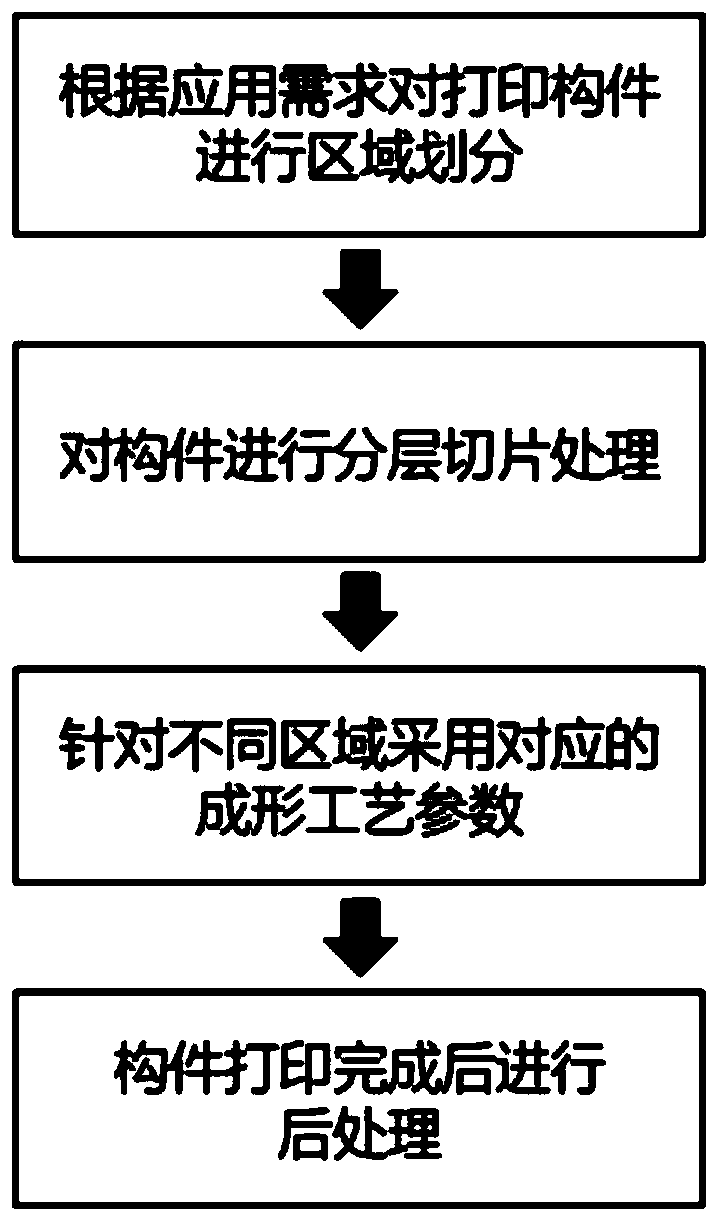

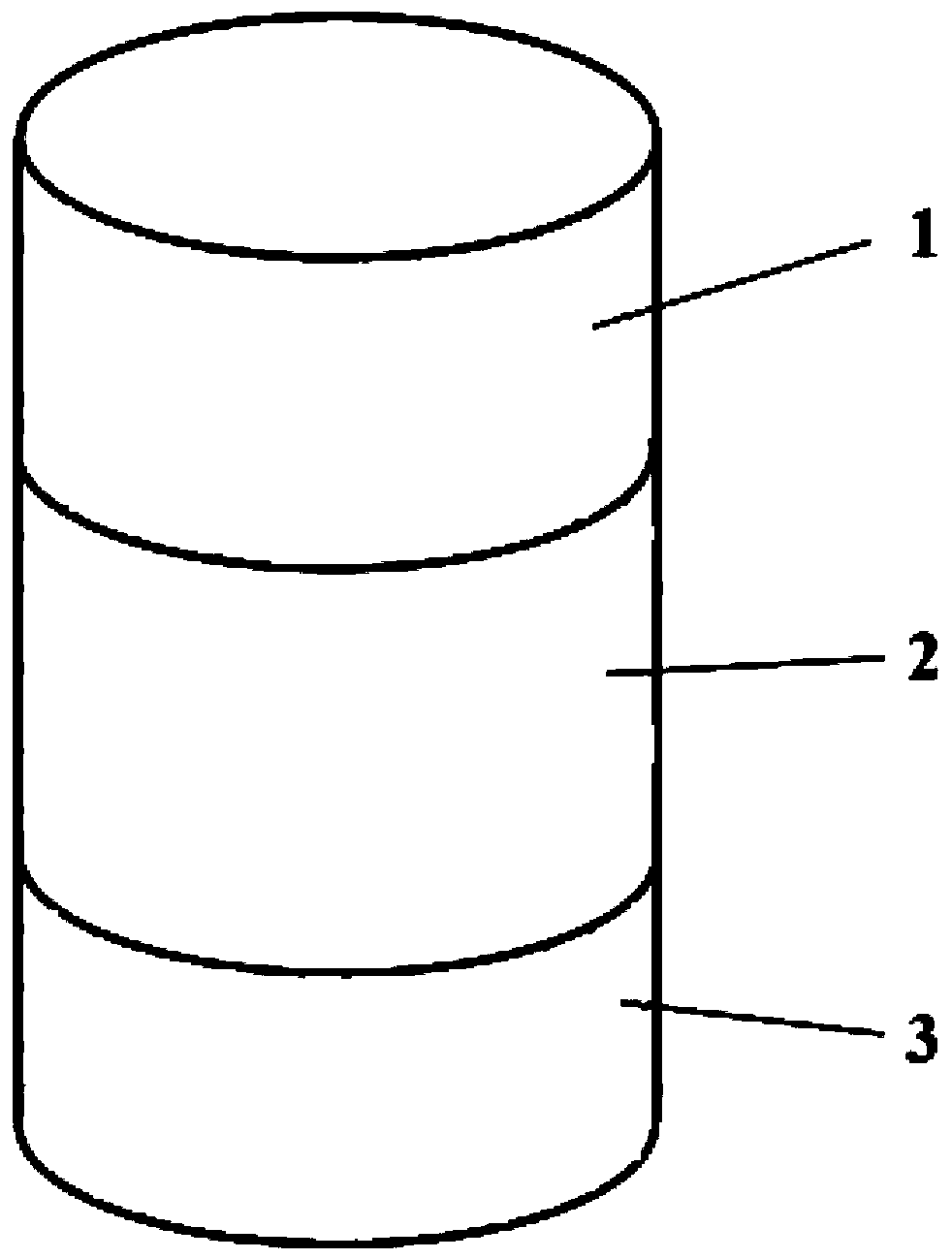

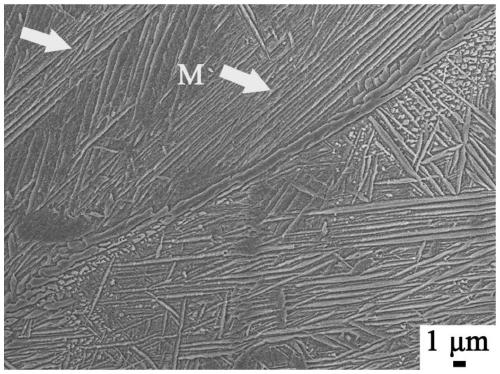

4D printing method and product of functionally graded copper-based shape memory alloy smart components

ActiveCN110434331BAchieve continuous changeSimple preparation processAdditive manufacturing apparatusIncreasing energy efficiencyShape-memory alloyManufactured material

Owner:HUAZHONG UNIV OF SCI & TECH

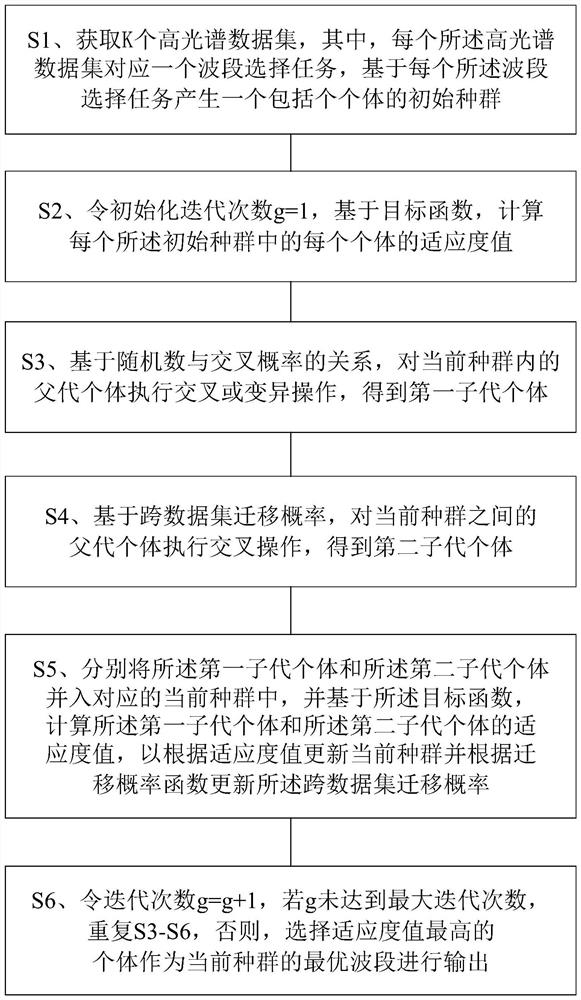

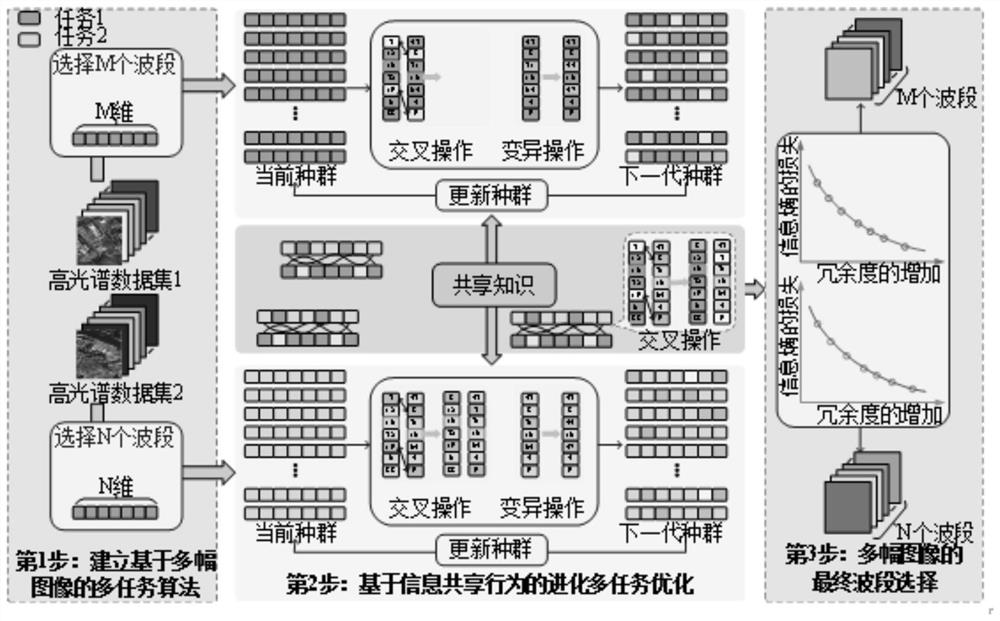

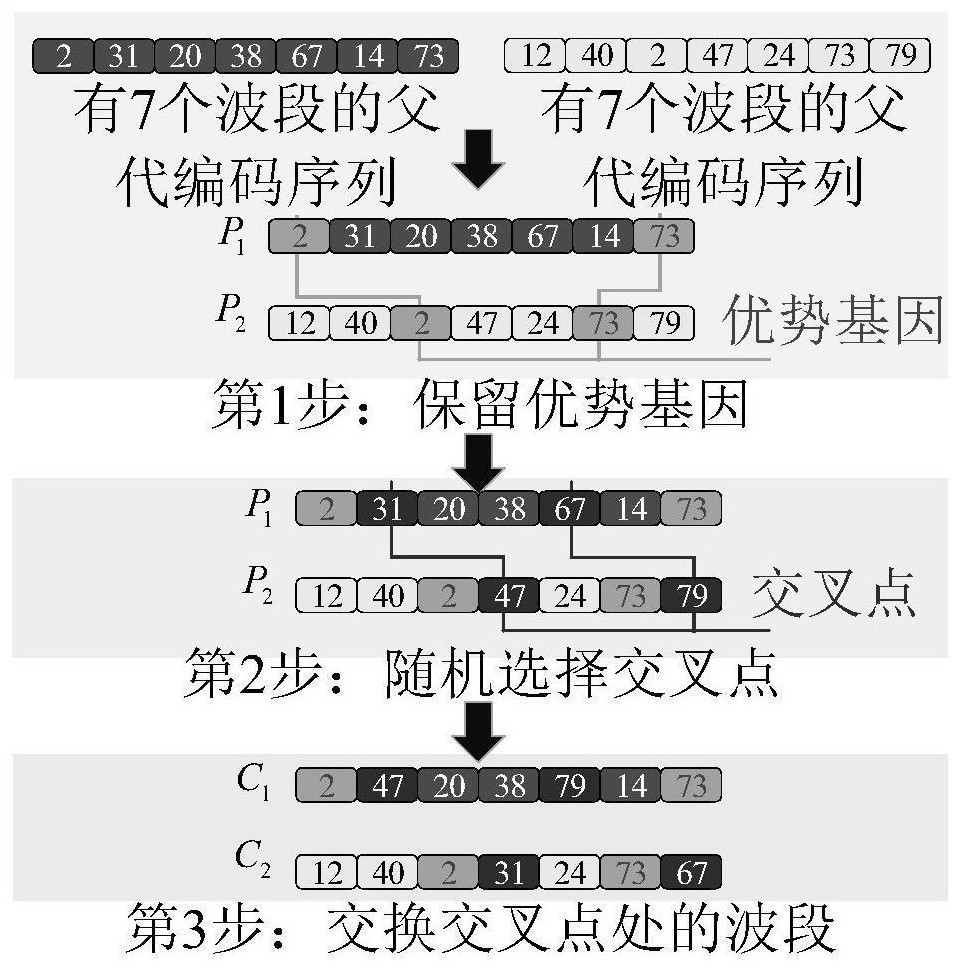

Hyperspectral band selection method based on multi-data-set collaborative analysis, and storage medium

PendingCN113988139AImprove band selectivityImprove collaborationCharacter and pattern recognitionData setData mining

The invention discloses a hyperspectral band selection method based on multi-data-set collaborative analysis, and a storage medium. The method comprises the following steps: acquiring K hyperspectral data sets; calculating fitness values of individuals in each initial population; performing crossover or mutation operation on parent individuals in a current population to obtain first offspring individuals; performing crossover operation on parent individuals among the current population according to a cross-data migration probability to obtain second filial generation individuals; updating the current population according to the fitness values and updating the cross-dataset migration probability according to a migration probability function; selecting individuals with a highest fitness value as an optimal wave band of the current population and outputting the optimal wave band. According to the invention, a hyperspectral multi-data-set waveband selection collaborative analysis framework is constructed, and the waveband selection performance of each data set is improved by using a same spectral range and similar spectrum-space structures of the data sets.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for oil mass signal synchronous compensation of on-vehicle positioning terminal

InactiveCN101865715BEliminate mutationAccurate monitoringElectric signal transmission systemsCurrent/voltage measurementCommunication unitRemote control

The invention discloses a method for oil mass signal synchronous compensation of an on-vehicle positioning terminal. The on-vehicle positioning terminal employing the method comprises a central processing unit, a GPS positioning unit, a communication unit, a display unit, a keyboard and an oil mass information acquisition system, wherein the GPS positioning unit, the communication unit and the display unit are connected with the central processing unit respectively; and the keyboard and the oil mass information acquisition system are also connected with the central processing unit respectively. In the method, by synchronously acquiring power supply signals and oil mass signals, and performing operation processing on the signals by the central processing unit through an analog-digital converter, the abrupt changes of the oil mass in an oil tank are eliminated, a real oil mass value is input to a local display unit or is sent to a remote control center by the communication unit so as torealize the real-time accurate monitoring of the oil mass of the oil tank of a vehicle.

Owner:天合导航通信技术有限公司

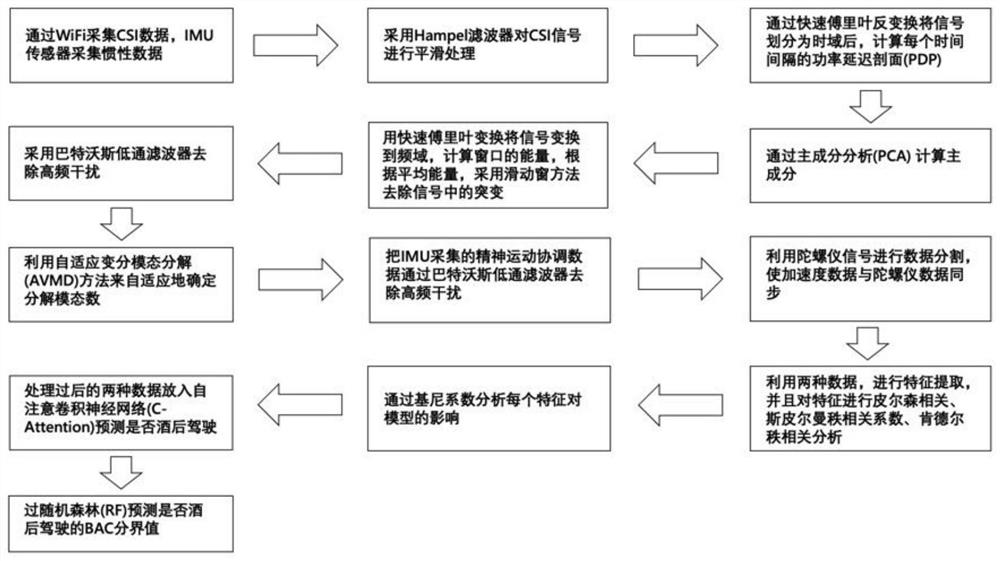

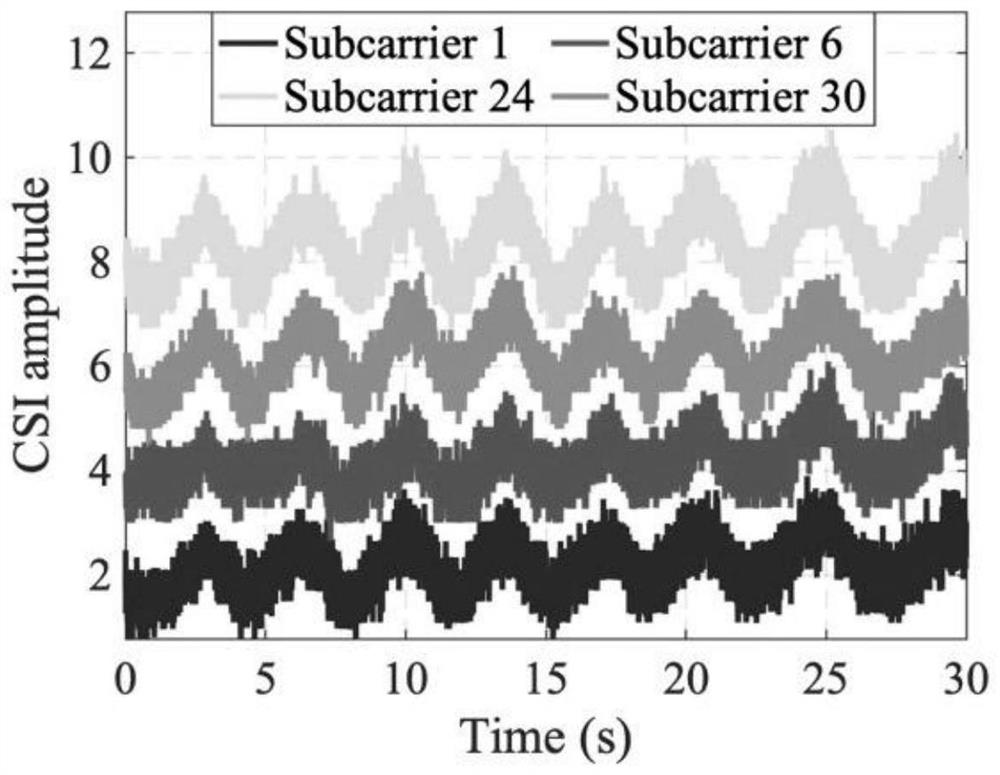

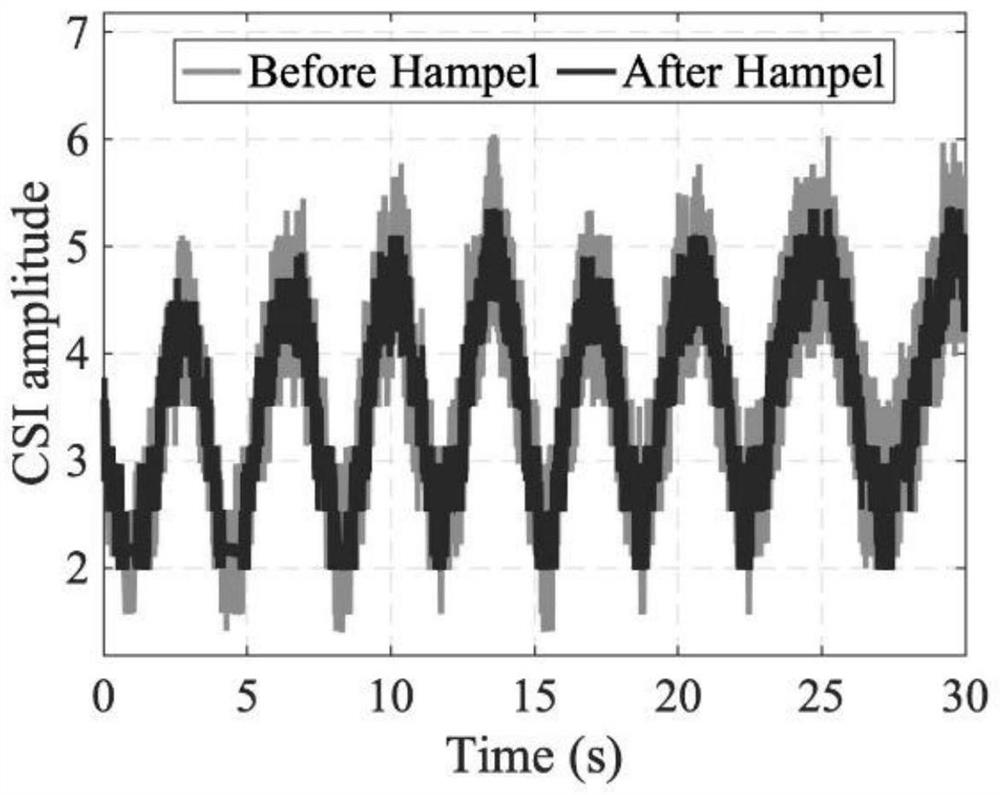

Method for monitoring drunk driving by using wireless network and storable medium

InactiveCN114492525AEliminate mutationCompact environmentNetwork topologiesCharacter and pattern recognitionNerve networkMonitoring system

The invention discloses a method for monitoring drunk driving by using a wireless network and a storable medium, and relates to the field of intelligent detection. The method comprises the following steps: acquiring vital signs and mental movement coordination data; de-noising processing is performed on the vital sign and mental movement coordination data; inputting the vital signs and the mental movement coordination data into a self-attention convolutional neural network for processing; and predicting whether drunk driving occurs or not according to the self-attention convolutional neural network, and estimating the blood alcohol concentration (BAC) by using a random forest. The invention provides a series of signal processing methods and a self-attention convolutional neural network (namely C-Attention) integrating vital signs and mental movement coordination to realize a non-contact, non-intrusive and real-time drunk driving monitoring system.

Owner:ZHEJIANG UNIV

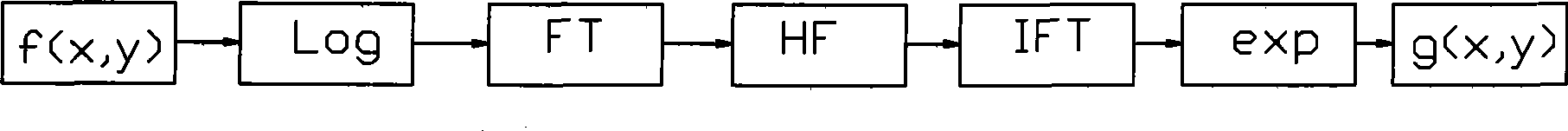

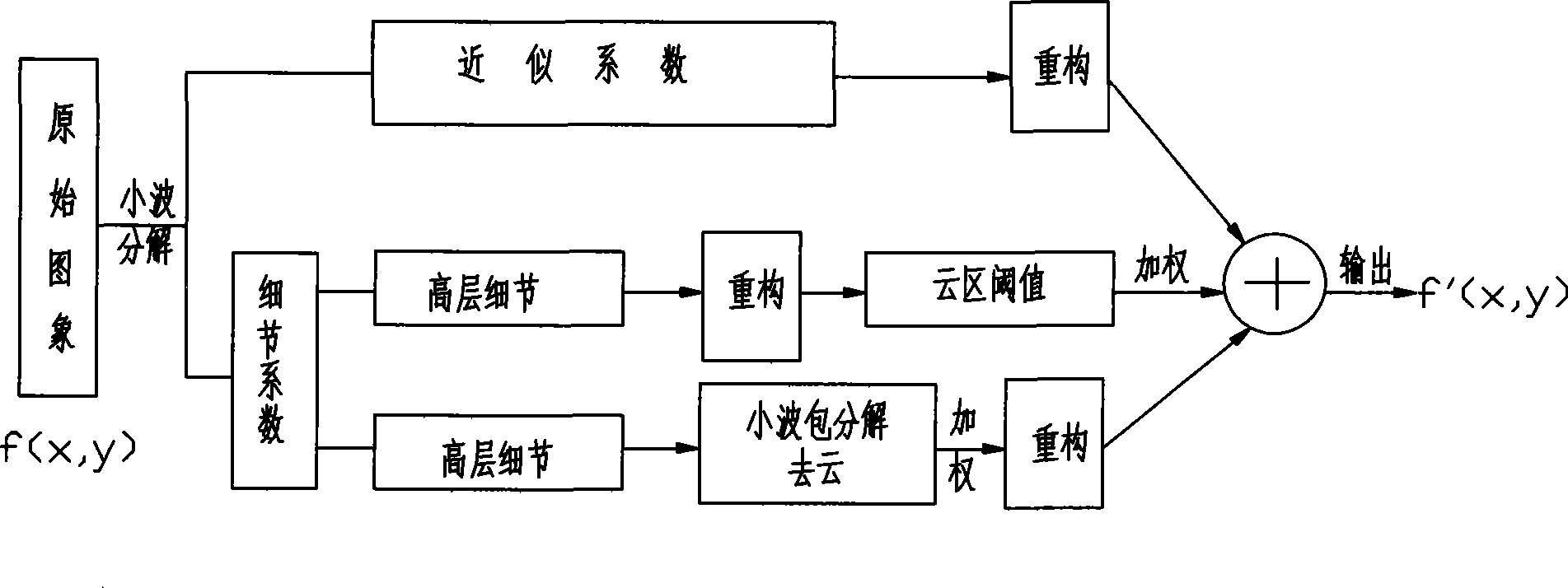

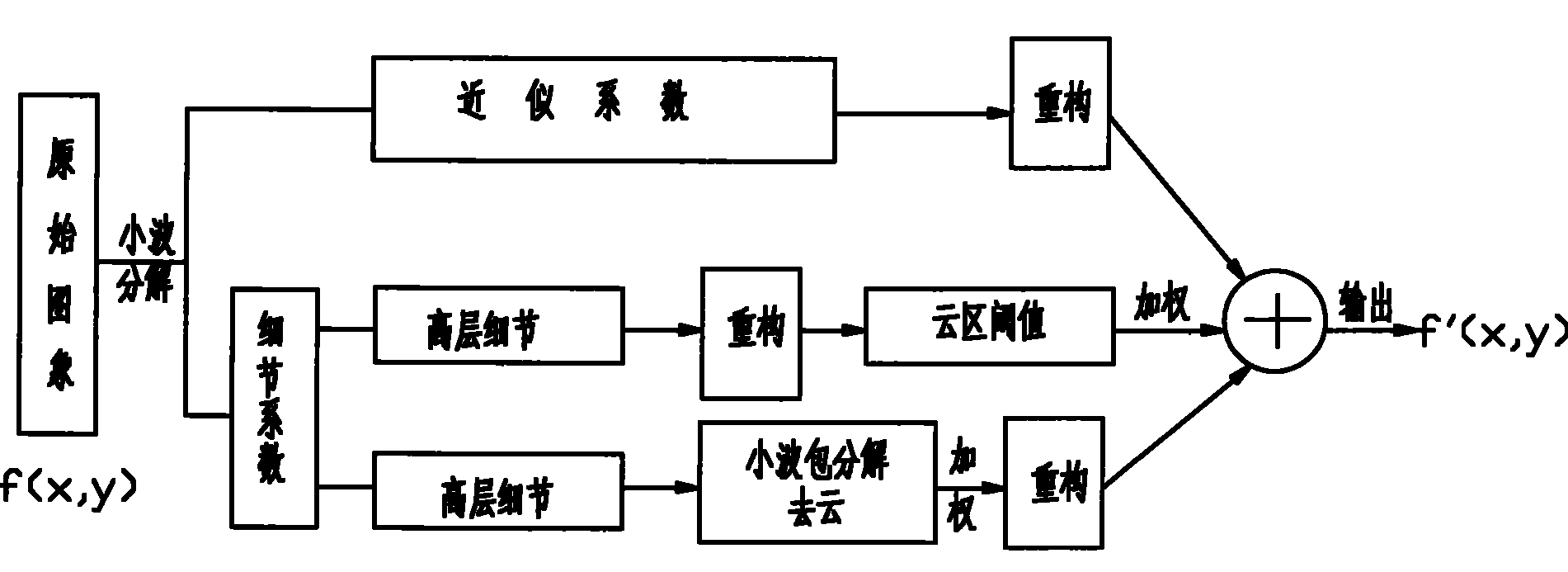

Cloud-removing method for optical image

InactiveCN101359399BSolve problemsWeaken and eliminate the impactImage enhancementElectromagnetic wave reradiationWavelet decompositionBackground information

The invention discloses an optical image cloud removal method. The reasonable demarcation layer number l is selected after the optical image covered by the cloud is processed with n-layer wavelet decomposition; the background information, the scenery information and the cloud noise are respectively distributed to the approximate coefficient, 1-l low-layer detail coefficient and the l+1 high-layerdetail coefficient as far as possible. Then the high-layer detail coefficient is reconstructed; the cloud noise is removed through the setting of the brightness threshold Delta. The low-layer detail coefficient is processed with wavelet packet decomposition to remove the residual cloud noise. Finally, the detail coefficient and the approximate coefficient are reconstructed to obtain the processedimage; wherein, n and l are both integers; n is more than l which is more than 1. the optical image cloud removal method can effectively retain the background information and the scenery information out of the cloud area, weaken or eliminate the influence caused by the cloud covering, highlight the scenery information and obtain the high quality processing effects. Because the optical image cloudremoval method provides quantitative indexes for determining the optimum demarcation layer number l, the brightness threshold Delta, and the detail coefficient weight w; the optical image cloud removal method has good operability.

Owner:CHANGZHOU INST OF TECH

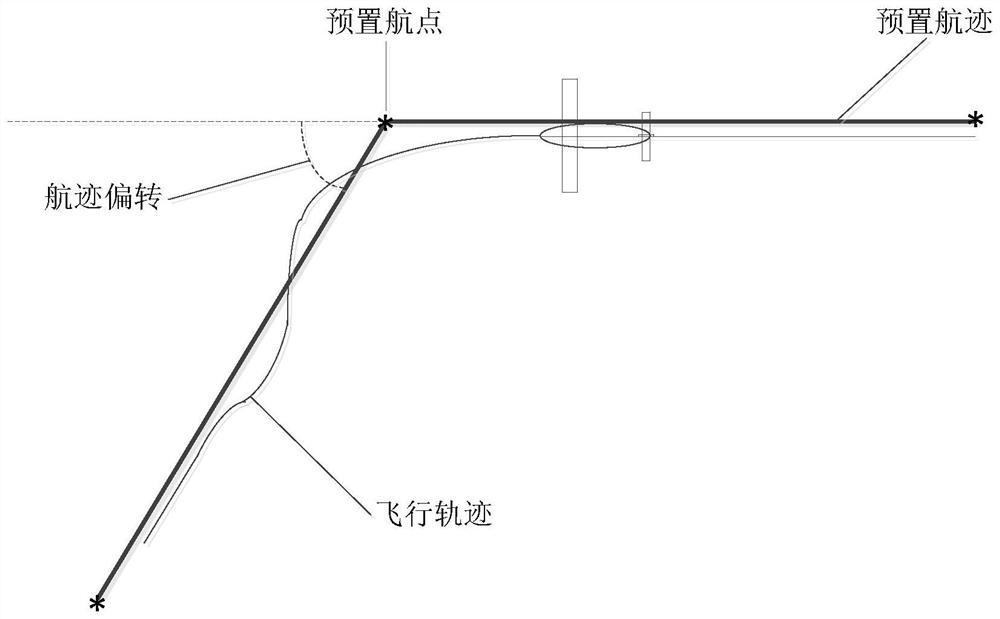

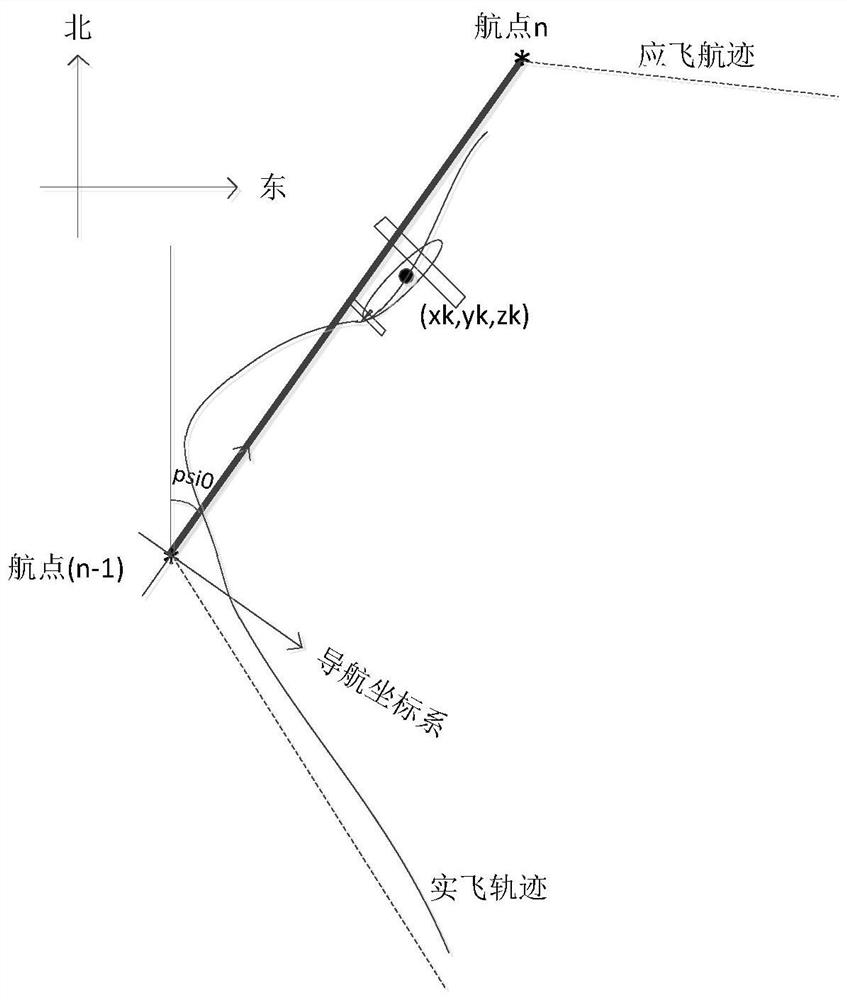

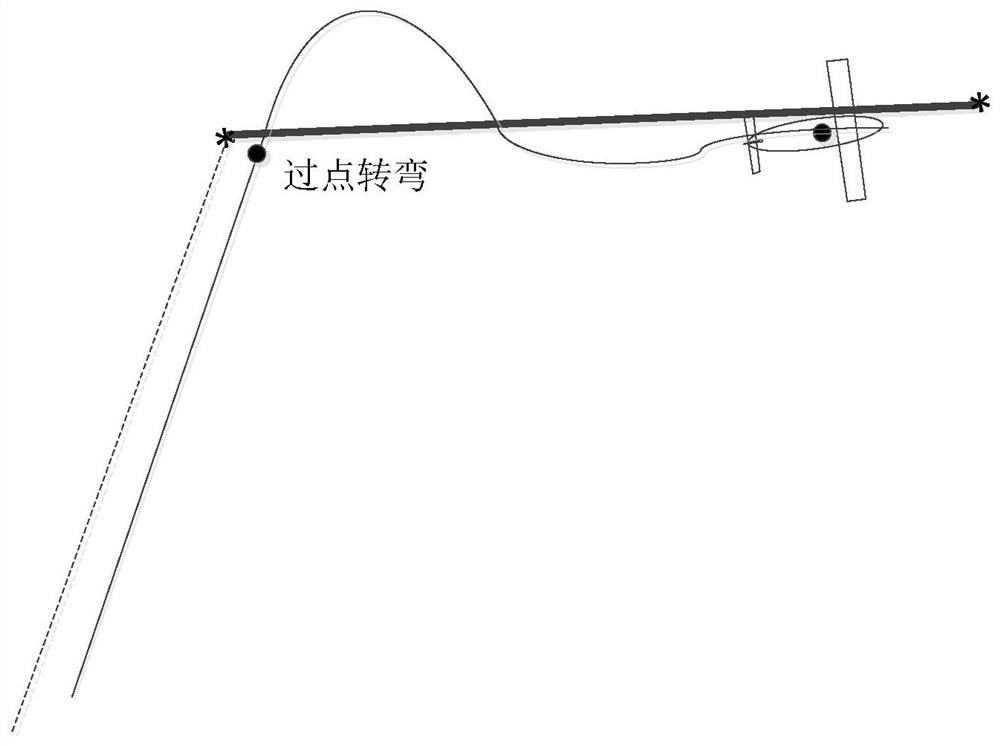

Fixed-wing unmanned aerial vehicle route re-planning method

PendingCN113515138AEliminate sudden changes in route directionEliminate mutationPosition/course control in three dimensionsAutomotive engineeringAirplane

The invention relates to a fixed-wing unmanned aerial vehicle route re-planning method. The method comprises the steps of preprocessing a route consisting of broken line segments into a route consisting of straight line segments and arc segments, eliminating sudden change of the direction of the route, and continuously changing the direction of the route, so that a course instruction is continuous and step-free when an aircraft flies along the route, the turning radius is the minimum turning radius of the aircraft, and the turning performance of the aircraft is fully exerted. According to the method, the turning performance of the aircraft is fully exerted, and an accurate and feasible flight route is provided in occasions where the flight path needs to be accurately controlled, such as reconnaissance tasks, formation flight and the like.

Owner:XIAN AISHENG TECH GRP +1

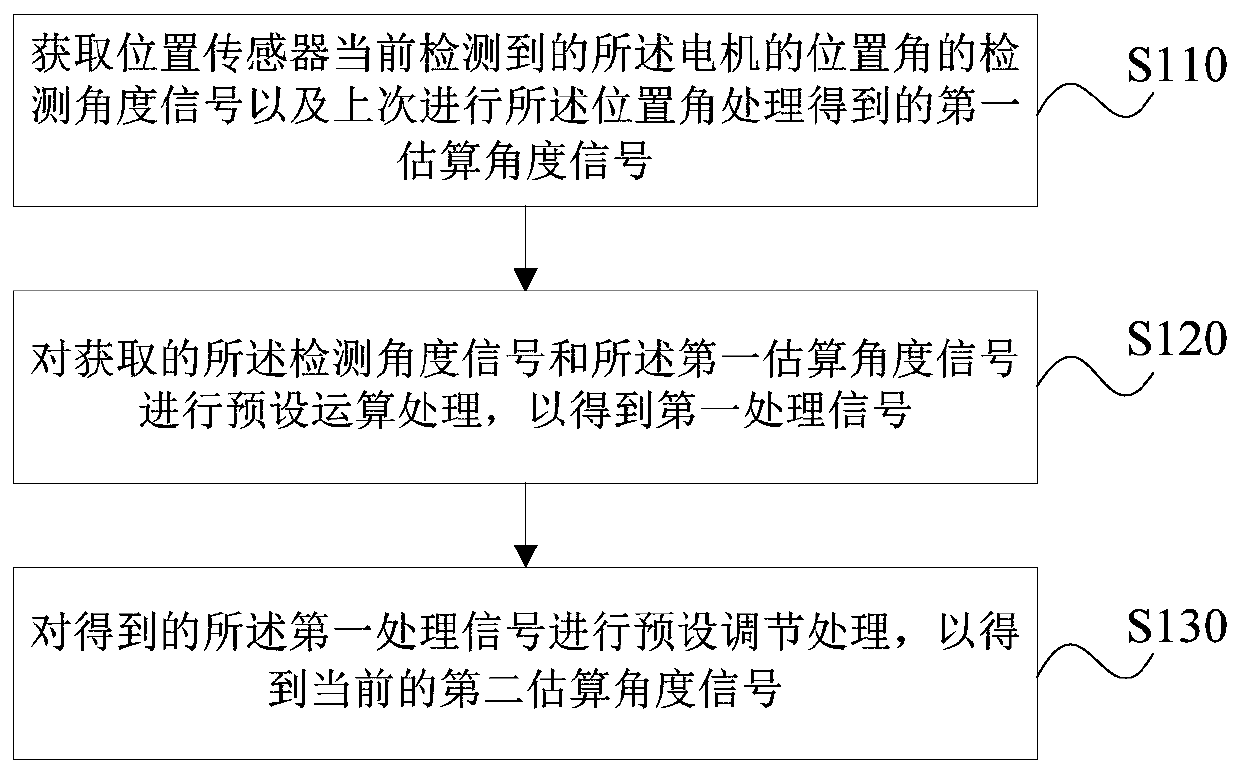

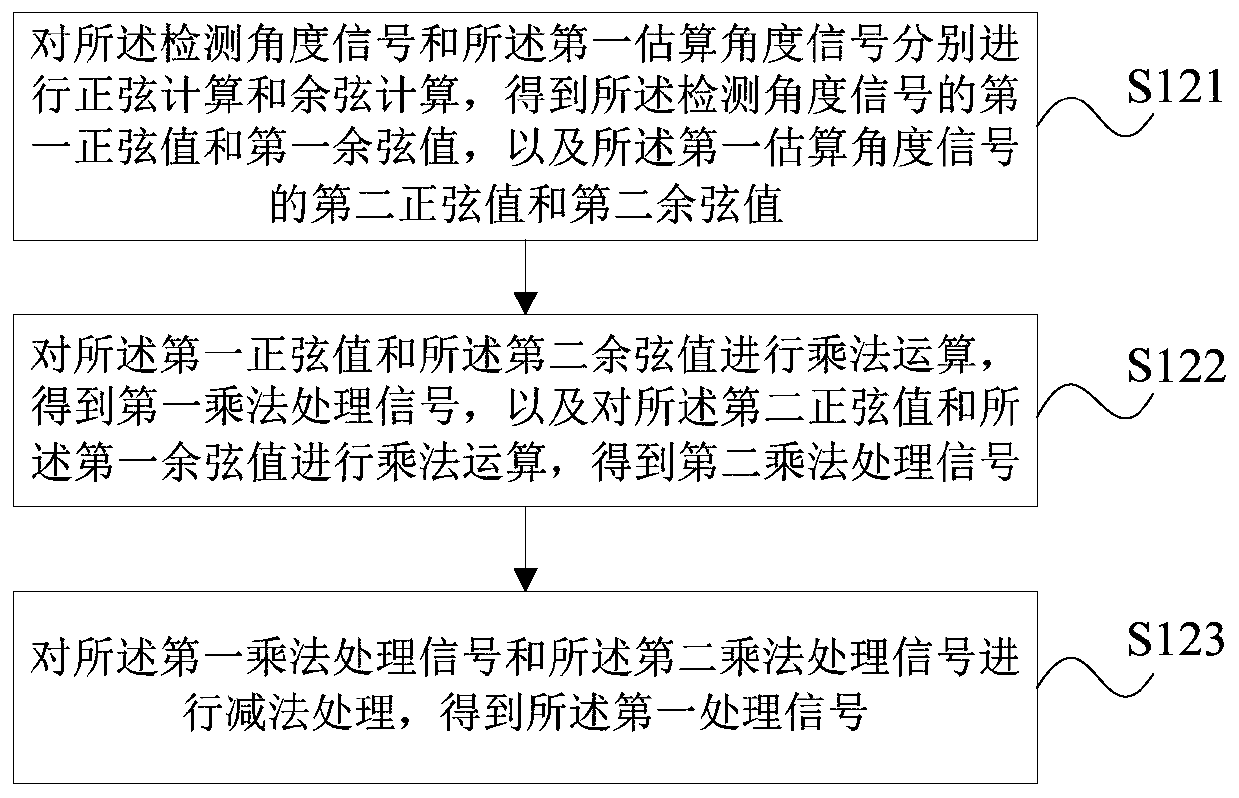

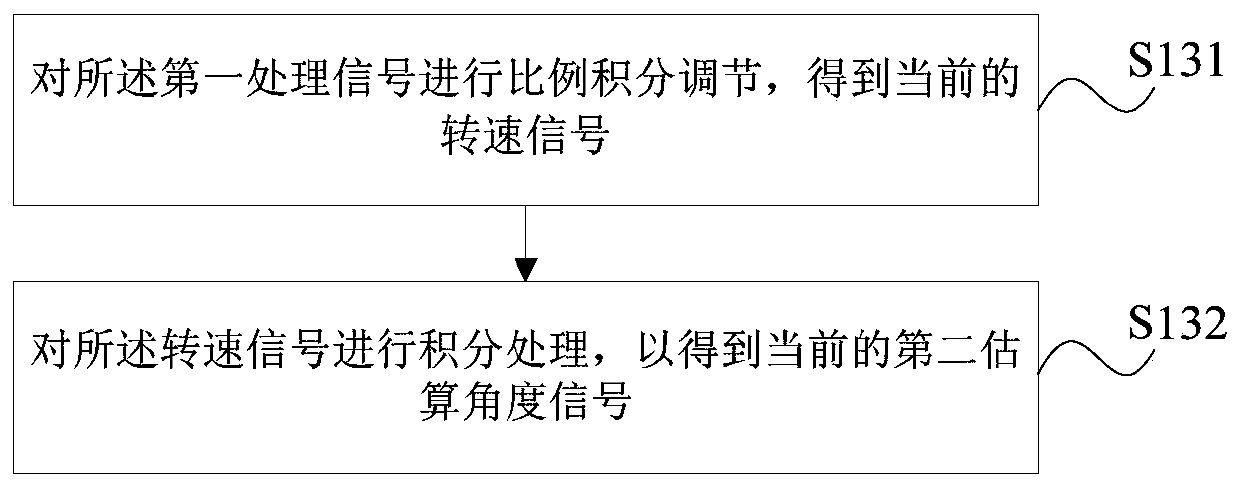

A motor position angle processing method, device and motor driver

ActiveCN108900130BEliminate mutationReduce mechanical shockElectronic commutation motor controlVector control systemsElectric machineryPosition sensor

The invention provides a motor position angle processing method and device and a motor driver. The method comprises the steps of a signal obtaining step used for obtaining a detection angle signal ofa motor position angle which is detected by a position sensor currently and a first estimation angle signal which is obtained by conducting position angle processing last time, a calculation processing step used for conducting preset calculation processing on the obtained detection angle signal and first estimation angle signal to obtain a first processed signal and an angle estimation step used for conducting preset adjustment processing on the obtained first processed signal to obtained a current second estimation angle signal. By means of the technical scheme, abrupt change of the motor position angle can be eliminated, and thus abrupt change of torque is inhibited so that jitters can be eliminated.

Owner:GREE ELECTRIC APPLIANCES INC

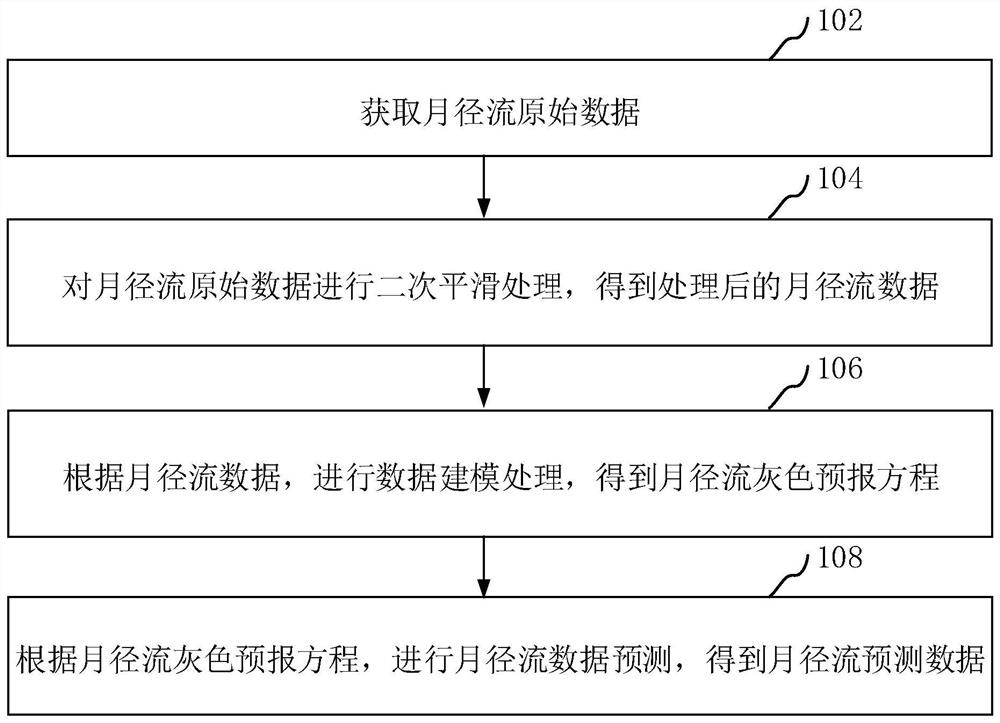

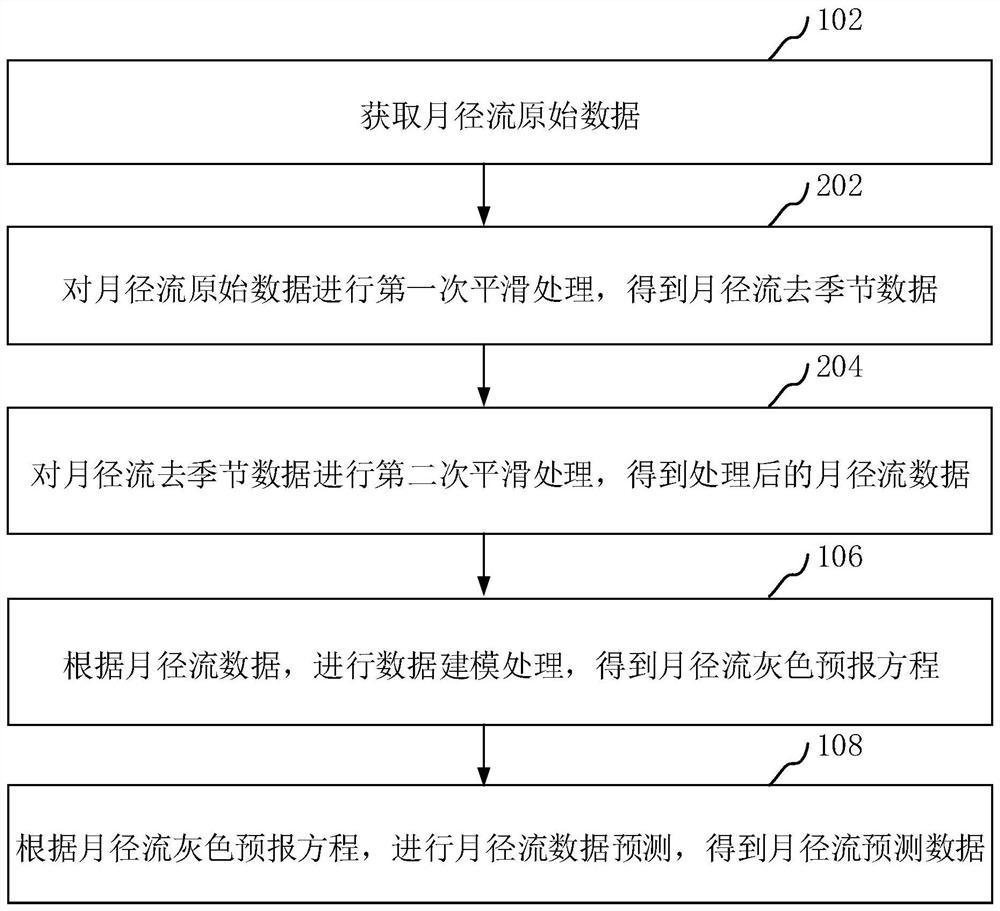

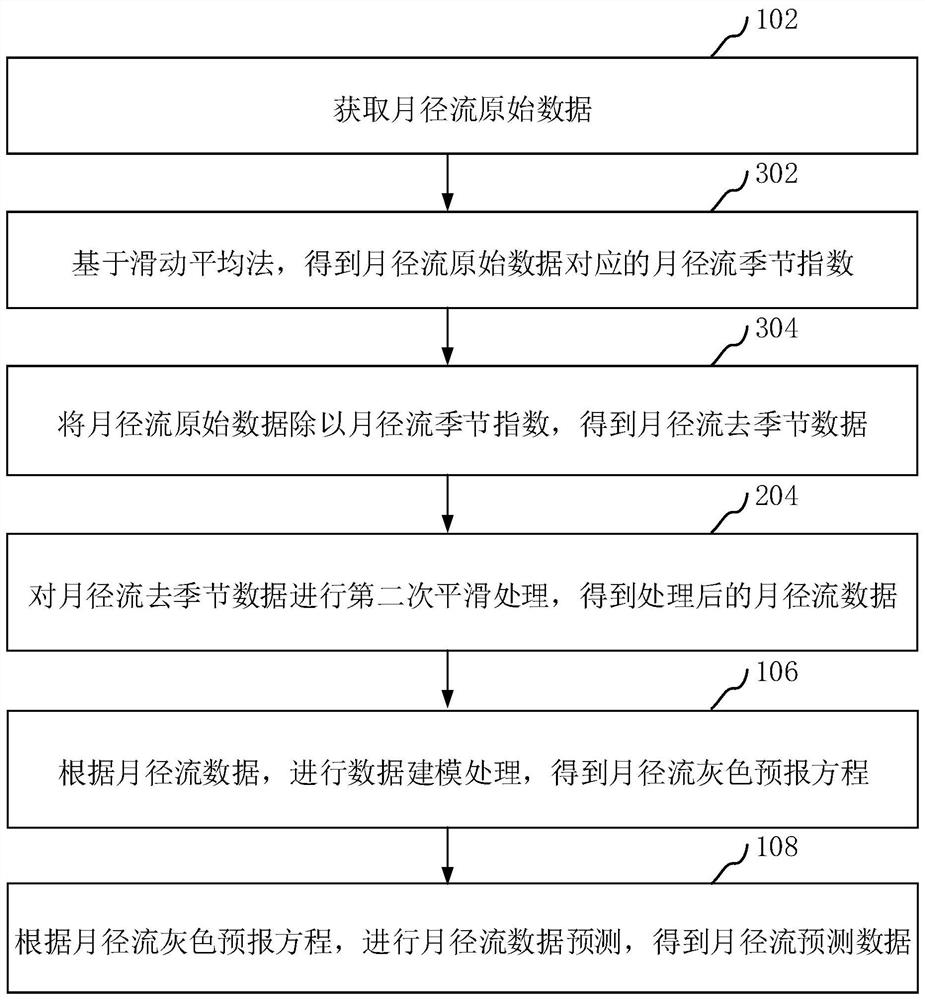

Monthly runoff grey prediction method and device, computer equipment and storage medium

PendingCN112529274AEliminate mutationEliminate unsmooth dataForecastingDesign optimisation/simulationData predictionStreaming data

The invention relates to a monthly runoff grey prediction method and device, computer equipment and a storage medium. The method comprises the steps of obtaining monthly runoff original data; carryingout secondary smoothing processing on the monthly runoff original data to obtain processed monthly runoff data; performing data modeling processing according to the monthly runoff data to obtain a monthly runoff grey forecasting equation; and performing monthly runoff data prediction according to the monthly runoff grey prediction equation to obtain monthly runoff prediction data. Modeling processing is carried out on monthly runoff data after secondary smoothing processing, a more accurate monthly runoff grey prediction equation can be established, monthly runoff prediction data with small errors are obtained, and the prediction precision of the simulated monthly runoff prediction data is guaranteed.

Owner:HNAC TECH

A method for eliminating sudden changes in transmitter power supply voltage or current when transmitting high-power signals

ActiveCN103728610BGuaranteed Emission EfficiencySecure your hardwareWave based measurement systemsSonarEngineering

The invention discloses a method for solving voltage or current mutation of a transmitter power supply during high power signal transmission and belongs to the technical field of sonar detection. A plurality of discrete points are inserted into the connection position of two sections of signals with discrete phases to enable the phases of the head signal and the tail signal of the two sections of signals to be connected. The method includes the following steps: calculating the number N of the inserted discrete points, calculating the sum theta0 of the phases of the inserted discrete points, calculating the stepping phase theta of the discrete points and conducting signal transmission. The method has the advantage that the method finishes real-time calculation for smooth connection of the head phase and the tail phase of pulse signals in different transmitting directions, enables the discrete signal phases to be connected smoothly, ensures transmission efficiency of the transmitter, and ensures hardware safety of the transmitter. The method is simple in calculation and good in adaptability. High power transmitting tests prove that the method can effectively remove voltage or current mutation of the transmitter power supply and has high practical value.

Owner:中国船舶重工集团公司第七〇五研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com