Method for controlling output power of rotor side of double-fed draught fan

A doubly-fed fan and output power technology, applied in the generator control circuit, control system, control generator and other directions, can solve problems such as difficult to achieve, and achieve the effect of ensuring stable output, fast power, and eliminating sudden changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

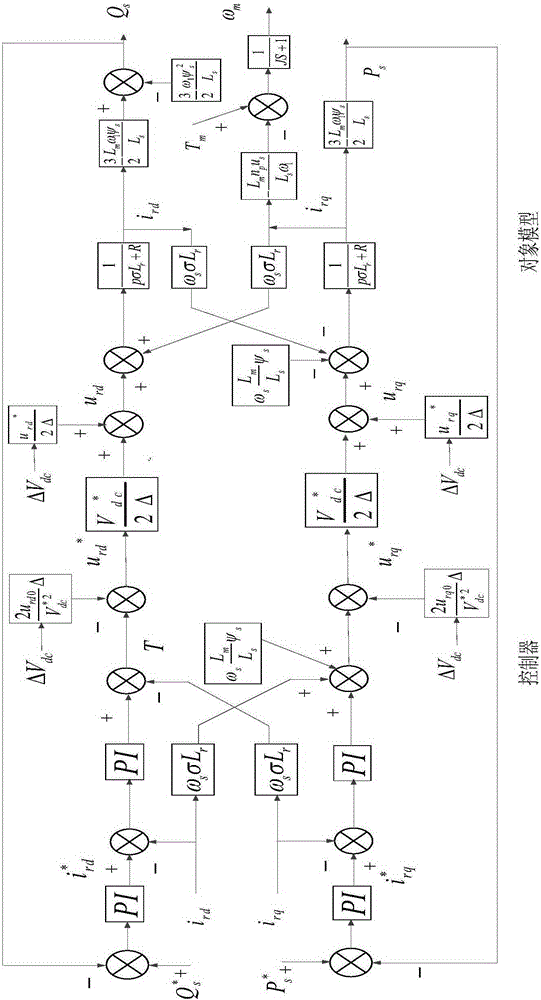

[0020] as attached figure 1 as shown, figure 1 An overall diagram of the object and the improved rotor-side controller model for a DFIG.

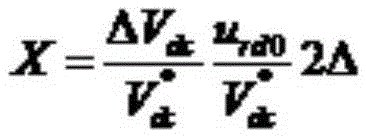

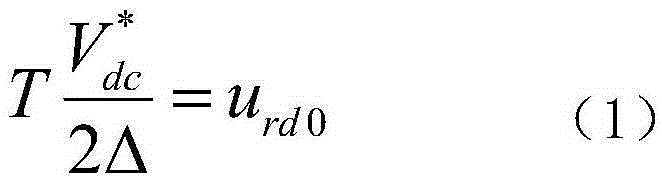

[0021] In the object model, the input is the d and q axis components of the rotor voltage, and the output is the active and reactive components output by the fan; in the control model, the input is the active and reactive components output by the object model, and the output is Control system rotor voltage control reference. The relationship between the rotor voltage control reference value and the actual input of the rotor voltage of the object model

[0022] The specific control is as follows: 1. The outer loop adopts active and reactive power decoupling control, and the inner loop adopts direct current control. 2. In the outer loop control, the actual value of active and reactive power output in the object model is compared with the reference value, and the difference is controlled by PI to obtain the d and q components of the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com