Method and device for manufacturing low-loss micro-nanometer fiber bragg grating sensor in chemical corrosion method

A grating sensor, chemical corrosion technology, which is applied in the direction of using optical devices to transmit sensing components, phase influence characteristic measurement, etc. Micro-nano fiber grating and other problems, to achieve the effect of being suitable for mass production, eliminating the sudden change of the corrosion interface, and having a simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

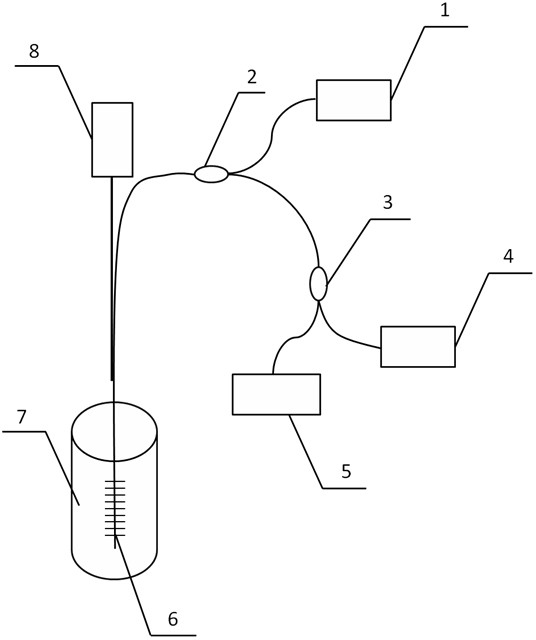

[0029] like figure 1 As shown, the device includes a broadband light source 1, a spectrometer 4, an optical power meter 5, a stepping motor 8 and an optical fiber 6 written with Bragg gratings, wherein the light emitted by the broadband light source 1 is transmitted through a fiber circulator 2 to The fiber 6 with Bragg grating written on it, the reflected signal of the fiber 6 with Bragg grating written on it is transmitted to the 3-dB fiber coupler 3 through the fiber circulator 2, and the optical signal transmitted to the 3-dB fiber coupler 3 is respectively transmitted to the spectrometer 4 And the optical power meter 5, the end of the optical fiber 6 with Bragg gratings is placed vertically in the PTFE container 7, the upper end of the optical fiber 6 with Bragg gratings is vertically fixed on the stepping motor 8, the Bragg gratings The optical fiber 6 is an ordinary single-mode optical fiber treated with hydrogen, with a grating length of 1 cm, and is located at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com