Selective laser melting device and preparation method for gradient material

A selective laser melting and powder technology, applied in the field of 3D printing, which can solve the problems such as the inability to achieve a smooth transition of composition and organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

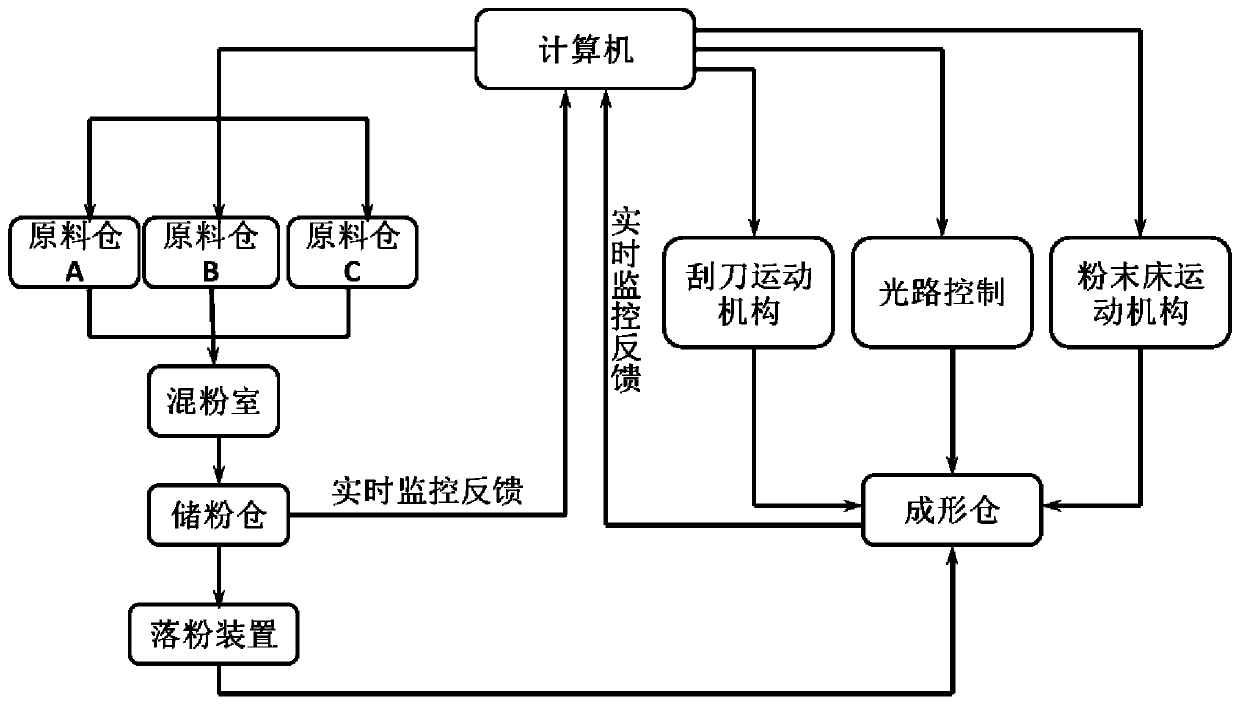

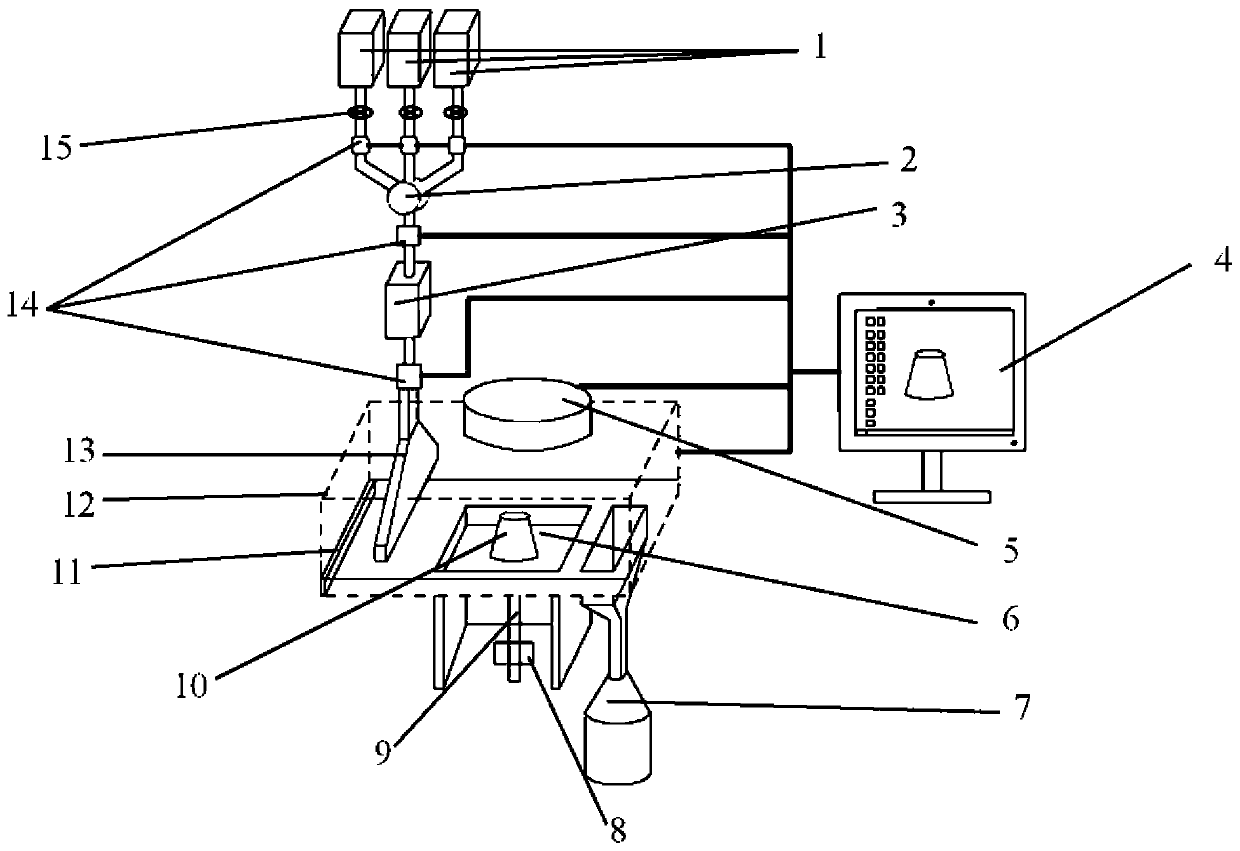

[0059] This embodiment is a selective laser melting device, including a raw material bin 1, a powder mixing chamber 2, a powder storage bin 3, a powder dropper 13, a forming chamber 12, a powder recovery bin 7, a servo motor 8, a piston 9 and a computer 4, wherein , the number of raw material bins 1 is 2 to 5 according to actual printing requirements, and they are named in sequence from the first raw material bin to the Pth raw material bin, where P is the number of raw material bins, and P≤5. The number of the raw material bins is the same as the number of powder types required for actually printing the target sample.

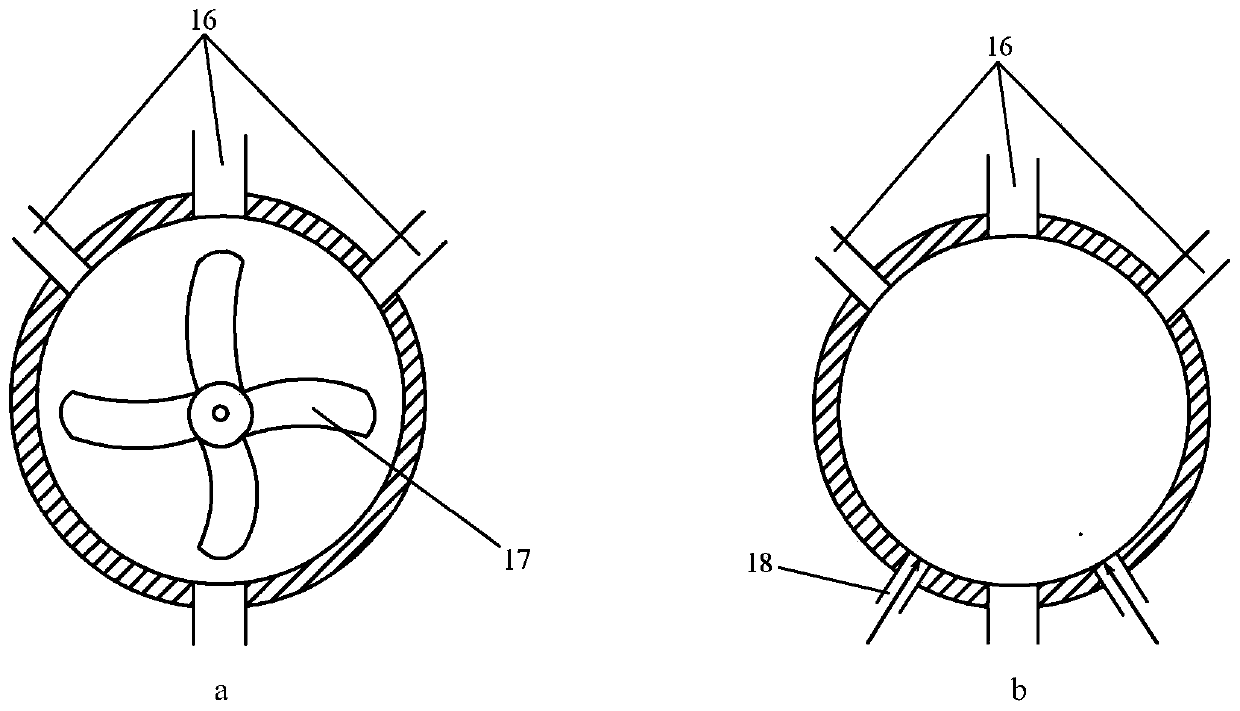

[0060] The outlets of each of the raw material bins communicate with the inlet of the powder mixing chamber 2 through powder delivery pipes, and a flow monitor 15 and a control valve 14 are installed between the outlets of each raw material bin and the inlet of the powder mixing chamber 2 . The outlet of the powder mixing chamber communicates with the powder s...

Embodiment 2

[0069] This embodiment is a method for preparing composite gradient parts using the selective laser melting device. Said part is made of TC4-TA15.

[0070] The concrete process of this embodiment is:

[0071] Step 1, material pretreatment.

[0072] The material pretreatment is the drying of powder.

[0073] TC4 powder and TA15 powder were selected as raw materials, and the two powders were dried under vacuum conditions at 120°C to reduce the moisture in the powder and improve the fluidity of the powder.

[0074] The particle diameters of the TC4 powder and the TA15 powder are both 15-53 μm. Each of the powders is respectively placed in two raw material bins of the selective laser melting device.

[0075] In this embodiment, the forming width of the powder bed 5 is a×d=300mm×250mm, where a and d are the side lengths of the powder bed.

[0076] Step 2, establish the 3D model of the formed part.

[0077] The formed part 10 is a cuboid. A three-dimensional model of the part i...

Embodiment 3

[0120] This embodiment is a method for preparing composite gradient parts using the selective laser melting device. Said part adopts TC4-TA15-Ti 2 Made of AlNb.

[0121] The concrete process of this embodiment is:

[0122] Step 1, material pretreatment.

[0123] The material pretreatment is the drying of powder.

[0124] Choose TC4 powder, TA15 powder and Ti 2 AlNb powder was used as the raw material, and the three powders were dried under vacuum at 120°C to reduce the moisture in the powder and improve the fluidity of the powder.

[0125] The TC4 powder, TA15 powder and Ti 2 The particle size of the AlNb powder is 15-53 μm. Each of the powder materials is respectively placed in three raw material bins of the selective laser melting device.

[0126] In this embodiment, the forming width of the powder bed 5 is a×d=250mm×250mm, and a and d are both side lengths of the powder bed.

[0127] Step 2, establish the 3D model of the formed part.

[0128] The formed part 10 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com