Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Easy to fill gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

Early-strength shield wall post-grouting formula

The invention belongs to the field of underground construction, and particularly discloses an early-strength shield wall post-grouting formula. The early-strength shield wall post-grouting formula comprises the following substances in parts by weight: 800 to 1000 parts of fine sand, 35 to 50 parts of bentonite, 110 to 220 parts of coal ash, 400 to 600 parts of Portland cement, 70 to 100 parts of gypsum, 5 to 8 parts of an early strength agent and 400 to 600 parts of water. The early-strength shield wall post-grouting formula has relatively high condensation rate, and also has the characteristic of high early strength; and moreover, the long-term strength and shear resistance of the grouting are further effectively guaranteed, ground deformation and duct piece floating are controlled, and the damage of duct pieces is reduced.

Owner:HOHAI UNIV

High temperature-resistant and anticorrosive oil hydraulic cylinder sealing strip and making method thereof

InactiveCN106939139AImprove dispersibility and compatibilityGood corrosion resistance and high temperature resistanceFireproof paintsWax coatingsAmmonium sulfateAmmonium bicarbonate

The invention discloses a high temperature-resistant and anticorrosive oil hydraulic cylinder sealing strip. The high temperature-resistant and anticorrosive oil hydraulic cylinder sealing strip comprises 9-13 parts of black silicon carbide, 10-16 parts of fine-grained alumina, 18-22 parts of antimony trioxide, 10-16 parts of barium sulfate, 15-20 parts of ammonium bicarbonate, 13-18 parts of ammonium thiosulfate, 11-14 parts of ammonium sulfonate, 9-14 parts of ammonium sulfate nitrate, 28-30 parts of polyurethane, 2-9 parts of diethylenetriamine, 12-17 parts of caprolactam, 16-19 parts of triethylenediamine, 1-7 parts of o-ethylaniline, 8-13 parts of N-butylaniline, 10-15 parts of sodium carbonate, 19-24 parts of calcium carbonate, 17-24 parts of potassium carbonate, 11-15 parts of ammonium nitrate, 22-28 parts of calcium nitrate, 14-17 parts of nanometer silica sol, 10-14 parts of sodium citrate, 19-22 parts of polyacrylamide, 24-28 parts of nanometer borate, 7-14 parts of potassium dihydrogen phosphate, 7-13 parts of zinc dialkyl dithiophosphate, 6-10 parts of zinc naphthenate, 40-48 parts of a solvent, 3-10 parts of a dispersant and 7-14 parts of a film forming assistant.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Manufacturing method for multilayer thick copper circuit board and manufacturing method for two-sided thick copper circuit board

ActiveCN103813658AEasy to updateHigh densityHigh current circuit adaptationsMultilayer circuit manufactureEtchingCopper

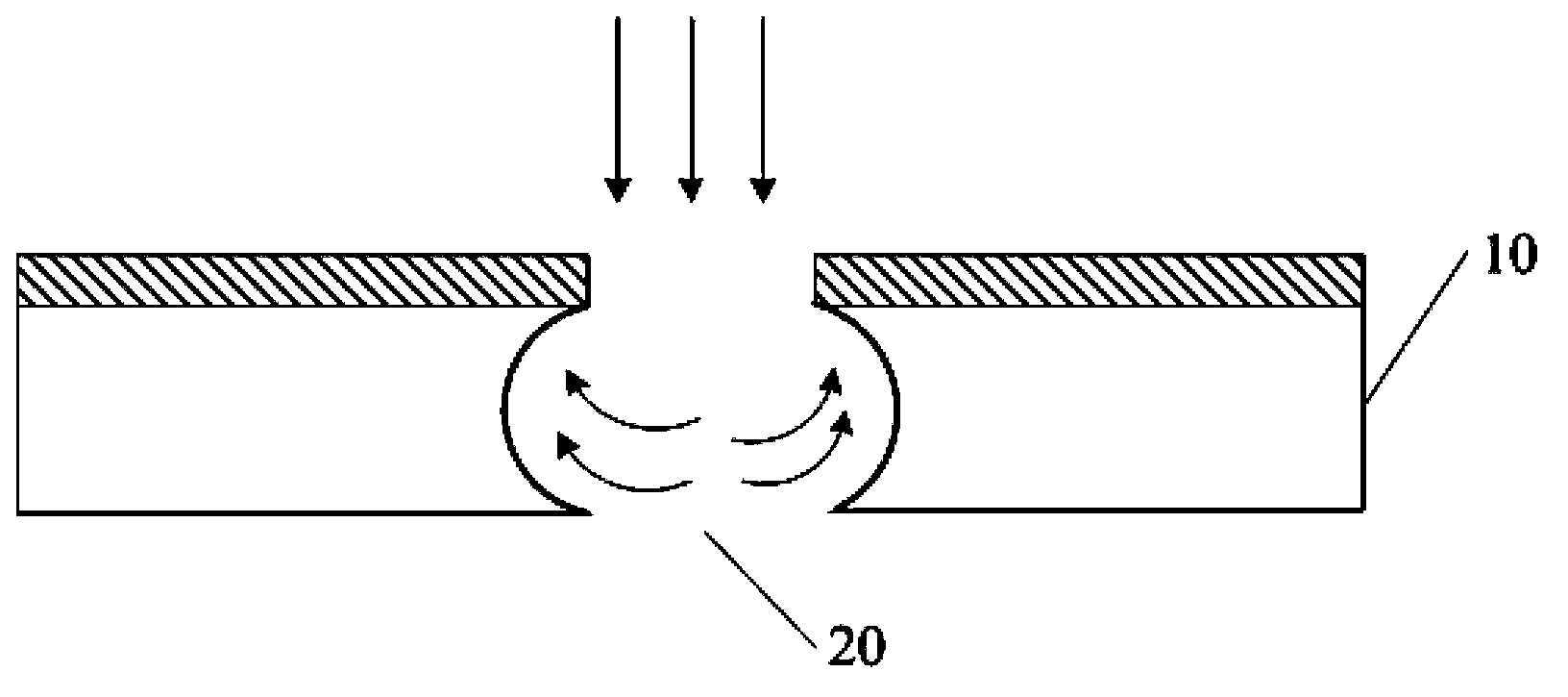

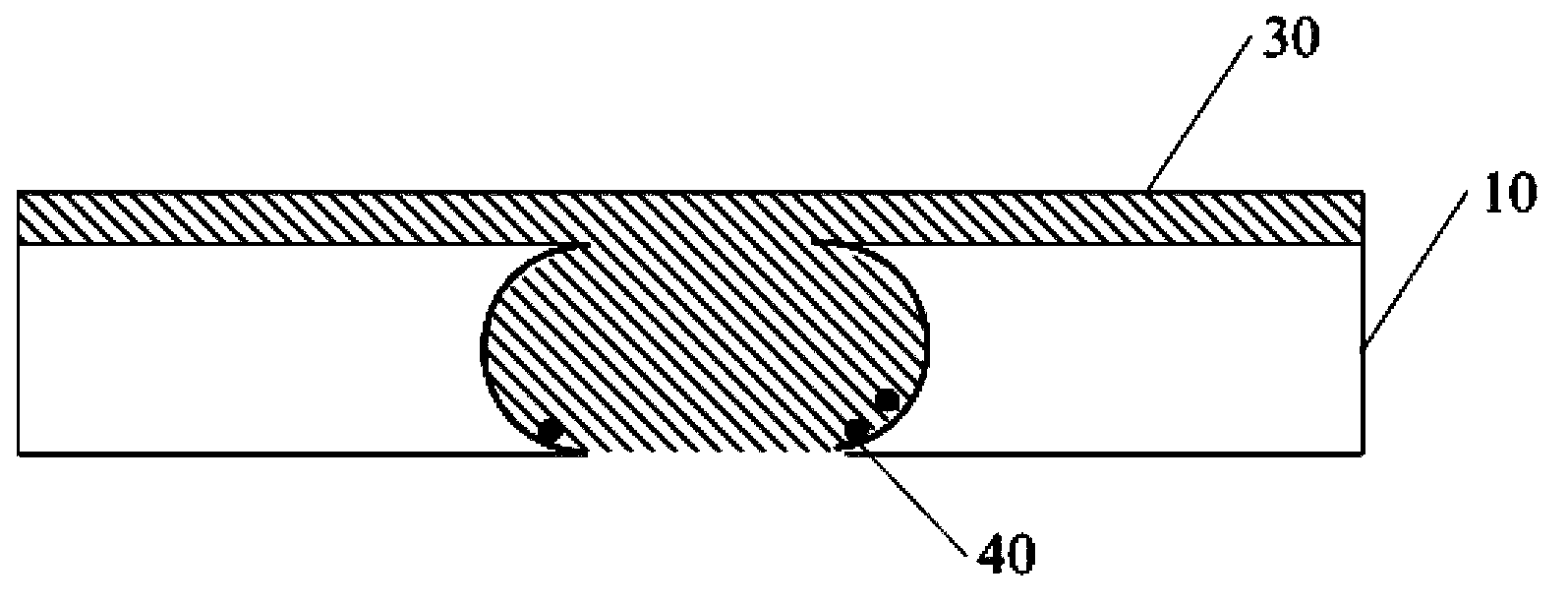

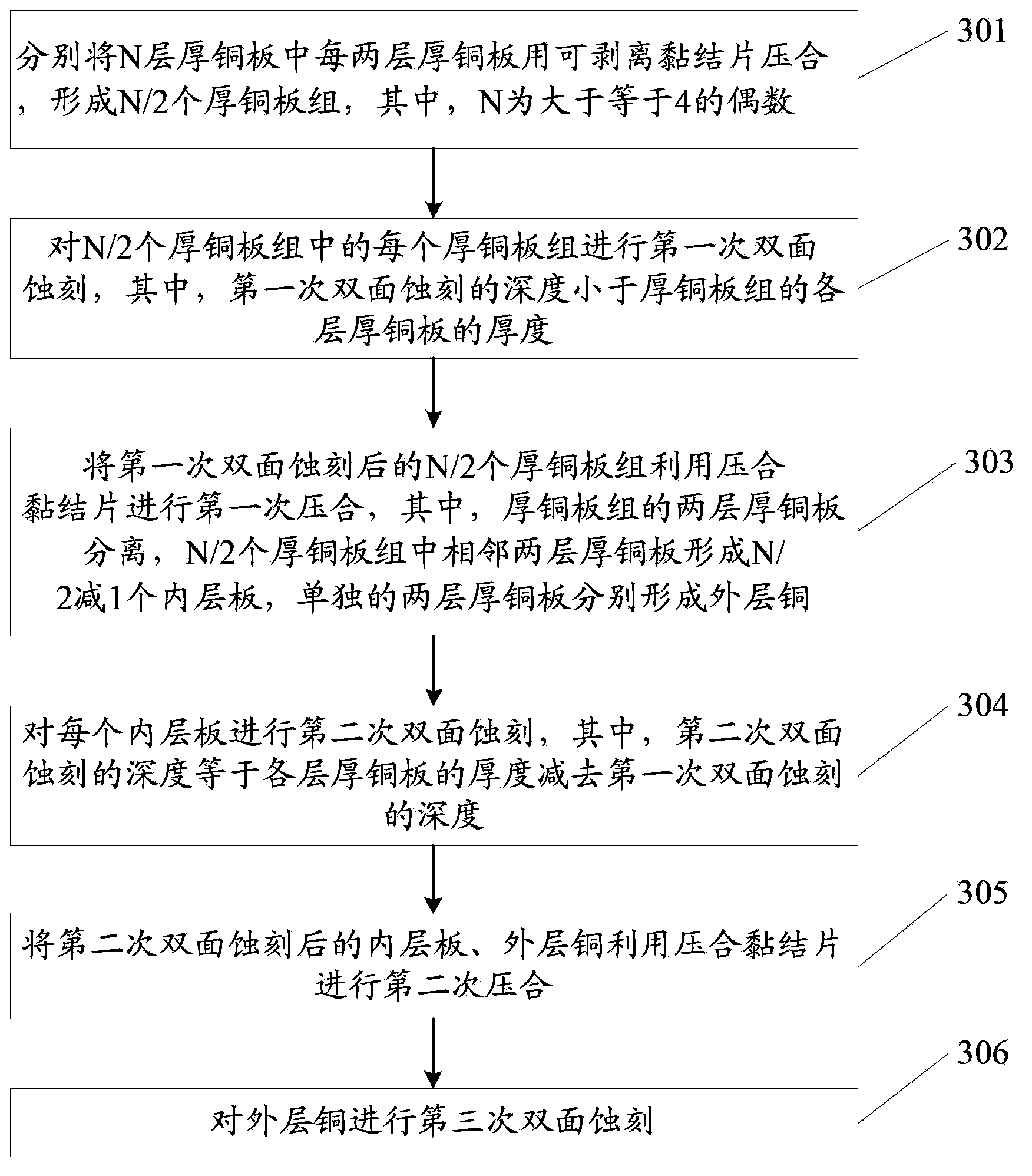

The invention discloses a manufacturing method for a multilayer thick copper circuit board and a manufacturing method for a two-sided thick copper circuit board. The manufacturing method for the multilayer thick copper circuit board comprises the steps of enabling every two of N layers of thick copper plates to undergo press fit through strippable adhesion pieces to form N / 2 thick copper plate groups; performing primary two-sided etching on every thick copper plate group, and enabling the primary two-sided etching depth to be smaller than the thickness of every layer of thick copper plate of the thick copper plate groups; utilizing press fit adhesion pieces to perform primary press fit on the thick copper plate groups after the primary two-sided etching, separating every two layers of thick copper plates of the thick copper plate groups, enabling every two adjacent layers of thick copper plates in the thick copper plate groups to form (N / 2-1) inner layer plates, and enabling two independent layers of thick copper plates to respectively form outer layer copper; performing secondary two-sided etching on every inner layer plate, and enabling the secondary two-sided etching depth to be equal to the difference between the thickness of every layer of thick copper plate and the primary two-sided etching depth; utilizing press fit adhesion pieces to perform secondary press fit on the inner layer plates and the outer layer copper after the secondary two-sided etching; and performing two-sided etching on the outer layer copper for a third time.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +2

Household socket and flame-retardant treatment process thereof

InactiveCN107868577AHigh affinityPrevent flocculationFireproof paintsContact member cases/bases manufactureEpoxyEmulsion

The invention discloses a household socket. The household socket comprises a socket box, wherein an insertion surface butted with a plug is arranged on the socket box; a cover body is also arranged onthe socket box; a protection layer is arranged on the inner wall of the cover body. The protection layer is prepared from the following components in parts by mass: 20-30 parts of organosilicone modified epoxy resin, 10-15 parts of a polyvinyl acetate emulsion, 0-15 parts of a plasticizer, 2-4 parts of a flame retardant, 5-8 parts of diatomite, 1-3 parts of pigments and fillers, 5-7 parts of a silane coupling agent, 4-6 parts of a curing agent, 0.5-1 part of a flame-retardant synergist, 0.1-0.5 part of an antioxidant and 0.2-0.4 part of composite rare earth. The flame-retardant treatment process is simple and is easy to operate; the treated socket has extremely high flame resistance; the service life of the socket is prolonged; and the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

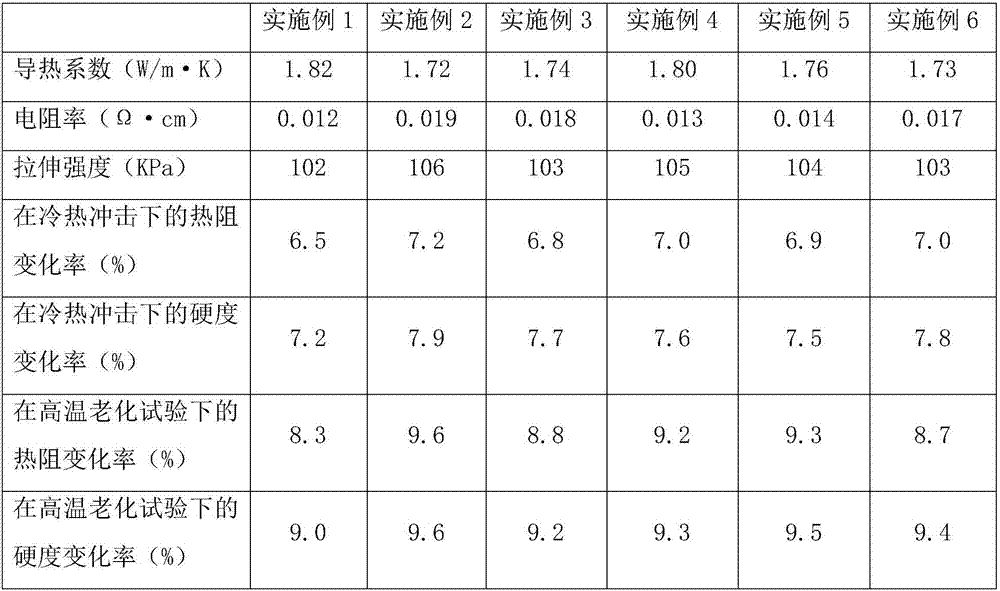

High heat conductivity and electric conductivity organic silicon adhesive and preparation method thereof

InactiveCN107216850AGood thermal conductivityImprove hydrophilicityNon-macromolecular adhesive additivesElectrically-conducting adhesivesLow speedAdhesive

The invention provides a high heat conductivity and electric conductivity organic silicon adhesive and a preparation method thereof. The high heat conductivity and electric conductivity organic silicon adhesive comprises a flaky and spherical nano silver material, cylindrical alpha-aluminum oxide and boron nitride that graphene is adhered to the surface. The preparation method specifically comprises the following steps: performing mechanical stirring on boron nitride in a mixed solution of hydrogen peroxide and concentrated sulfuric acid, taking out, sufficiently washing, and drying so as to obtain hydroxylated boron nitride; putting the hydroxylated boron nitride into a graphene oxide solution, uniformly stirring, dropping glucose, and heating while stirring so as to obtain boron oxide that graphene is adhered to the surface; diluting a coupling agent into an ethanol solution, putting into a reaction kettle of a high-speed stirring machine, stirring, putting the boron oxide that graphene is adhered to the surface, aluminum oxide and silver paste, stirring at a high speed, stirring at a low speed in vacuum, and removing ethanol so as to obtain composite heat conduction packing; and putting silica gel into the composite heat conduction packing, stirring at low temperature, putting a crosslinking agent and a catalyst, and continuously stirring at low temperature, thereby obtaining the high heat conductivity and electric conductivity organic silicon adhesive.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

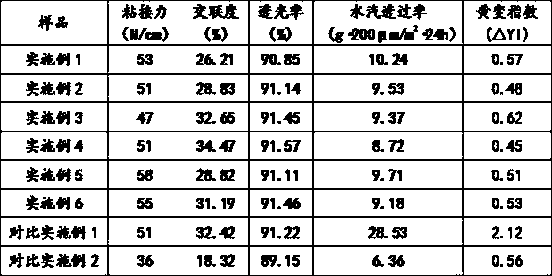

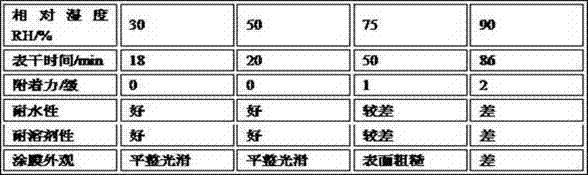

EMMA optical film for full fitting of electronic screen and preparation method thereof

InactiveCN108165181AImprove processing phenomenonSolve process defects such as difficulty in laminationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveControl layerWater vapor

The invention discloses an EMMA optical film for full fitting of an electronic screen and a preparation method thereof. The EMMA optical film for full fitting of the electronic screen is prepared by pre-mixing 100 parts by weight of an ethylene-methyl methacrylate copolymer (EMMA), 0.5-2.0 parts by weight of a photoinitiator, 0.3-1.5 parts by weight of a crosslinking agent, 0.3-1.2 parts by weightof a tackifier, 0.1-0.6 part by weight of an optical stabilizer, 0.1-1.1 parts by weight of a plasticizer and 0.2-1.0 part by weight of an antioxidant by a stirrer, putting the mixture into a single-screw tape-casting machine and tape-casting into the optical film according to set process parameters. The prepared EMMA optical film has the advantages of excellent bonding properties, high light transmittance, low water vapor transmittance and high weather resistance, also is in thermal plasticity before curing, easily fills segment gaps, adapts to the complex interface fitting, and can adapt torequirements of fitting of electronic screen protection layers, touch control layers and display layers with different sizes.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

Waterproof layer for PVC (Polyvinyl Chloride) conveyor belt and preparation method of waterproof layer

InactiveCN106752438AImprove waterproof performanceImprove wear resistanceFireproof paintsLignin material coatingsFiberCarbon fibers

The invention discloses a waterproof layer for a PVC (Polyvinyl Chloride) conveyor belt. The waterproof layer is prepared from the following components: 35 to 40 parts of type 5 PVC, 9 to 12 parts of sodium silicate, 9 to 11 parts of dispersant, 16 to 20 parts of graphite powder, 3 to 7 parts of potassium biphthalate, 13 to 16 parts of nano-silica, 13 to 22 parts of benzyl alcohol, 11 to 16 parts of propylene carbonate, 5 to 10 parts of PVC foaming control agent LP-40, 9 to 14 parts of 3-butanediol, 12 to 17 parts of 3-methyl phenol, 8 to 14 parts of plasticizer, 7 to 11 parts of C5 hydrogenated petroleum resin, 6 to 8 parts of antioxidant, 9 to 14 parts of dimethylethanolamine, 33 to 36 parts of wood fiber powder, 25 to 30 parts of carbon fiber powder, 15 to 18 parts of sodium silicate, 20 to 33 parts of fire retardant, 15 to 18 parts of curing agent, 12 to 19 parts of defoamer, 20 to 22 parts of solvent and 25 to 33 parts of auxiliary material. According to the waterproof layer disclosed by the invention, the working efficiency can be improved, the pollution to the environment is reduced, the service life of a product is prolonged, and the practicality of the product is improved.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Anticorrosive high-speed gear case and preparation method thereof

InactiveCN106497187AHigh affinityPrevent flocculationFireproof paintsAnti-corrosive paintsEpoxyFire retardant

The invention discloses an anticorrosive high-speed gear case and a preparation method thereof. The surface of the high-speed gear case is coated with a layer of an anticorrosive coating which is prepared by compounding a component A and a component B according to a ratio of 2: 1. The component A comprises, by mass, 22 to 26 parts of organosilicon-modified epoxy resin, 25 to 28 parts of pigment, 10 to 13 parts of a filling material, 9 to 13 parts of a plasticizer, 4 to 8 parts of a dispersing agent, 20 to 23 parts of itaconic acid, 19 to 25 parts of a film-forming aid, 9 to 14 parts of an antifoaming agent and 11 to 14 parts of active carbon. The component B comprises, by mass, 18 to 24 parts of polyphenyl ether resin powder, 13 to 16 parts of styrene butadiene rubber, 13 to 18 parts of toluene, 6 to 10 parts of a plasticizer, 8 to 11 parts of a leveling agent, 11 to 14 parts of silica, 9 to 15 parts of a coupling agent, 2 to 4 parts of an auxiliary material, 45 to 49 parts of water and 9 to 15 parts of a fire retardant. The anticorrosive high-speed gear case is reduced in a rejection rate and production cost and improves work efficiency.

Owner:南京创贝高速传动机械有限公司

Casting process of corrosion-resistant pipeline valve

InactiveCN107876707AImprove dispersibility and compatibilityImprove flame retardancyFoundry mouldsFurnace typesCorrosion resistantMetallurgy

The invention discloses a casting process of a corrosion-resistant pipeline valve. The valve comprises a valve body and a protecting layer coating the valve body. The casting process of the valve specifically includes the following steps of manufacturing of a casting mold, melting, pouring, grinding, heat treatment and coating of the protecting layer. The casting process is simple and easy to implement, and low in casting cost, the cast valve has good corrosion resistance, and the service life is prolonged.

Owner:郑媛媛

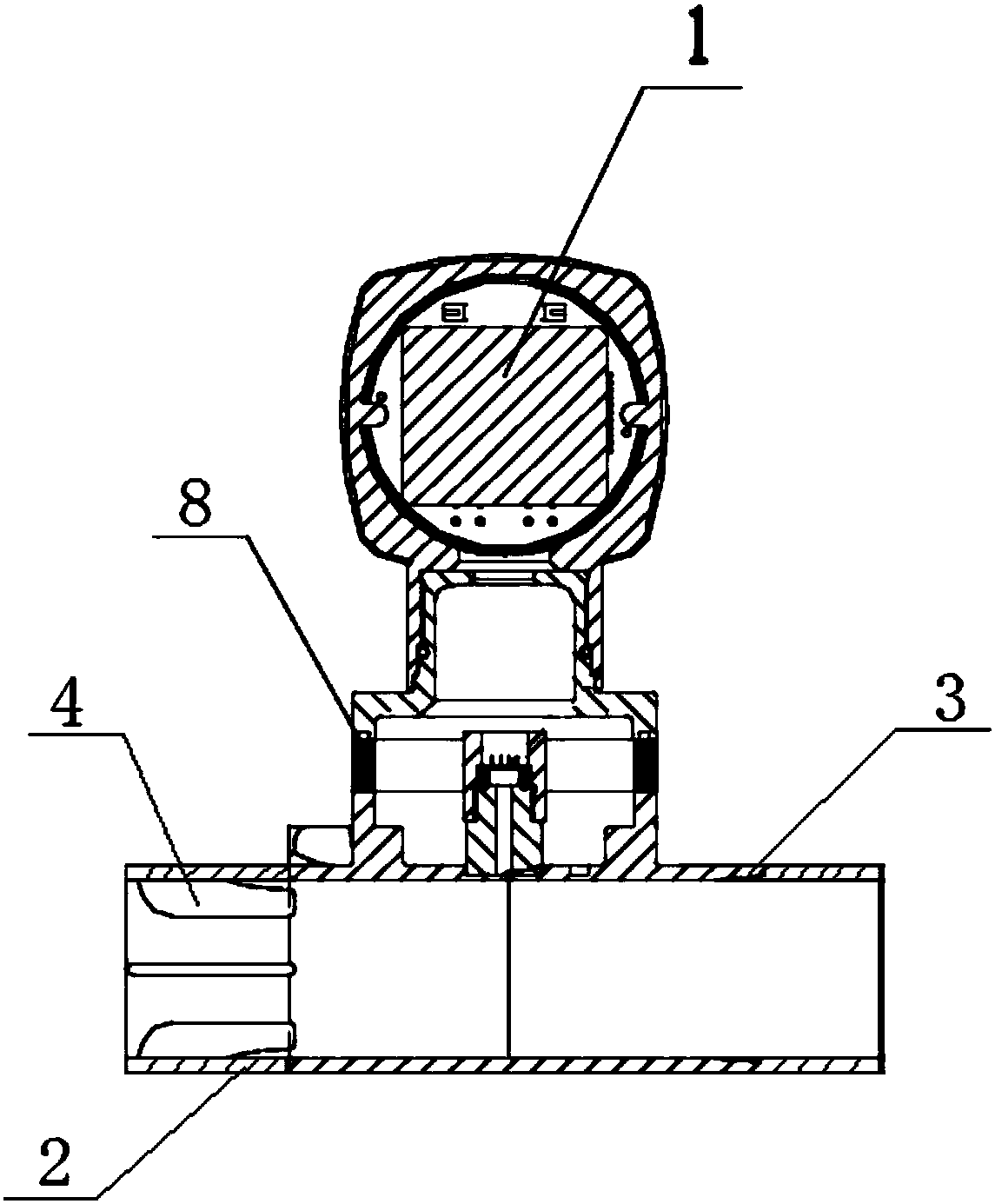

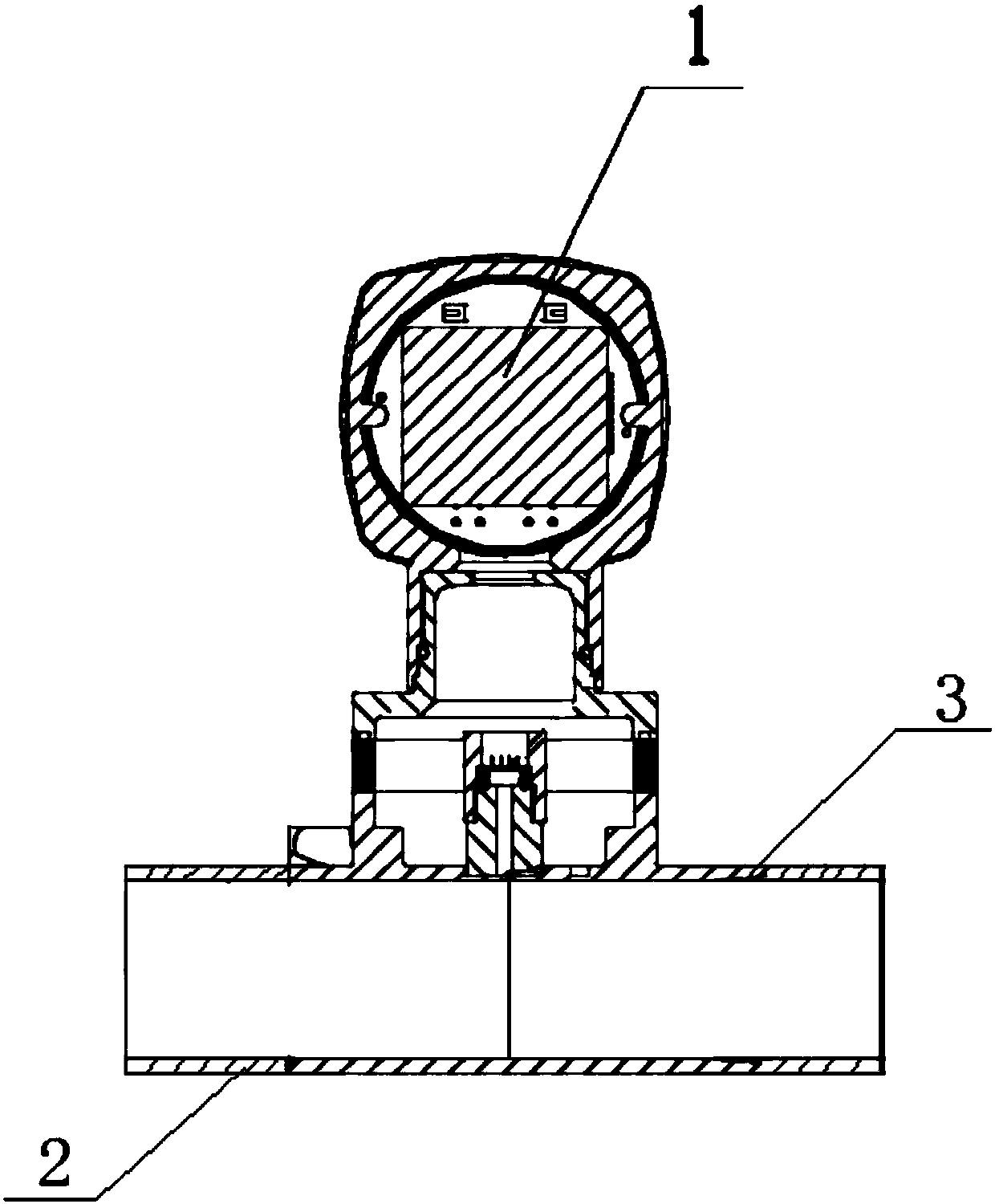

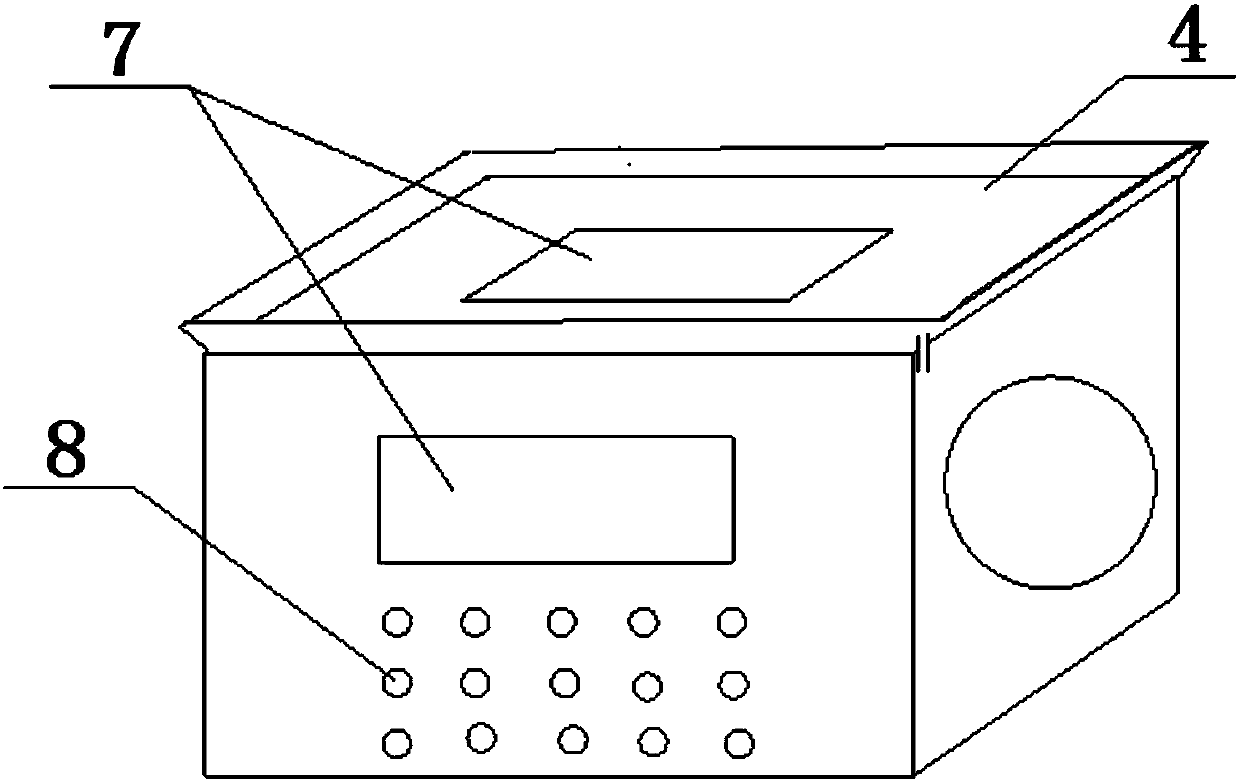

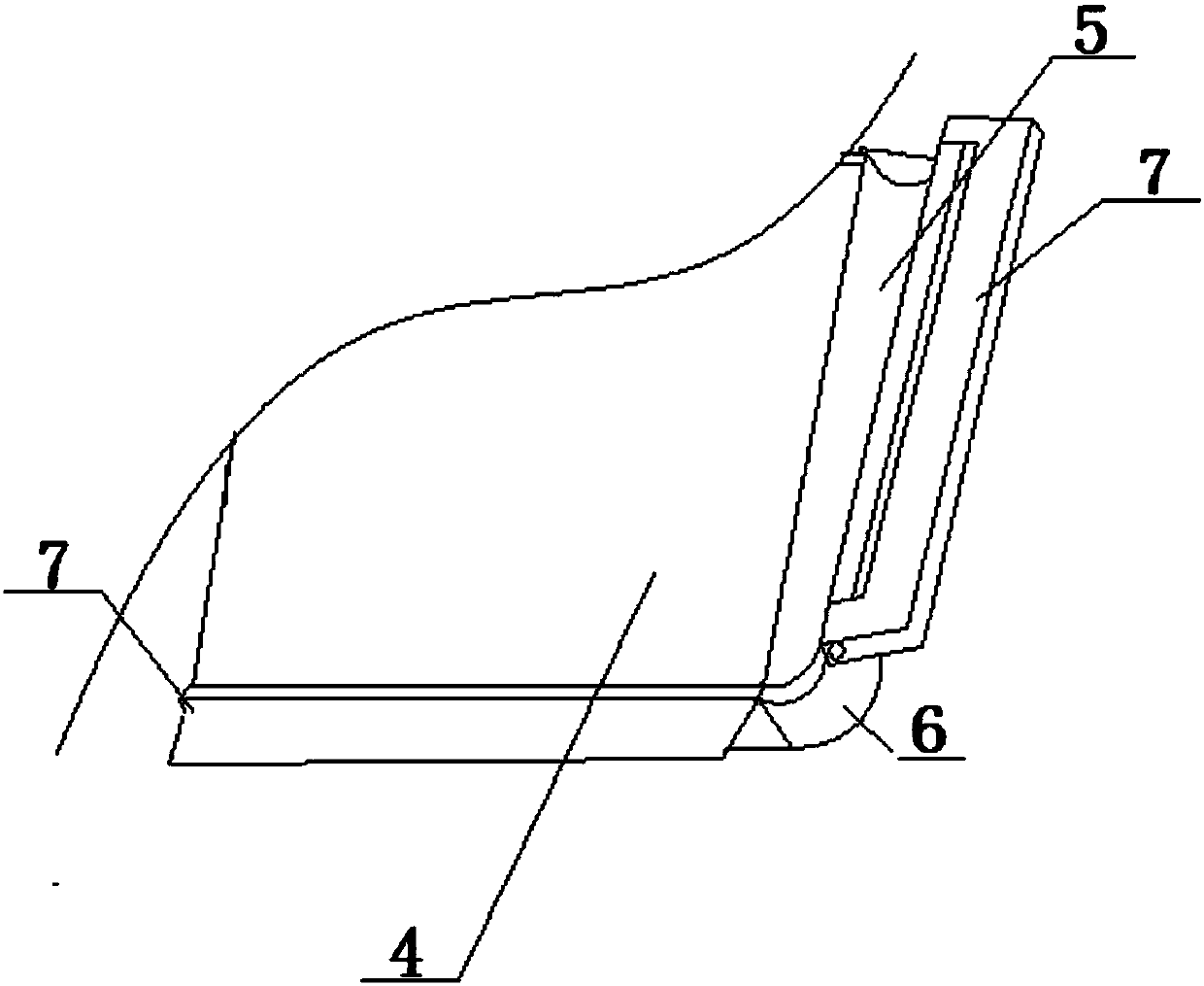

Flow meter with protective hood and mounting method

PendingCN107643109AGreat tasteImprove filtering effectVolume/mass flow measurementPolyurea/polyurethane coatingsTime efficientEngineering

The invention discloses a flow meter with a protective hood, comprising a flow meter head and a flow tube that is of hollow tubular structure. The flow tube is composed of a liquid incoming tube and aliquid outgoing tube, and the flow meter head is positioned in the middle of the flow tube along the length direction; the flow meter also comprises a filter and the protective hood, the filter is releasably arranged at an inlet of the liquid incoming tube, and the protective hood sleeves the flow meter. The invention also designs a mounting method of the flow meter with the protective hood; themounting method is simple and feasible and is time efficient, and the flow meter is simple and compact in structure, convenient to mount and demount, and long in service life.

Owner:镇江佳鑫精工设备有限公司

Compressor for refrigeration system

InactiveCN108034288AHigh strengthReduce internal stressPositive displacement pump componentsPretreated surfacesEngineeringRefrigeration

The invention discloses a compressor for a refrigeration system. The compressor comprises a shell and a cylinder, wherein the cylinder is arranged in a shell; a through hole is formed in the side wallof the shell; a protective layer is arranged on the outer wall of the shell. A refrigeration device disclosed by the invention is simple and compact, and good in wear resistance effect, and a reinforcing process is simple and feasible; the reinforced refrigeration device is higher in wear resistance performance, and the service life of the refrigeration device is prolonged.

Owner:博维恩冷冻科技(苏州)有限公司

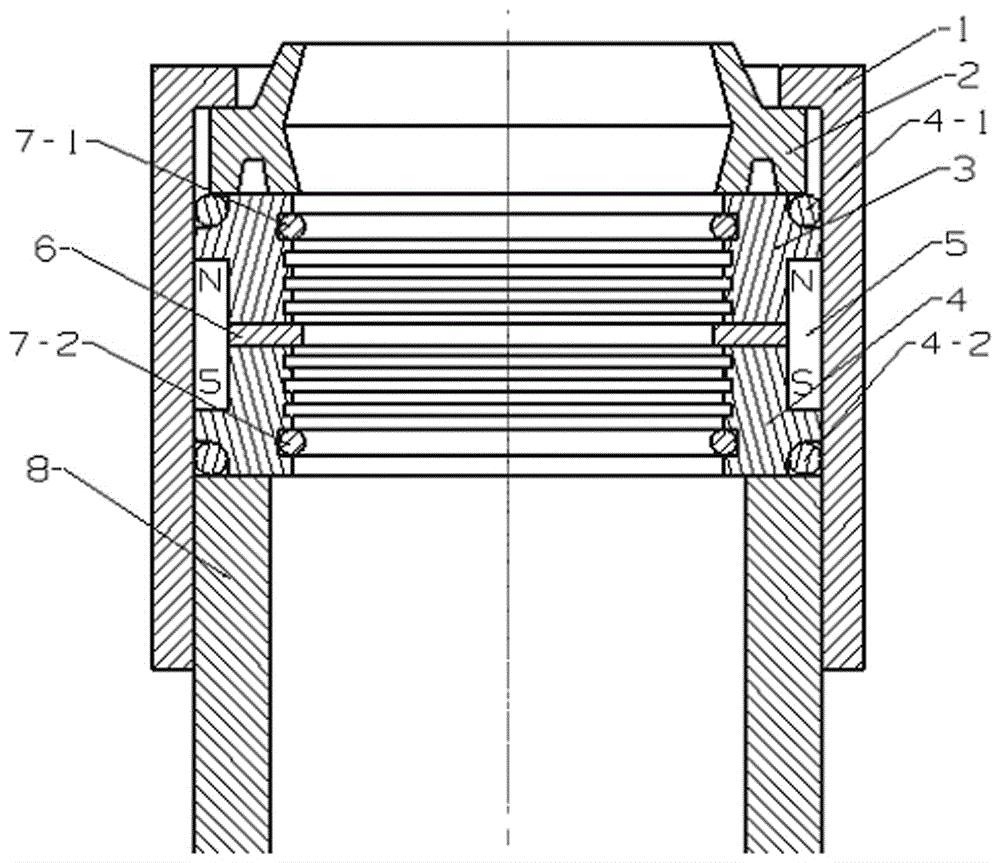

Magneticfluid sealing device applied to electric push rod

The invention provides to a magneticfluid sealing device applied to an electric push rod. The magnetic fluid sealing device comprises a positioning piece, a dustproof sealing ring, a first magnetic conductive pole shoe, a non-conductive magnet, a second magnetic conductive pole shoe, and a permanent magnet, wherein the dustproof sealing ring is arranged at the front part of the positioning piece; the permanent magnet, the first magnetic conductive pole shoe and the second magnetic conductive pole shoe are arranged in the positioning piece in parallel; the first magnetic conductive pole shoe and the second magnetic conductive pole shoe are separated through the non-conductive magnet; pole teeth and sealing ring grooves are arranged / formed on / in the inner annular surface of the first magnetic conductive pole shoe and the inner annular surface of the second magnetic conductive pole shoe, and the pole teeth are filled with magnetic fluids. The magnetic fluid sealing device disclosed by the invention is mainly applied between a push rod and an outer sleeve to isolate water, air and pollution damaging factors, and effective waterproof and dustproof effects are achieved.

Owner:上海舜拓电机有限公司

Flowmeter provided with protective cover

InactiveCN107796445AWon't splashImprove rain resistanceFireproof paintsVolume/mass flow measurementEngineering

Owner:博维恩冷冻科技(苏州)有限公司

Anti-pollution flashover paint for insulator in power transmission line and preparation process thereof

InactiveCN107903813AHigh affinityPrevent flocculationFireproof paintsAntifouling/underwater paintsAntioxidantRare earth

The invention discloses anti-pollution flashover paint for an insulator in a power transmission line and a preparation process thereof. The anti-pollution flashover paint is prepared from the following ingredients in parts by mass: 20 to 30 parts of acrylic water dispersion resin, 40 to 45 parts of fluorosilicon resin, 3 to 5 parts of aluminum oxide, 6 to 8 parts of silicon dioxide, 2 to 4 parts of titanium dioxide, 0.3 to 0.5 part of dispersing agents, 1 to 3 parts of antioxidants, 0.4 to 0.6 part of surfactants, 0.4 to 0.6 part of antifoaming agents, 1 to 3 parts of mouldproof sterilizing agents, 1 to 3 parts of flame retardant synergists, 2 to 4 parts of fire retardants, 2 to 6 parts of curing agents, 3 to 5 parts of silane coupling agents, 30 to 40 parts of solvents and 0.2 to 0.4 partof composite rare earth. The anti-pollution flashover paint has the advantages that the preparation process is simple; the implementation is easy; the prepared paint has good waterproof performance;the service life is prolonged; the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

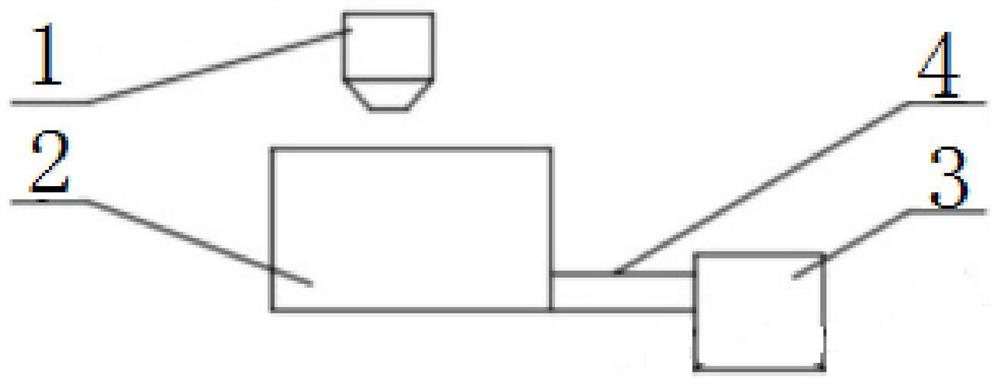

Full-automatic slag sample preparation system

PendingCN112304672AGuaranteed uptimeReduce labor intensityWithdrawing sample devicesPreparing sample for investigationSlagStructural engineering

The invention discloses a full-automatic slag sample preparation system, and the system comprises an automatic sampling machine, a crusher, a division machine and a conveying belt; the crusher is arranged at the lower end of the sampling machine, the division machine is arranged on one side of the crusher, the conveying belt is arranged between the crusher and the division machine, and the automatic sampling machine samples slag regularly; the crusher crushes the slag output by the automatic sampler, and the crushed slag is conveyed to the division machine through the conveying belt; a filterscreen is arranged at an outlet of the crusher; a plurality of material distributing grooves are formed in the division machine, material distributing bags are correspondingly arranged at the bottom ends of the material distributing partition grooves, and outlets of the material distributing bags correspond to the material receivers respectively. Protective layers are arranged on the inner surfaces and the outer surfaces of the crusher and the splitting machine and formed by spraying and drying protective paint. According to the system, the slag is continuously sampled according to the actualoperation condition of the boiler, the accuracy of the slag is effectively improved, the labor intensity is reduced, and the cost is reduced.

Owner:江苏南冶智能装备研究院有限公司

Dangling runner for fitness and wear-resisting treatment process thereof

InactiveCN108048722AImprove the extrusion effectGrain refinementCoatingsMovement coordination devicesRare-earth elementMetallurgy

The invention discloses a dangling runner for fitness. The runner comprises, by mass, 4-7% of Al, 0.12-0.13% of C, 3-6% of Mn, 10-13% of Zn, 1-3% of Ni, 1-3% of Cu, 2-3% of Sc, 0.005-0.008% of P, 0.01-0.02% of S, 1-3% of Zr, 2-5% of Ca, 0.01-0.05% of Nb, 0.2-0.4% of B, 2-5% of Sr, 2-4% of Co, 0.01-0.03% of V, 0.15-0.17% of Ti, 0.01-0.02% of Na, 0.02-0.03% of Be, 0.1-0.3% of rare earth elements, and the balance Mg and trace impurities; and the sum of the components is 100%. A wear-resisting treatment process of the dangling runner for fitness is simple and practicable, the dangling runner afterprocessing has good performance, the service life is prolonged, and the cost is reduced.

Owner:苏州胤宗智能科技有限公司

Wear-resisting valve and heat treatment technology thereof

InactiveCN107893190AImprove atomic activityHigh hardnessFurnace typesValve housingsRare-earth elementWear resistance

The invention discloses a wear-resisting valve. The wear-resisting valve comprises the following components which include, by mass, 0.18-0.3% of C, 0.6-1.1% of Si, 1.0-1.9% of Mn, 0.05-0.2% of Cr, 0.01-0.05% of Nb, 0.1-0.3% of Mo, 0.03-0.05% of Cu, 0.15-0.17% of Ti, 0.01-0.03% of V, 0.1-0.2% of rare earth elements, and the balance Fe and trace impurities, and the sum of all the components is 100%.The rare earth elements comprise, by mass, 5-7% of Pr, 10-13% of Sm, 2-4% of Ce, 10-13% of Lu, 15-18% of Eu and the balance La. The invention further designs a heat treatment technology of the wear-resisting valve. The technology is simple and easy to implement, the cost is low, and the valve obtained after heat treatment is excellent in performance and has good wear resistance.

Owner:朱建海

High-wear-resistance refrigeration device and reinforcing process thereof

InactiveCN108007036AImprove atomic activityHigh hardnessDomestic refrigeratorsAnti-corrosive paintsWear resistantEngineering

The invention discloses a high-wear-resistance refrigeration device and a reinforcing process thereof. The high-wear-resistance refrigeration device comprises a box body, a door body, a drying filterand a heater; and the door body is movably connected to the box body, a refrigeration chamber is arranged in the box body, the drying filter is arranged on the box body, and the heater is used for heating the drying filter. According to the high-wear-resistance refrigeration device, the structure is simple and compact, the wear-resistant effect is good, the reinforcing process is simple and easy to conduct, the reinforced refrigeration device has higher wear resistance, and the service life of the refrigeration device is prolonged.

Owner:博维恩冷冻科技(苏州)有限公司

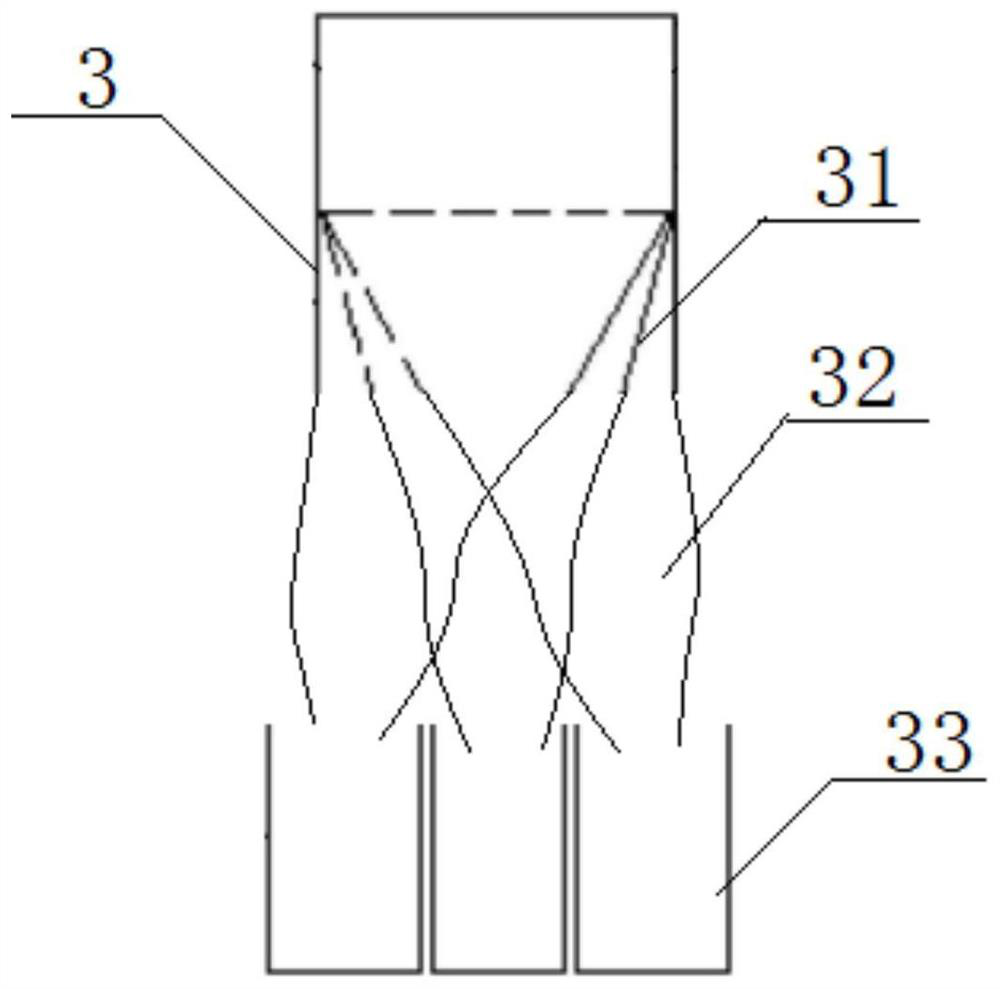

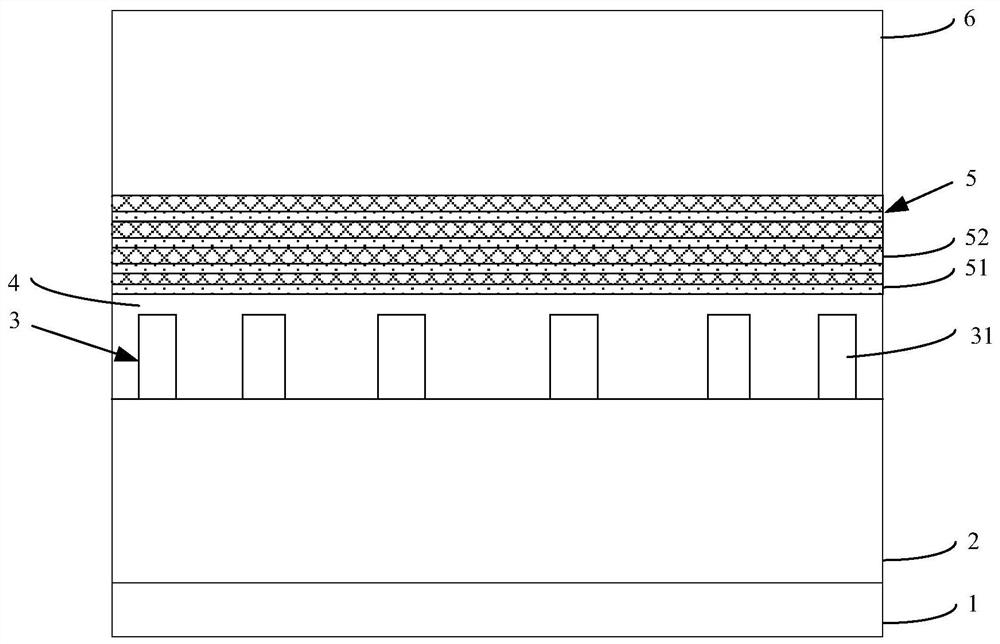

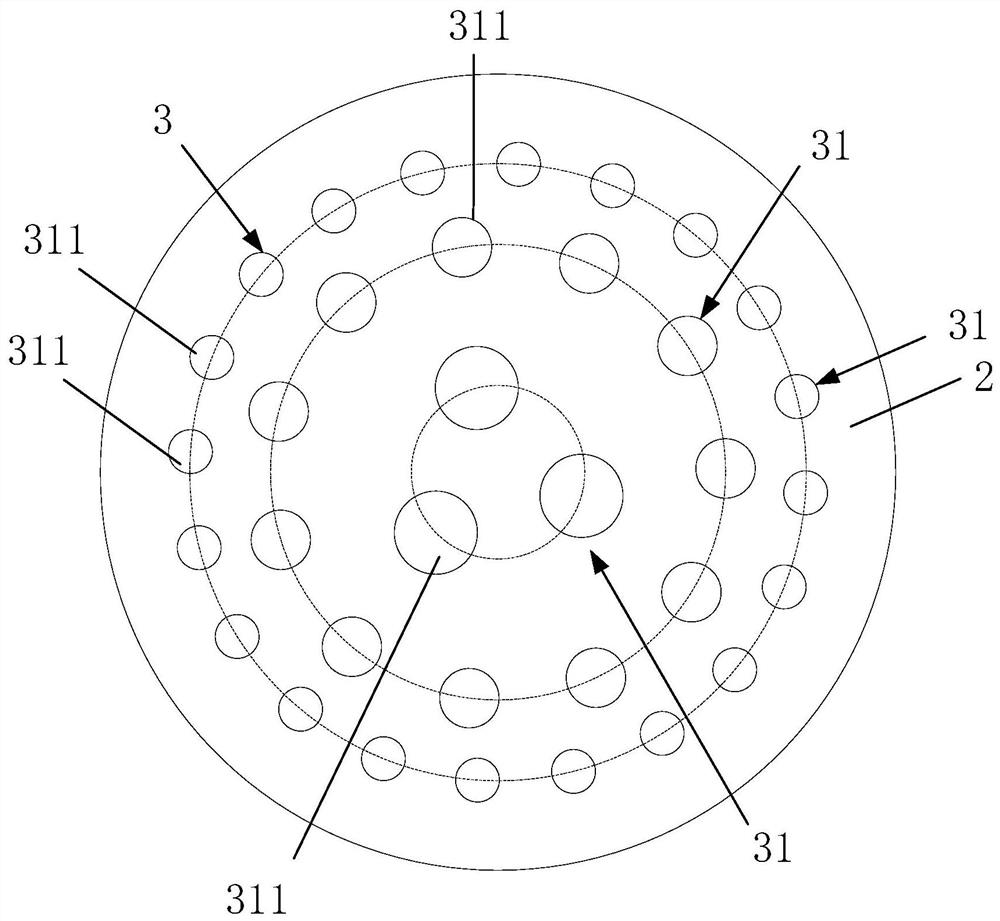

Light emitting diode epitaxial wafer and preparation method thereof

ActiveCN112687777AIncreasing the thicknessUniform thicknessSemiconductor devicesEngineeringMaterials science

The invention discloses a light emitting diode epitaxial wafer and a preparation method thereof, and belongs to the field of light emitting diode manufacturing. A SiO2 adjusting layer is added on a first n-type GaN layer, the SiO2 adjusting layer comprises a plurality of concentric SiO2 adjusting circular rings distributed on the surface of the first n-type GaN layer at intervals, the circle centers of the concentric SiO2 adjusting circular rings are the circle center of the surface of the first n-type GaN layer, and each SiO2 adjusting circular ring comprises a plurality of SiO2 adjusting columns distributed at equal intervals. The diameter of the SiO2 adjusting columns is reduced along with the increase of the diameter of the SiO2 adjusting circular rings, and the growth speed of a second n-type GaN layer near the circle center of a substrate is slightly faster than the growth speed of the second n-type GaN layer near the edge of the substrate, so that the thickness difference formed between the area near the edge and the area near the circle center due to temperature is counteracted, the overall growth thickness of the second n-type GaN layer is more uniform, and the light emitting uniformity of the light emitting diode is improved.

Owner:HC SEMITEK SUZHOU

Anticorrosive wood-plastic composite material and production process thereof

InactiveCN110423478AStrong adhesionImprove adhesionSynthetic resin layered productsWood layered productsGlass fiberPlasticizer

The invention discloses an anticorrosive wood-plastic composite material and a production process thereof, and belongs to the technical field of wood-plastic composite materials. The anticorrosive wood-plastic composite material comprises the following components: 30-45 parts of wood powder, 20-35 parts of wheat straw powder, 15-25 parts of epoxy resin, 5-15 parts of cashew nut shell oil modifiedphenolic amine resin, 5-10 parts of graphite, 10-20 parts of shell powder, 5-10 parts of quartz micro powder, 10-15 parts of sanding powder, 2-8 parts of an epoxy reactive diluent, 6-12 parts of an auxiliary agent, 3-9 parts of a coupling agent, 4-8 parts of a stabilizer, 6-10 parts of a plasticizer and 8-15 parts of a filler, wherein the epoxy resin is organic silicon modified epoxy resin, the graphite is expandable graphite, and the stablizer is composite rare earth. According to the invention, through use of epoxy resin, expandable graphite, quartz micro powder and shell powder, corrosion resistance of the material is improved; and meanwhile, through use of composite rare earth and nano glass fibers, fireproof flame-retardant performance and mechanical strength performance of the wood-plastic composite material are further improved.

Owner:安徽淮宿建材有限公司

High-temperature-resistant intelligent vehicular charger

InactiveCN107955474AHigh strengthImprove toughnessFireproof paintsBatteries circuit arrangementsRare-earth elementFoaming agent

The invention discloses a high-temperature-resistant intelligent vehicular charger. The high-temperature-resistant intelligent vehicular charger comprises a shell and a main circuit board arranged inside the shell and is characterized in that each of the inner surface and the outer surface of the shell is provided with a protecting layer, and each protecting layer comprises acrylic resin, poly(phthalazinone ether sulfone ketone) modified resin, polyvinyl methyl ether, fluorinated graphene, talcum powder, chlorinated paraffin, a stabilizer, an ADC foaming agent, silicone oil, a composite flameretardant, a chain extender, a neutralizing agent, a catalyst and rare-earth elements. The charger is good in high-temperature resistance, long in service life and capable of lowering cost.

Owner:苏州威斯道智能科技有限公司

Low-density high-temperature-resistant tray and preparation method thereof

InactiveCN107043588AHigh purityGood adhesionFireproof paintsPolyether coatingsChemistryBENZYL ALCOHOL/WATER

The invention discloses a low-density high-temperature-resistant tray. A component A comprises the following components in parts by mass: 5-8 parts of propylene carbonate, 7-11 parts of 3-butanediol, 5-8 parts of diethylene glycol, 6-9 parts of a polyvinyl chloride resin, 15-18 parts of a brightener, 9-15 parts of a coalescing agent, 9-11 parts of a plasticizer and 13-17 parts of auxiliary materials; a component B comprises the following components in parts by mass: 2-7 parts of tetrahydrofuran, 7-10 parts of diiodomethane, 2-5 parts of 2-butoxyethanol, 6-9 parts of dibutyl phthalate, 17-19 parts of nano-silica, 20-22 parts of benzyl alcohol, 8-12 parts of a curing agent, 11-14 parts of an antifoaming agent and 20-23 parts of a solvent; and a component C comprises the following components in parts by mass: 22-25 parts of polyphenylene oxide resin powder, 9-12 parts of methylbenzene, 5-8 parts of a plasticizer, 13-16 parts of a coupling agent, 2-7 parts of a flame retardant, 12-16 parts of wood fiber powder, 25-28 parts of carbon fiber powder, 9-11 parts of a cross-linking agent and 15-19 parts of a coalescing agent.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Supporting rod used for automobile hood and treatment process thereof

InactiveCN108048698AEasy to fill gapsGood dispersionSuperstructure subunitsCoatingsWear resistanceImpurity

The invention discloses a supporting rod used for an automobile hood. The supporting rod used for the automobile hood mainly comprises a supporting rod body and the supporting rod body comprises the following components, in percentage by mass, 0.18-0.19% of C, 0.3-0.5% of Cu, 0.01-0.03% of Ti, 0.003-0.005% of B, 0.6-1.1% of Si, 1.0-1.9% of Mn, 0.05-0.08% of Cr, 0.01-0.03% of Nb, 0.01-0.02% of V, 0.04-0.06% of Fe, 1-3% of molybdenum disulfide, with the balance being Al and inevitable impurities. The sum of the above components is 100%. The supporting rod is good in wear resistance and capable of prolonging the service life and lowering the cost.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

Automobile heat radiator protection grid and processing process thereof

The invention discloses an automobile heat radiator protection grid which comprises the following components: polypropylene, PVC (Polyvinyl Chloride), a polyvinyl fluoride resin, a lubricant, glass beads, a plasticizer, a silane coupling agent, packing, a maleic anhydride-styrene solid resin, silicon carbide micro powder, carbon monofluoride and a rare-earth composite stabilizer. The invention further designs a processing process of the automobile heat radiator protection grid. The processing process is simple and feasible, and the heat radiator protection grid treated with the process is goodin property, long in service life and low in cost.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

Corrosion-resistant air cooler and reinforcing process thereof

InactiveCN107988559AImprove atomic activityHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsRare-earth elementEngineering

The invention discloses a corrosion-resistant air cooler. The corrosion-resistant air cooler is characterized in that the corrosion-resistant air cooler comprises an air cooler shell, a draught fan, arefrigerant circulation system and a control module. The draught fan and the refrigerant circulation system are arranged in the air cooler shell. The control module is used for controlling the draught fan and the refrigerant circulation system. The air cooler shell comprises, by mass percentage, 8-10% of Al, 1-3% of Mn, 0.18-0.3% of C, 0.05-0.1% of Cr, 0.01-0.05% of Nb, 0.01-0.03% of Cu, 2-5% ofSr, 0.0002-0.005% of Nb, 0.005-0.008% of N, 0.0002-0.005% of S, 0.5-0.8% of Zn, 1.5-1.8% of Si, 3-5% of Ca, 0.5-0.8% of Ti, 0.3-0.5% of Ni, 0.002-0.004% of B, 0.1-0.4% of V, 0.5-0.8% of a rare earth element and the balance Fe. The invention further designs a reinforcing process of the corrosion-resistant air cooler. The air cooler is simple and compact in structure and good in corrosion resistingeffect; the service life of the air cooler is prolonged; and the cost is lowered.

Owner:博维恩冷冻科技(苏州)有限公司

Heat pump with sound insulating effect

InactiveCN107987669AGood heat resistanceExtended service lifeFireproof paintsAnti-corrosive paintsEngineeringHeat pump

The invention discloses a heat pump with a sound insulating effect. The heat pump with the sound insulating effect comprises a heat pump machine set box body, a heat exchanger and a fan; the heat exchanger is arranged in the heat pump machine set box body; the fan is arranged on one side of the heat exchanger; a sound insulating layer is arranged on the surface of the heat pump machine set box body. The heat pump with the sound insulating effect disclosed by the invention is simple and compact, and has a good sound insulating effect.

Owner:博维恩冷冻科技(苏州)有限公司

Valve for sea water desalination treatment

InactiveCN107904505AHigh strengthHigh elongationFoundry mouldsFurnace typesRare-earth elementWater desalination

The invention discloses a valve for sea water desalination treatment. The valve is prepared from the following components in percentage by mass: 3-5% of Al, 1.15-1.17% of Mn, 0.5-1% of Zn, 0.02-0.03%of Si, 0.1-0.3% of Co, 4-7% of Cr, 0.15-0.17% of C, 0.1-0.4% of V, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.20% of Cu, 0.15-0.17% of Ti, 0.25-0.39%of Mo, 0.002-0.004% of NB, 0.05-0.08% of Pa, 0.5-0.8% of rare earth elements and the balance of Fe. The valve is good in corrosion resistance, long in service life and simple and feasible in production process.

Owner:张剑

Forming process for outdoor high and low parallel bars

InactiveCN108060367AReduce porosityReduce tensionFoundry mouldsParallel barsEngineeringForming processes

Owner:苏州胤宗智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com