Magneticfluid sealing device applied to electric push rod

A magnetic fluid sealing, electric push rod technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem that the outside liquid cannot be effectively prevented from entering the push rod, the push rod actuator is difficult to seal, and the push rod circuit structure Damage and other problems, to achieve the effect of small installation volume, low power loss and no heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

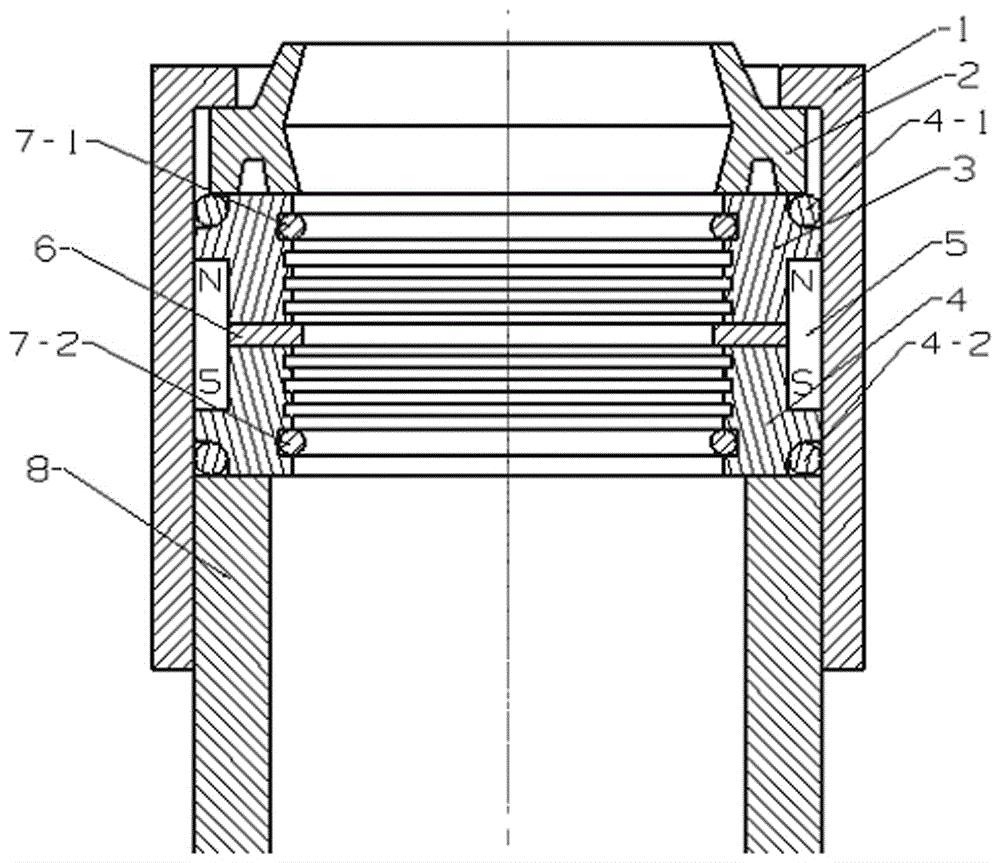

[0025] The present invention provides a magnetic fluid sealing device applied to an electric push rod, including a positioning member 1, a dust-proof sealing ring 2, a first magnetically conductive pole piece 3, a non-magnetically conductive body 6, a second magnetically conductive pole piece 4, and a permanent magnet 5 The dust-proof sealing ring 2 is installed on the front part of the positioning member 1, and the permanent magnet 5 is installed side by side with the first magnetically conductive pole piece 3 and the second magnetically conductive pole piece 4 on the positioning The interior of part 1, the first magnetically conductive pole piece 3 and the second magnetically conductive pole piece 4 are separated by the non-magnetically conductive body 6; the first magnetically conductive pole piece 3 and the second magnetically conductive pole piece 4 The inner ring surface of each is provided with pole teeth and sealing ring grooves, wherein the pole teeth are filled with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com