High heat conductivity and electric conductivity organic silicon adhesive and preparation method thereof

A silicone adhesive, high electrical conductivity technology, applied in conductive adhesives, adhesives, non-polymer adhesive additives and other directions, can solve the problems of thermal conductivity filler and adhesive performance influence, thermal conductivity and other issues, to achieve a simple preparation method, pro- The effect of enhanced water performance and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

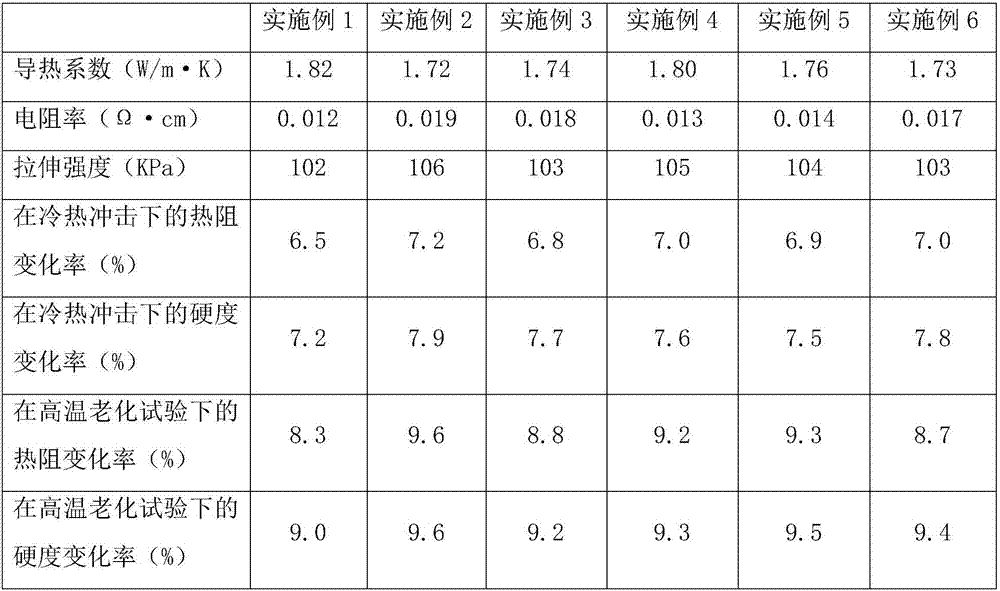

Examples

Embodiment 1

[0025] (1) Put boron nitride in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 1:3, mechanically stir at 150r / min for 1h, take it out, wash and dry thoroughly to obtain hydroxylated boron nitride.

[0026] (2) Put the hydroxylated boron nitride in a 15 mg / mL graphene oxide solution, stir at 60°C for 5 hours until uniform, add glucose dropwise, heat and stir evenly, and obtain boron oxide with graphene attached on the surface, wherein The graphene content in the graphene-attached boron oxide was 3%.

[0027] (3) According to the mass ratio of boron oxide, aluminum oxide and silver paste with graphene attached on the surface is 1:3:0.8, dilute the silane coupling agent in ethanol solution and add it to the reaction kettle of the high-speed mixer to stir evenly, add the surface-adhered Graphene boron oxide, cylindrical α-Al2O3 with a size of 2-5μm, spherical silver ions with a particle size of 1-2μm and silver paste with flake silver p...

Embodiment 2

[0030] (1) Put boron nitride in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 1:3, mechanically stir at 200r / min for 2h, take it out, wash and dry thoroughly to obtain hydroxylated boron nitride.

[0031] (2) Put hydroxylated boron nitride in a 20 mg / mL graphene oxide solution, stir at 65°C for 7 hours until uniform, add glucose dropwise, heat and stir evenly, and obtain boron oxide with graphene attached to the surface, wherein The content of graphene in the graphene-attached boron oxide was 10%.

[0032] (3) According to the mass ratio of boron oxide, aluminum oxide and silver paste with graphene attached on the surface as 1:5:1.5, dilute the silane coupling agent in ethanol solution and add it to the reaction kettle of the high-speed mixer to stir evenly, add the surface-adhered Graphene boron oxide, cylindrical α-Al2O3 with a size of 2-5μm, spherical silver ions with a particle size of 1-2μm and silver paste with flake silver p...

Embodiment 3

[0035] (1) Put boron nitride in a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 1:3, mechanically stir at 180r / min for 1.5h, take it out, wash and dry thoroughly to obtain hydroxylated boron nitride.

[0036] (2) Put hydroxylated boron nitride in 18 mg / mL graphene oxide solution, stir at 62°C for 6 hours until uniform, add glucose dropwise, heat and stir evenly, and obtain boron oxide with graphene attached on the surface, wherein The content of graphene in the graphene-attached boron oxide was 5%.

[0037](3) According to the mass ratio of boron oxide, aluminum oxide and silver paste with graphene attached on the surface as 1:4:1, dilute the silane coupling agent in ethanol solution and add it to the reaction kettle of the high-speed mixer to stir evenly, add the surface-adhered Graphene boron oxide, cylindrical α-Al2O3 with a size of 2-5μm, spherical silver ions with a particle size of 1-2μm and silver paste with flake silver parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com