Full-automatic slag sample preparation system

A sample preparation system and fully automatic technology, applied in sampling, sampling device, preparation of samples for testing, etc., can solve the problems of random sampling and preparation, poor working environment, high labor intensity, etc., to reduce the reduction process and improve the Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

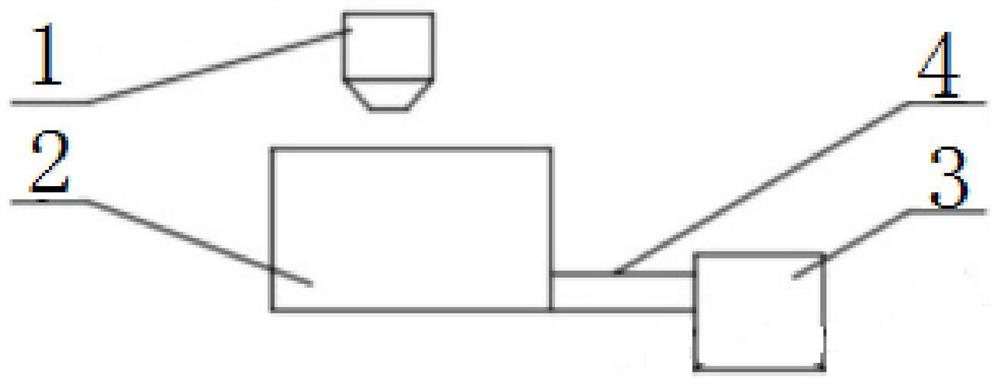

[0043] A fully automatic slag sample preparation system provided in this embodiment has a structure such as Figure 1-2 As shown, it includes an automatic sampling machine 1, a crusher 2, a shrinking machine 3 and a conveyor belt 4. The crusher 2 is set at the lower end of the sampling machine 1, the shrinking machine 3 is set at one side of the In the middle of machine 2 and shrinking machine 3, automatic sampling machine 1 regularly samples the slag, and crusher 2 crushes the slag output by automatic sampling machine 1, and the crushed slag is sent to shrinking machine 3 through conveyor belt 4;

[0044] A filter screen is provided at the outlet of the crusher 2;

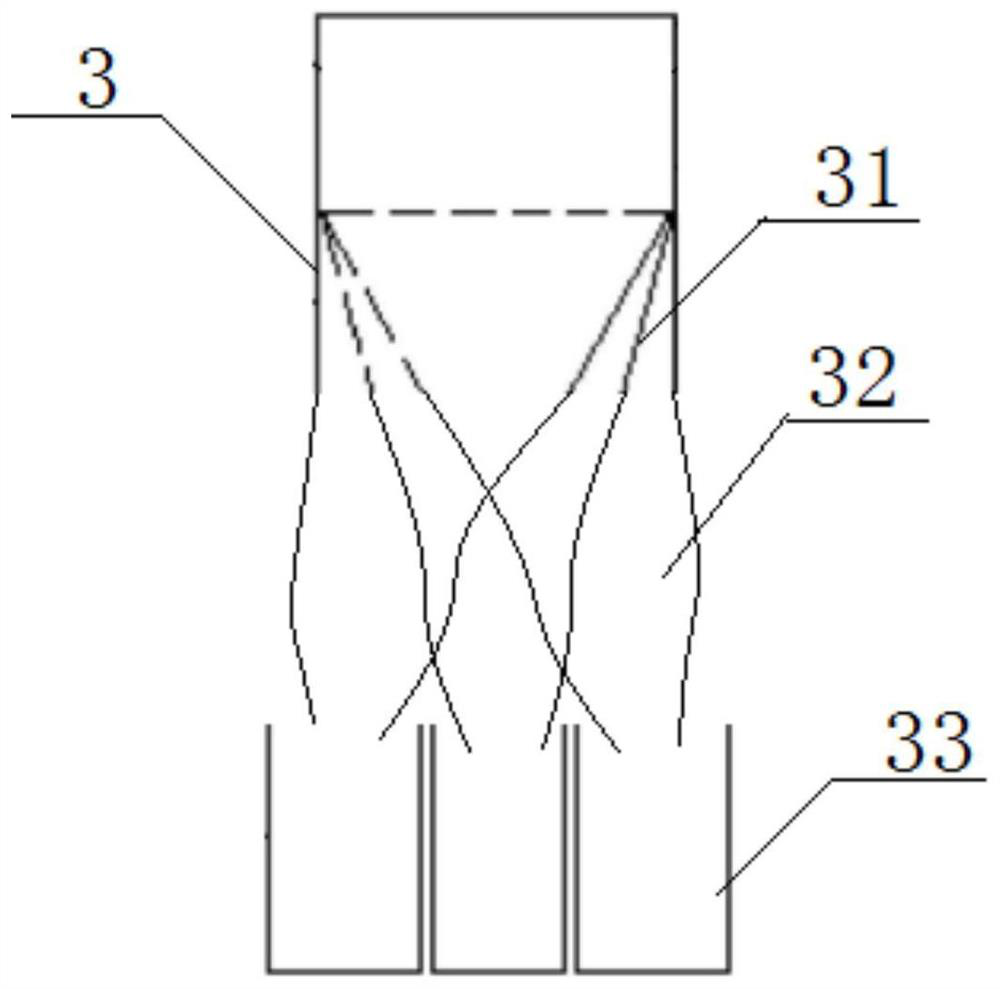

[0045] The shrinking and dividing machine 3 is provided with a plurality of material distribution compartments 31, the bottom of the material distribution compartment 31 is correspondingly provided with a material distribution bag 32, and the outlet of the material distribution bag 32 corresponds to a material rec...

Embodiment 2

[0062] A fully automatic slag sample preparation system provided in this embodiment has a structure such as Figure 1-2 As shown, it includes an automatic sampling machine 1, a crusher 2, a shrinking machine 3 and a conveyor belt 4. The crusher 2 is set at the lower end of the sampling machine 1, the shrinking machine 3 is set at one side of the In the middle of machine 2 and shrinking machine 3, automatic sampling machine 1 regularly samples the slag, and crusher 2 crushes the slag output by automatic sampling machine 1, and the crushed slag is sent to shrinking machine 3 through conveyor belt 4;

[0063] A filter screen is provided at the outlet of the crusher 2;

[0064] The shrinking and dividing machine 3 is provided with a plurality of material distribution compartments 31, the bottom of the material distribution compartment 31 is correspondingly provided with a material distribution bag 32, and the outlet of the material distribution bag 32 corresponds to a material rec...

Embodiment 3

[0081] A fully automatic slag sample preparation system provided in this embodiment has a structure such as Figure 1-2 As shown, it includes an automatic sampling machine 1, a crusher 2, a shrinking machine 3 and a conveyor belt 4. The crusher 2 is set at the lower end of the sampling machine 1, the shrinking machine 3 is set at one side of the In the middle of machine 2 and shrinking machine 3, automatic sampling machine 1 regularly samples the slag, and crusher 2 crushes the slag output by automatic sampling machine 1, and the crushed slag is sent to shrinking machine 3 through conveyor belt 4;

[0082] A filter screen is provided at the outlet of the crusher 2;

[0083] The shrinking and dividing machine 3 is provided with a plurality of material distribution compartments 31, the bottom of the material distribution compartment 31 is correspondingly provided with a material distribution bag 32, and the outlet of the material distribution bag 32 corresponds to a material rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com