EMMA optical film for full fitting of electronic screen and preparation method thereof

A fully laminating, optical film technology, applied in the direction of non-polymer adhesive additives, non-polymer organic compound adhesives, adhesive additives, etc., can solve the problem of incompatibility of tackifiers or coupling agents Instable bonding, poor storage stability, etc., to achieve the effects of guaranteed bonding performance, easy filling of gaps, and low yellowing index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

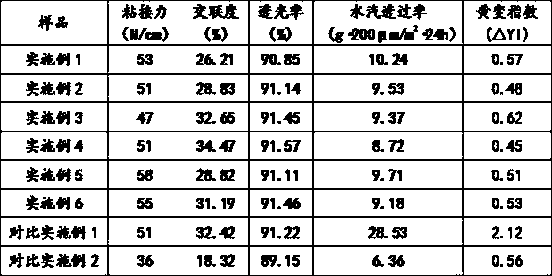

Examples

Embodiment 1

[0024] Add 0.5 parts of photoinitiator benzophenone and 1.5 parts of crosslinking agent trimethylolpropane to 100 parts by weight of ethylene-methyl methacrylate copolymer with a methyl methacrylate content of 24% and a melting point of 80 °C Trimethacrylate, 1.0 part tackifier γ-methacryloxypropyltrimethoxysilane, 0.1 part light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl ) sebacate, 1.1 parts of plasticizer diisooctyl phthalate, 0.8 parts of antioxidant bis(2.4-di-tert-butylphenyl) pentaerythritol diphosphite, added to the high-speed mixer for premixed to obtain a premix. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer is obtained through extrusion, upper and lower protective film, stretching, traction, and winding processes. 0.2mm EMMA optical film.

Embodiment 2

[0026] Add 1.2 parts of photoinitiator 1-hydroxycyclohexyl phenyl ketone, 0.8 parts of cross-linked Agent triallyl cyanurate, 0.7 parts of tackifier γ-glycidyl ether propyl trimethoxysilane, 0.3 parts of light stabilizer bis (2,2,6,6-tetramethyl-4-piperidine base) sebacate, 0.2 parts of plasticizer di-isooctyl phthalate, 1.0 parts of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, added to the high-speed mixer Premixing is carried out to obtain a premix. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer is obtained through extrusion, upper and lower protective film, stretching, traction, and winding processes. 0.2mm EMMA optical film.

Embodiment 3

[0028]Add 1.7 parts of photoinitiator benzophenone, 0.3 parts of crosslinking agent pentaerythritol triacrylate, 0.5 parts of tackifier vinyltrimethoxysilane, 0.4 parts of light stabilizer bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.8 parts of plasticizer dioctyl phthalate , 0.3 parts of antioxidant tris (2, 4-di-tert-butylphenyl) phosphite, added to a high-speed mixer for pre-mixing to obtain a pre-mix. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer is obtained through extrusion, upper and lower protective film, stretching, traction, and winding processes. 0.2mm EMMA optical film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com