Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid reciprocal reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing full natural quick dissolving green tea

InactiveCN101049120APrevent oxidationPrevent oxidation and discolorationTea extractionVitamin CFruit juice

An instant granular solid green tea with unique tea smell is prepared from natural green tea through proportionally extracting in water at 75-95 deg.C, adding carambola juice and beta-cyclodextrin, stirring, concentrating and freeze-drying. It is rich in nutrients including amino acids, tea polyphenol, flavone, VC and trace elements.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Solidified essence and flavoring agent for cigarette and its preparing process

InactiveCN1907150AImprove heat resistanceImprove stabilityTobacco treatmentEssential-oils/perfumesFlavorAlcohol

The invention discloses a smoke solid essence and preparing method, which comprises the following steps: (1) adopting essence extract or essential oil as raw material; preparing essence or essence particle through spraying drying method; (2) condensing essence extract into grease or essential oil; adding 1-3 times 95% alcohol and fitful beta-cyclodextrin; stirring at constant temperature for 1-12h; drying to produce essence and essential particle; (3) selecting gelatin and acacia as wall material; adopting essence extract and essential oil as core material to prepare micro-capsule solid perfume or essence.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

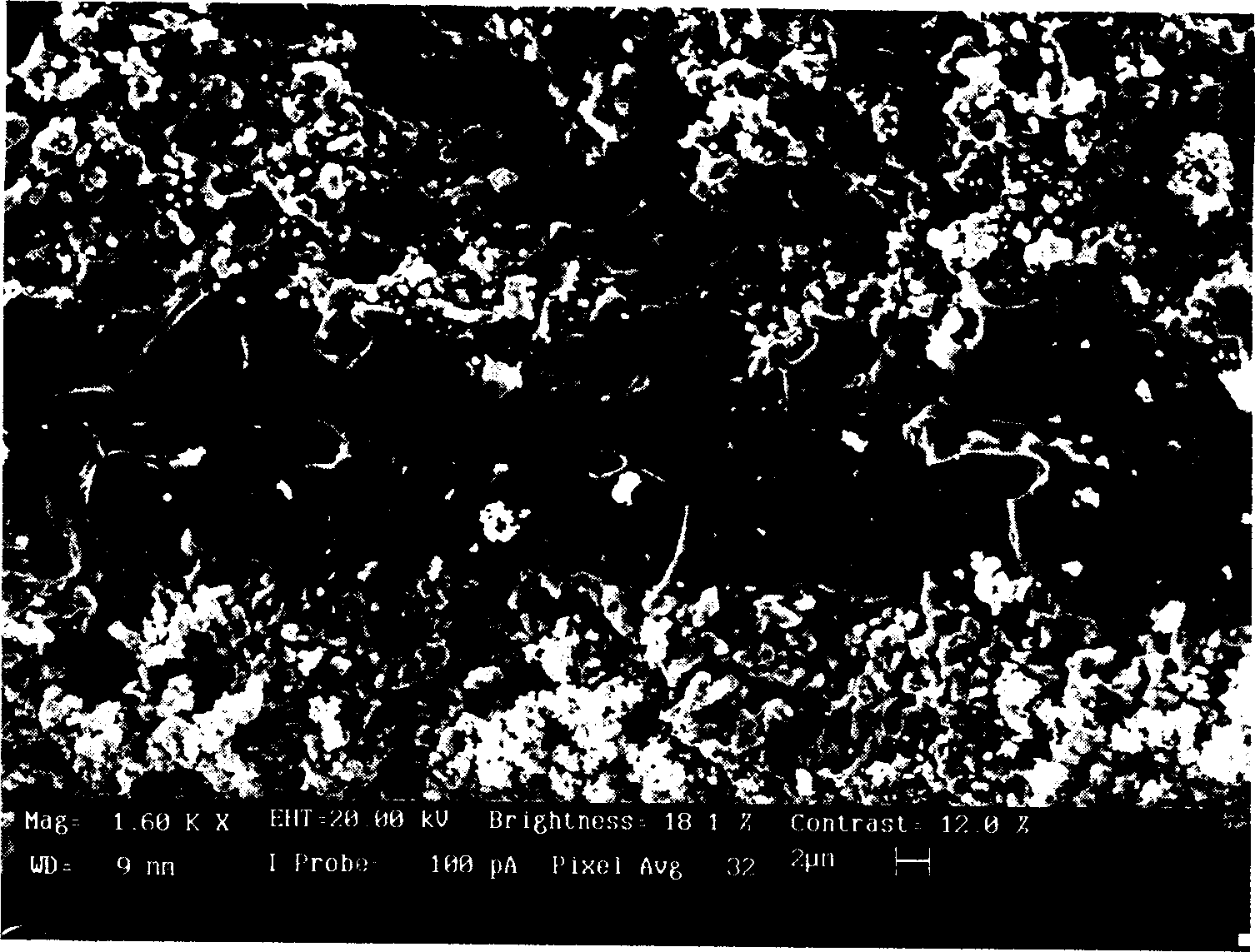

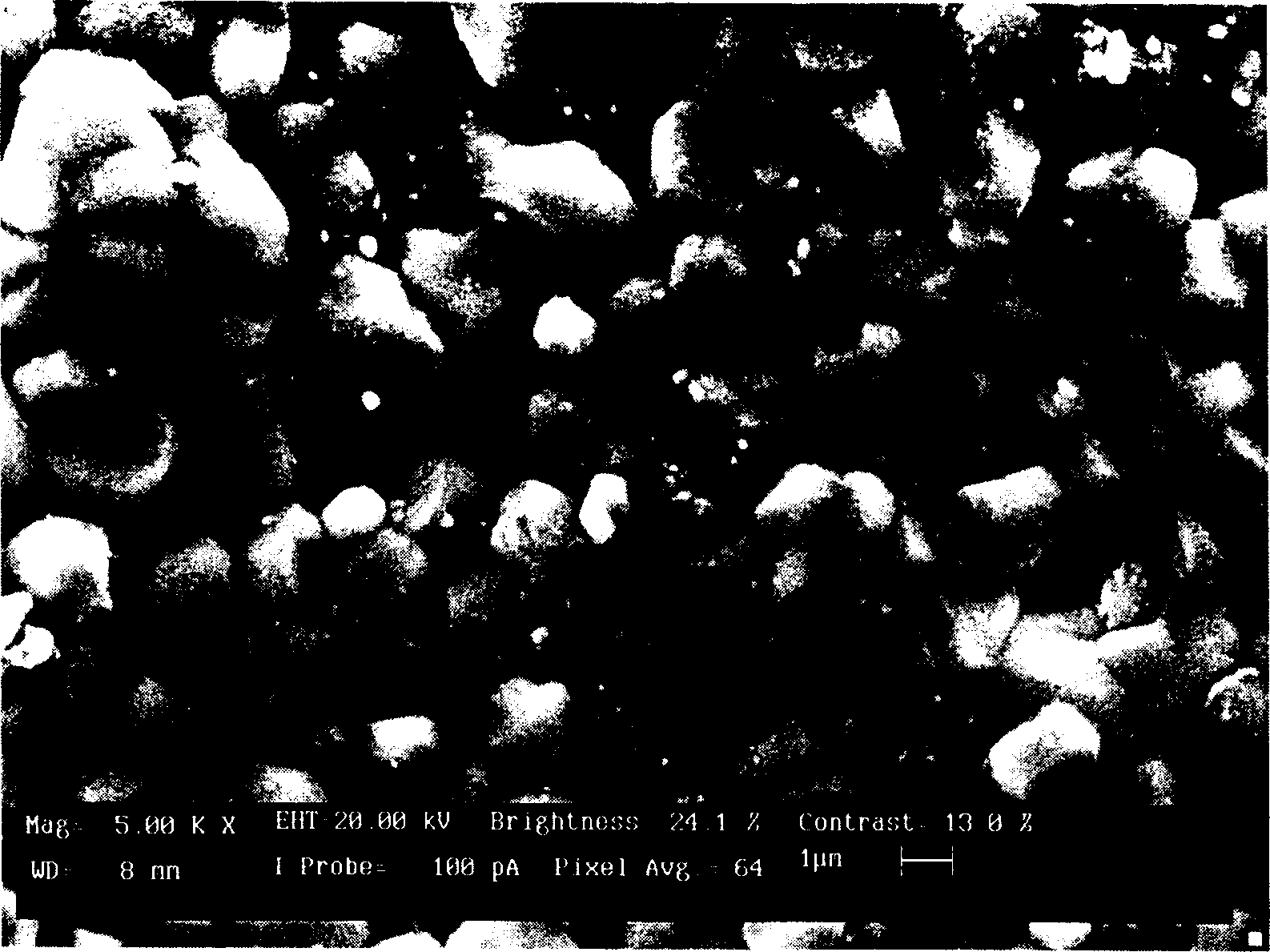

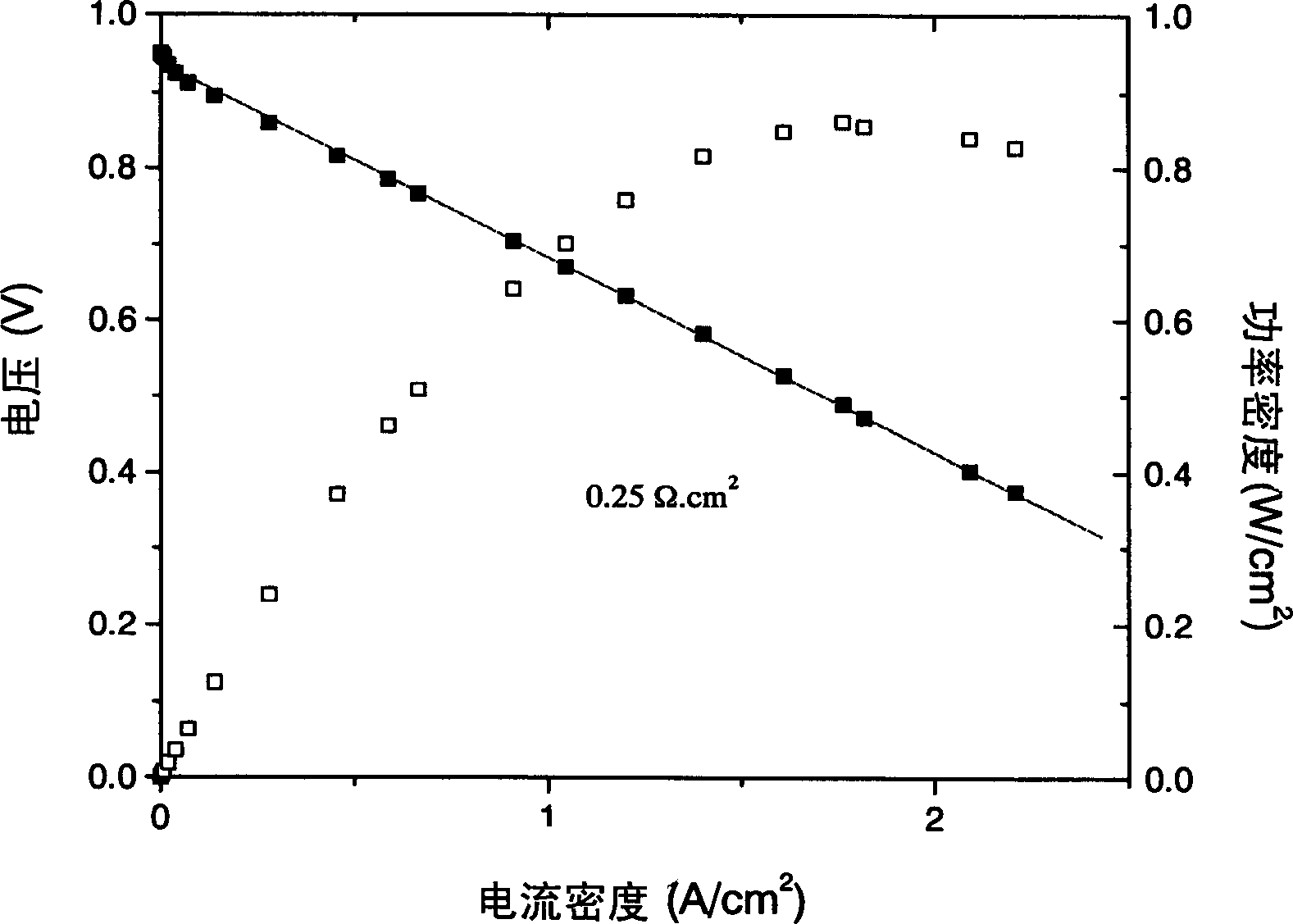

Method for mfg. anode carried thin film medium-temp. solid oxide fuel cell

InactiveCN1402372AAvoid reciprocal reactionsIncreased open circuit potentialFinal product manufactureSolid electrolyte fuel cellsOxidePower density

The method for manufacturing the integrated part of the anode-dielectric-cathode used in the solid oxide full cell (SOFC) includes following steps. The flow casting method providing low cost and easy to scale-up is accepted for preparing the dielectric membrane. The densification of the dielectric membrane is carried out at high temperature. The specific preparing technique is utilized so as to prevent the chemical reaction of the anode catalyst Ni with LSGM membrane in the densification processing. The thickness of the even and compact LSGM membrane is 5-100 micros. The LSGM membrane can be used as the dielectric membrane in SOFC single cell in plateau form at middle temperature. The maximum output power density of the said SOFC single cell can reach to 850 mW / cm2 at temperature 800 deg.C (hydrogen as fuel, air as oxide agent).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Equalizing nutrient effervescent tablet and its preparing method

InactiveCN1408363AAvoid reciprocal reactionsImprove absorption rateOrganic active ingredientsMetabolism disorderEffervescent tabletNutrition supplementation

The equalizing nutrient effervescent tablet is prepared with nutrient matters containing vitamins and trace elements and capable of providing human body with essential nutrient matters. It has its acid and alkali nutrient matters separately embedded. It has the advantages of long guarantee period, good taste, easy absorption and capacity of providing equalized nutrients.

Owner:北京劲得健康科技有限公司

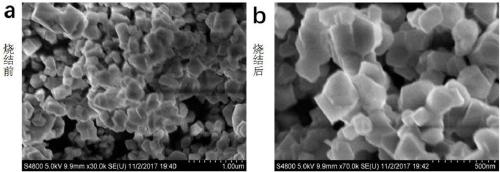

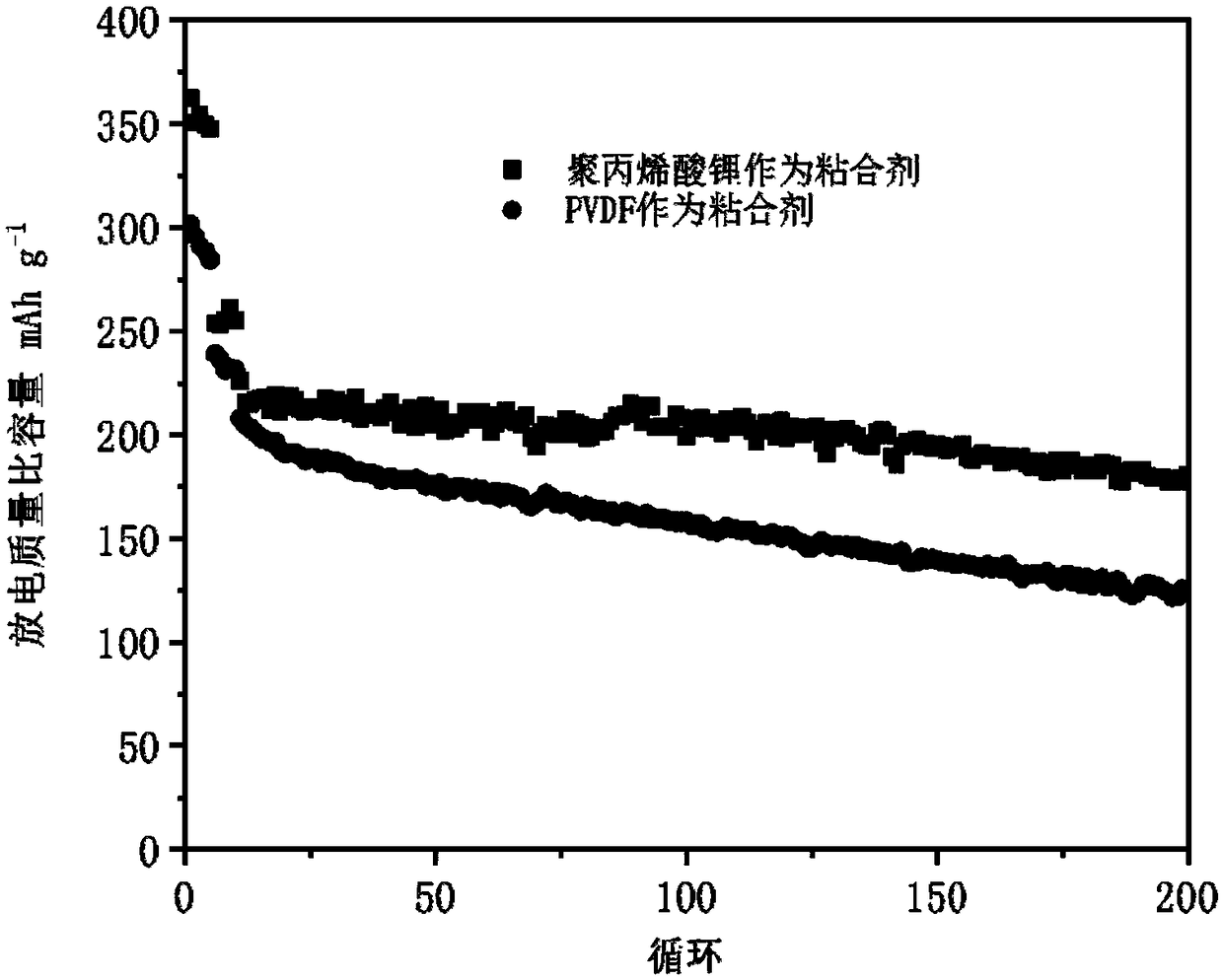

Lithium polyacrylate, preparation method and uses thereof, and lithium ion battery

InactiveCN109251257APrevent deteriorationAvoid destructionCell electrodesSecondary cellsLithium electrodePolyacrylic acid

The invention relates to a lithium polyacrylate, a preparation method and uses thereof, and a lithium ion battery. The preparation method comprises: taking polyacrylic acid having a molecular weight of 200000-600000, and carrying out a mixing reaction on the polyacrylic acid and lithium hydroxide to obtain the lithium polyacrylate. According to the invention, the lithium polyacrylate used as the lithium-rich manganese-based lithium ion battery binder, the preparation method and the uses thereof are provided, and the lithium polyacrylate preparation method is simple, is suitable for industrialproduction, and has outstanding advantages in the improvement of the performances of lithium-rich manganese-based lithium ion batteries.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for producing cationic starch by using homogeneous phase drying method

The invention relates to a method for producing cationic starch by using a homogeneous phase drying method. The method comprises the following steps of: mixing an etherifying agent with starch and mixing alkali with the starch; mixing the starch in which two reagents are added to reduce a destroy function of alkali on the etherifying agent; acquiring a cationic starch crude product in an extruding bulking machine with high temperature, high pressure and high shearing force; taking out the cationic starch crude product; directly drying the crude product until the water content is 11-14 percent; and pulverizing the dried product to obtain a cationic starch product. With the adoption of the method, the problems that the mixture of the cationic starch is not uniform and the product solubility is poor by using the conventional drying method are solved; and the production energy consumption of the cationic starch is low, the reaction is uniform, the waste is not discharged, and the method is effective and continuous. The starch is activated under a high-temperature high-pressure condition, the starch is stirred at high speed, and the etherifying agent and the starch can be uniformly dispersed at the molecular level by virtue of a function of the high shearing force, so that the reaction activity of the starch molecules and the reaction efficiency of the etherifying agent are obviously improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Liquid dressing for treating hemorrhoids, and preparation method thereof

The invention relates to a liquid dressing for treating hemorrhoids, and a preparation method thereof. The liquid dressing is prepared from the following components: alginate, modified chitosan, allantoin, tetracaine hydrochloride, glycerinum, hyaluronic acid, human collagen, growth factor, polyethylene glycol, didecyl dimethyl ammonium chloride, phmg, N-isopropyl acrylamide, and the like. The dressing is used for improving bleeding pain, porta hepatis fall-swell and other syndromes caused by internal hemorrhoid, external hemorrhoid, mixed hemorrhoid, anal fissure, anal fistula surgery, promoting hemorrhoid reduction, preventing hemorrhoid prolapse, relieving the syndromes of prolapsed and hemorrhoids congestion and the like, and performing treatment and anti-bacterial nursing of porta hepatis diseases of hemorrhoids and the like.

Owner:广西达庆生物科技有限公司

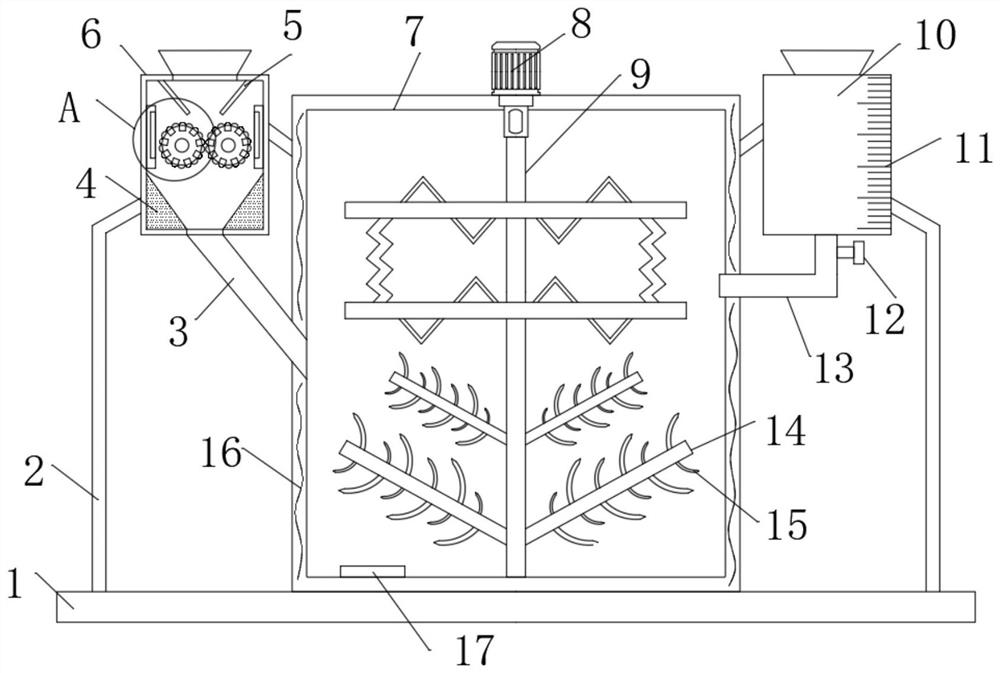

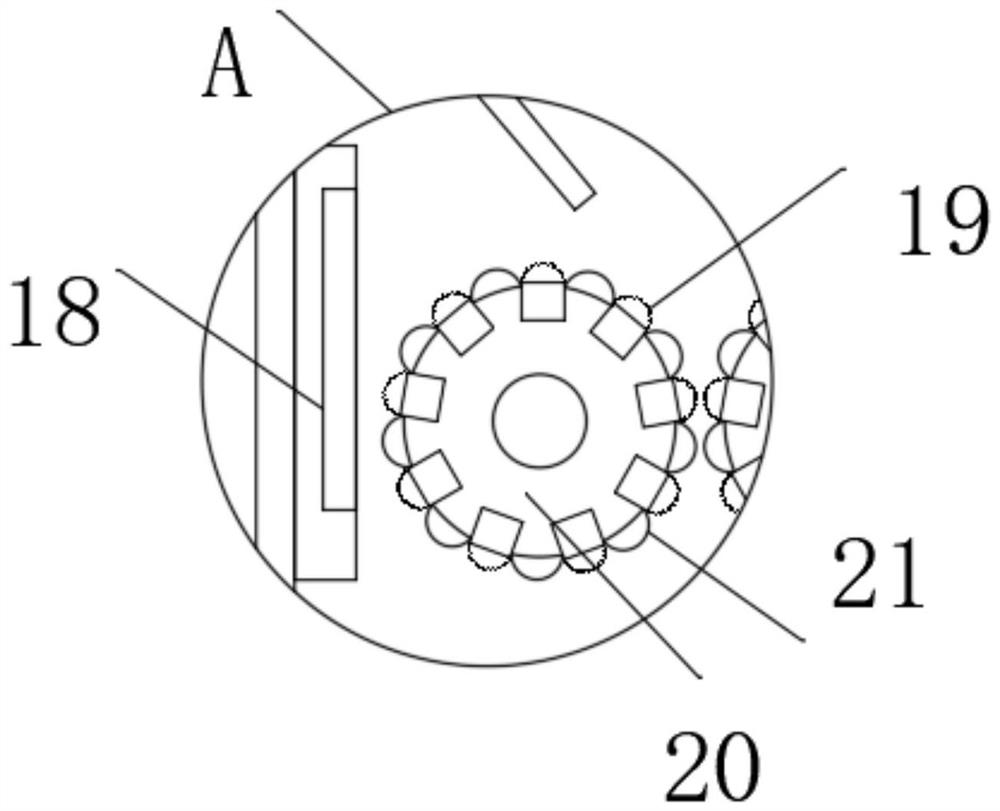

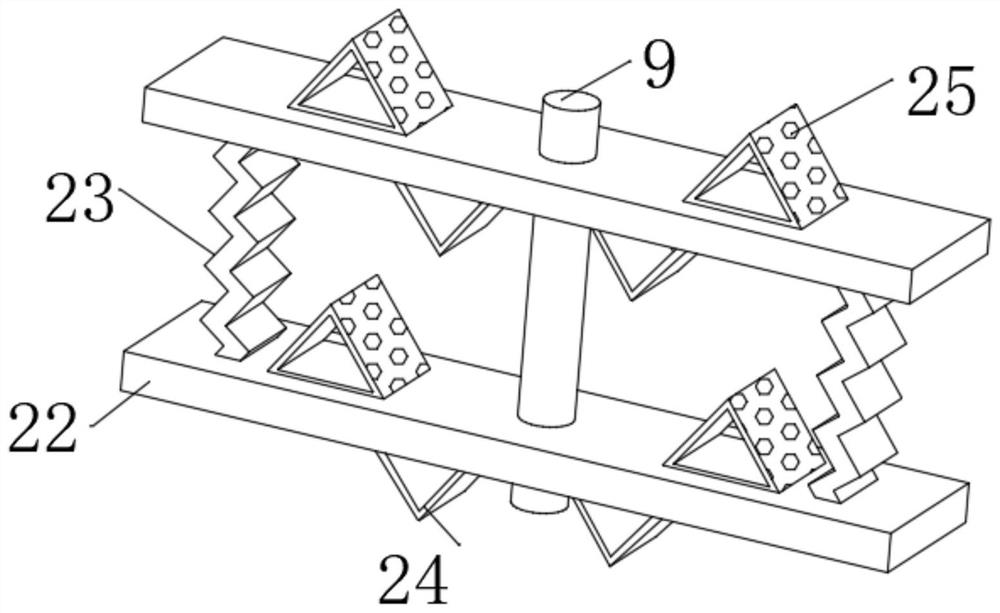

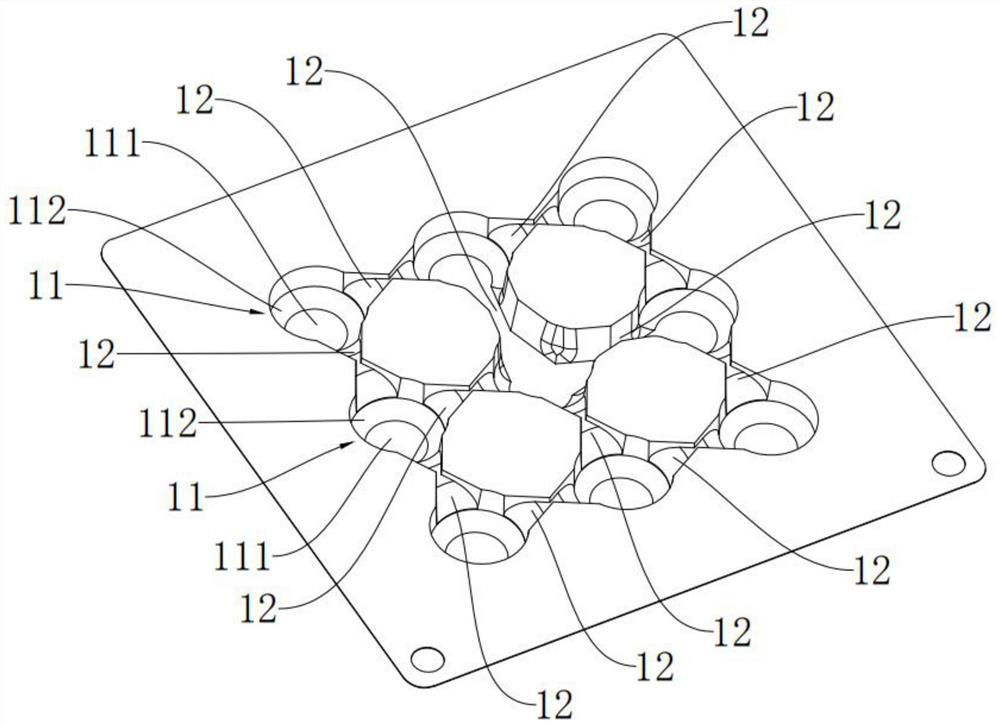

Efficient mixing device for medical granular medicines

InactiveCN111760496AAvoid stickingImprove the mixing effectRotary stirring mixersTransportation and packagingMedical equipmentPharmaceutical drug

The invention belongs to the technical field of medical equipment, and particularly relates to an efficient mixing device for medical granular medicines. In allusion to the problem of poor mixing effect, the invention proposes the following scheme: the device comprises a bottom plate, supporting frames are arranged on the two sides of the outer wall of the top of the bottom plate, a solid feedingbox and a liquid feeding box are arranged on the outer wall of one side of the supporting frame, a second motor is arranged on the outer wall of one side of the solid feeding box, an output shaft of the second motor is connected with an extrusion roller through a coupling, a first extrusion block and a second extrusion block are arranged on the outer wall of the extrusion roller, and the first extrusion block is of a sawtooth-shaped arc-shaped structure. According to the invention, the extrusion roller, the first extrusion block, the second extrusion block, a drying lamp and a triangular material guide block are arranged; solid granular medicines are ground into powder through the extrusion roller, the first extrusion block is of the sawtooth-shaped arc-shaped structure, the second extrusion block is of a rough semicircular structure, and the medicines can be further ground into powder through the sawtooth-shaped structure and the rough semicircular structure.

Owner:钱椰丽

Production method and application of blueberry fruit microcapsules

InactiveCN107822016AImprove stabilityImprove product flavorDough treatmentFood homogenisationSpecific gravityHorticulture

The invention particularly discloses a production method and application of blueberry fruit microcapsules. The production method of the blueberry fruit microcapsules comprises the following steps of blanching thoroughly-treated blueberry fruits, performing mashing to obtain juice, milling fruit residues with a colloid mill to obtain pulp of which the particle size is smaller than 5 <mu>m, then merging the pulp to obtain a homogeneous sizing agent, performing enzymolysis treatment, performing fermentation with a lactic acid bacteria fermenting agent, and concentrating fermentation liquid untilthe proportion is 1.20, so that a concentrated solution is obtained; and adding an embedding agent which is 100% by weight of the blueberry fruits and an emulsifying agent which is 1% by weight of theblueberry fruits to the concentrated solution, performing homogenizing treatment, performing granulation and drying with a built-in fluidized bed spray drying granulation machine, performing discharging, performing cooling, and performing screening with a 60-80-mesh sieve, so as to obtain the blueberry fruit microcapsule products. The method not only provides a new method for application of the blueberry fruits in foods, but also enables the stability of prepared foods to be greatly improved. The closed microcapsule outer walls can effectively prevent oxygen, rays, temperature and humidity from damaging encapsulated blueberry fruits, so that the stability of products is greatly improved.

Owner:徐州绿之野生物食品有限公司

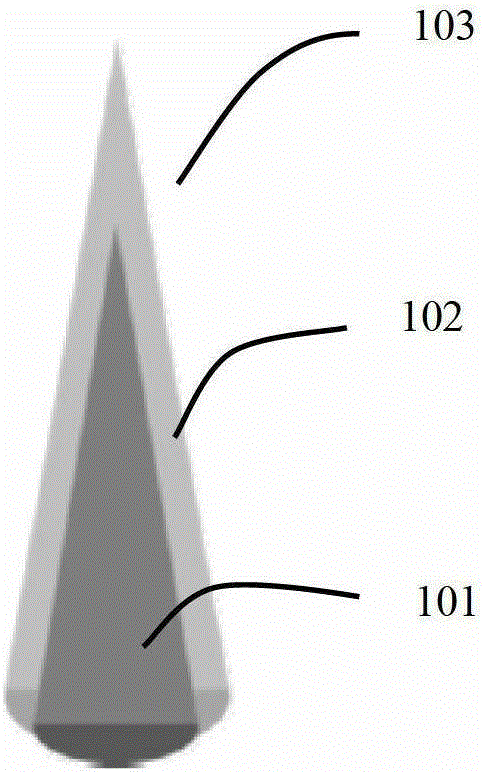

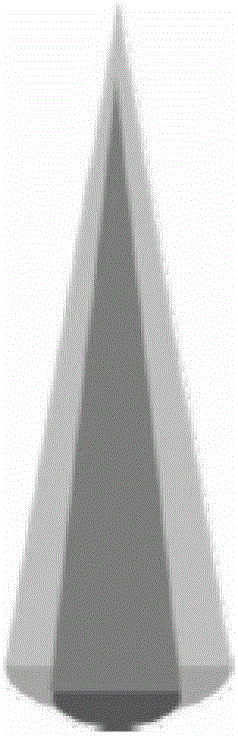

Soluble coaxial cone multilayer microneedle, microneedle array and preparation method thereof

ActiveCN103301563BEfficient drug releaseStable drug releaseMedical devicesMicroneedlesSkin treatmentsBiochemical engineering

The invention discloses a soluble coaxial cone multi-layer microneedle. Its appearance is cone-shaped, and its internal structure includes a cone-shaped or cone-cylindrical central layer and one or more outer layers wrapped around the central layer. The central layer and the outer layer are both made of active drugs and / or structural materials, and the mass ratio of the active drugs and structural materials is 10:1 to 1:100. The multi-layer structure of the microneedle can be dissolved layer by layer during contact with body fluids in the skin, thereby achieving programmable control of the release time and amount of one or more drugs, and can be used locally on the skin. treatment or systemic administration.

Owner:SUN YAT SEN UNIV

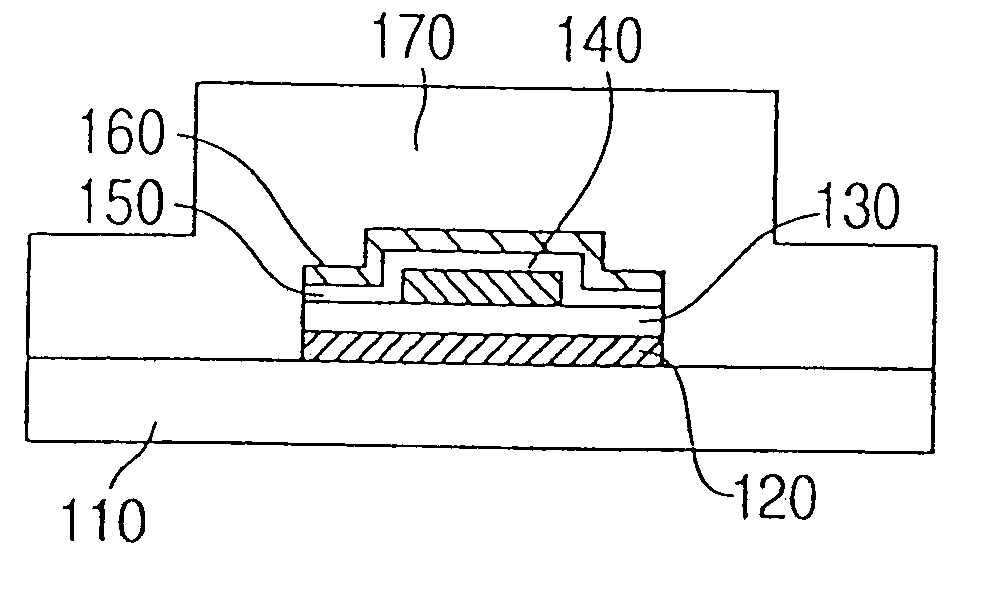

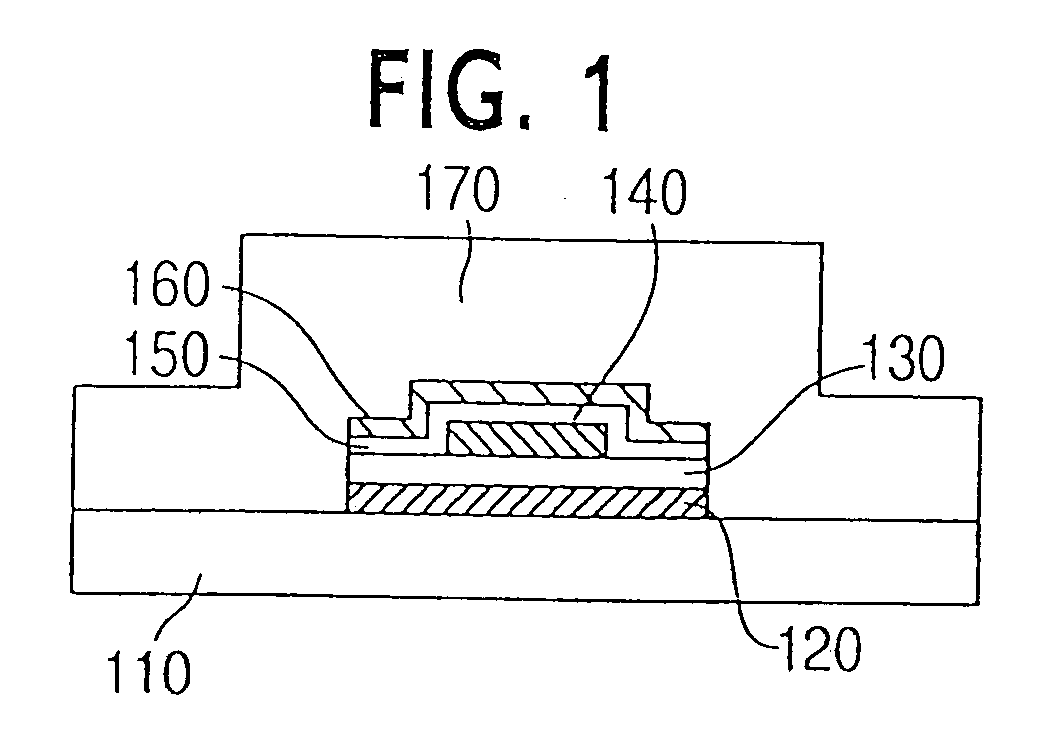

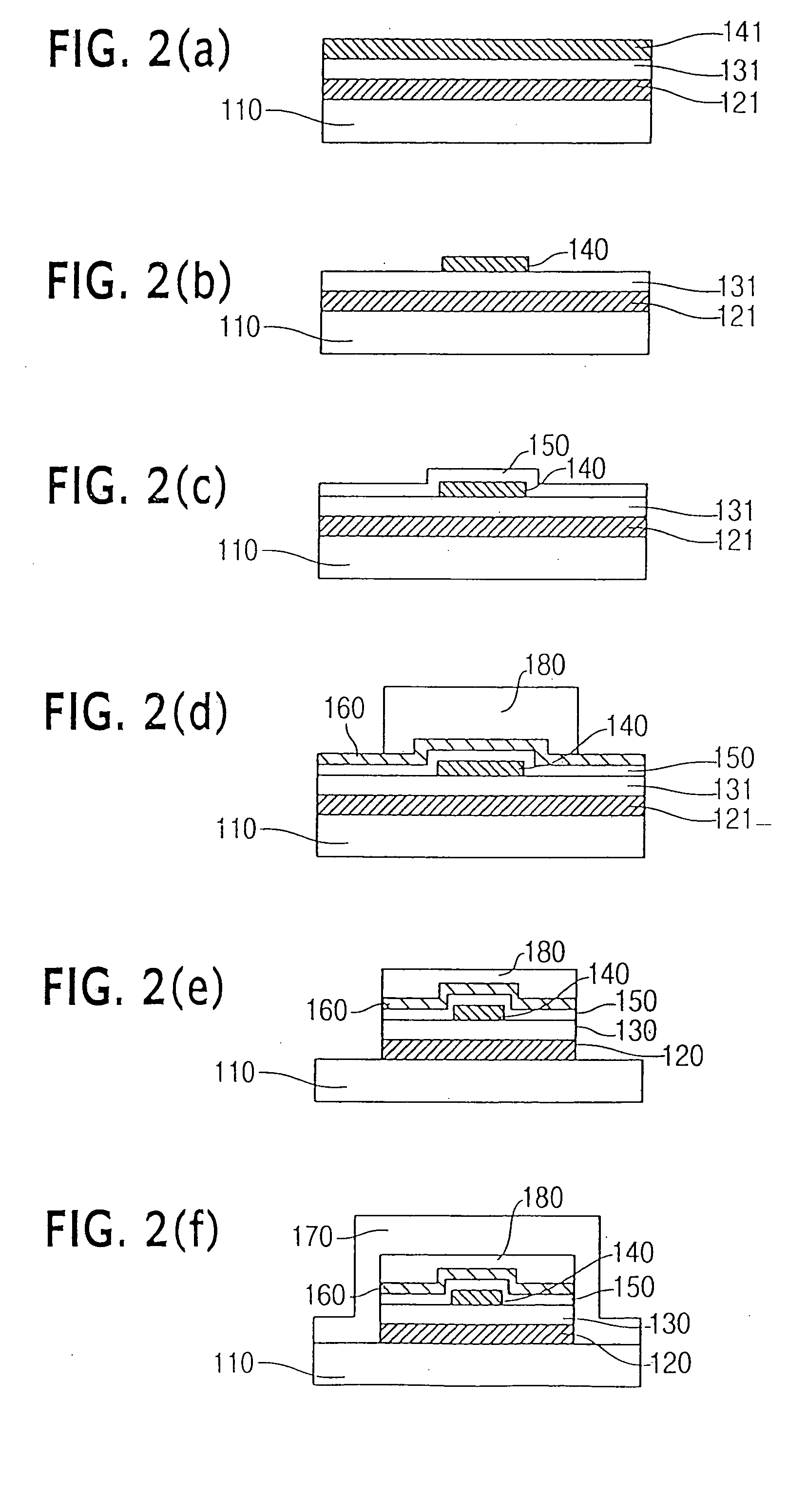

Semiconductor device and manufacturing method thereof

InactiveUS20050161724A1Highly reliable semiconductorInhibited DiffusionTransistorSolid-state devicesDevice materialEngineering

Owner:LAPIS SEMICON CO LTD

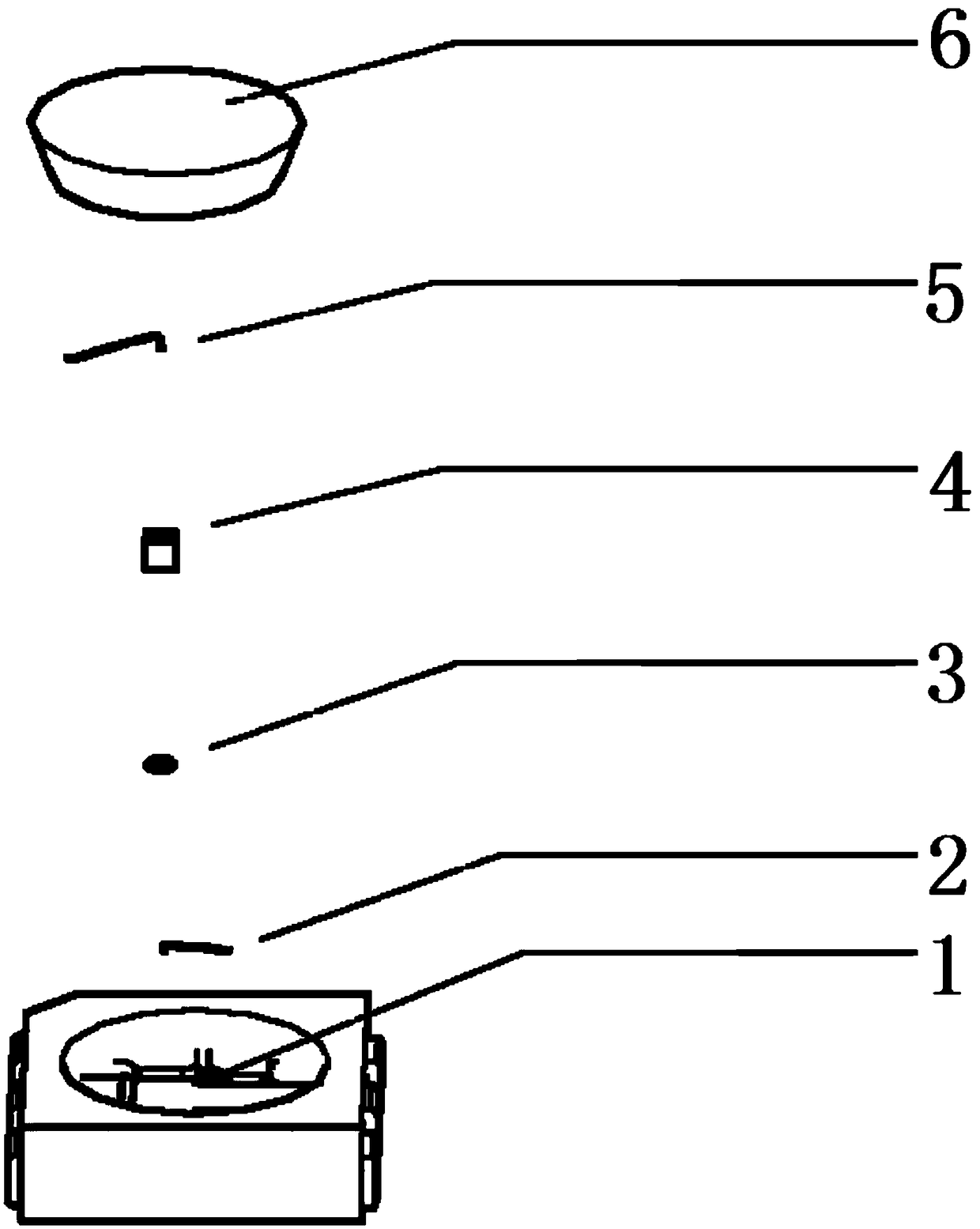

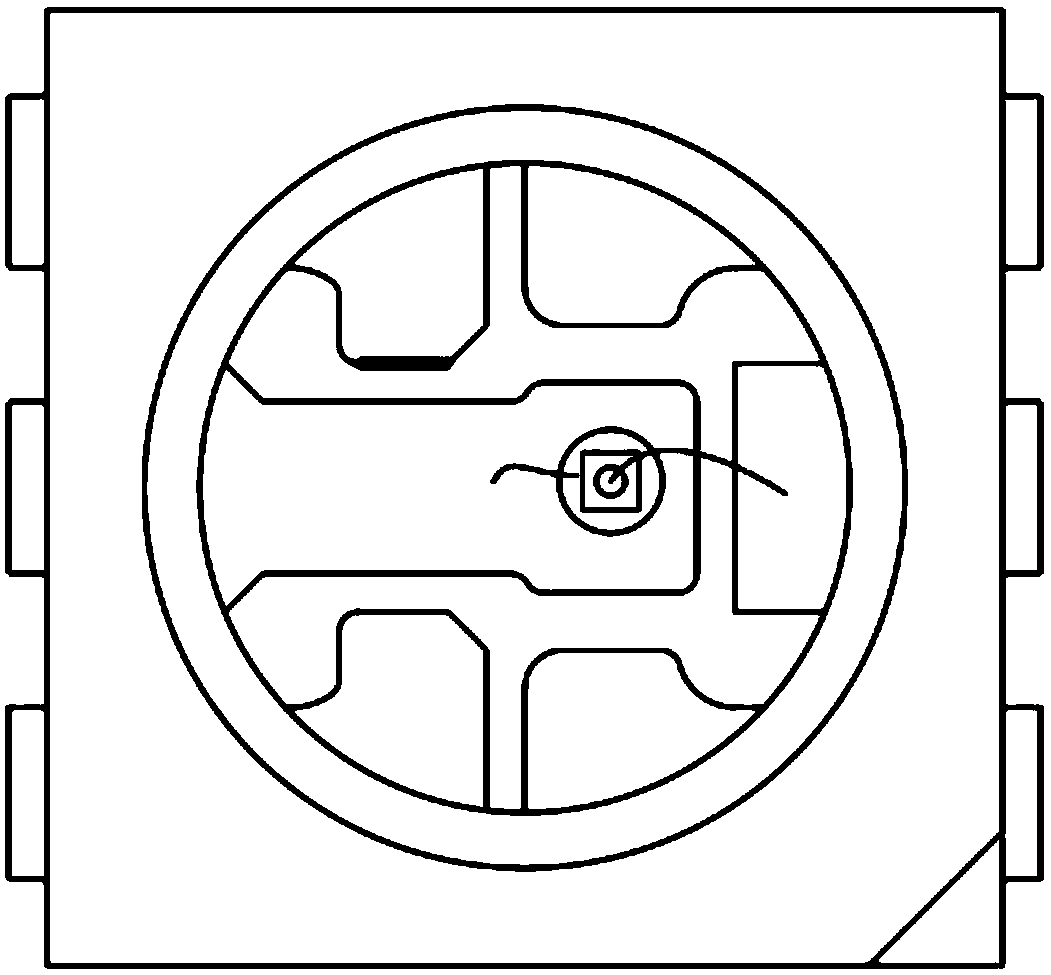

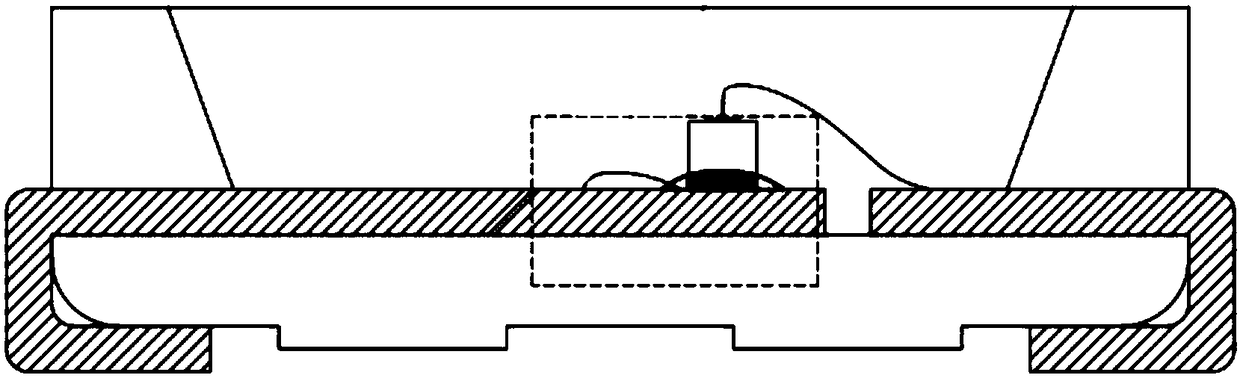

Structure for preventing LED conductive adhesive from loosening during soldering or use

The invention discloses a structure for preventing LED conductive adhesive from loosening during soldering or use and relates to the field of LED manufacturing. The structure is characterized by comprising a bracket bowl cup, a cup bottom wire, the conductive adhesive, an LED wafer, a wire and packaging adhesive. At present, for preventing a substrate in a silver layer from affecting use of an LEDdue to oxidation, many manufacturers increase the anti-silver oxidant on the silver layer on a surface of a solid crystal region plate through the existing electroplating technology, however, the anti-silver oxidant solidifies when the anti-silver oxidant does not completely volatilize before the LED is produced, which causes chemical substances in the conductive adhesive to react with the anti-silver oxidant, in the subsequent high-temperature process or daily use, a problem that the LED wafer can not continue to work due to the conductive adhesive loosening away from the solid crystal region plate occurs. For solving the problem, a medium capable of connecting the conductive adhesive and the solid crystal region plate and realizing conduction is added between the conductive adhesive andthe solid crystal region plate, even if the LED wafer is disengaged from the solid crystal region plate due to the lack of adhesion of the conductive adhesive, such a problem of an open dead lamp does not occur.

Owner:ZHONGSHAN JINGDE OPTOELECTRONICS

Ti-MAX-based open ceramic for TiAl-based alloy filtration and preparation method thereof

InactiveCN109354499ALow densitySmall expansion coefficientFiltration separationCeramicwareAlloySlurry

The invention relates to Ti-MAX-based open ceramic for TiAl-based alloy filtration and a preparation method thereof. The preparation method includes: mixing well Ti-MAX fine powder, carbon black finepowder, a carbon-containing binder, deionized water, polypropylene glycol, a polycarboxylate superplasticizer, polymethyl cellulose sodium and ammonia lignosulfonate to obtain slurry I; mixing well Ti-MAX fine powder, deionized water, polycarboxylate superplasticizer and polymethyl cellulose sodium to obtain slurry II; impregnating a polyurethane foam baseplate in the slurry I, taking out, extruding, curing, impregnating in the slurry II, curing, heating to 1100-1300 DEG C in a weak oxidation protective atmosphere, holding the temperature, heating to 1400-1600 DEG C, holding the temperature toattain Ti-MAX-based open ceramic for TiAl-based alloy filtration. The ceramic prepared herein has high bonding strength between an in-situ coating and a base, excellent thermal shock resistance and capability of effectively avoiding adverse influence of new inclusions due to hot stripping, and interaction can be effectively avoided in order to prevent TiAl-based alloy pollution.

Owner:WUHAN UNIV OF SCI & TECH

Method for extracting volatile oil by supercritically extracting pre-degreased great burdock achene and application

InactiveCN102002426BEfficient removalImprove qualityTobacco preparationTobacco treatmentBiotechnologyFragrance extraction

The invention discloses a method for extracting volatile oil by supercritically extracting pre-degreased great burdock achene and application, and belongs to spice extraction technology in the technical field of cigarettes. The method comprises the following steps of: pre-degreasing the great burdock achene; and then extracting the volatile oil by the supercritical extraction method. The prepared great burdock achene volatile oil is diluted into 1 percent by 95 percent ethanol and then the diluted great burdock achene volatile oil in an amount which is 0.01 to 0.05 percent based on the weight of cut tobacco is added into the cut tobacco. The product obtained by the method has high yield, contains a great number of aroma-enhancing materials required by the tobacco and does not contain materials which influence smoke flavor and quality of the tobacco. The method can improve the quality of the tobacco product when used for the tobacco.

Owner:HUBEI CHINA TOBACCO IND +1

Pesticide and preparation method thereof

InactiveCN109315442AStrong killing effectBroad spectrum of actionBiocideAnimal repellantsSide effectActive component

The invention relates to a pesticide and a preparation method thereof. According to the pesticide, cucurbit leaves, apricot leaves, halogeton arachnoideus and garlic root hairs are adopted as raw materials and subjected to proper weight ratio, thus the pest-killing functional components of all the raw materials interact and are synergistically enhanced, the pesticide has the significant killing effect on crop pests and has the broad-spectrum effect. According to the preparation method of the pesticide, by optimizing the preparation process, the extracting efficiency is significantly improved,and active components are better reserved. In addition, the pesticide is extracted from natural plants, environmental protection is achieved, the toxic and side effects on the human body are avoided,using is safer, and the preparation method is simple, the cost is low, and the pesticide is suitable for industrial production.

Owner:周翠秀

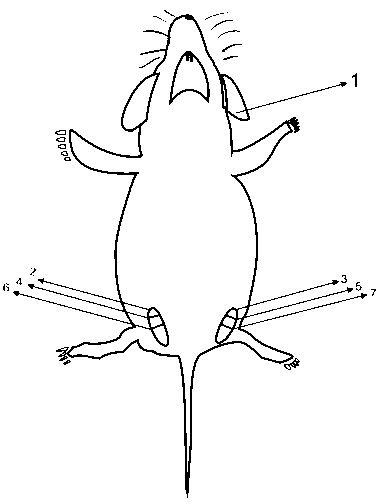

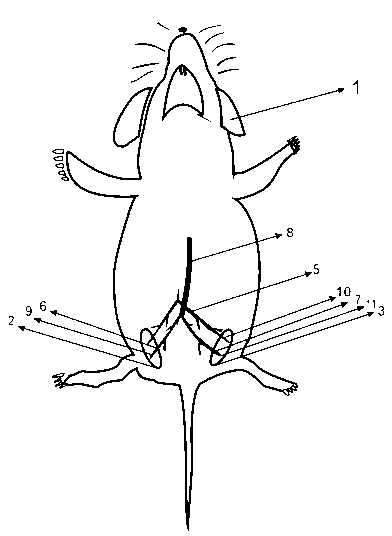

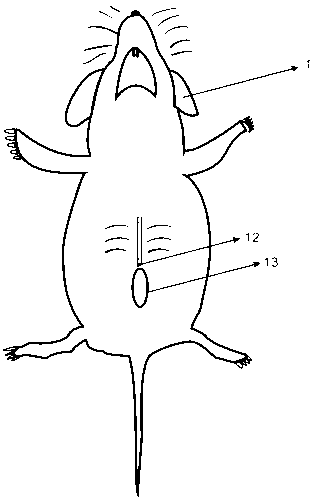

Construction method for rat model of increased abdominal pressure

InactiveCN102697574AEasy to makeEasy accessDrug compositionsAnhydride/acid/halide active ingredientsDiseaseTreatment effect

The invention relates to a construction method of animal models, which comprises the following steps of: 1, preparing an experimental animal; 2, carrying out anesthesia and incision; 3, carrying out intubation and connecting with an infusion and detection device; 4, making narrow portal vein backbone constant; 5, sewing up the incision and putting an abdominal binding belt; 6, exsanguinating and decompressing till shock; 7, recovering after shock; and 8, constructing a model successfully. The invention includes a series of correlative factors of abdominal hypertension occurrence and development, such as hemorrhagic shock, fluid resuscitation in quantity, and damage control operation, which are in accord with the course of disease in the clinical practice, provides a stable and reliable construction method which accords with the clinical practice for studying the abdominal hypertension, and thus the experimental study data obtained by using the method is more objective and accurate; the construction method can be widely used for studying the pathogenesis of the abdominal hypertension, the physiopathologic change of the body, the treatment effectiveness evaluation and the like.

Owner:常明涛 +1

Formula and process of magnetic dot membrane cloth for promoting skin microcirculation and skin care component absorption

InactiveCN111001088APromote blood circulationPromotes nutrient absorptionCosmetic preparationsElectrotherapyAdhesiveAbsorption (skin)

The invention discloses a formula and a process of magnetic dot membrane cloth for promoting skin microcirculation and skin care component absorption. The formula comprises the following components inpercentage by mass: 10-50% of ferrite magnetic powder, 2-20% of negative ion powder, 10-50% of far infrared powder and 20-60% of an adhesive. The process comprises following steps: adding 20% of ferrite magnetic powder, 10% of negative ion powder and 20% of far infrared powder into tencel spunlace fabric through a plastic dropping process, dropping a high polymer material onto an obtained fabric,and drying at the temperature of 300 DEG C or lower to form a surface film layer. The invention has the following beneficial effects: 1, end circulation of human blood is facilitated, and nutrient absorption of skin is promoted; 2, moisture is effectively prevented from entering magnetic points, and mutual reaction between the magnetic points is avoided; 3, the magnetic powder, the negative ion powder and the far infrared powder are adopted, and can be tested by professional instruments.

Owner:广州悦荟化妆品有限公司

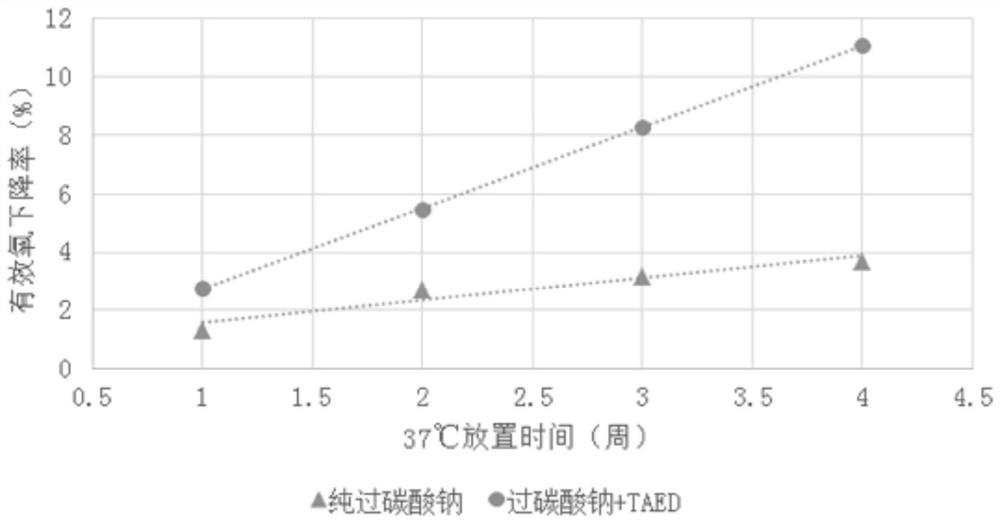

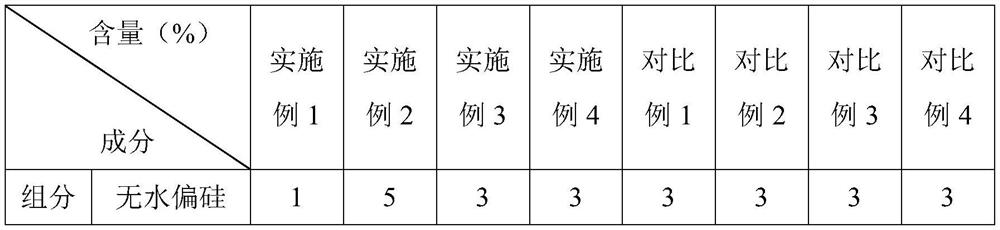

Stable and efficient machine dishwashing agent

ActiveCN114686319AHas alkali resistanceAvoid reciprocal reactionsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateActive agent

The invention relates to a stable and efficient machine dishwashing agent, and relates to the technical field of detergents. According to the stable and efficient machine dishwashing agent, a polyethylene-vinyl alcohol water-soluble film serves as a carrier, and a cavity A, a cavity B and a cavity C are formed in the carrier; the component A in the cavity comprises the following components in percentage by mass: 1%-5% of anhydrous sodium metasilicate, 15%-30% of sodium percarbonate and the balance of sodium carbonate; the component B in the cavity comprises 10%-20% of tetraacetyl ethylenediamine, 5%-10% of ethylenediamine tetraacetic acid, 5%-10% of a dispersing agent and the balance of citric acid; the component C in the cavity comprises 3%-6% of propylene glycol, 1%-3% of water, 2%-5% of an enzyme preparation and the balance of a surfactant; the mass ratio of the component A to the component B to the component C is 10: (2-5): (1-4). According to the stable and efficient machine-used dishwashing agent, the water-soluble film is used as a carrier to coat all the components in a cavity manner, so that forming auxiliaries are reduced; the components are prevented from reacting with one another, the shelf life is prolonged, the washing performance of the product is improved, and good washing and sterilizing effects can be achieved with a small dosage.

Owner:WALCH GUANGZHOU COMMODITY

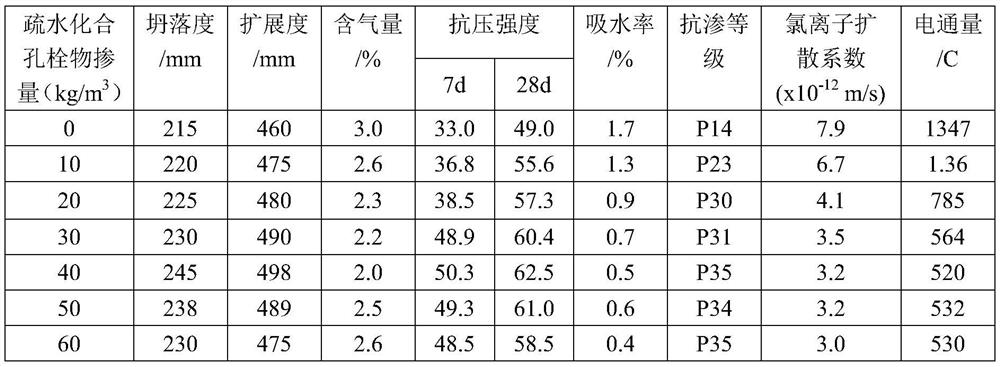

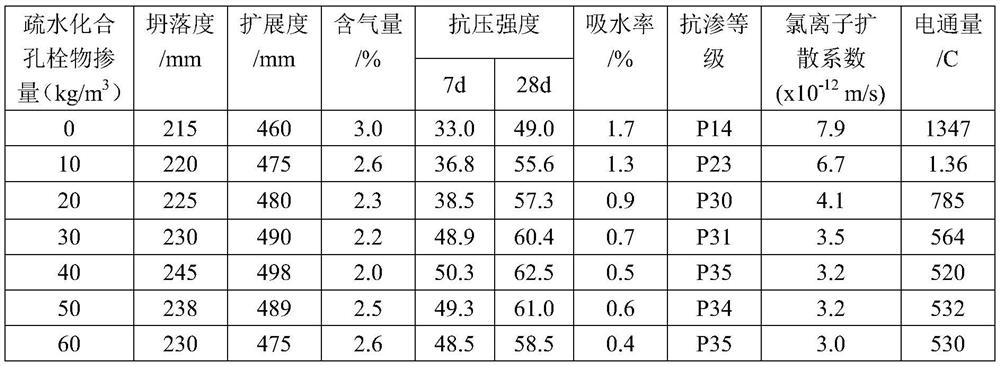

A kind of preparation method of hydrophobic pore plug for composite biografted concrete

ActiveCN112408852BGood acid and alkali resistanceGood solvent performanceOrganic chemistryMaterials science

The invention relates to the technical field of building admixtures, more specifically, to a method for preparing a composite biografted concrete hydrophobic pore plug. After adding alkylene polyoxyethylene ether into hydrogen peroxide and continuously stirring for 5 minutes, the liquid A , B solution and C solution are added dropwise for 2 hours, 2.5 hours and 1.5 hours respectively; the product has a very high degree of purification during the compounding process, and has good anti-corrosion, anti-acid and anti-alkali effects in use. After a certain proportion After being added to concrete, it can well replace traditional hydrophobic compounds, and the synthesis process is relatively simple, which is easy for industrial production.

Owner:山西科腾环保新材料股份有限公司

A kind of preparation method of superfine active β gypsum micropowder material

The invention discloses a preparation method of an ultrafine active beta gypsum micro-powder material and belongs to the technical filed of inorganic materials. Natural gypsum and industrial byproduct gypsum are taken as raw materials, a stabilizer is added in a grinding process, and ultrafine active gypsum micro-powder is prepared. The problem of lack of natural gypsum resources at present is solved through comprehensive use of waste residues such as the industrial byproduct gypsum, the sieving rate of the gypsum micro-powder material prepared with the method is 90% or higher, the breaking strength of the prepared micro-powder material dried for 2 h or longer is 2 MPa or higher, and the gypsum micro-powder material has high strength and good activity in the aspect of product performance and is applied more widely.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Preparation method of hydrophobic pore suppository for composite biological grafted concrete

ActiveCN112408852AGood acid and alkali resistanceGood solvent performanceMaterials sciencePOLYOXYETHYLENE ETHER

The invention relates to the technical field of building admixtures, in particular to a preparation method of a hydrophobic pore suppository for composite biological grafted concrete. The preparationmethod comprises the following steps: adding hydrogen peroxide into alkylene alkenyl polyoxyethylene ether, continuously stirring for 5 minutes, and dropwise adding a solution A, a solution B and a solution C for 2 hours, 2.5 hours and 1.5 hours respectively. The product is very high in purification degree in the compounding process, has very good corrosion resistance, acid resistance and alkali resistance in use, can well replace a traditional hydrophobic compound after being added into concrete according to a certain proportion, and is relatively simple in synthesis process and easy for industrial production.

Owner:山西科腾环保新材料股份有限公司

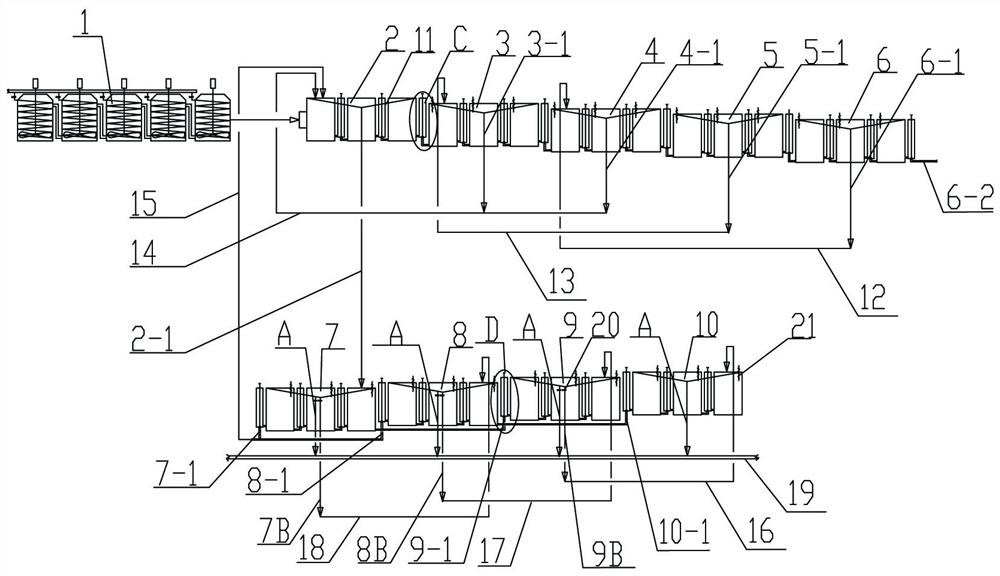

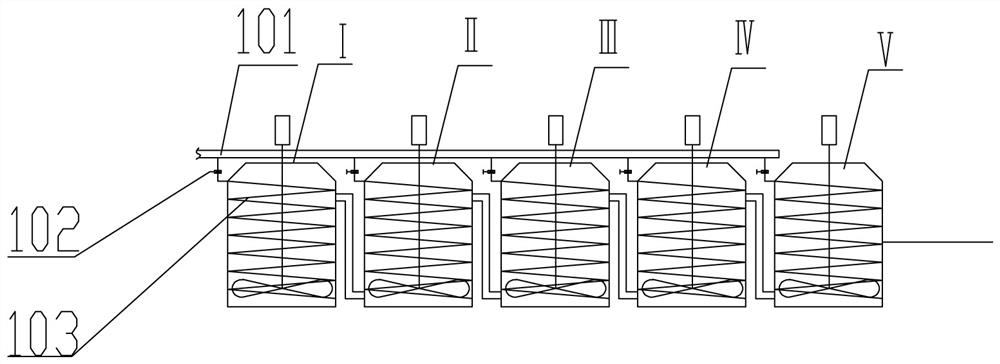

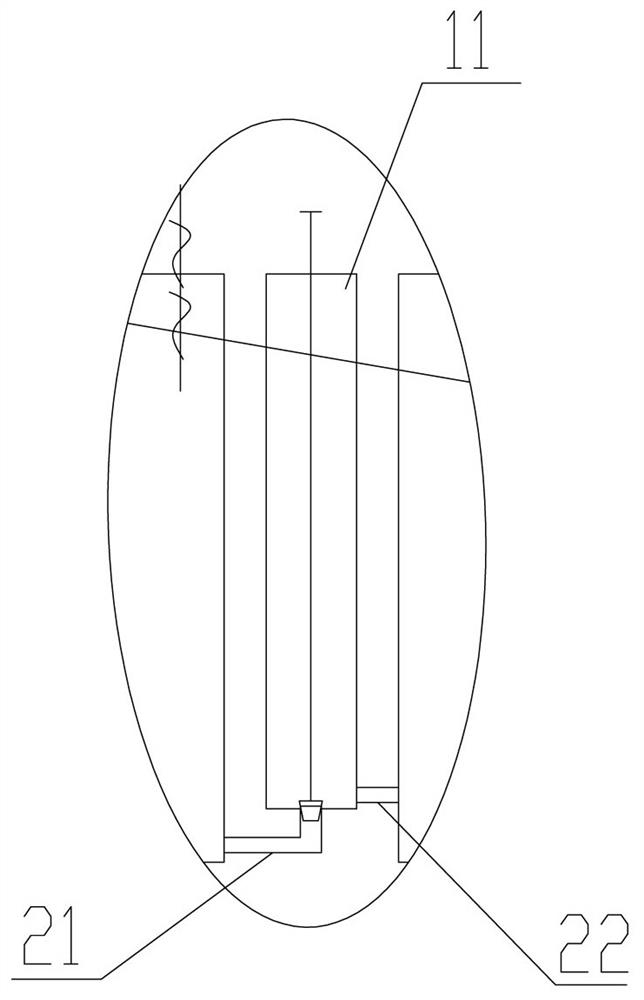

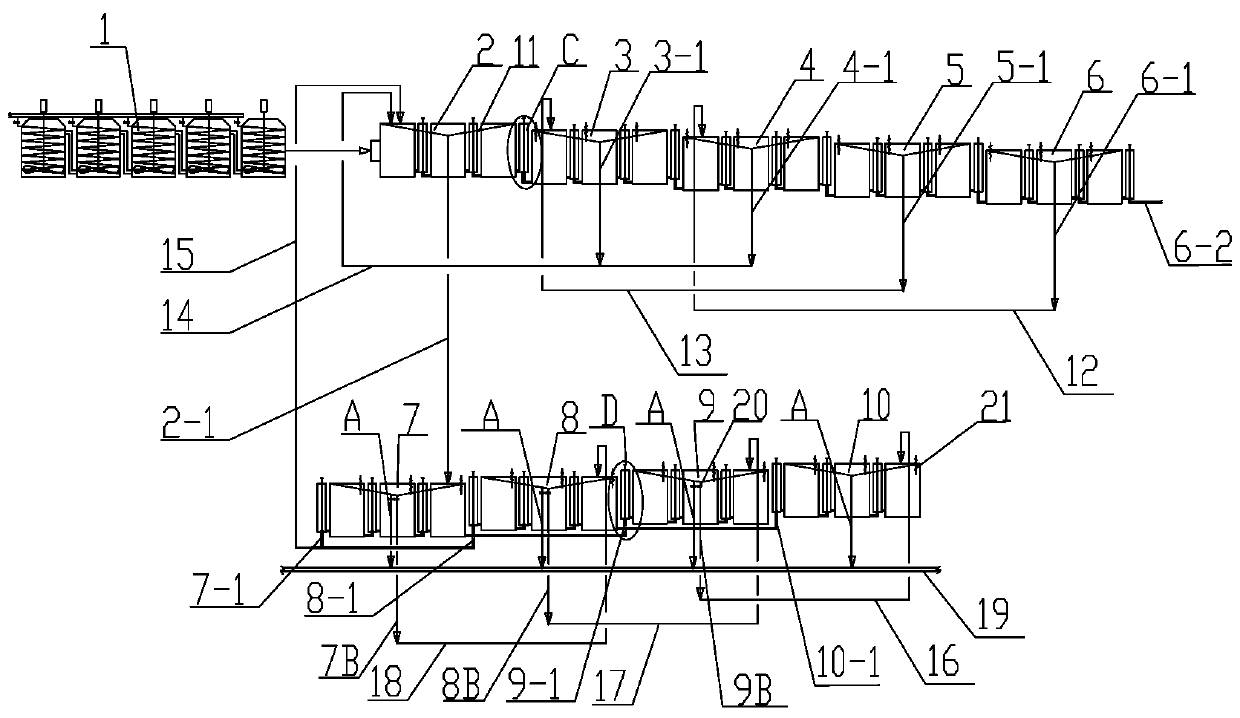

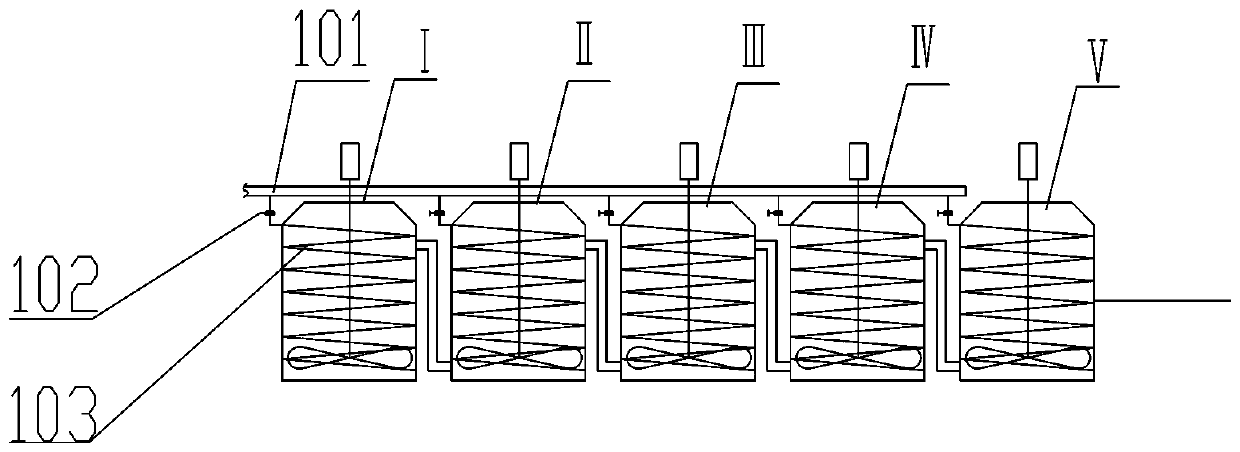

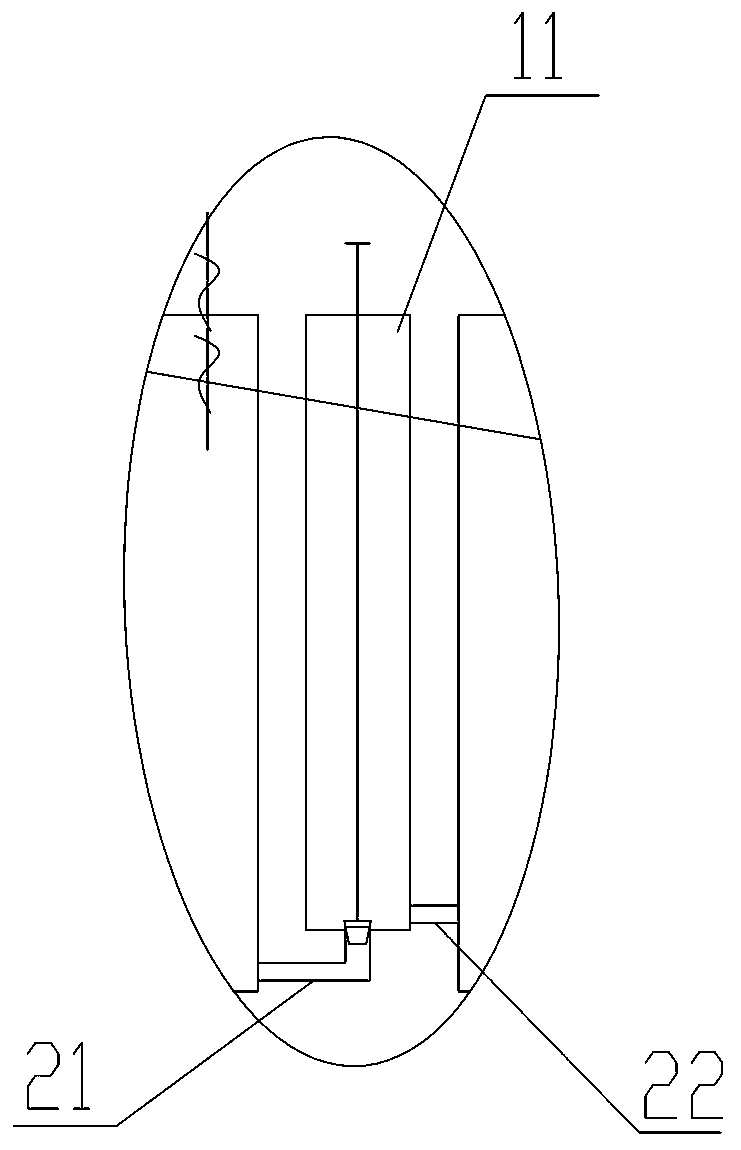

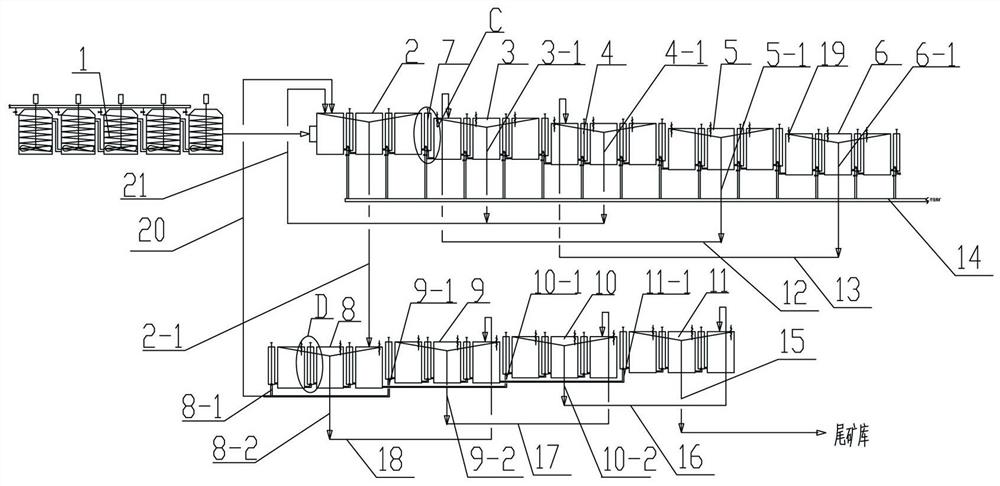

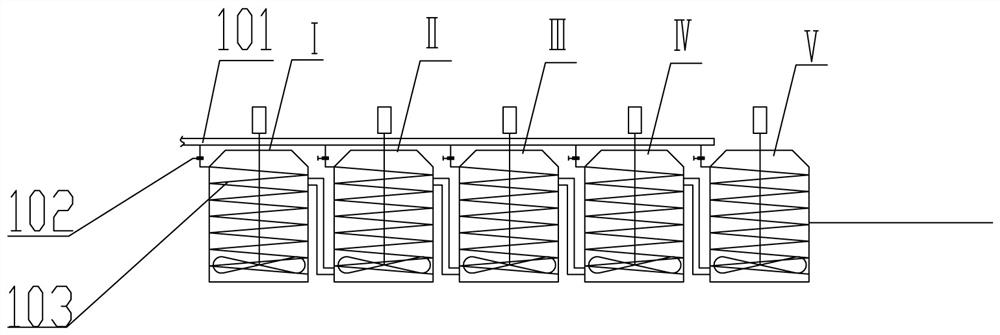

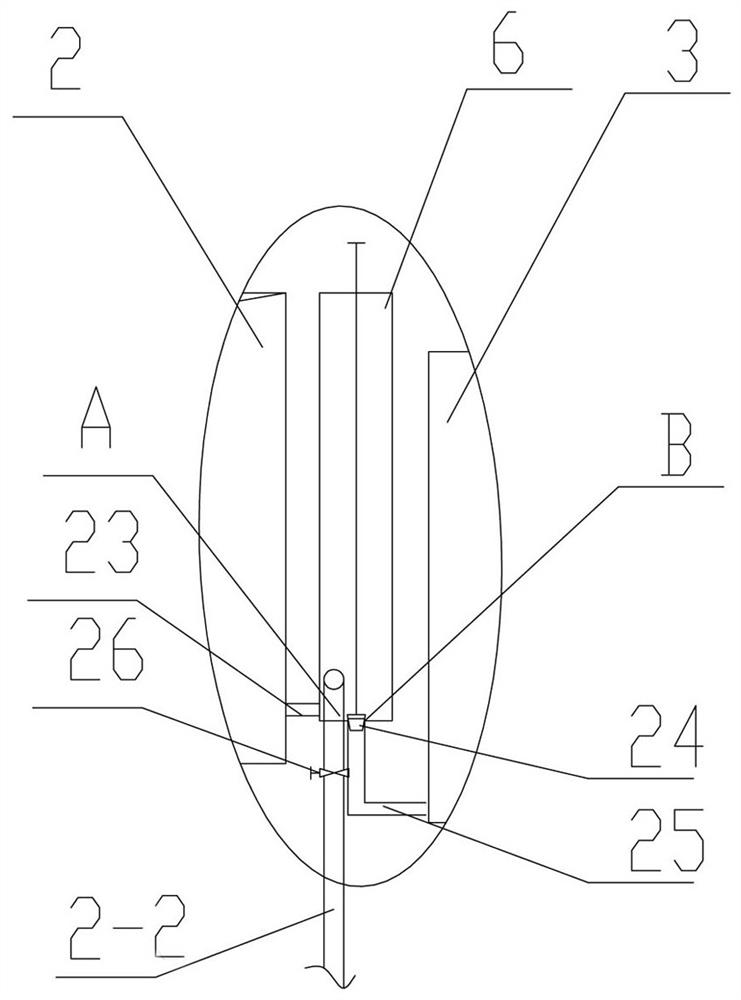

A positive flotation system with adjustable energy-saving iron ore concentrate product index

ActiveCN108672105BAvoid reciprocal reactionsGuarantee normal performanceFlotationMining engineeringProcess engineering

The invention relates to an energy-saving type index-adjustable direct flotation system for iron ore concentrate products. A flotation chemical agent stirring system, a rough flotation operation system, a sweeping flotation operation system and a fine flotation operation system are included; five sequentially connected flotation chemical agent stirring grooves are adopted for the flotation chemical agent stirring system; the rough flotation operation system is composed of a segment of rough flotation operation groove; the sweeping flotation operation system is composed of four segments of continuous fine flotation operation grooves communicating with one another; the fine flotation operation system is also composed of four segments of continuous fine flotation operation grooves communicating with one another; and the lower portions of the fine flotation operation grooves are provided with an ore concentrate bypass main pipeline. According to the energy-saving type index-adjustable direct flotation system for the iron ore concentrate products, by closing a gate plate valve on any segment of fine flotation ore concentrate discharging pipe A in fine flotation operation and opening a gate plate valve of a discharging port of the ore concentrate bypass main pipeline, subsequent fine flotation operation of the segment of flotation operation can be cut off, and therefore the ore concentrate grade of flotation products and the recycling rate are adjusted, flotation operation adjustable in ore grade is achieved, and different market requirements are met.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

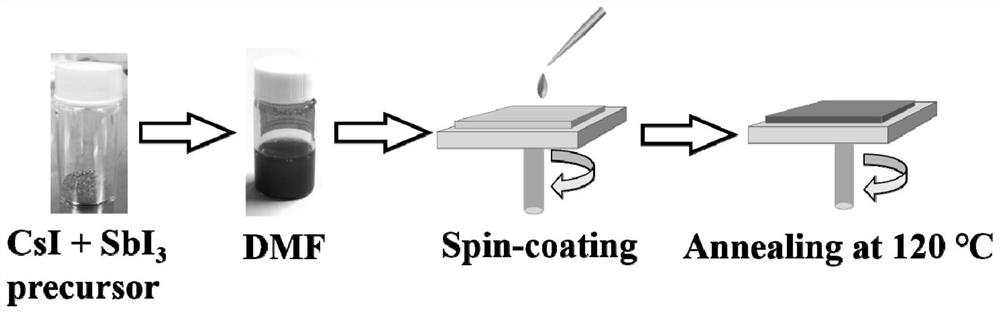

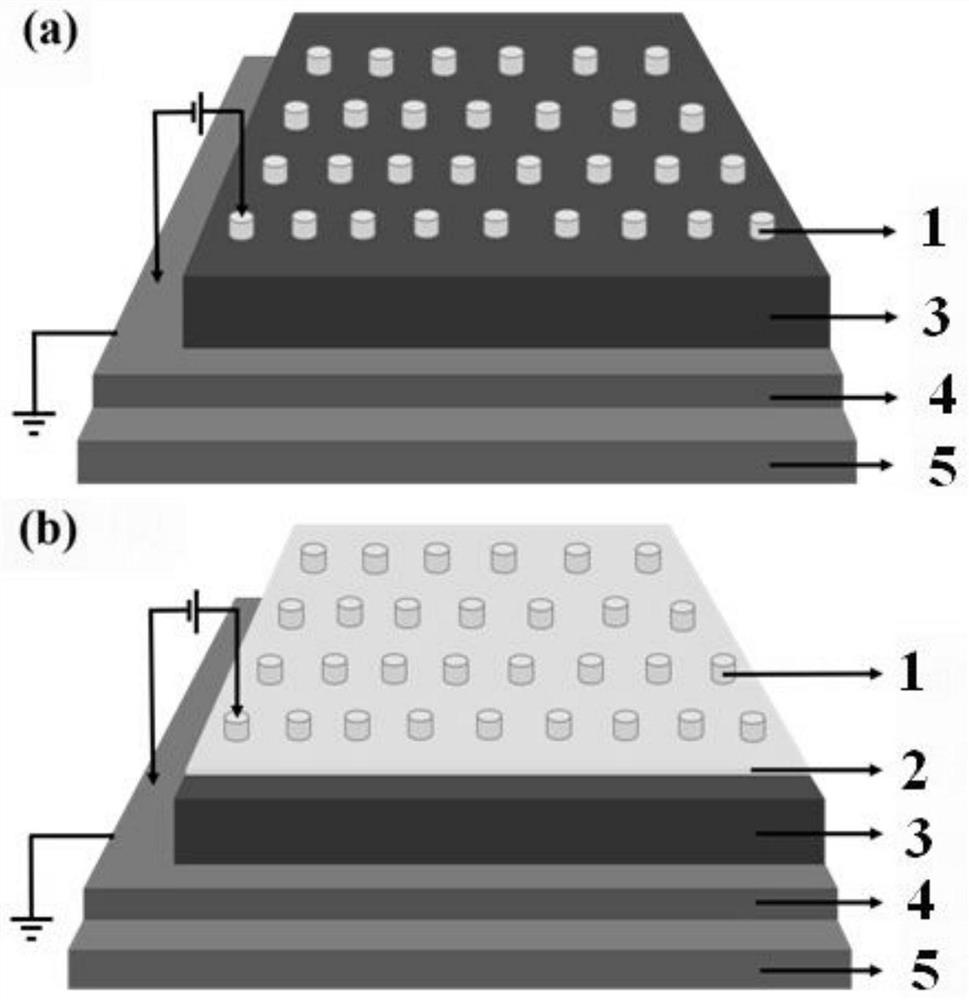

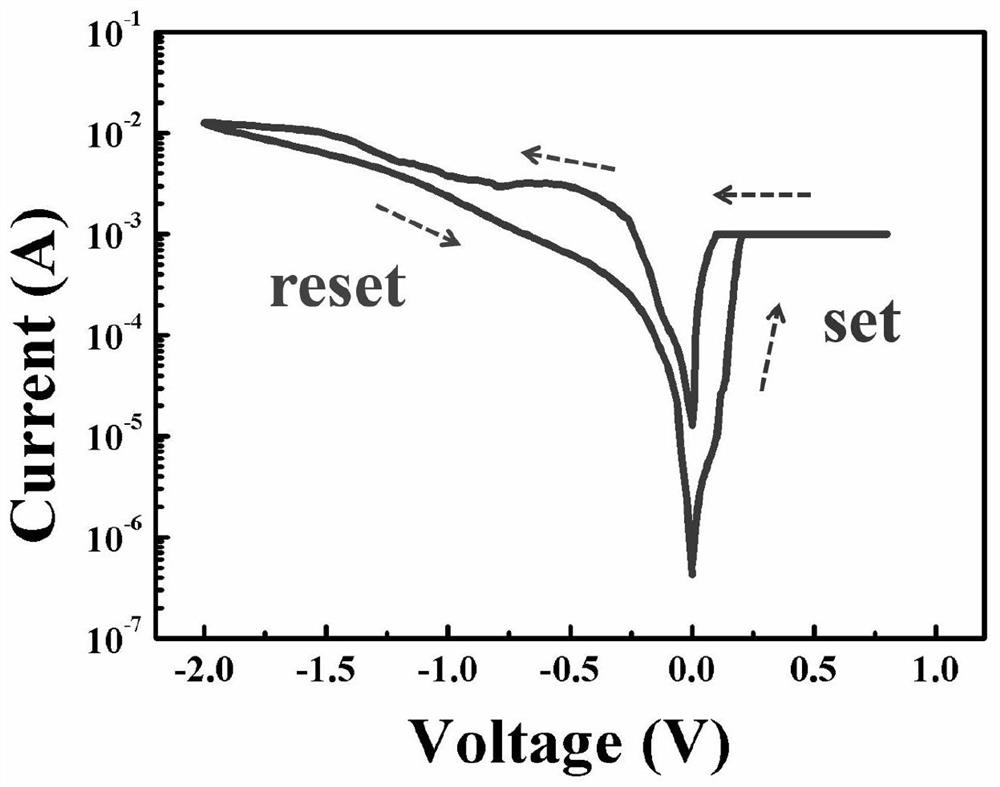

Resistive random access memory based on lead-free cesium antimony iodine perovskite and preparation method thereof

PendingCN113948639AImprove stabilityImprove reliabilityElectrical apparatusPerovskite (structure)Physical chemistry

The invention relates to a resistive random access memory based on lead-free cesium antimony iodine perovskite and a preparation method thereof, and belongs to the technical field of perovskite resistive random access memories. According to the resistive random access memory based on the lead-free cesium antimony iodine perovskite and the preparation method of the resistive random access memory, the process is simple, and lead is replaced by antimony in the perovskite resistive random access layer, so that the preparation process of a device is green, environment-friendly and low in toxicity; and meanwhile, the prepared lead-free cesium antimony iodine perovskite resistive random access memory is simple in structure, is a nonvolatile memory, has good storage durability, relatively long data retention, excellent stability and repeatability, is low in erasing voltage, and can realize data storage in a low power consumption state. Various defects in the prior art are effectively overcome, and high industrial utilization value is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

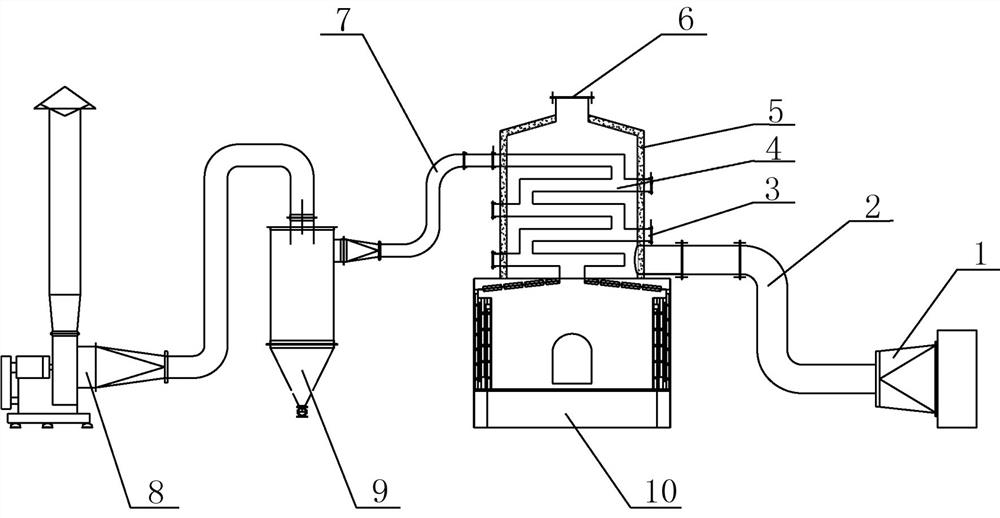

Fertilizer production process hot air supply system using waste heat of flue gas

ActiveCN106403280BEasy to cleanSave energyAir heatersExothermal chemical reactions for heatingAir filterFlue gas

The present invention is a hot air supply system for fertilizer production process utilizing waste heat of flue gas, which includes a heat exchange tower with a normal temperature air inlet and a hot air outlet, the normal temperature air inlet is connected with an air filter; the heat exchange tower is equipped with A heat exchanger, the inlet end of the heat exchanger communicates with the smoke outlet of the boiler, the outlet end is connected with a dust collector, and the smoke outlet end of the dust collector is connected with an induced draft fan. This system makes full use of the heat energy of the high-temperature flue gas produced by boiler combustion, and transfers the heat energy to the air through heat exchange. The hot air is used for drying and heating of the fertilizer production process. It has the outstanding effects of saving energy and reducing production costs.

Owner:WUZHOUFENG AGRI SCI & TECH

Energy-saving type index-adjustable direct flotation system for iron ore concentrate products

ActiveCN108672105AAvoid reciprocal reactionsGuarantee normal performanceFlotationEngineeringChemical agent

The invention relates to an energy-saving type index-adjustable direct flotation system for iron ore concentrate products. A flotation chemical agent stirring system, a rough flotation operation system, a sweeping flotation operation system and a fine flotation operation system are included; five sequentially connected flotation chemical agent stirring grooves are adopted for the flotation chemical agent stirring system; the rough flotation operation system is composed of a segment of rough flotation operation groove; the sweeping flotation operation system is composed of four segments of continuous fine flotation operation grooves communicating with one another; the fine flotation operation system is also composed of four segments of continuous fine flotation operation grooves communicating with one another; and the lower portions of the fine flotation operation grooves are provided with an ore concentrate bypass main pipeline. According to the energy-saving type index-adjustable direct flotation system for the iron ore concentrate products, by closing a gate plate valve on any segment of fine flotation ore concentrate discharging pipe A in fine flotation operation and opening a gate plate valve of a discharging port of the ore concentrate bypass main pipeline, subsequent fine flotation operation of the segment of flotation operation can be cut off, and therefore the ore concentrate grade of flotation products and the recycling rate are adjusted, flotation operation adjustable in ore grade is achieved, and different market requirements are met.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Method for extracting volatile oil from geotrichum candidum through fermentation of burdock by utilizing supercritical extraction method and application

InactiveCN102002428BIncrease the sour aroma of cigarette agingLess irritatingTobacco preparationTobacco treatmentOrganic acidFlavor

Owner:HUBEI CHINA TOBACCO IND +1

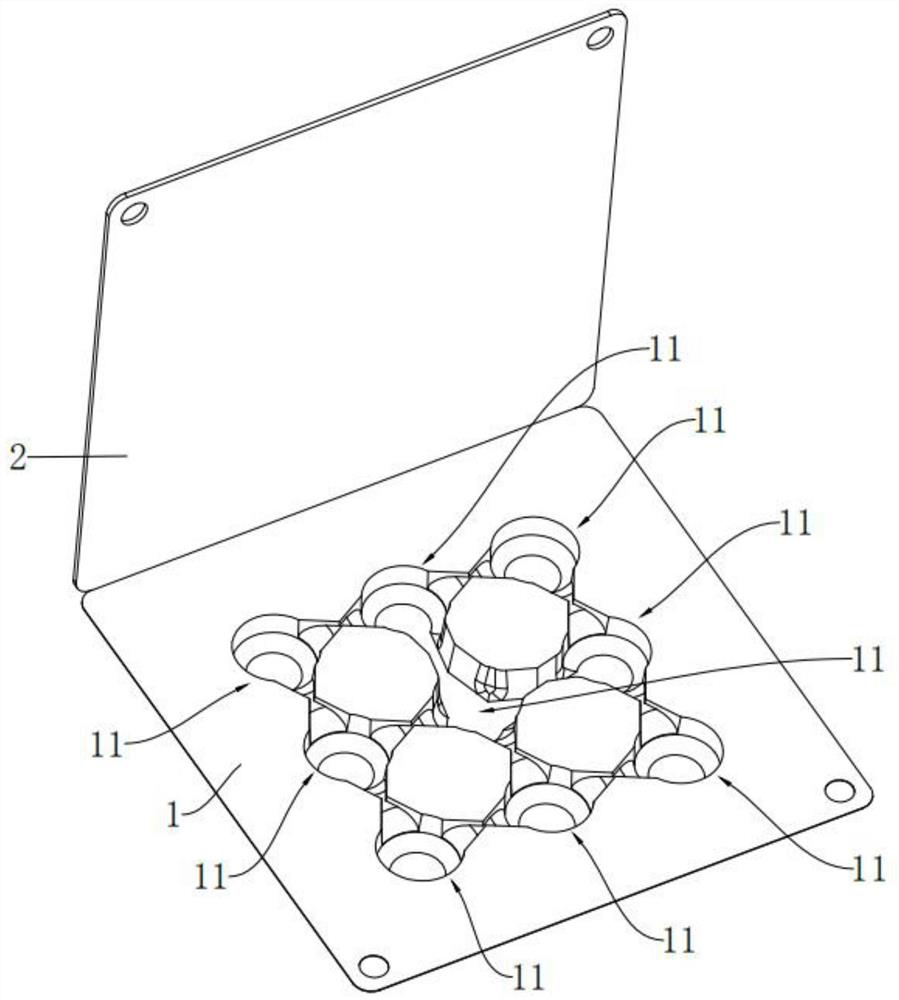

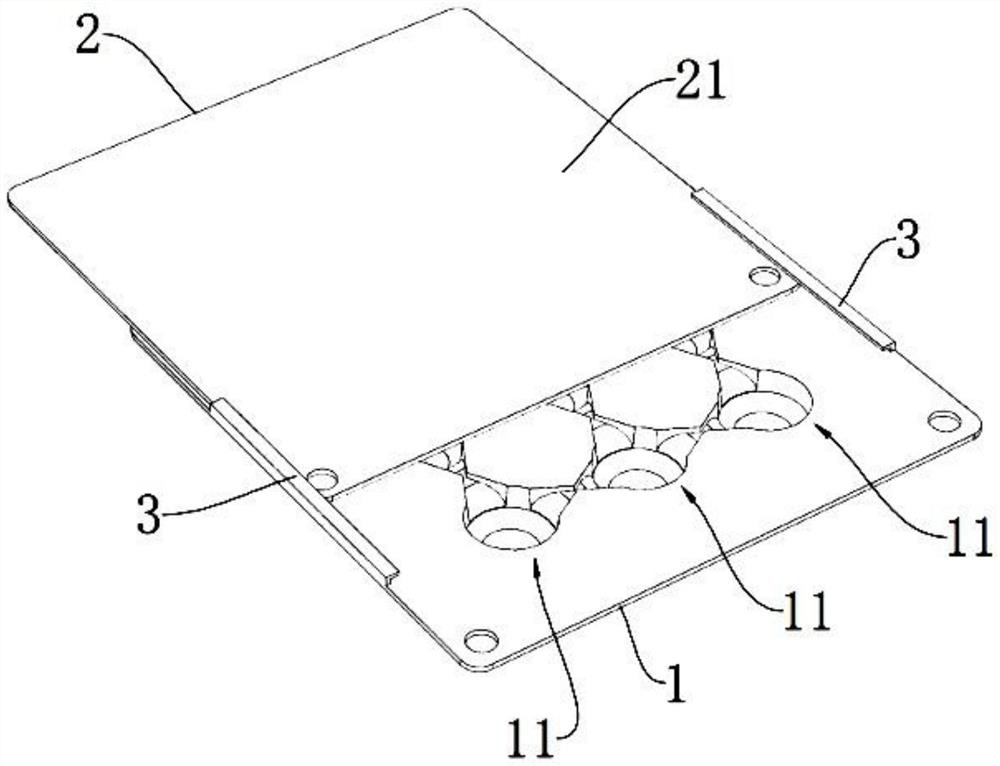

Magnetic digital microfluidic chip and loading structure thereof

ActiveCN112934279AImprove protectionImprove storage effectLaboratory glasswaresFluid controllersMechanical engineeringMicro fluidic

The invention discloses a magnetic digital microfluid chip, which relates to the field of magnetic digital microfluid and comprises a chip bottom plate and a chip cover plate, a plurality of liquid drop chambers with openings in the upper parts are arranged on the chip bottom plate; a magnetic flow channel for communicating two adjacent liquid drop chambers can be arranged between every two adjacent liquid drop chambers; the liquid drop chamber comprises a chamber bottom and a chamber wall which is obliquely or vertically arranged on the periphery of the chamber bottom and used for limiting flowing of liquid drops; the chip cover plate is used for covering the upper openings of the plurality of liquid drop chambers; an area of the cover plate part above the droplet chamber can be opened so as to add liquid; the upper end face, back on to the chip bottom plate, of the chip cover plate is a binding face where the magnet moves. The invention also discloses a loading structure of the magnetic digital microfluidic chip. The technical problems that existing liquid drops containing magnetic digital microfluid are prone to evaporation and pollution, the liquid drops are inconvenient to transfer or mix with other liquid drops, magnetic particles and the liquid drops are inconvenient to separate, and usability is poor are solved.

Owner:CHINA-SINGAPORE INT JOINT RES INST

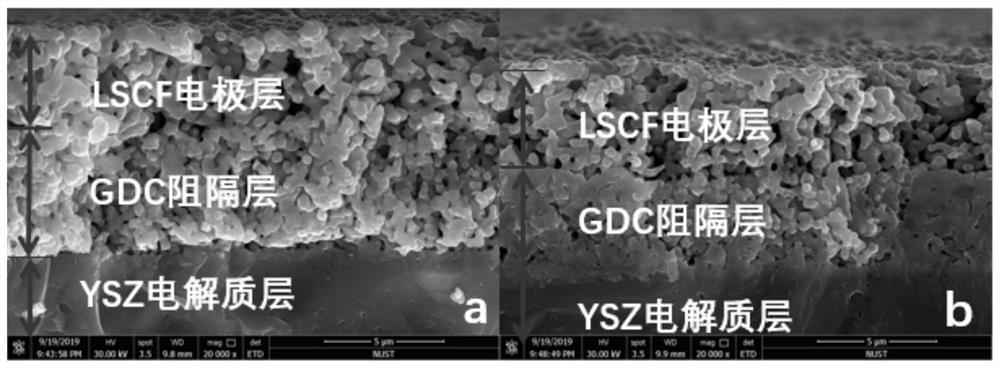

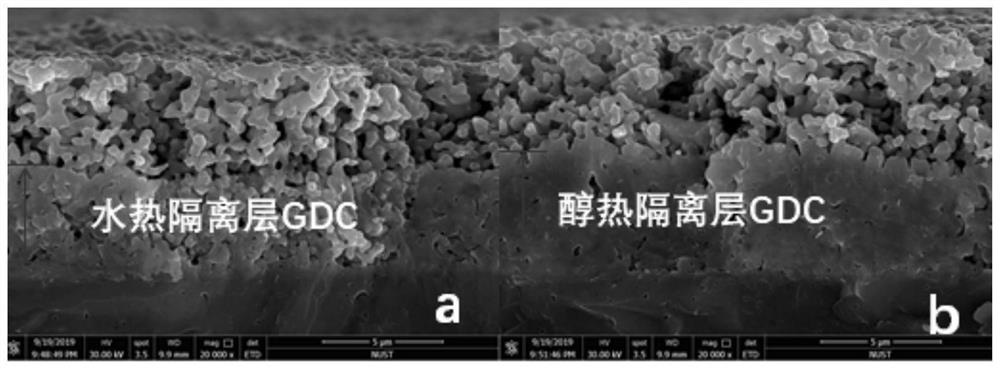

A kind of method for densification of barrier layer of solid oxide battery

ActiveCN111574244BLower densification calcination temperatureAvoid reciprocal reactionsCell electrodesFuel cellsFuel cellsElectrical battery

The invention discloses a method for densifying the barrier layer of a solid oxide battery. The commonly used electrolyte material for a solid oxide battery is YSZ (8%molY 2 o 3 Stabilized ZrO 2 , the chemical formula is: Zr 0.84 Y 0.16 o 2‑x ), YSZ has poor chemical compatibility with many highly active cathode and anode perovskite materials, and is prone to reactions during high-temperature preparation and long-term operation. Cerium oxide-based electrolyte materials mostly form a double electrolyte layer with electrolytes such as YSZ, or serve as an isolation layer to prevent the reaction between electrode materials and electrolytes during high-temperature preparation and long-term operation. The dense GDC isolation layer can effectively reduce the ohmic impedance of the fuel cell and improve the electrical conductivity and catalytic performance of the cell. Ge(NO 3 ) 3 ·6H 2 O and Ce(NO 3 ) 3 ·6H 2 O in a molar ratio of 0.1:0.9 (Ce 0.9 Gd 0.1 o 2‑m ) into a hydrothermal solution, and the battery screen-printed on the GDC barrier layer was reacted at 180° C. for 24 hours by a hydrothermal method, and then a complete battery was prepared. The resulting batteries have higher electrical conductivity and catalytic activity as well as lower ohmic resistance.

Owner:NANJING UNIV OF SCI & TECH

A reverse flotation system with adjustable iron concentrate grade

ActiveCN108672104BAvoid reciprocal reactionsGuarantee normal performanceFlotationProcess engineeringReverse flotation

The invention relates to a reverse flotation system with adjustable iron concentrate grade. The system comprises a flotation reagent stirring system, a roughing flotation work system, a fine flotationwork system and a sweeping flotation work system and is characterized in that the flotation reagent stirring system adopts five flotation reagent stirring tanks which are connected in sequence, the roughing flotation work system is composed of a segment of roughing flotation work tank, the fine flotation work system is composed of continuous four segments of fine flotation work tanks which communicate, the sweeping flotation work system is composed of continuous four segments of sweeping flotation work tanks which communicate, and concentrate bypass main pipelines are arranged on the lower portions of the roughing flotation work tank and the fine flotation work tanks. A rubber plug valve of any section flotation tank in the reverse flotation system is closed, a passage of flowing of flotation underflow ore pulp to the subsequent flotation tanks can be cut off, the flotation and selection time can be shortened, the aim of selecting iron concentrates of different grades can be achieved,and the flotation work of multi-product schemes can be achieved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

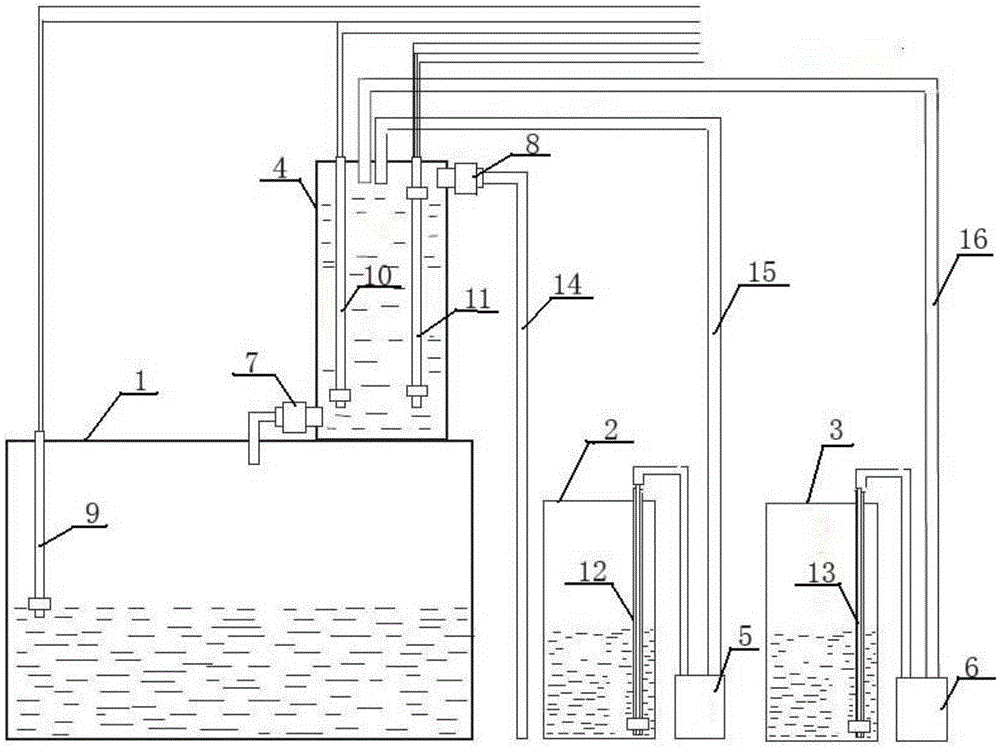

Alcohol-free fountain solution distributing device and operating method thereof

InactiveCN105644130AAvoid reciprocal reactionsGood printabilityRotary lithographic machinesAlcohol freeAgricultural engineering

The invention discloses an alcohol-free fountain solution distributing device. The alcohol-free fountain solution distributing device comprises a water tank, a fountain solution barrel, a fountain solution supplementing and distributing barrel and a water supplementing barrel, wherein a first float switch is mounted in the water tank; the water tank is connected with the water supplementing barrel through a water outlet device; a second float switch and a third float switch are mounted in the water supplementing barrel; a first pipe is mounted outside the water supplementing barrel; the water supplementing barrel is connected with the fountain solution barrel through a second pipe; a first metering device is mounted on the second pipe; the water supplementing barrel is connected with the fountain solution supplementing and distributing barrel through a third pipe; and a second metering device is mounted on the third pipe. By the device and the method, different addition proportions of a fountain solution and supplementing solution of the fountain solution in water every time can be adjusted, the error of a metering pump is 1-2%, proportion stability of the fountain solution and the supplementing solution of the fountain solution in the water tank can be ensured, and on the basis of not using alcohol, printed products are high in latitude and small in dot gain, have rich gradation, and are bright in color.

Owner:陈崇元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com