Structure for preventing LED conductive adhesive from loosening during soldering or use

A conductive adhesive and loosening technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as the lack of adhesive force of conductive adhesives and the inability of LED chips to continue to work, so as to reduce the number of rework of finished products and solve the effect of unqualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

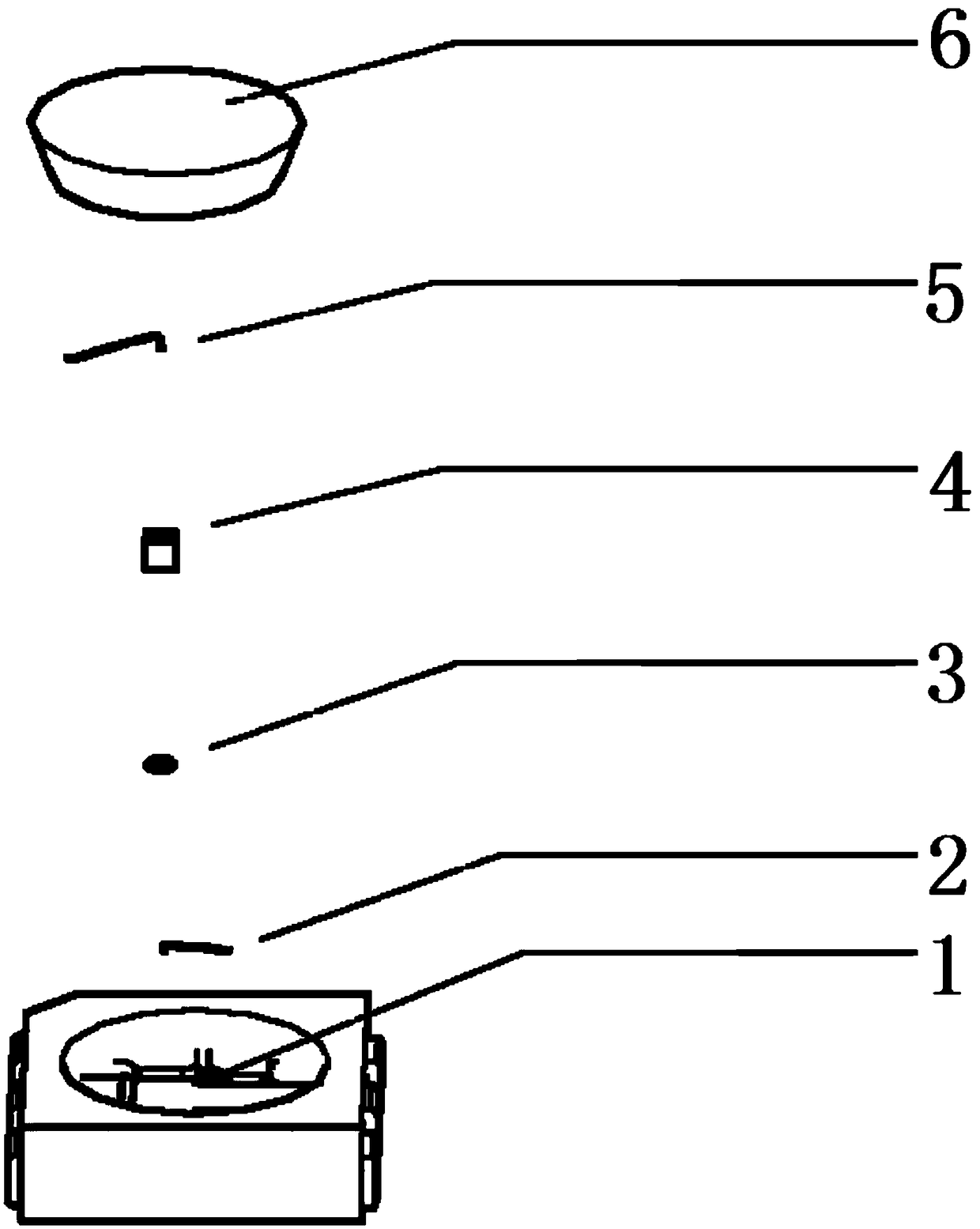

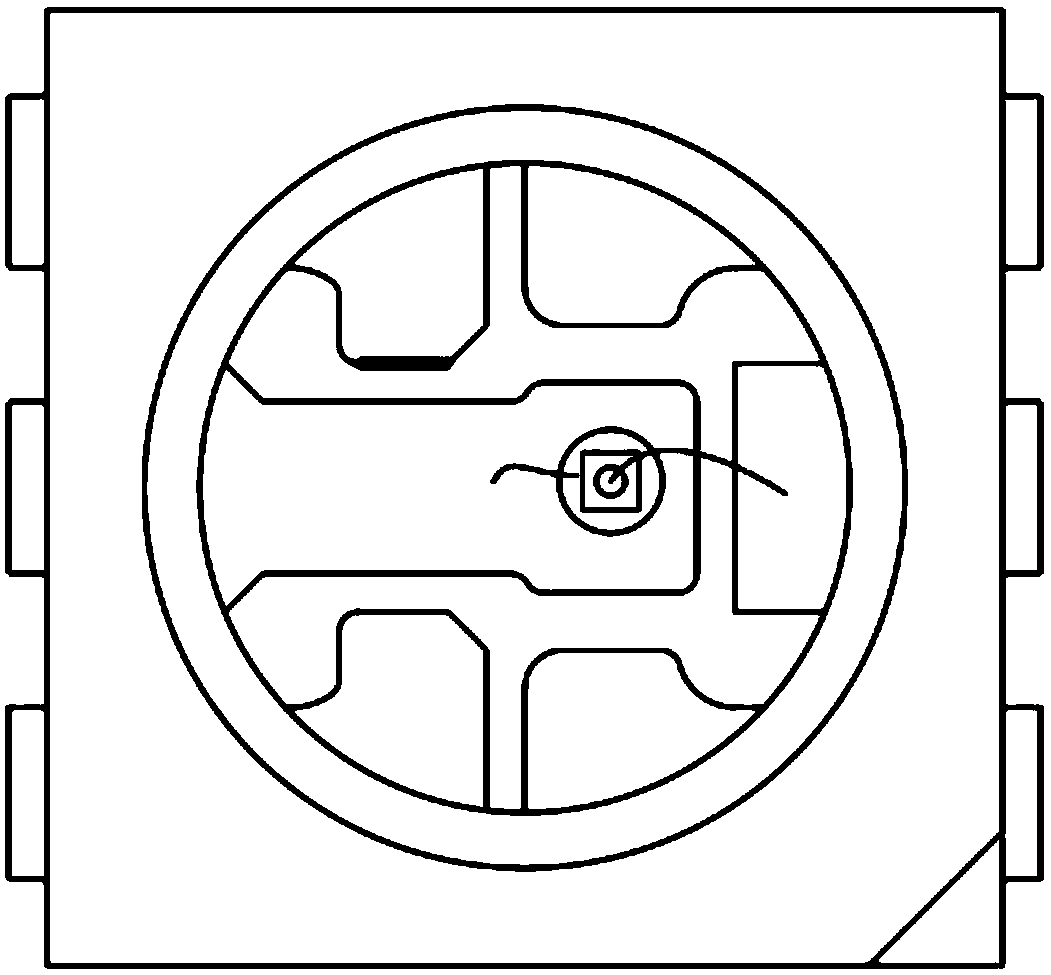

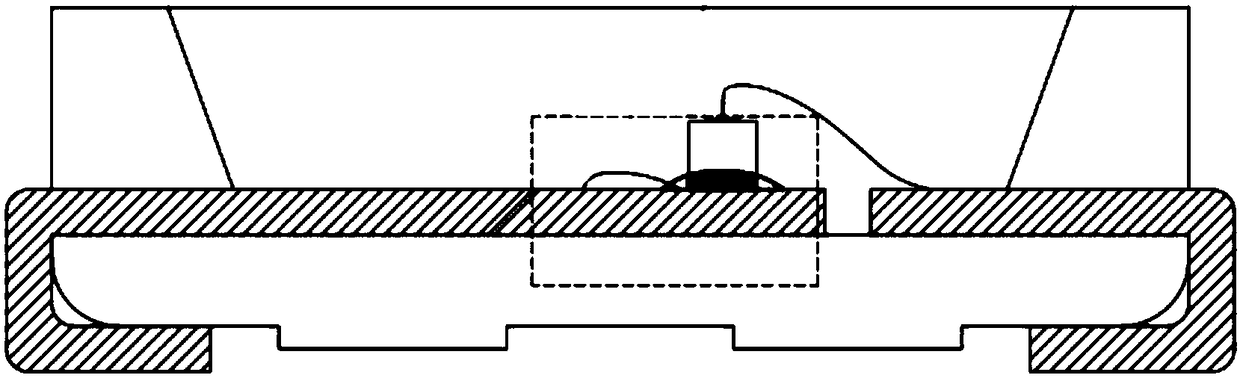

[0026] refer to figure 1 , this specific embodiment adopts the following technical solutions: a structure to prevent the LED conductive adhesive from loosening during welding or use, which is characterized in that it includes a bracket bowl cup (1), a cup bottom wire (2), conductive adhesive (3), LED chips (4), wires (5), and encapsulation glue (6), the bracket cup (1) is fixed with a crystal-bonding area plate inside; the conductive glue (3) is arranged on the crystal-bonding area plate; One end of the cup bottom wire (2) is welded on the die-bonding area plate, and the other end is placed inside the conductive glue (3); the bottom of the LED chip (4) is placed in the conductive glue (3); the wire (5) ) one end is welded on the top of the LED chip (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com