Method for mfg. anode carried thin film medium-temp. solid oxide fuel cell

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, circuits, etc., to avoid mutual reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT Example 1: Preparation of Porous YSZ Substrate

[0044] With product Y 2 o 3 Stable ZrO 2 (YSZ) Preparation of porous YSZ substrates. Y in YSZ 2 o 3 The doping amount is 8% (molar ratio) (TZ-8Y). Graphite is mixed into YSZ powder as a pore-forming agent. The doping amount of the pore forming agent is 45-50wt%. Grind the above powder evenly in an agate crucible, after drying, apply an axial pressure of 0.5-15Mpa in a Φ25 stainless steel abrasive tool, and press it into a substrate with a thickness of 1.5mm. Baking the substrate at 1000-1100 DEG C, removing the pore-forming agent, and making a porous YSZ substrate with certain mechanical strength, the porosity of the substrate is in the range of 60-80%. Example 2: Preparation of LSGM electrolyte film on porous YSZ substrate

example 2

[0044] With product Y 2 o 3 Stable ZrO 2 (YSZ) Preparation of porous YSZ substrates. Y in YSZ 2 o 3 The doping amount is 8% (molar ratio) (TZ-8Y). Graphite is mixed into YSZ powder as a pore-forming agent. The doping amount of the pore forming agent is 45-50wt%. Grind the above powder evenly in an agate crucible, after drying, apply an axial pressure of 0.5-15Mpa in a Φ25 stainless steel abrasive tool, and press it into a substrate with a thickness of 1.5mm. Baking the substrate at 1000-1100 DEG C, removing the pore-forming agent, and making a porous YSZ substrate with certain mechanical strength, the porosity of the substrate is in the range of 60-80%. Example 2: Preparation of LSGM electrolyte film on porous YSZ substrate

[0045] First prepare the LSGM slurry. Disperse the self-made LSGM superfine powder in ethanol, add polyvinyl alcohol as a gelling agent, the addition amount is 4-6% of the LSGM powder mass, add 0.3-0.5% of the LSGM powder mass fish oil as a dispe...

example 3

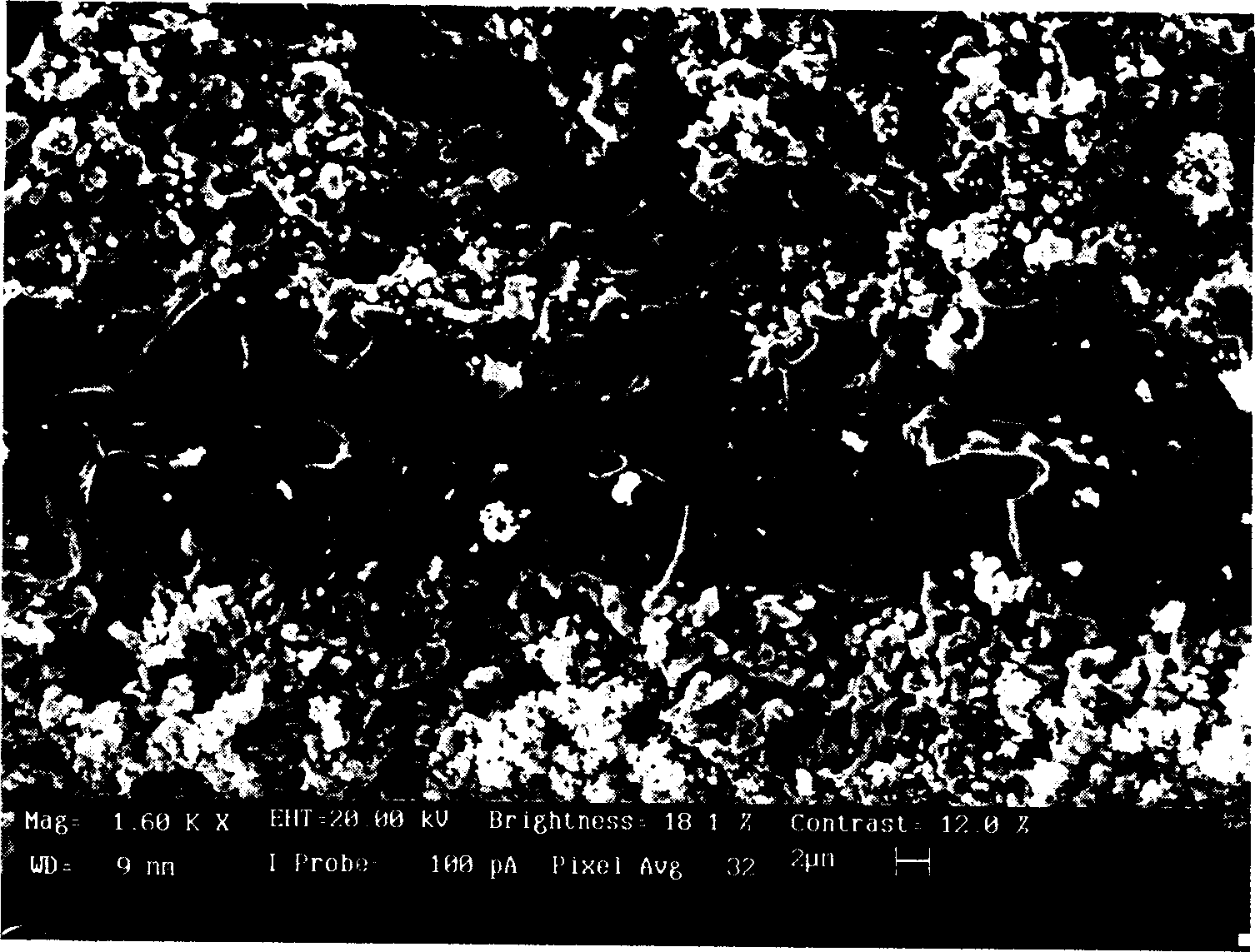

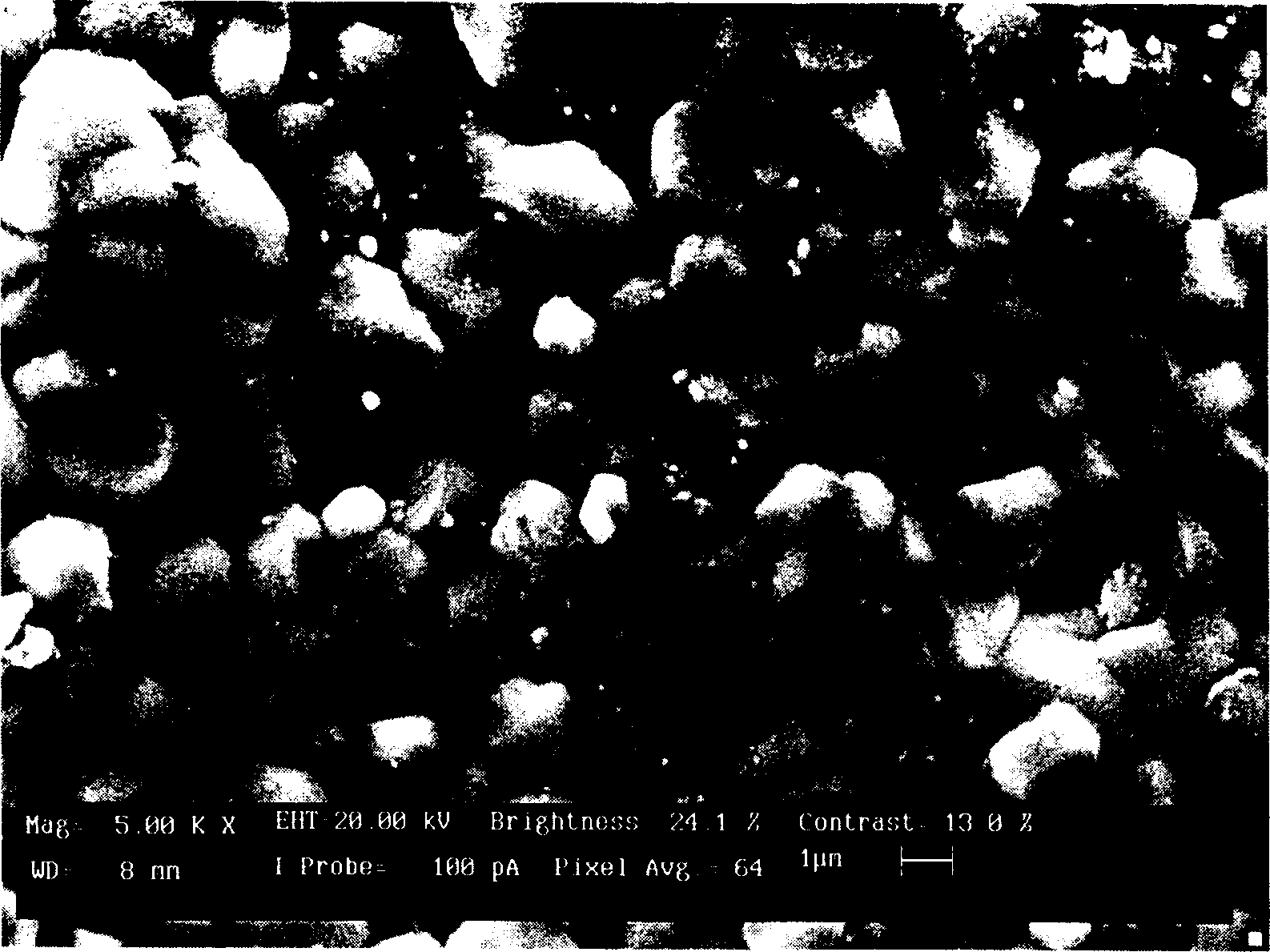

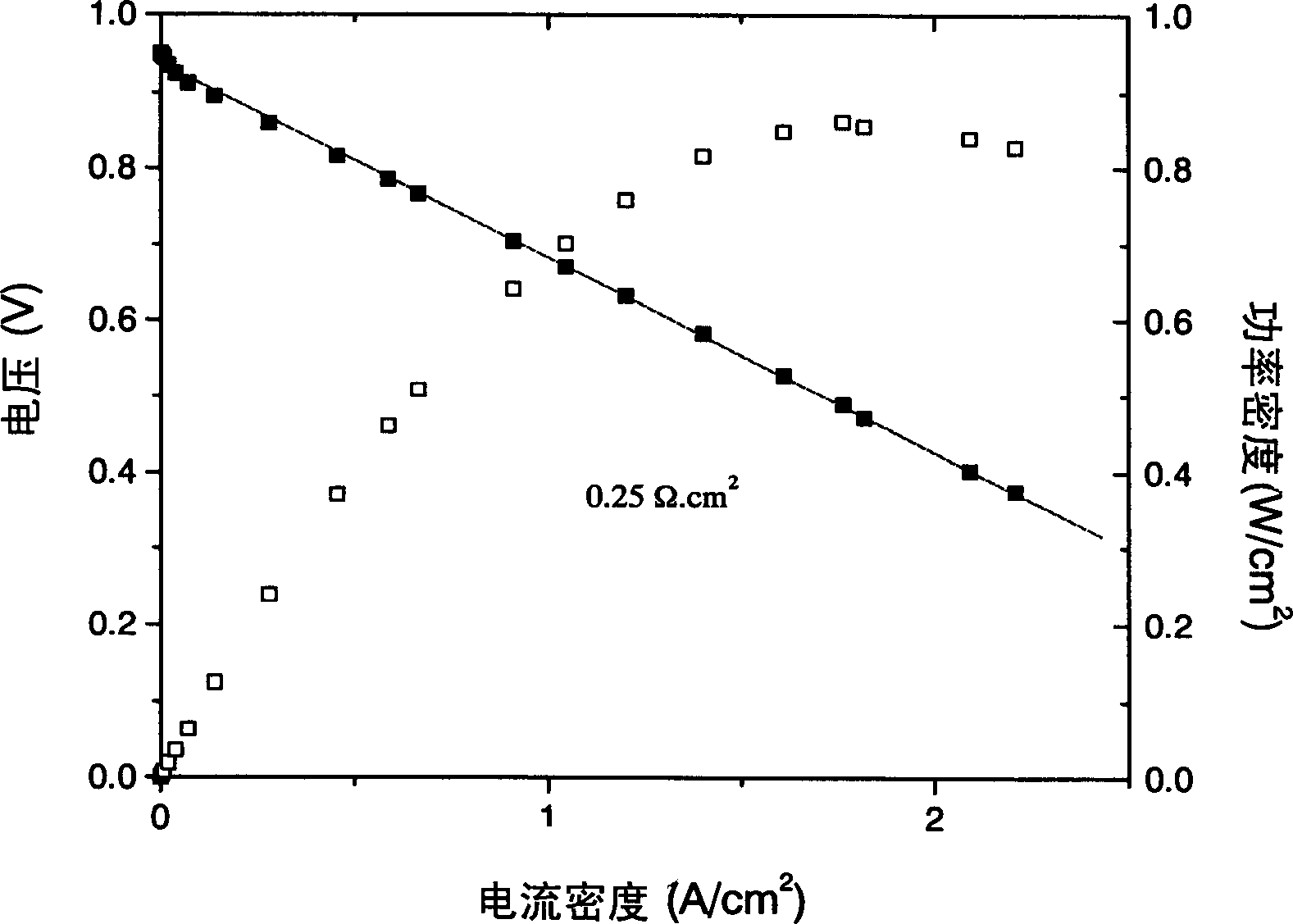

[0046] The prepared LSGM slurry is evenly spread on one surface of the porous YSZ film by casting method, and the thickness is controlled at 100-150 microns. Co-sinter the YSZ substrate and the LSGM film at 1300-1500°C to make the LSGM film dense and bond closely with the YSZ substrate. The thickness of the dense LSGM film prepared after sintering is controlled at 50-80 microns. The cross-section and surface morphology of the supported LSGM film prepared by this method are as follows: figure 1 , 2 shown. exist figure 1 The upper part of the middle photo is the Ni-YSZ cermet anode prepared by impregnation method, in which the fine particles distributed in the porous YSZ framework are metal Ni catalysts. The middle part of the photo is the loaded LSGM electrolyte film. It can be seen that the electrolyte film is relatively dense and tightly combined with Ni-YSZ. The lower part of the photo is the LSM-YSZ composite cathode. The prepared cathode layer also has a porous struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com