Efficient mixing device for medical granular medicines

A mixing device and technology for medical use, applied in the field of high-efficiency mixing devices for medical granules and medicines, can solve the problems of time-consuming, reduced medicine mixing efficiency, long medicine mixing time, etc., and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

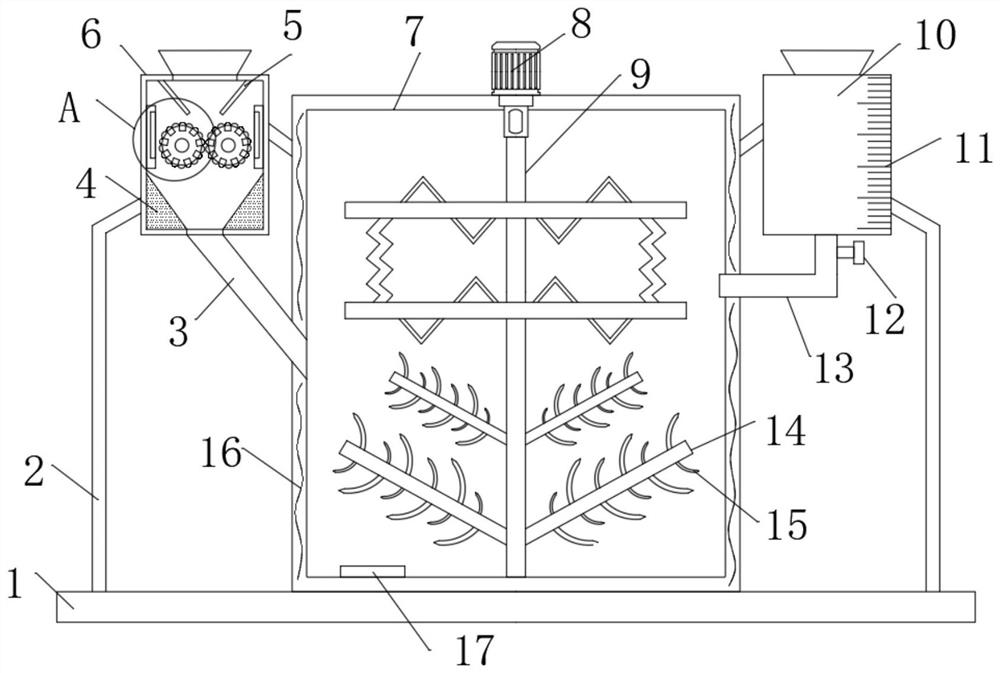

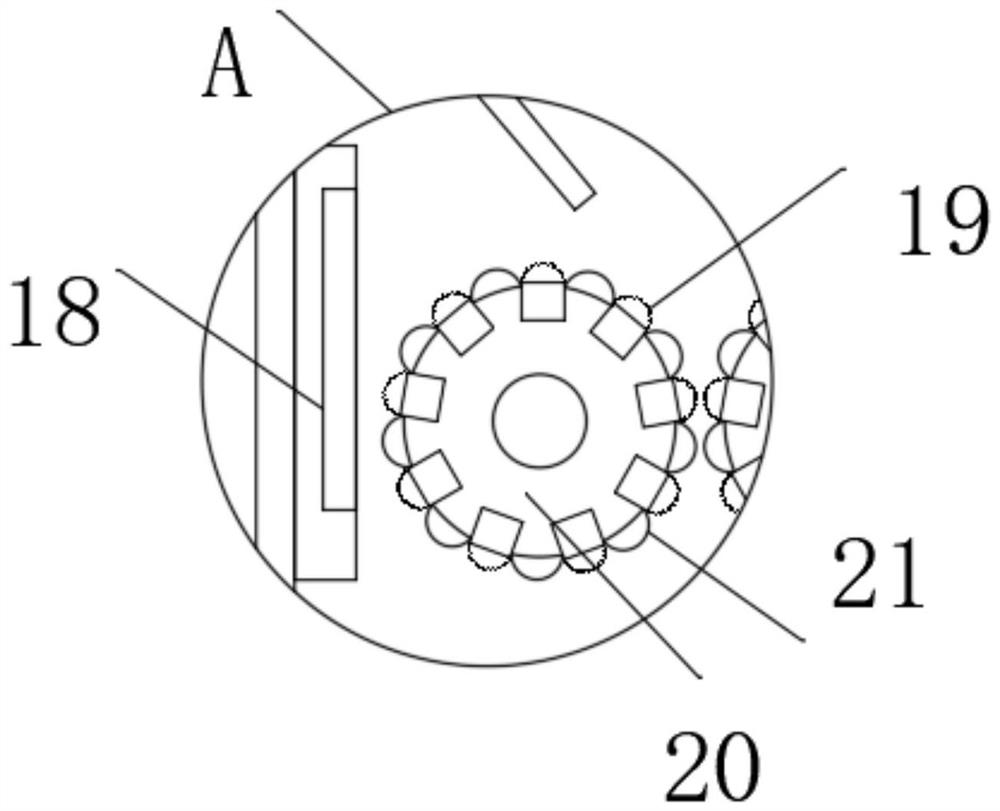

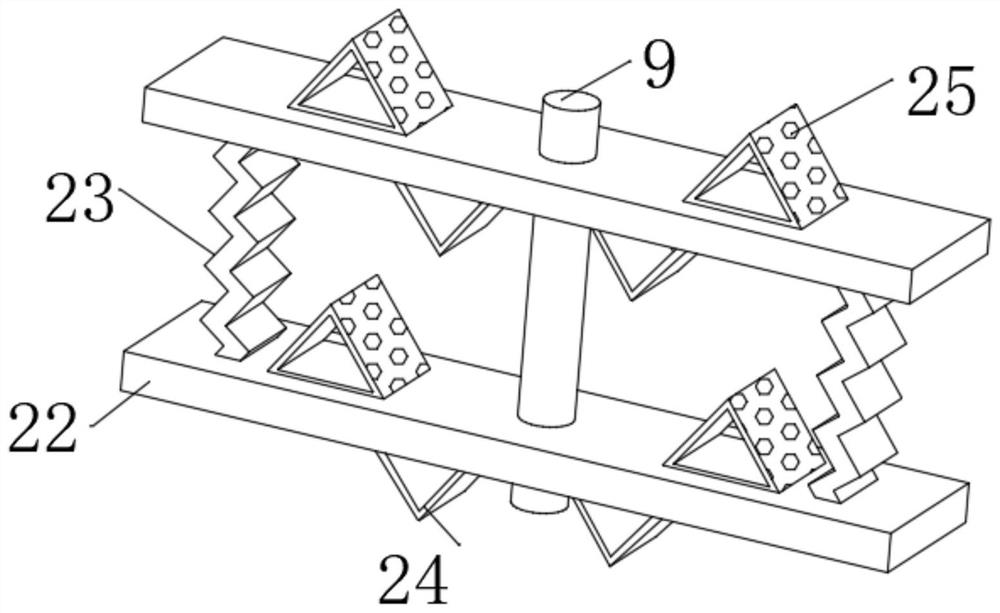

[0030] refer to Figure 1-4 , a high-efficiency mixing device for medical granular medicine, comprising a bottom plate 1, a support frame 2 is welded on both sides of the top outer wall of the bottom plate 1, and a solid feed box 6 and a liquid feed box 6 are respectively fixed on the outer wall of the support frame 2 by screws. Material box 10, one side outer wall of solid feed box 6 is fixed with the second motor by screw, and the output shaft of the second motor is connected with extrusion roller 20 through coupling, and the outer wall of extrusion roller 20 is provided with the first extruder Pressing block 19 and second extruding block 21, and first extruding block 19 is a zigzag circular arc structure, and second extruding block 21 is rough semicircular structure, and the inner wall both sides of solid feeding box 6 The triangular material guide block 4 and the inclined plate 5 are all fixed by screws, and both sides of the inner wall of the solid feed box 6 are fixed wi...

Embodiment 2

[0038] refer to Figure 5, a high-efficiency mixing device for medical granular medicine. Compared with Embodiment 1, this embodiment also includes a temperature sensor 27 fixed to the inner wall of one side of the mixing box 7 by screws, and a fixing rod 26 is welded on one side of the outer wall of the mixing box 7. And the other end of fixed rod 26 is fixed with display screen 28 by screw, and the signal input end of display screen 28 is connected with processor by signal line, and the signal output end of temperature sensor (27) and the signal input end of processor are connected by signal line. connect.

[0039] Connect the device to the power supply, add solid medicine into the solid feed box 6, turn on the second motor and the drying lamp 18, the second motor drives the extrusion roller 20 to rotate, the first extrusion block 19 and the second extrusion block 21 The medicine is crushed, and the broken solid medicine enters the mixing box 7 along with the triangular mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com