Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Tar/pitch/asphalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pitch is a name for any of a number of viscoelastic polymers. Pitch can be natural or manufactured, derived from petroleum, coal tar or plants. Various forms of pitch may also be called tar, bitumen or asphalt. Pitch produced from plants is also known as resin.

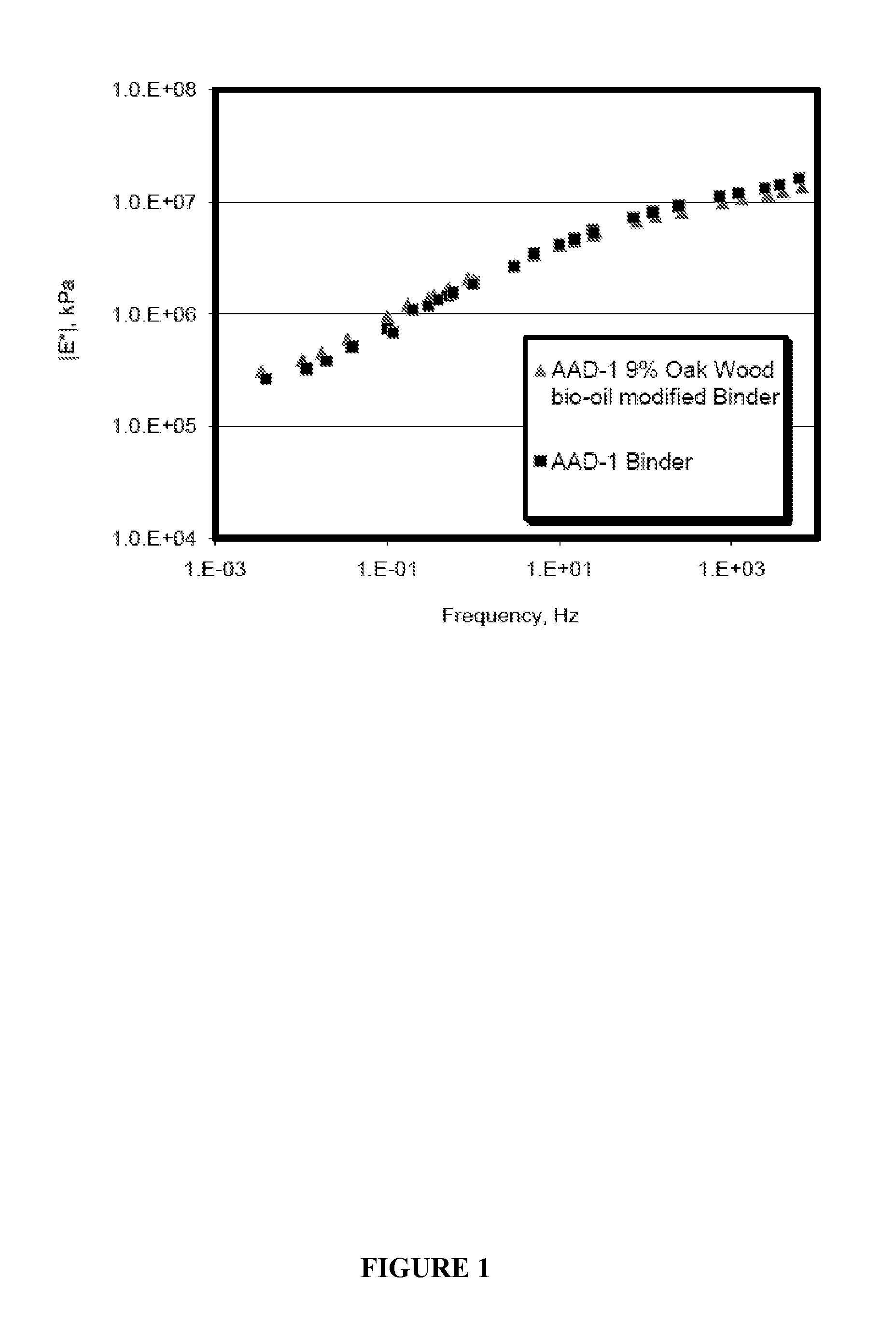

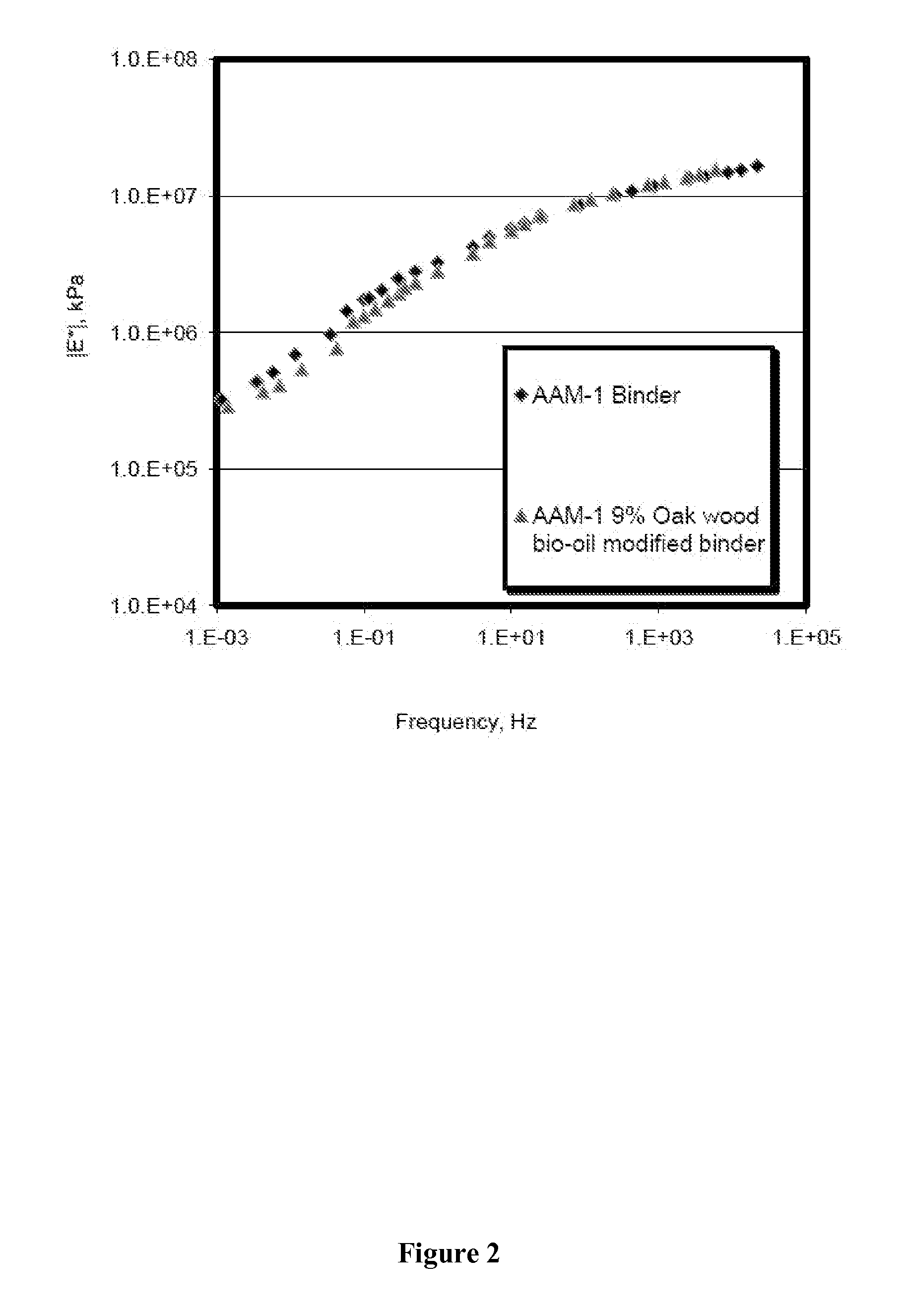

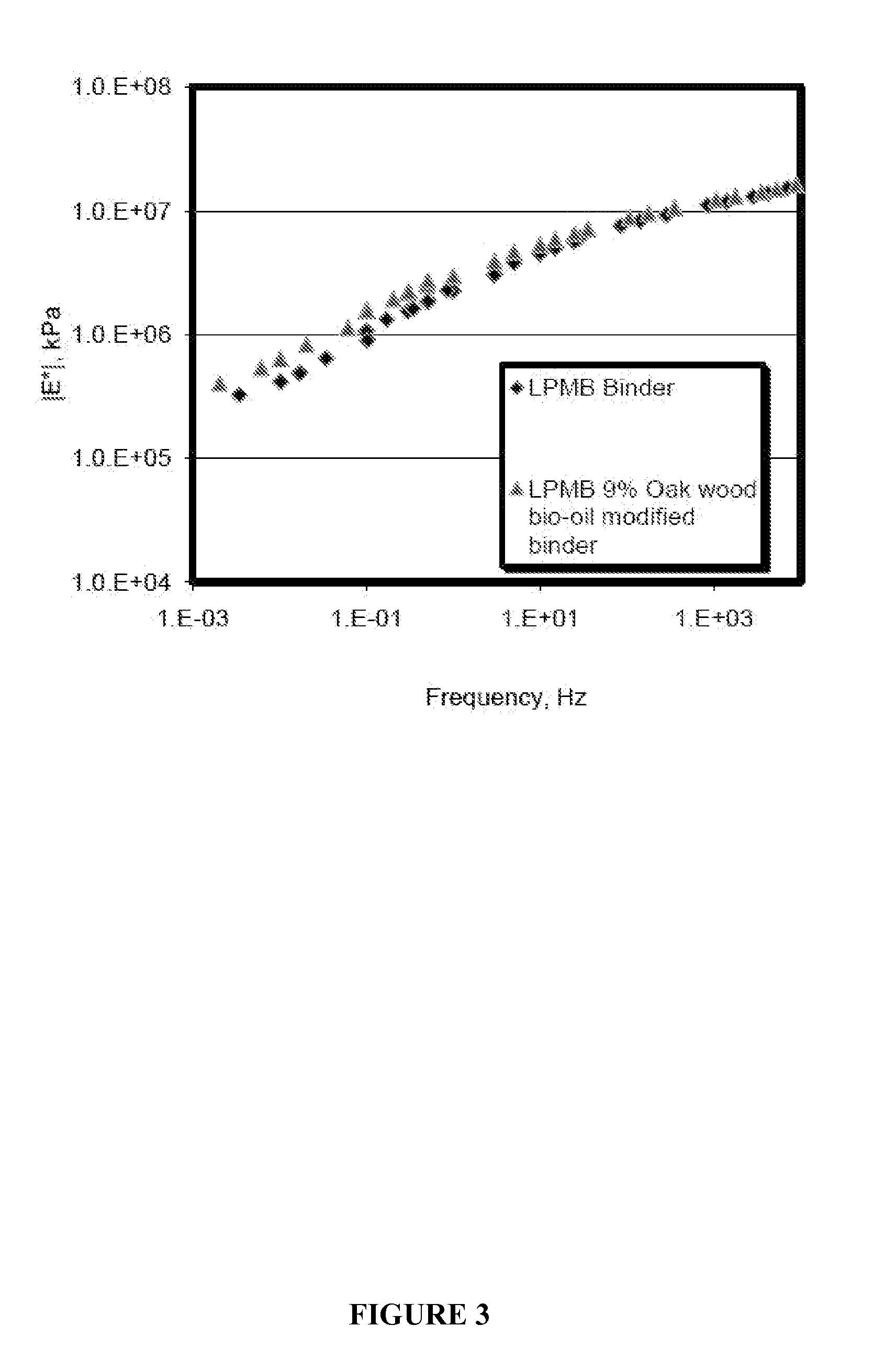

Asphalt materials containing bio-oil and methods for production thereof

An asphalt binder includes asphalt and an asphalt binder modifier, which includes bio-oil. The asphalt binder can include a carboxyl additive. The asphalt can optionally include polymer-modified asphalt. An asphalt material includes mineral aggregate, an asphalt material binder including asphalt, and an asphalt binder modifier including bio-oil. A method for making the asphalt binder is disclosed. The asphalt material includes asphalt pavement and roofing shingles. The asphalt binder can be emulsified with water and a surfactant for use as a weatherproofing sealant or as an adhesive.

Owner:IOWA STATE UNIV RES FOUND

Modified asphalt binder material using crumb rubber and methods of manufacturing a modified asphalt binder

ActiveUS20060243163A1Increase elasticityAcceptable rotational viscosityIn situ pavingsBuilding insulationsEngineeringTruck

In a first aspect, bituminous asphalt binder materials which are modified by the addition of crumb rubber or ground tire rubber are described. In a second aspect, the present invention is directed to methods of producing a modified asphalt binder containing crumb rubber or ground tire rubber. The modified asphalt binders comprise neat asphalt, crumb rubber, one or more synthetic polymers, and one or more acids. The crumb rubber may be obtained from recycled truck and / or automobile tires.

Owner:INNOPHOS INC

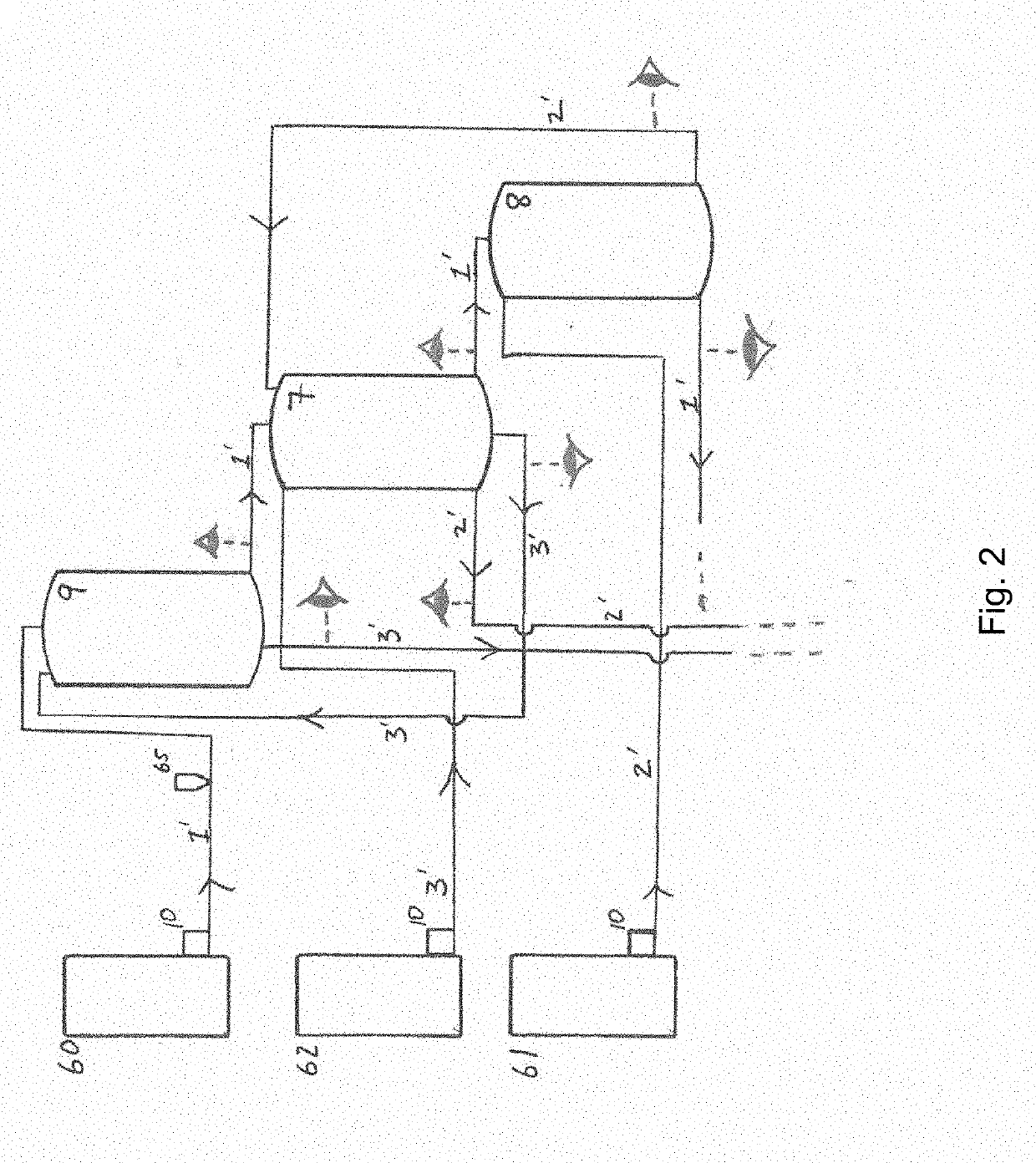

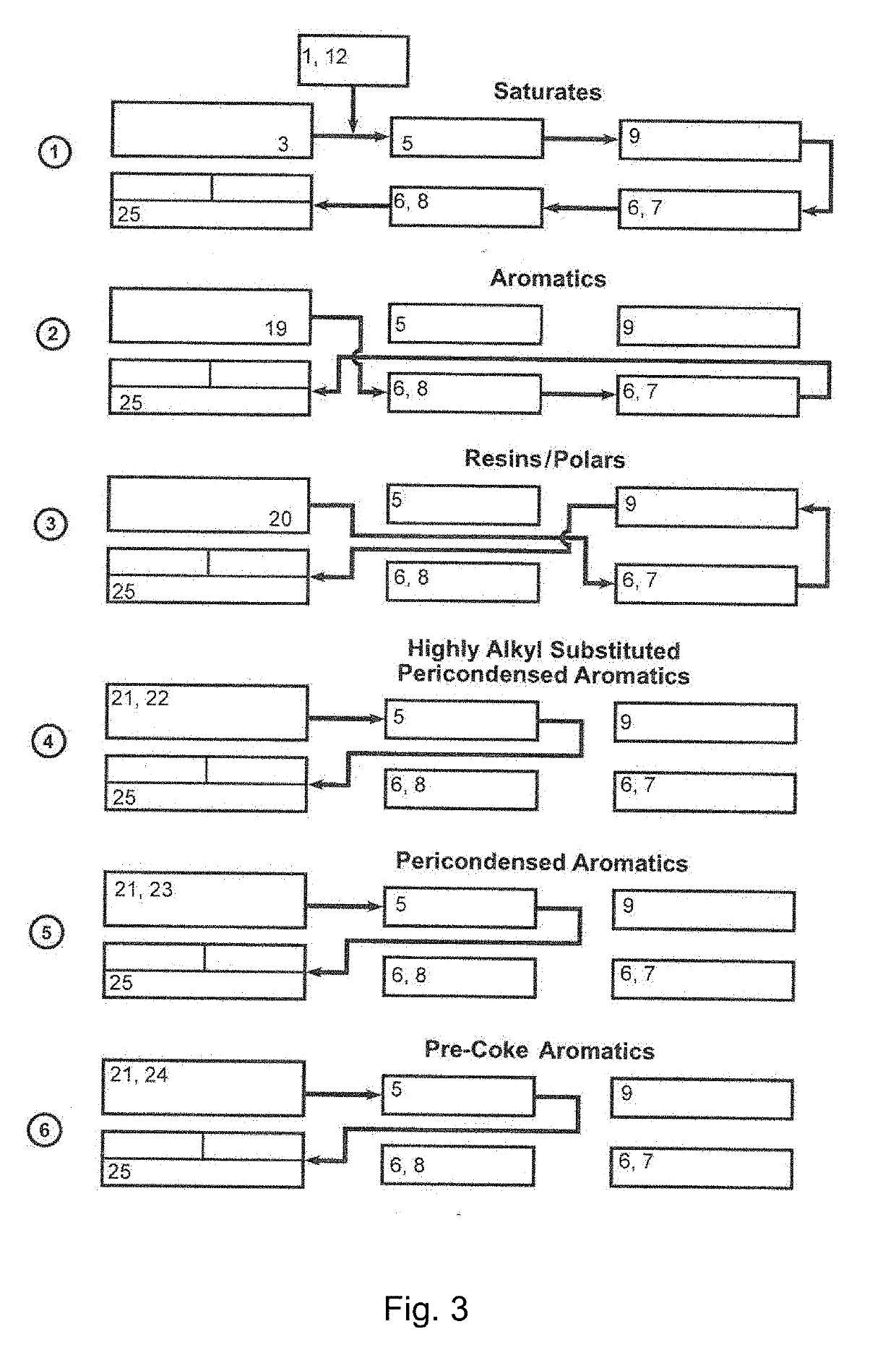

Methods For Analyzing Hydrocarbons And Hydrocarbon Blends For Chemical Compositions

ActiveUS20190106639A1Increase volumeUseful characteristicOther chemical processesComponent separationSolubilityPolymer modified

The present invention is generally related to the analysis of chemical compositions of hydrocarbons and hydrocarbon blends. This method applies specifically to the problem of analyzing extremely complex hydrocarbon-containing mixtures when the number and diversity of molecules makes it impossible to realistically identify and quantify them individually in a reasonable timeframe and cost. The advantage to this method over prior art is the ability to separate and identify chemical constituents and solvent fractions based on their solvent-solubility characteristics, their high performance liquid chromatographic (HPLC) adsorption and desorption behaviors, and their interactions with stationary phases; and subsequently identify and quantify them at least partially using various combinations of non-destructive HPLC, destructive HPLC, and stand-alone detectors presently not routinely used for HPLC but reconfigured to obtain spectra on the fly. This analytical method is especially useful for, but not limited to, asphalt binders and asphalt binder blends, modified asphalts, asphalt modifiers, asphalt additives, polymer-modified asphalts, asphalts containing rejuvenators and softening agents, asphalts containing recycled products, aged asphalts, and air-blown asphalts, which may contain wide varieties of different types of additives and chemistries, and forensic applications, and environmental pollutant identification.

Owner:WESTERN RES INST INC

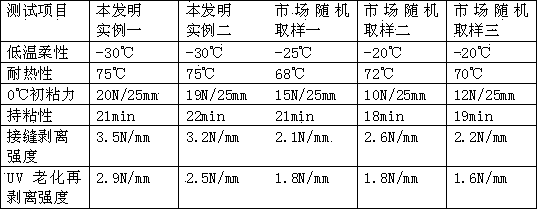

Asphalt-based hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN103965829AGood initial adhesionIncrease stickinessNon-macromolecular adhesive additivesRoof covering using flexible materialsCross linkerHot melt

The invention discloses an asphalt-based hot-melt pressure-sensitive adhesive and a preparation method thereof. The asphalt-based hot-melt pressure-sensitive adhesive comprises the following ingredients in percentage by weight: 35-50% of asphalt, 10-20% of an asphalt modifier, 20-40% of a softener, 5-15% of a tackifier, 10-20% of a filler, 1-3% of a cross-linker and 0.5-1.5% of an antiager. The hot-melt pressure-sensitive adhesive is superior to an asphalt adhesive for a self-adhesion waterproof roll in performance, and has the advantages of low cost, convenient preparation and the like compared with hot-melt pressure-sensitive adhesives such as EVA (ethylene-vinyl acetate copolymer); meanwhile, the invention discloses the preparation method of the product, which is convenient to produce and can be produced by a traditional reaction kettle for producing a waterproof roll asphalt mixture without the need of a special precise reaction kettle for a hot-melt adhesive.

Owner:宿迁金倍尔建筑材料有限公司

Nonvolatile ordinary temperature modified asphalt binder and nonvolatile ordinary temperature regenerated asphalt mixture using same

ActiveUS20200199024A1Improve mechanical propertiesMarshall stabilityIn situ pavingsDrilling compositionPolymer scienceIsoprene

A nonvolatile cold modified asphalt binder and a nonvolatile cold recycled asphalt mixture using the same are manufactured by optimally mixing a petroleum asphalt, a native asphalt, a polymer modifier, process oil, and an adhesive strength enhancer. The nonvolatile cold modified asphalt binder includes at least one petroleum asphalt selected from a straight asphalt or a blown asphalt; at least one native asphalt selected from gilsonite, glance pitch, and grahamite; a rubber-modified-compound (RMC) polymer modifier which is a vinyl aromatic hydrocarbon-conjugated diene block copolymer including at least one of a styrene-butadiene block copolymer (SBS), a styrene-isoprene block copolymer (SIS), and a styrene-ethylene-butylene block copolymer (SEBS); at least one process oil selected from paraffin oil, naphthenic oil, aromatic oil, natural oil, and mineral oil; and at least one adhesive strength enhancer selected from rosin esters, modified acryls, modified silicones, polyvinyl esters, and silicone resins.

Owner:HANSOO ROAD IND CO LTD

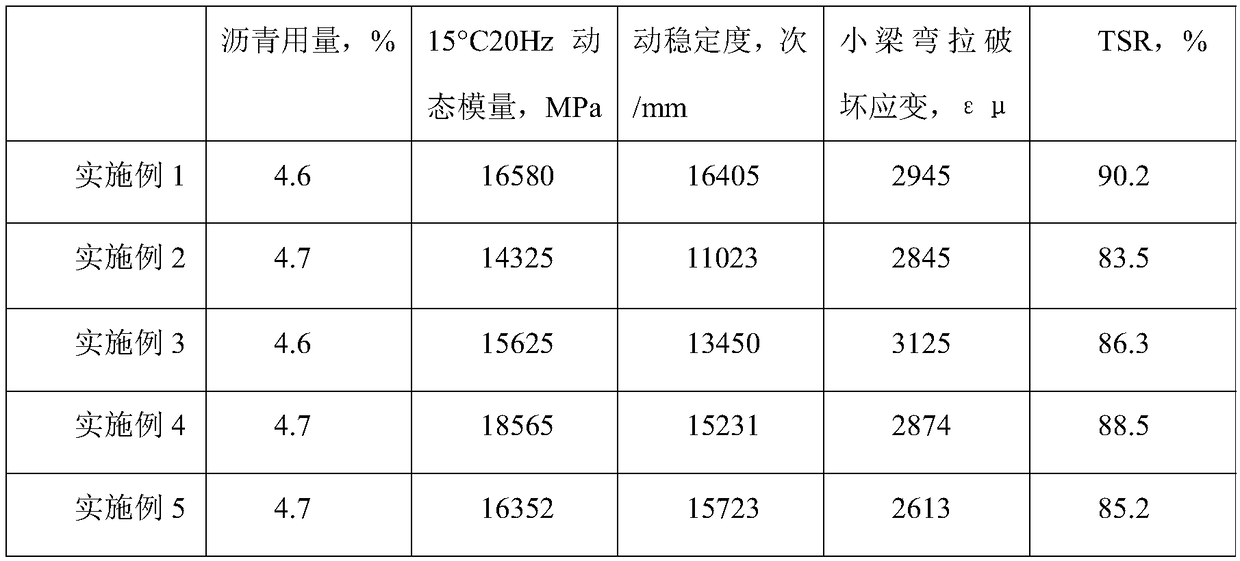

High-modulus asphalt modifier, high-modulus composite modified asphalt, asphalt mixture and preparation method thereof

InactiveCN109233313ASolve the problem of poor compatibility, easy to separate from asphalt and float upEvenly distributedBuilding insulationsPolyolefinRoad surface

The invention provides a high-modulus asphalt modifier, high-modulus composite modified asphalt, an asphalt mixture and a preparation method thereof. The high-modulus asphalt modifier is prepared from40 to 60 parts of desulfurized rubber tire powder, 30 to 60 parts of polyolefin plastic particles, 0 to 20 parts of petroleum resin or solid asphalt and 0 to 6 parts of a stabilizing agent. The high-modulus composite modified asphalt comprises 80 to 85 parts of matrix asphalt, 10 to 15 parts of the high-modulus asphalt modifier, 0 to 0.4 part of sulfur and 0 to 7 part of a light oil component. The asphalt mixture comprises 100 parts of mineral aggregate and 4.0 to 5.5 parts of the high-modulus composite modified asphalt. By adopting the high-modulus composite modified asphalt provided by theinvention, the problems that the compatibility of plastic and the asphalt is poor and the plastic is easy to separate and float from the asphalt are solved; and when an asphalt road surface is formedby the asphalt mixture, the modulus and anti-rutting capability of an asphalt structure layer can be remarkably improved.

Owner:SHANGHAI RENJU NEW MATERIAL TECH

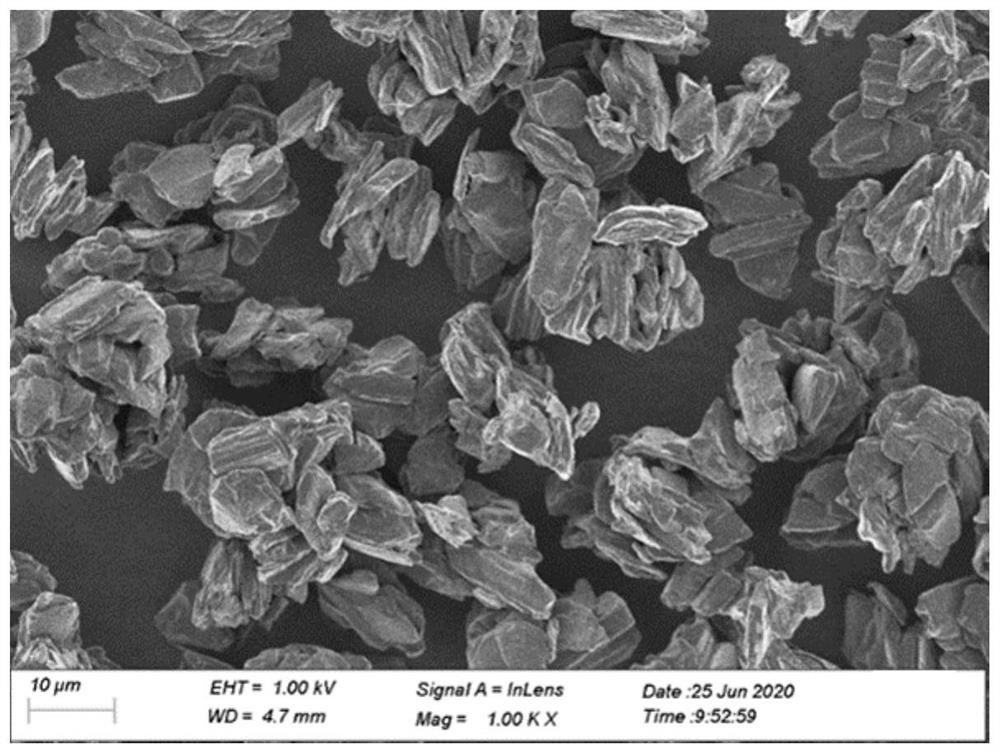

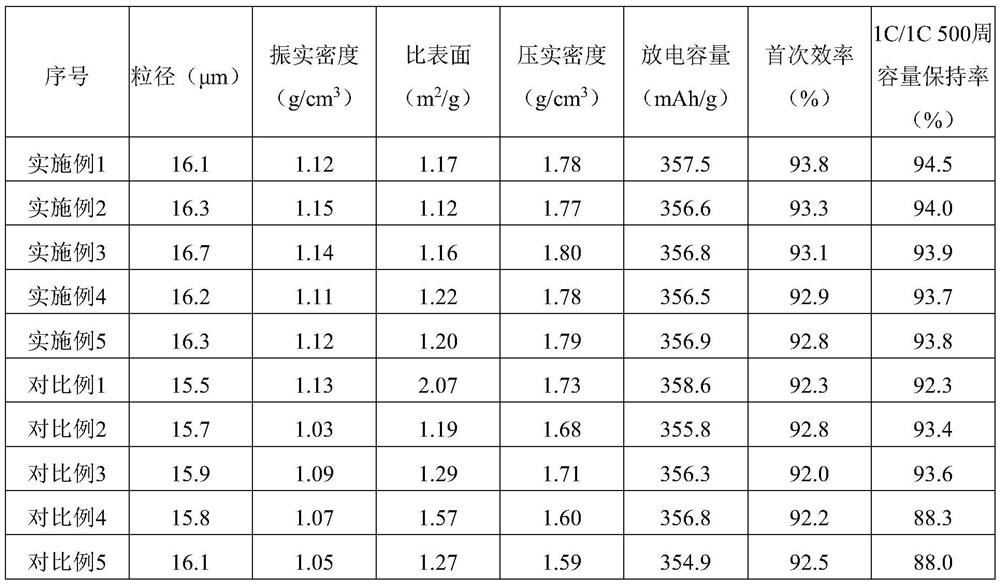

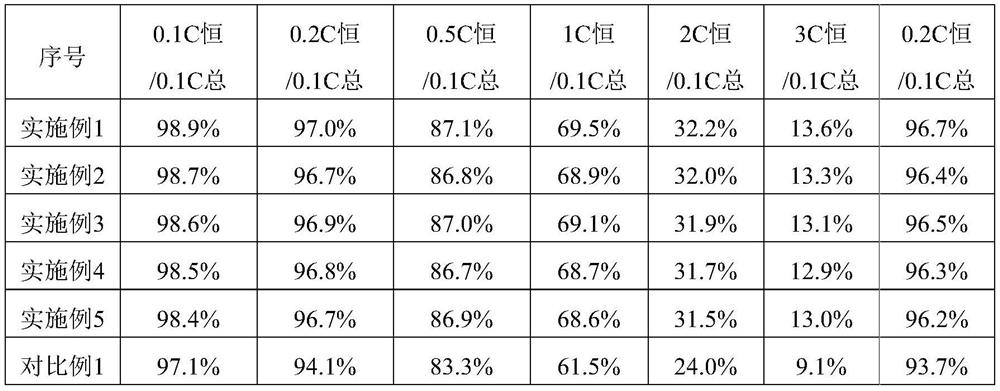

Coated modified artificial graphite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN113023725ABuild to achieveImprove power performanceCarbon compoundsSecondary cellsSlurryLithium-ion battery

The invention discloses a coated modified artificial graphite negative electrode material, a preparation method thereof and a lithium ion battery, and the method comprises the following steps: sequentially carrying out wet coating and carbonization treatment on secondary particles of artificial graphite. The raw materials of the secondary particles of the artificial graphite comprise petroleum coke and / or coal coke and asphalt. The softening point of the asphalt is 130-160 DEG C. A coating agent adopted in the wet coating process comprises coal tar residual oil and graphene slurry. The mass ratio of the coal tar residual oil to the graphene in the graphene slurry is 6: 0.005-6: 0.64. The coated modified artificial graphite negative electrode material is obtained by the method. The coated modified artificial graphite negative electrode material prepared by the preparation method disclosed by the invention takes charge-discharge rate and high-capacity first efficiency into account, and has excellent performance in the aspects of discharge capacity, first efficiency, high-rate charge-discharge, circulation and the like.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

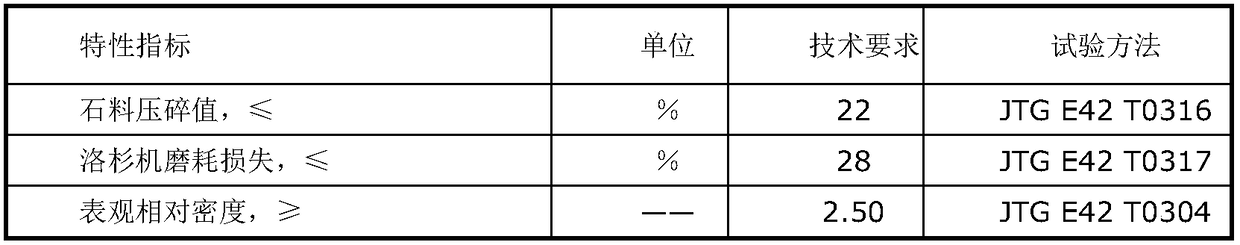

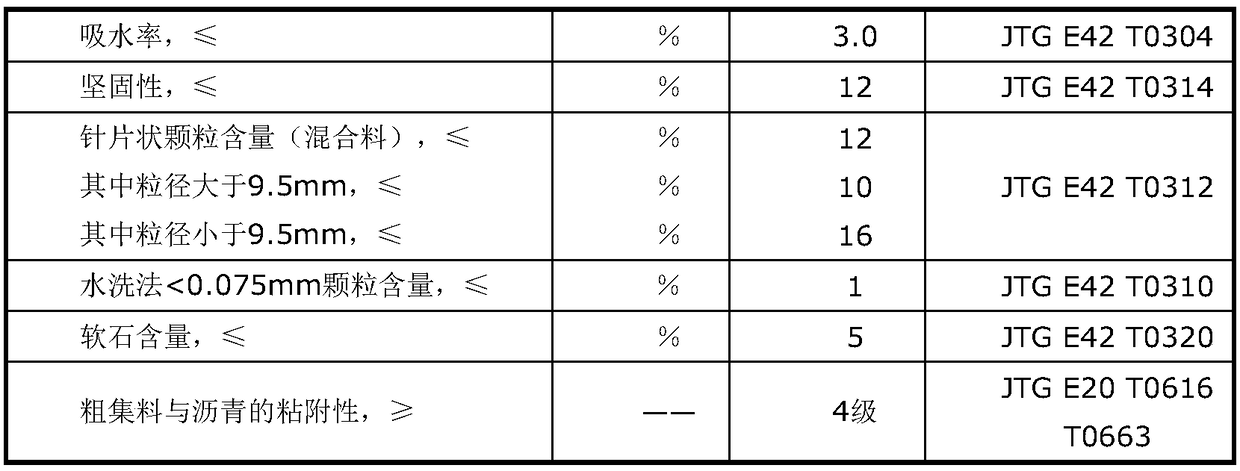

Ultraviolet aging test method for asphalt material in tension state

ActiveCN105784575AComprehensive analysis of UV aging degreeReasonable designWeather/light/corrosion resistancePreparing sample for investigationUltraviolet lightsBituminous materials

The invention relates to an ultraviolet aging test method for an asphalt material (including asphalt, asphalt mortar and an asphalt mixture) in a tension state. The ultraviolet aging test method comprises the following steps: selecting a light source for an ultraviolet aging simulation test, and determining the change of the irradiation intensity of the light source along with space and time; preparing samples of the asphalt material; carrying out an ultraviolet aging test on the asphalt material in the tension state, carrying out a subsequent performance test, and analyzing test results. By implementing the test method provided by the invention, a light aging process of an asphalt pavement under a traffic load and ultraviolet light irradiation can be well simulated; an ultraviolet light aging degree of the asphalt material can be comprehensively analyzed; the light aging rules of the asphalt material can be revealed. The test method is reasonable in design, and is detailed and specific.

Owner:TONGJI UNIV

Production method for high-softening point asphalt

ActiveCN103805221AIncrease profitLow viscosityWorking-up pitch/asphalt/bitumen by chemical meansMolten stateProduct gas

The invention discloses a production method for high-softening point asphalt. The method is characterized by comprising: mixing an asphalt raw material A mixed with an oxygen-containing gas, leading the oxygen-containing gas mixed asphalt raw material A into an oxidation reactor to fully contact a molten state asphalt raw material B and undergo common reaction, and then introducing the oxygen-containing gas to undergo oxidation reaction, thus obtaining the high-softening point asphalt. Specifically, the asphalt raw material A is coal asphalt, and the asphalt raw material B is petroleum asphalt. The method provided by the invention has the advantages of simple process, convenient operation, high reaction efficiency and low energy consumption, and the obtained product has excellent high temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

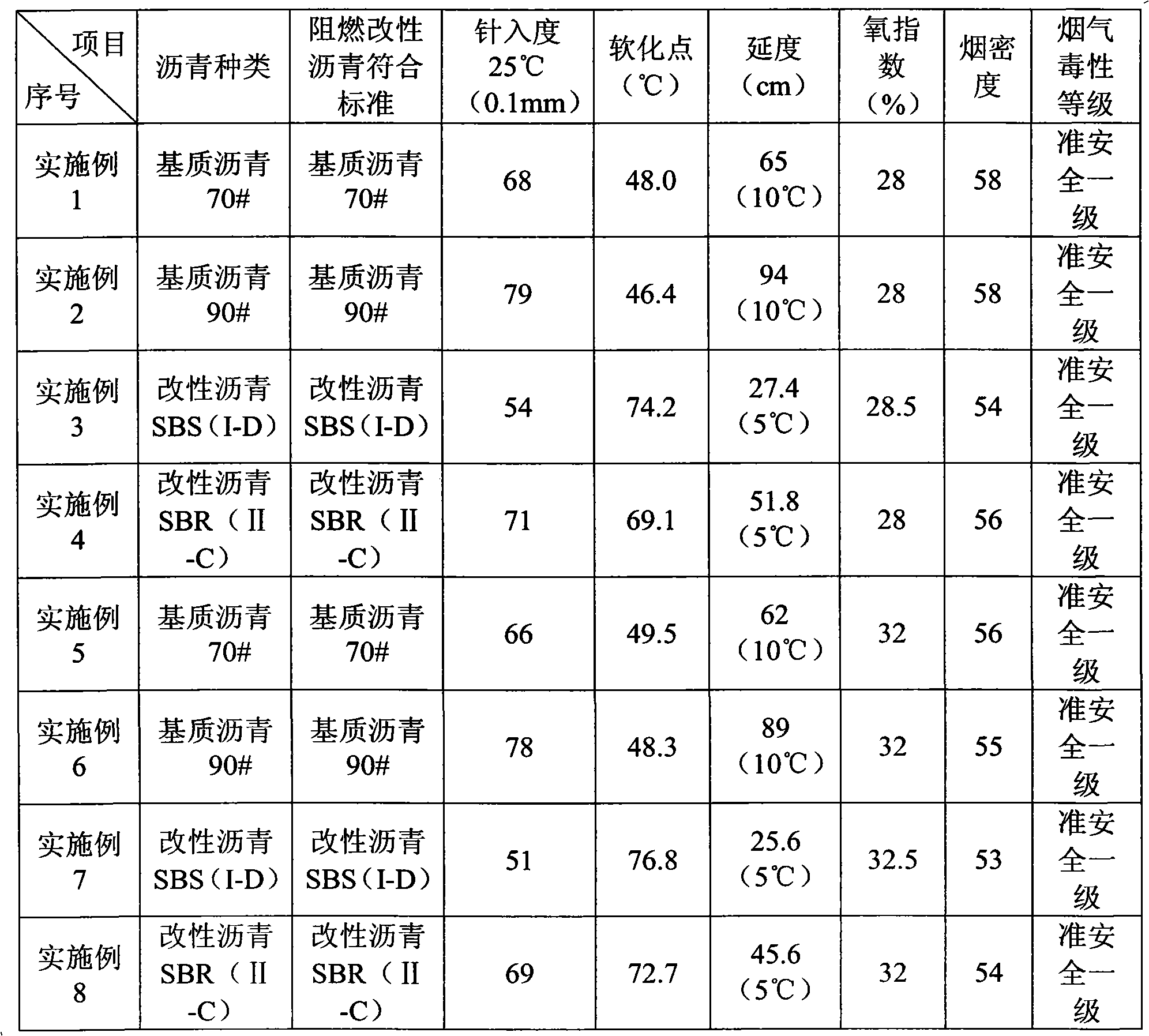

Toughened asphalt modifier, toughened compound modified asphalt, asphalt mixture and preparation method thereof

The invention provides a toughened asphalt modifier, toughened compound modified asphalt, an asphalt mixture and a preparation method thereof. The toughened asphalt modifier comprises 65 to 92 parts of desulphurized rubber tire powder, 0 to 20 parts of polyolefin plastic particles, 0 to 15 parts of SBS, 0 to 15 parts of SBR and 0 to 6 parts of a stabilizer. The toughened compound modified asphaltcomprises 60 to 85 parts of matrix asphalt, 15 to 40 parts of toughened asphalt modifier, 0 to 0.3 part of sulfur and 0 to 7 parts of light-weight oil component. The asphalt mixture comprises 100 parts of mineral aggregates and 5.0 to 6.0 parts of toughened compound modified asphalt. By adopting the toughened compound asphalt modifier, the problems of the rubber and plastic modified asphalt that the processing difficulty is high and the stability of the finished product is poor can be solved. When the asphalt mixture is used for forming the asphalt pavement, the asphalt mixture of the invention has high anti-cracking capacity and long pavement service life.

Owner:SHANGHAI RENJU NEW MATERIAL TECH

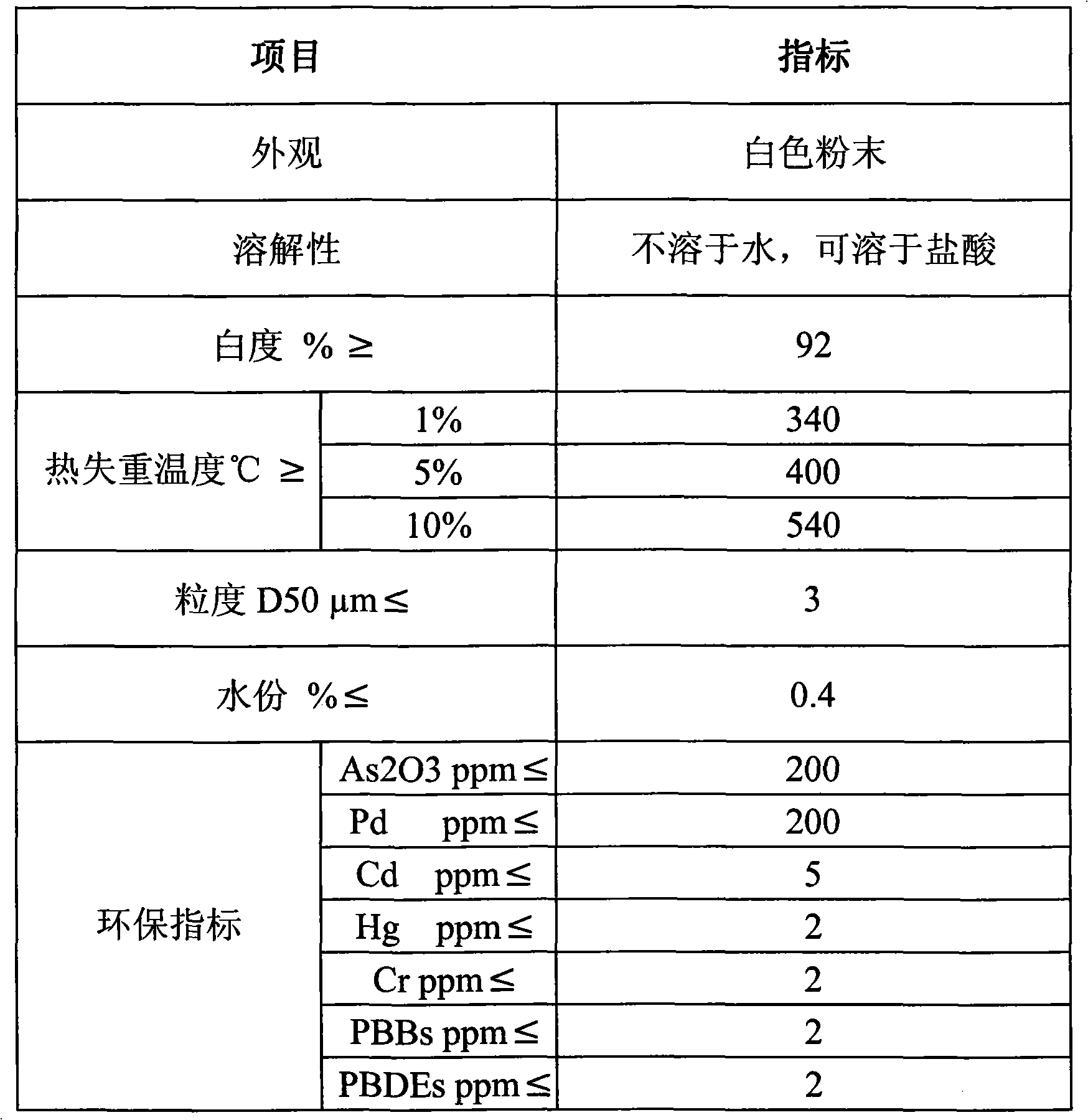

Asphalt flame-retardant modifier, and flame-retardant modified asphalt and preparation thereof

InactiveCN102040745AImprove flame retardant performanceExcellent economic and environmental indicatorsBuilding insulationsMagnesium silicateAsphalt

The present invention discloses an asphalt flame-retardant modifier comprising following components: decabromodiphenyl ether, antimony white and other flame retardants, hydrated magnesium silicate and smoke-suppressant. The invention further discloses a flame-retardant modified asphalt prepared with the asphalt flame-retardant modifier and the preparation method thereof, wherein the flame-retardant modified asphalt comprises following components: asphalt, asphalt flame-retardant modifier, blender and stabilizing agent; and the preparation method of the flame-retardant modified asphalt comprises following steps of: heating and melting asphalt, stirring and dehydrating, then successively adding the asphalt flame-retardant modifier, blender and stabilizing agent to obtain the flame-retardant modified asphalt. The flame-retardant modified asphalt disclosed in the present invention has excellent anti-flaming and smoke-suppressing effect and good road performances, and has bright application prospect in the field of road materials.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Easily-prepared anti-adhesive emulsified asphalt achieving normal-temperature rapid demulsification and preparation method thereof

InactiveCN106928732AHigh softening pointHigh bonding strengthBuilding insulationsPolymer sciencePolymer adhesive

The invention relates to easily-prepared anti-adhesive emulsified asphalt achieving normal-temperature rapid demulsification and a preparation method thereof, and belongs to the technical field of road engineering materials. The anti-adhesive emulsified asphalt is prepared from heavy traffic road asphalt, deoiled asphalt, an asphalt interface modifier, polymer latex, an auxiliary, an emulsifier, an acidifying or alkalizing agent and water; the preparation method comprises the steps that the emulsifier, the polymer latex and an auxiliary-aqueous solution are added into water, the PH value is adjusted, liquid soap is prepared, the heavy traffic road asphalt, the deoiled asphalt and the asphalt interface modifier are stirred to be uniform at a high temperature and heated to reach a proper temperature, the mixture and the liquid soap are subjected to colloid mill high-speed shear preparation, and the anti-adhesive emulsified asphalt is obtained. The anti-adhesive emulsified asphalt has the advantages that the emulsifying temperature of the asphalt is low, emulsification is easy, and the emulsification technology is simple and easy to operate; demulsification can be conducted rapidly at a normal temperature, and the construction efficiency is improved; the anti-adhesive emulsified asphalt has the advantage of being resistant to wheel adhesion when serving as a road adhesion layer, the phenomenon that due to damage of a construction vehicle to the adhesion layer, the adhesion layer loses efficacy is avoided, and the service life of a road is prolonged.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE BUILDING MATERIALGRP +1

Process of polymer modified asphalt preparation

A process of preparing a polymer modified asphalt (PMA) comprising mixing a predetermined amount of a polymer-asphalt master batch with a predetermined amount of an asphalt-cross linking agent blend. The polymer-asphalt master batch comprises at least one polymer and a first asphalt. The asphalt-cross linking agent blend comprises a second asphalt and at least one cross linking agent. A predetermined amount of the polymer-asphalt master batch is blended with a predetermined amount of the asphalt-cross linking agent blend to form a PMA blend. Mixing of the PMA blend is performed without substantial delay following blending of the polymer-asphalt master batch with the asphalt-cross linking agent blend.

Owner:HUSKY OIL OPERATIONS

Polymer modified asphalt for industrial applications

ActiveUS11053391B2Reduced thermal historyEmission reductionWorking-up pitch/asphalt/bitumen by chemical meansClimate change adaptationPolymer sciencePolymer modified

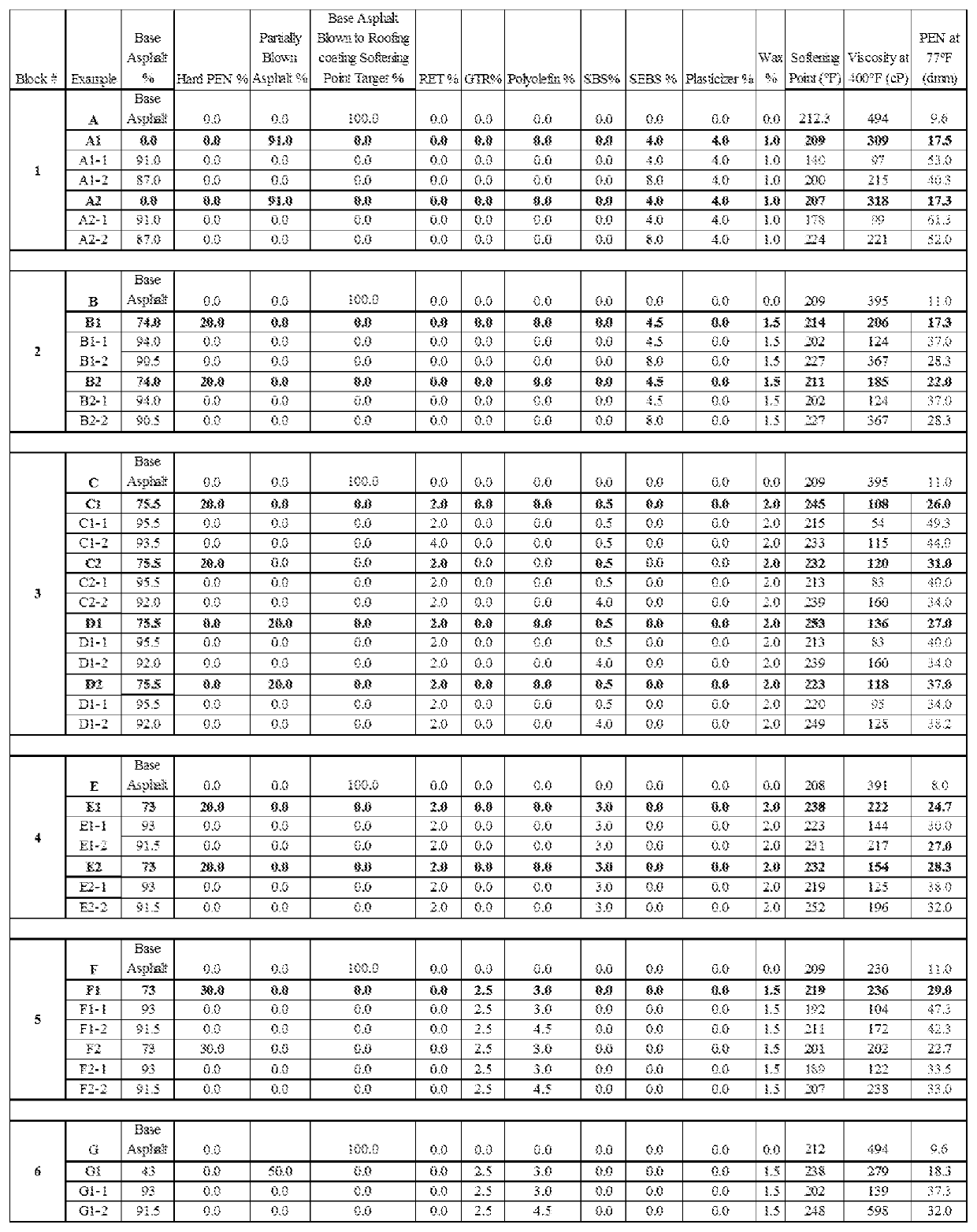

This invention provides for a method for producing polymer modified asphalt using base asphalt (bitumen) blended with partially air blown (“puffed”) asphalt which is further modified with polymers and additives to attain desired properties for industrial applications. The partially blown or blown asphalt is oxidized to a target softening point to suit the application. In another embodiment, the base asphalt is blended with hard PEN asphalt (“Zero PEN Asphalt”) which is further modified with polymers and additives to attain desired properties. By using the partially oxidized asphalt or blending the base asphalt with partially oxidized asphalt or hard PEN asphalt, the amount of polymers and additives needed to achieve desired properties and performance are significantly reduced. This technique can be used to attain polymer modified asphalt having a highly desirable combination of characteristics not otherwise attainable using the base asphalt.

Owner:BMIC LLC

Treatment for Upgrading Heavy Crude Oil

ActiveUS20200216764A1Improve oil well productionIncrease valueDrilling compositionHydrocarbon oils refiningHeavy crude oilFuel oil

The subject invention provides microbe-based products, as well as their use to improve oil well production and increase the value of heavy crude oil. Specifically, the subject invention provides cultivated yeast products, which can be applied to oil and / or oil and gas production equipment to improve production and increase the economic value of heavy crude oil by, for example, upgrading heavy oils and / or converting heavy hydrocarbon substances, such as asphalts, asphaltenes, tars, bitumens and / or petcokes into lighter hydrocarbon substances.

Owner:LOCUS SOLUTIONS IPCO LLC

A kind of production method of high softening point asphalt

ActiveCN103805221BIncrease profitLow viscosityWorking-up pitch/asphalt/bitumen by chemical meansProcess engineeringAsphalt

The invention discloses a production method for high-softening point asphalt. The method is characterized by comprising: mixing an asphalt raw material A mixed with an oxygen-containing gas, leading the oxygen-containing gas mixed asphalt raw material A into an oxidation reactor to fully contact a molten state asphalt raw material B and undergo common reaction, and then introducing the oxygen-containing gas to undergo oxidation reaction, thus obtaining the high-softening point asphalt. Specifically, the asphalt raw material A is coal asphalt, and the asphalt raw material B is petroleum asphalt. The method provided by the invention has the advantages of simple process, convenient operation, high reaction efficiency and low energy consumption, and the obtained product has excellent high temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

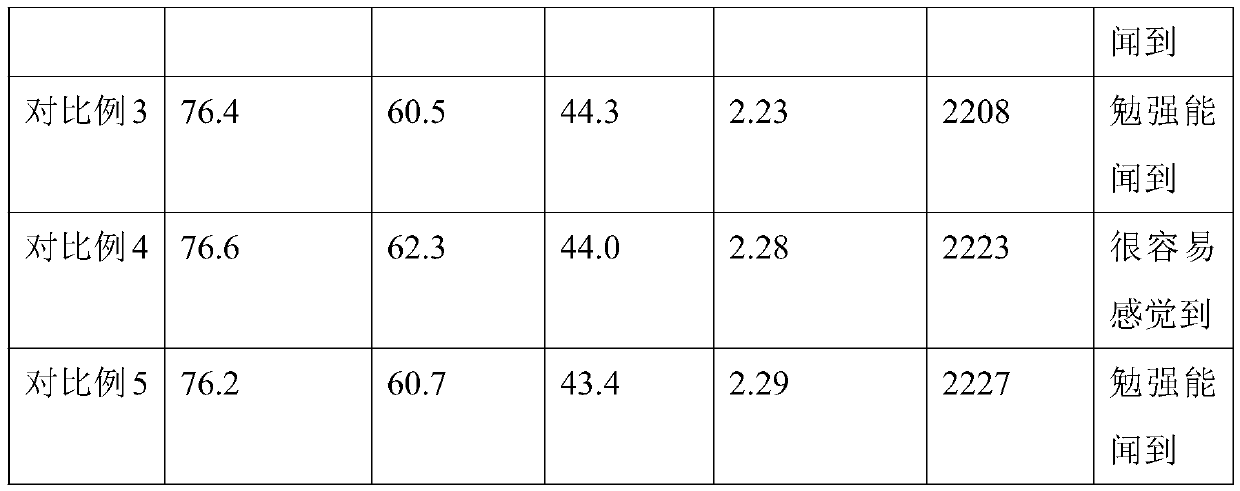

Odorless asphalt mixture, preparation method thereof and application of odorless asphalt mixture on pavement

ActiveCN111234541AHigh strengthImprove rheologyIn situ pavingsBuilding insulationsVegetable oilCarbon nanotube

Owner:湖南省溆怀高速公路建设开发有限公司

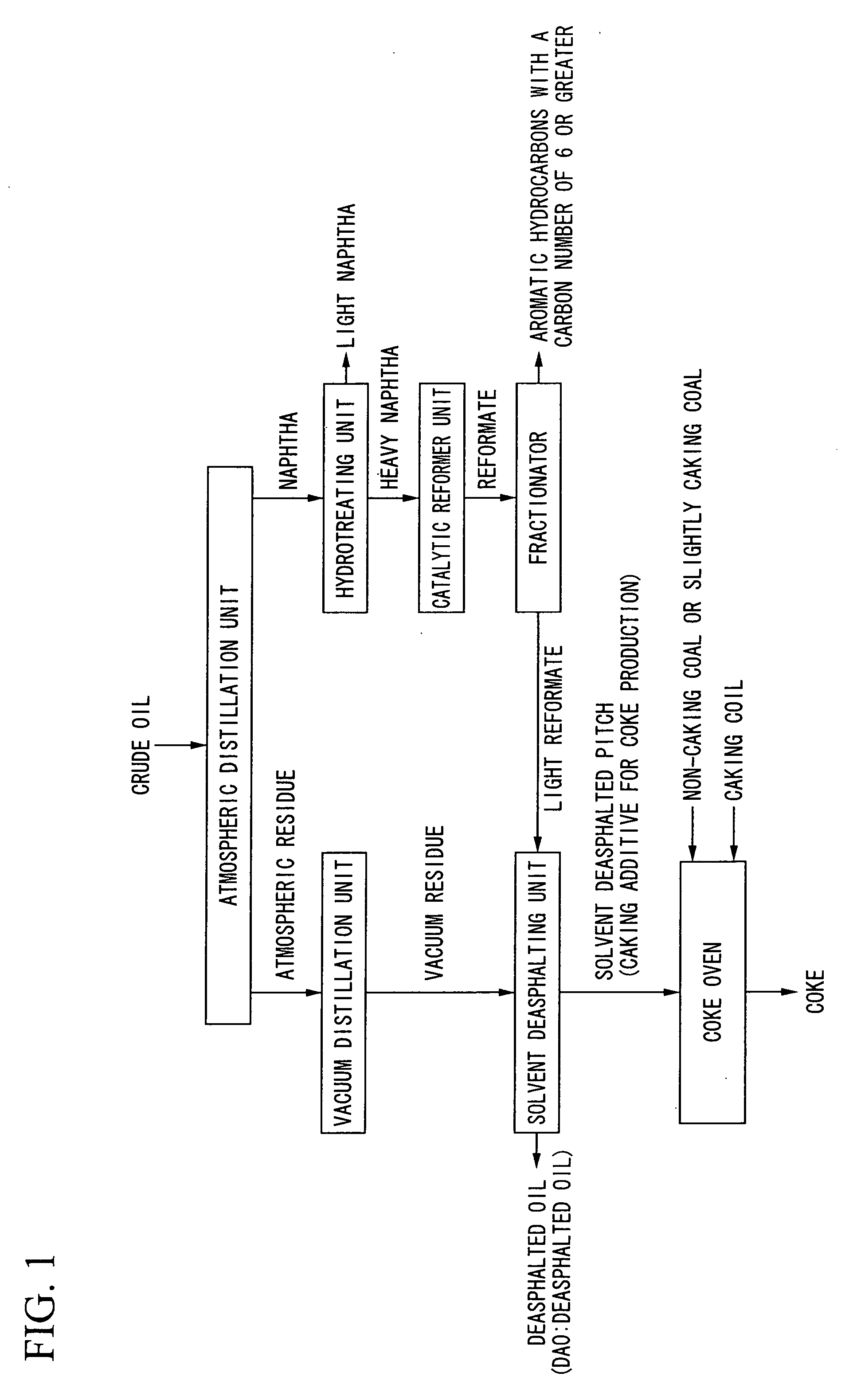

Process for producing caking additive for coke production and process for producing coke

ActiveUS20110284424A1Increase coke strengthFavorable caking additiveThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationCatalytic reformingNaphtha

A process for producing a caking additive for coke production, the process including a step of extracting a solvent deasphalted pitch that can be used as a caking additive for coke production from a residue containing at least one of an atmospheric residue obtained by atmospheric distillation of a crude oil and a vacuum residue obtained by atmospheric distillation and vacuum distillation of a crude oil, wherein the extraction is performed using, as a solvent, a light reformate obtained by catalytic reforming a naphtha fraction that is fractionated from a crude oil by atmospheric distillation of the crude oil.

Owner:MITSUBISHI CHEM CORP

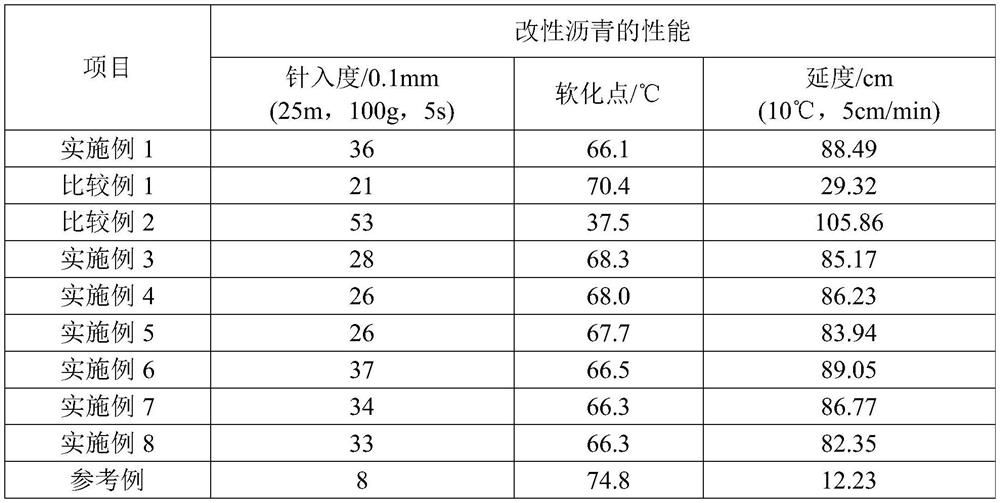

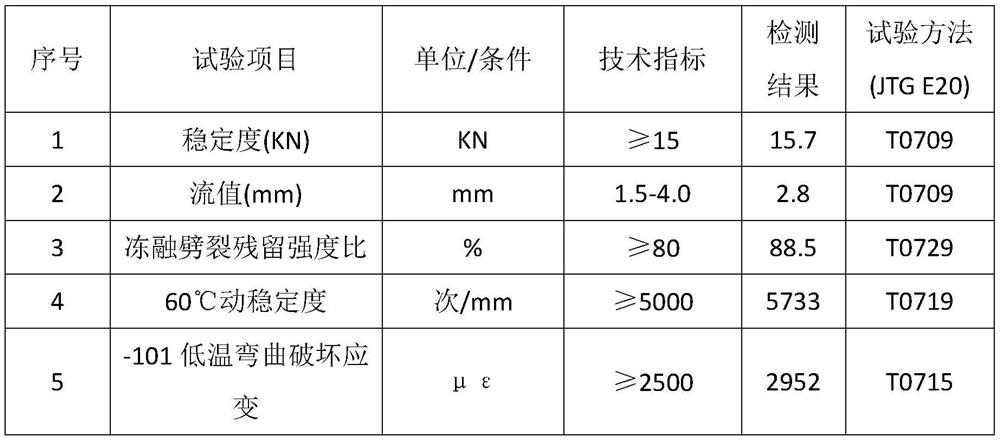

Composition for modifying asphalt, modified asphalt, production methods of the composition and modified asphalt, and asphalt mixture

The invention relates to a composition for modifying asphalt, modified asphalt, production methods of the composition and the modified asphalt, and an asphalt mixture. The composition for modifying asphalt comprises (A) natural asphalt, (B) an asphalt softening agent, (C) a cross-linking agent and (D) a coupling agent; relative to the total mass of the natural asphalt (A), the content of the asphalt softening agent (B) is 15-50% by mass, the content of the cross-linking agent (C) is 0.5-10% by mass, and the content of the coupling agent (D) is 1-6% by mass; and the size of mineral particles in the natural asphalt (A) is less than 800 meshes. The modified asphalt is a cured product of a mixture of the composition for modifying asphalt and matrix asphalt. The asphalt mixture provided by the invention contains the modified asphalt provided by the invention.

Owner:李威风 +1

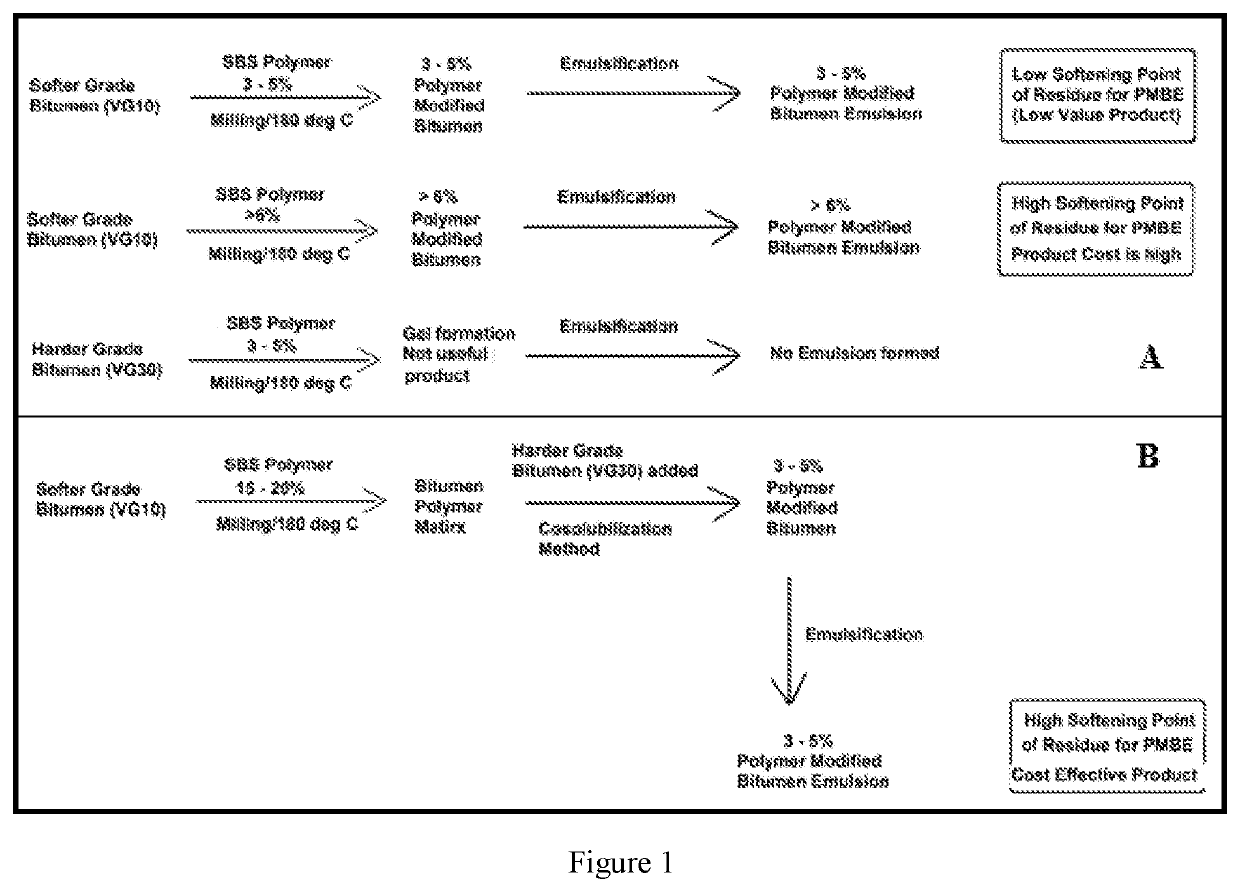

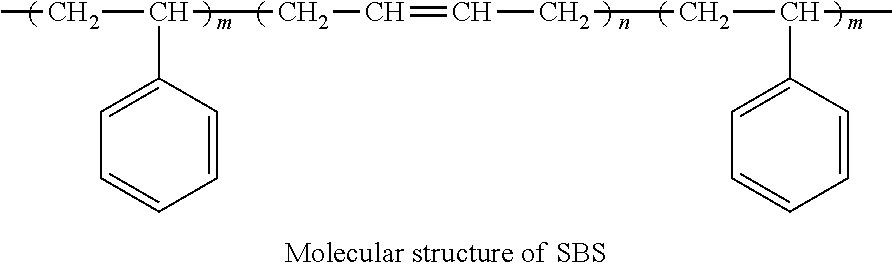

Co-solubilization process for preparing modified bitumen and product obtained thereof

The present invention relates to a co-solubilization process for preparation of a polymer modified bitumen / asphalt and emulsified polymer modified bitumen / asphalt from bitumen, polymer, emulsifier etc. The present invention further relates to a polymer modified bitumen comprising bitumen and styrene-butadiene-styrene (SBS) linear co-polymer having high softening point. The present invention also relates to the use of the polymer modified bitumen and its emulsion in in micro-surfacing for maintenance of pavements.

Owner:INDIAN OIL CORPORATION

Root-puncture-resistant self-healing waterproof coiled material and preparation method thereof

InactiveCN111363372AExcellent root resistance yearsExtended service lifeNon-macromolecular adhesive additivesFilm/foil adhesivesSodium perfluorooctanoateActive agent

The invention provides a root-puncture-resistant self-healing waterproof coiled material. The root-puncture-resistant self-healing waterproof coiled material is prepared from No.10 asphalt, No.60 asphalt, a composite root retarder, SBS, PVA, a KH-560 coupling agent, a filler, an active agent, a light stabilizer, coconut oil fatty acid, a sodium perfluoro-octanoate water solution and dicumyl peroxide. The preparation method comprises the steps of premixing, high-speed shearing and mixing, the high-speed shearing speed is 8-10 Kr / min, the environment humidity is kept at 60.5 + / - 0.5%; in the mixing process, the jacking pressure is 0.75-0.8 MPa, and the rotating speed is 65-70 rmp / min. The root-puncture-resistant self-healing waterproof coiled material has excellent root puncture resistance and a long service life, after thermal aging, the root puncture resistant is enhanced and the service life is prolonged; the coiled material also has a large excellent tensile force and good wind uplift resistance, the maximal peak tensile force is 1017-1105 N / 50 mm, the wind uplift resistance reaches 12.5-14.8 KPa, and the application range is wide.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

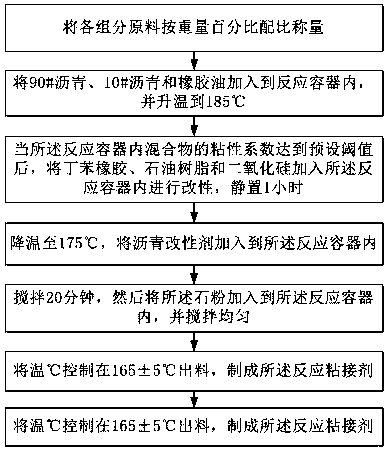

Reaction adhesive and preparation method thereof

The present disclosure relates to a reaction adhesive and a preparation method thereof, the reaction adhesive comprises 90# asphalt, 10# asphalt, rubber oil, SBS, PE, styrene butadiene rubber, petroleum resin, an asphalt modifier, a silane coupling agent, stone powder and silica. By adding of the silane coupling agent and the silica, the asphalt is modified, and by modifying of the characteristicsof the asphalt, when the reaction adhesive is applied, lean concrete grout is first used for paving, and then the reaction adhesive is laid on the surface of cement. During the solidification of thecement, hydration heat is formed, free silica molecules are released, the free silica molecules can be combined with active silica molecules released in the reaction adhesive, chemical bonds are formed in capillary pores of a cement base layer for crosslinking, and the bond strength is improved.

Owner:金华一方金雨伞防水科技有限公司

Manufacturing method for lightweight wall colorful asphalt brick

The invention discloses a manufacturing method for a lightweight wall colorful asphalt bricks. The method comprises the steps of selecting 10 # asphalt and 100 # asphalt and proportioning the 10 # asphalt and the 100 # asphalt according to a weight ratio of 50%-60% of the 10 # asphalt and 40%-50% of the 100 # asphalt; injecting conduction oil to the selected 10 # asphalt and 100 # asphalt, heating to a temperature of 200 DEG C-230 DEG C with stirring; adding PP polymer plastic particles and SBS elastomer materials for reinforcement treatment, stirring for 1-2 hours, adding a calcium bicarbonate raw material, stirring for 1-2 hours, taking out when the temperature reaches 180 DEG C-190 DEG C and injecting to an oil pot; performing double-faced dip coating by using a glass fiber blanket as a base matrix after the asphalt is taken out; coating colorful sand particles on the front surface and scattering isolation ore sand on the back surface after dip coating; cooling and cutting into the lightweight wall colorful asphalt bricks. The lightweight wall colorful asphalt bricks manufactured by the method have light mass, are waterproof and have beautiful appearance. The lightweight wall colorful asphalt bricks solve the problems that conventional wall ground tiles have ponderous in shapes, poor waterproof effect and inaesthetic appearance, and are not suitable for decorations.

Owner:杭州海博建材有限公司

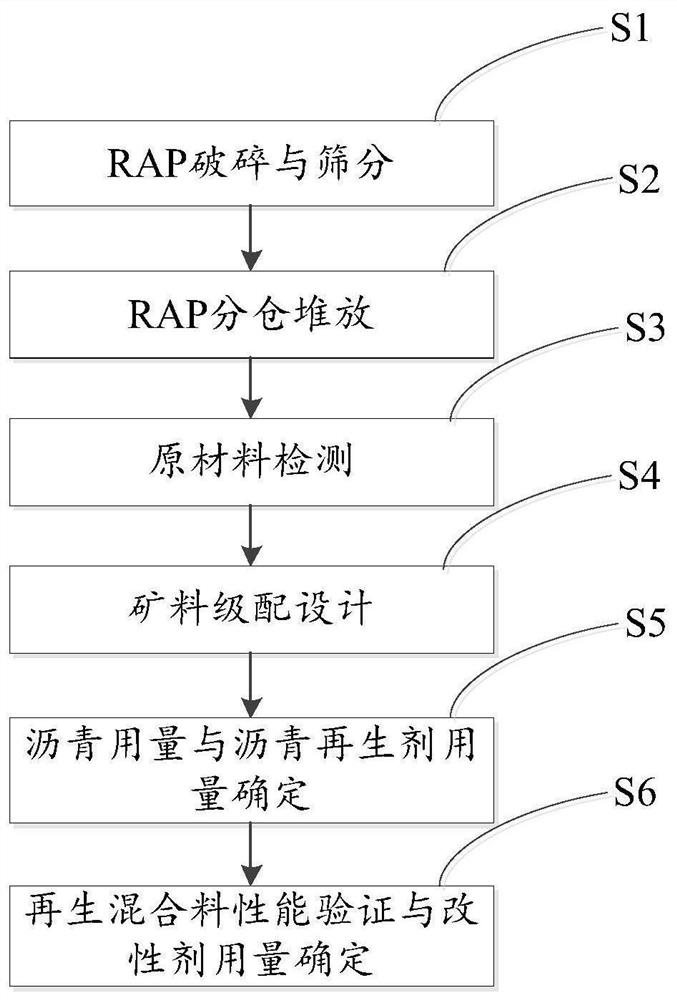

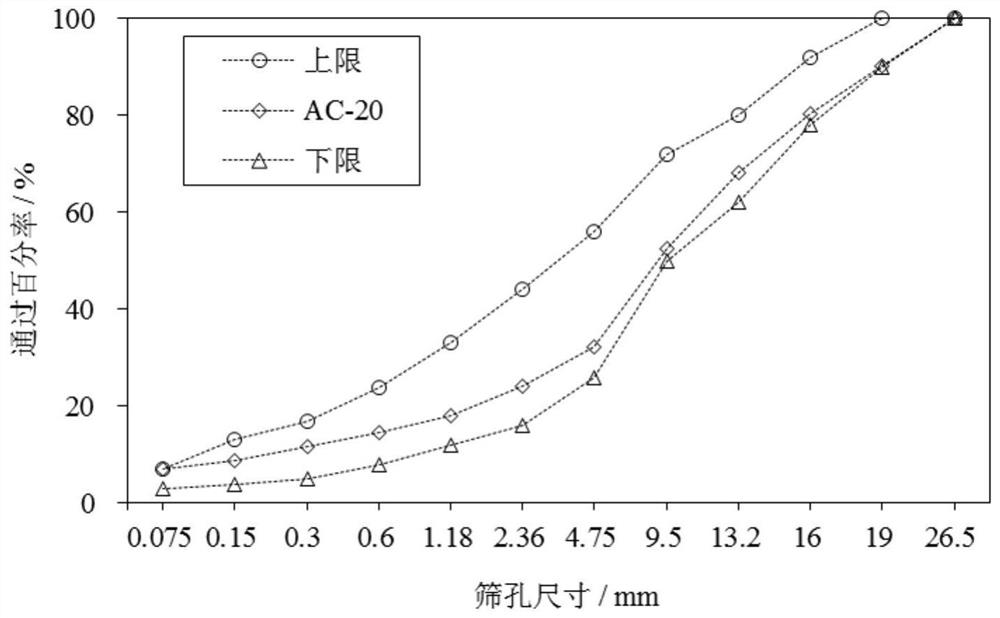

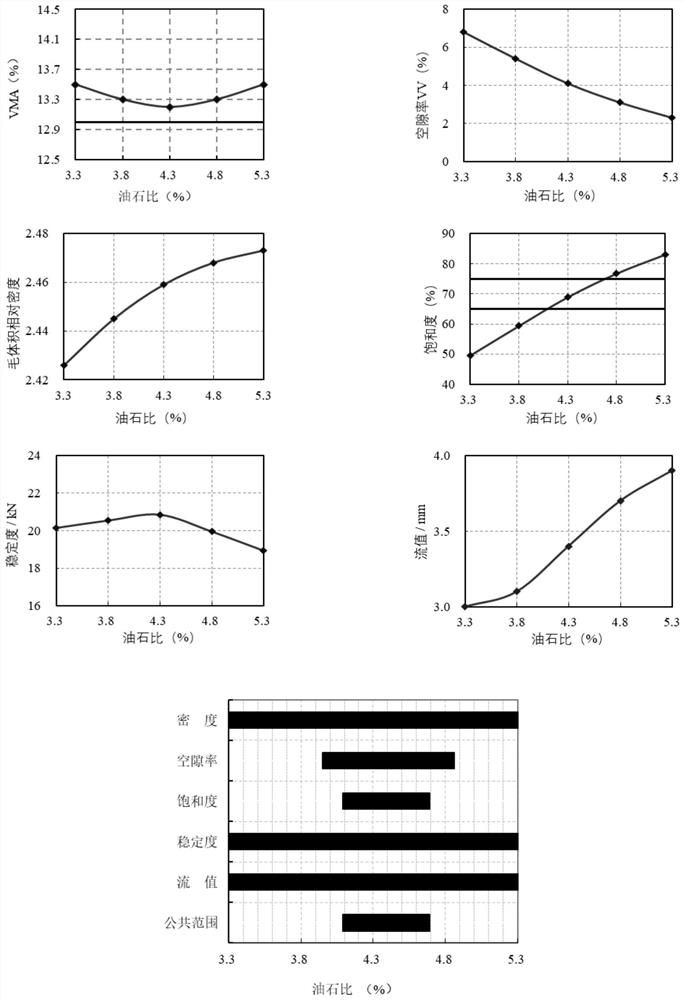

High-doping-amount RAP hot mix plant recycled modified asphalt mixture and preparation method thereof

The invention provides a high-doping-amount RAP hot mix plant recycled modified asphalt mixture. The high-doping-amount RAP hot mix plant recycled modified asphalt mixture is prepared from, by mass, 40%-70% of RAP, 23.4%-58.3% of new aggregate, 0%-3% of mineral powder, 1.5%-6% of new asphalt, an asphalt recycling agent accounting for 3%-5% of the mass of old asphalt in the RAP and 0.01%-0.3% of a recycled SBS modified asphalt mixture modifier. The preparation method comprises the following steps: RAP crushing and screening, raw material detection, mineral aggregate gradation design, determination of the amount of asphalt and the amount of the asphalt recycling agent, performance verification of a regenerated mixture, determination of the amount of the modifier, and material blending. By improving the dual performance of the aged asphalt and the recycled modified asphalt mixture, the utilization value and the utilization rate of the RAP are improved, the performance of the recycled modified asphalt mixture is improved, the preheating temperature of the RAP is reduced, and efficient regeneration and utilization of the modified asphalt mixture with high RAP doping amount are realized.

Owner:湖南省交通科学研究院有限公司

Hydroprocessing oil sands-derived, bitumen compositions

ActiveUS20150175893A1Easy to convertQuality improvementHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogen treatmentOrganic chemistry

Disclosed are processes for producing deasphalted bitumen and heavy bitumen compositions from oil sands and processes for upgrading the bitumen compositions. The processes for producing the deasphalted bitumen and heavy bitumen compositions involve a Phase I and / or Phase II extraction solvent. According to the Phase I process, a high quality oil sands-derived, deasphalted bitumen can be produced using a Phase I type solvent. According to the Phase II process, a substantial amount of the heavy bitumen on the oil sand can be extracted using a Phase II type solvent, while producing a relatively a tailings by-product that is non-harmful to the environment. The heavy bitumen from the Phase II type extraction process can be hydroprocessed for ready conversion into relatively high volumes of high quality transportation fuels.

Owner:EPIC OIL EXTRACTORS

Coated asphalt, asphalt felt and preparation method and application of asphalt felt

PendingCN111945439AImprove low temperature and gentlenessImprove heat resistanceCoatingsTextiles and paperInsulation layerFoam glass

The invention provides coated asphalt, an asphalt felt and a preparation method and application of the asphalt felt. The coated asphalt is prepared from the following components including, by weight,40-60 parts of oxidized asphalt and 15-40 parts of inorganic filler. The coated asphalt is obtained by firstly oxidizing matrix asphalt and then conducting filling with the inorganic filler, and has good high and low temperature performance and water damage resistance. The coated asphalt is applied to the asphalt felt, and the mass per unit area of each material contained in the asphalt felt is controlled, so that the asphalt felt is smooth in surface and uniform in thickness, can keep excellent flexibility at low temperature, can keep excellent heat resistance at high temperature, and has excellent compressive strength, tearing strength, shrinkage resistance and waterproof capacity; and in addition, the adaptability to foam glass bricks is excellent, the pressure bearing capacity and uniformity of the foam glass bricks can be remarkably improved, and the effects of water resistance, moisture resistance and shrinkage resistance are achieved on a cold insulation layer of an LNG storagetank.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Vulcanized crosslinked asphalt waterproof coiled material

InactiveCN111923531AHigh mechanical strengthImprove high temperature resistanceSynthetic resin layered productsConstructions elementsPolyesterFiber

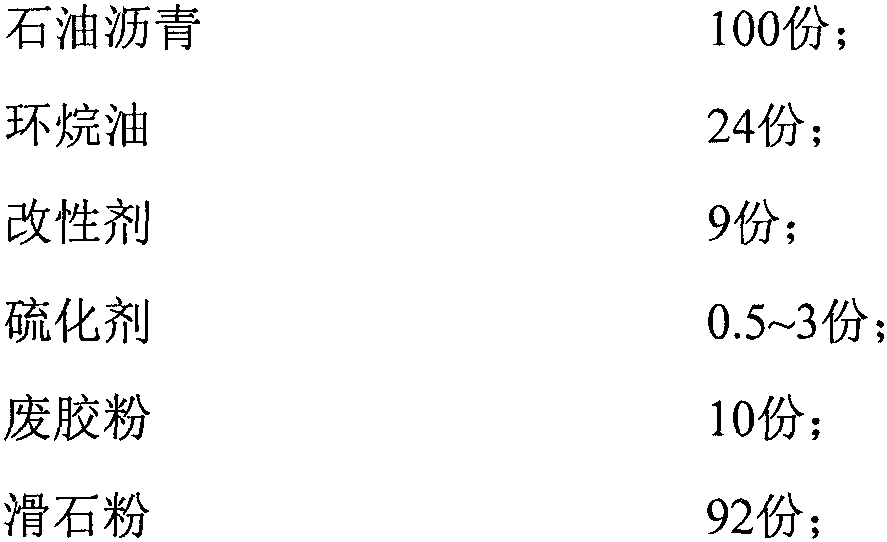

The invention relates to a vulcanized crosslinked asphalt waterproof coiled material. The vulcanized crosslinked asphalt waterproof coiled material is prepared from the following raw materials in parts by weight: 100 parts of petroleum asphalt, 24 parts of naphthenic oil, 9 parts of a modifier, 0.5-3 parts of a vulcanizing agent, 10 parts of waste rubber powder and 92 parts of talcum powder. Polyester fibers serve as a base, the upper surface and the lower surface of the base are coated with modified asphalt layers, the surfaces of the modified asphalt layers are coated with isolation layers;and the modified asphalt is located between the isolation layer and the base layer. A vulcanizing agent is added in the production process, so that asphalt and asphalt as well as asphalt and the modifier carry out a crosslinking reaction to form a three-dimensional crosslinked network structure, and the mechanical strength and the high-temperature resistance of the asphalt waterproof coiled material can be effectively improved. The invention provides a new idea for improving the high temperature resistance of the SBS waterproof coiled material, the adopted production process is simple, the energy consumption is lower, and the production cost can be effectively reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultrathin overlay mixture for preventive maintenance of asphalt pavement, preparation method and additive

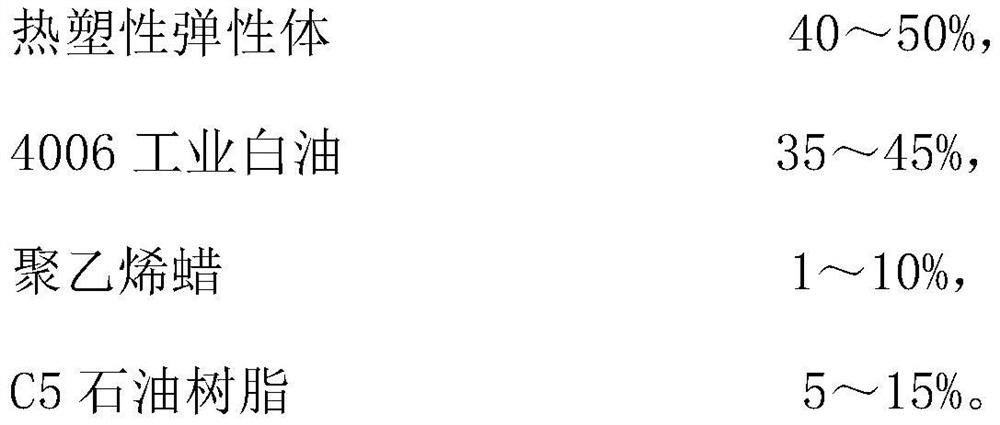

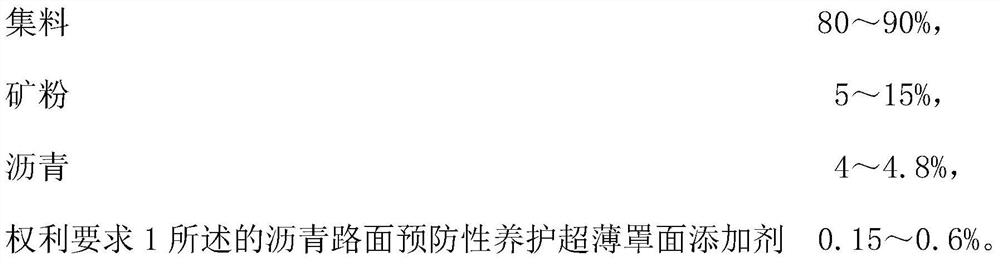

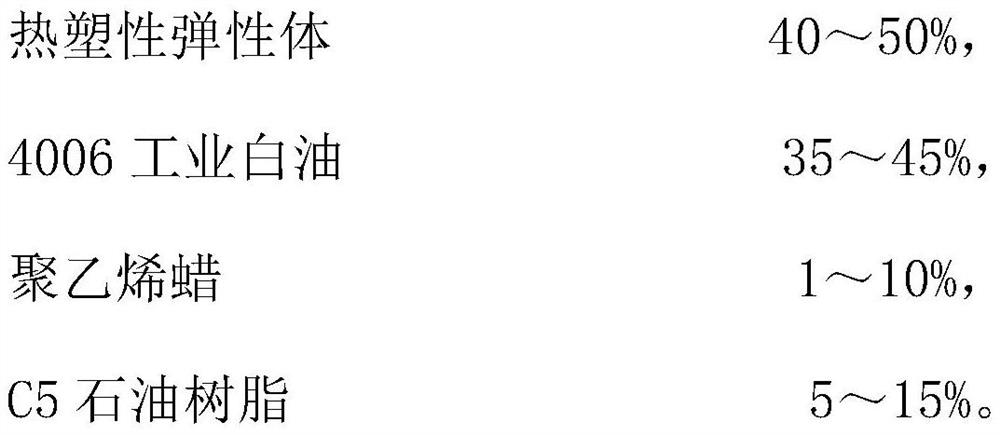

The invention discloses an ultrathin overlay mixture for preventive maintenance of an asphalt pavement, a preparation method and an additive. The mixture comprises the following components: 80-90% of aggregate, 5-15% of mineral powder, 4-4.8% of asphalt and 0.15-0.6% of an ultrathin overlay additive for preventive maintenance of asphalt pavement, wherein the ultrathin overlay additive for preventive maintenance of the asphalt pavement comprises the following components: 40-50% of a thermoplastic elastomer, 35-45% of 4006 industrial white oil, 1-10% of polyethylene wax and 5-15% of C5 petroleum resin. According to the present invention, the formula of the ultrathin overlay additive is reasonable, the anti-scattering ability and the water damage resistance of the ultrathin overlay additive can be improved, the flexibility of the surface layer concrete can be improved, and the good anti-fatigue and anti-cracking ability can be provided; and the additive is produced by directly putting the additive into a mixing station, special equipment is not needed, the process is simple, and wide popularization and application are facilitated.

Owner:北京中天路业科技有限公司

Modified asphalt with high adhesion and water resistance

InactiveUS20200181019A1Increases asphalt adhesionImprove adhesionIn situ pavingsSolid waste managementEpoxyPolymer science

Asphalt, chemically reacted, comprising a bifunctional organosilane of the epoxy, amino and ureide type in a proportion of 0.4 to 2% by weight; at least one petrous aggregate; and a catalyst in a proportion of 10 to 20% by weight; wherein said bifunctional organosilane is selected from the groups consisting of 2-(3,4-epoxycyclohexyl)-ethyltrimetoxisilane, 2-3,4-epoxycyclohexyl)-ethyltrietoxisilane, 3-aminopropyltriethoxysilane, 3-aminopropyl silanetriol, 3-aminopropyltrimethoxysilane, 3-aminopropylmethyldiethoxysilane, N-(2-aminoethyl)-3-aminopropylmethyldimetilsilane, 3-(2-aminoethylaminopropyl)-trimethoxysilane, N-(2-aminoethyl)-3 aminopropyl triethoxysilane, 3-(2-aminoethylamino)-propyl-dimethoxysilane, trimethoxysilane diethylenetriamine propyl-3, γ-piperazinyl butyl dimethyl propyl silane, 3-(N-phenylamine) propyltrimethoxysilane, 3-(N, N-dimethylaminopropyl) aminopropyl-methyldimethoxysilane, 3-ureidepropyltrimethoxysilane, 3-ureidepropyltrietoxisilano; and wherein said bifunctional organosilane increases the asphalt adhesion with the at least one petrous aggregate and the water resistance even in case of immersed into the same. Said asphalt is designed to be used in the production of hot and cold asphaltic mixtures as well as foamed asphalt, asphaltic emulsions and other applications related to the use thereof.

Owner:GRUPO ASFALTO PROCESADOS S A DE CV

Treatment for upgrading heavy crude oil

ActiveUS10907106B2Increase valueIncrease productionDrilling compositionHydrocarbon oils refiningFuel oilPetroleum oil

The subject invention provides microbe-based products, as well as their use to improve oil well production and increase the value of heavy crude oil. Specifically, the subject invention provides cultivated yeast products, which can be applied to oil and / or oil and gas production equipment to improve production and increase the economic value of heavy crude oil by, for example, upgrading heavy oils and / or converting heavy hydrocarbon substances, such as asphalts, asphaltenes, tars, bitumens and / or petcokes into lighter hydrocarbon substances.

Owner:LOCUS SOLUTIONS IPCO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com