High-doping-amount RAP hot mix plant recycled modified asphalt mixture and preparation method thereof

A technology for modifying asphalt and mixtures, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor performance of recycled mixtures, high RAP preheating temperature, and low RAP added value, etc. Achieve the effect of improving performance, strong practicability and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

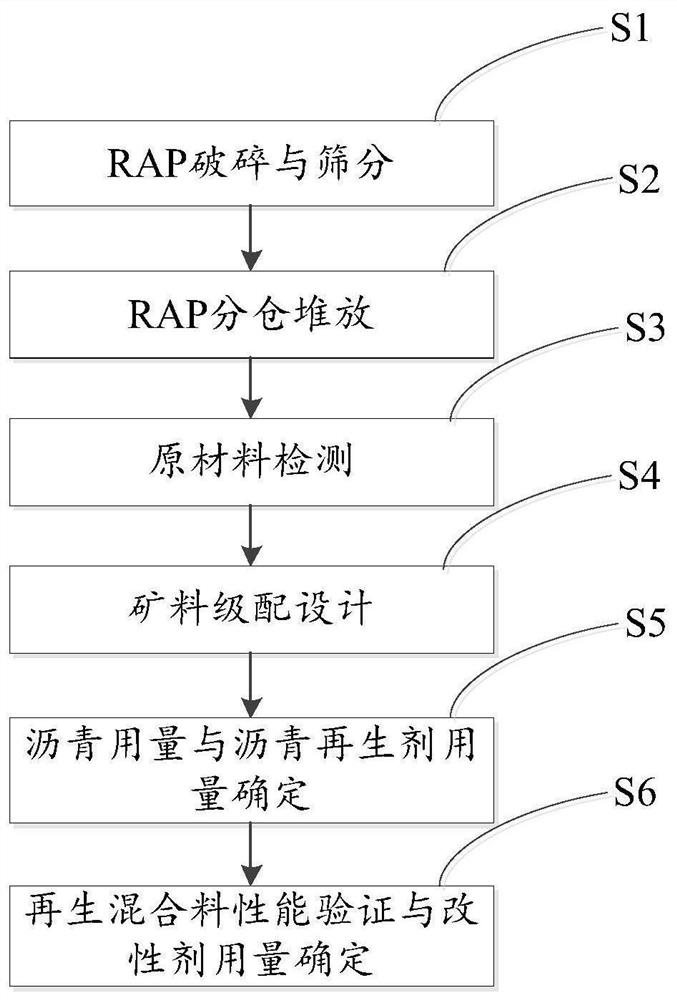

[0042] Such as figure 1 As shown, the present invention also provides a kind of preparation method of high-volume RAP plant-mixed heat regeneration modified asphalt mixture, comprising:

[0043] S1, RAP crushing and screening

[0044] The same batch of recycled materials obtained by milling and planing is fully mixed by machinery, crushed to a particle size ≤ 30mm, and then sieved, and sieved into grades 2 to 5 reference materials with different particle sizes;

[0045] S2, RAP separate warehouse stacking

[0046] The reference materials obtained in step S1 are evenly stacked on the hardened and well-drained site to avoid mixing of different types of reference materials. The stacking height is ≤ 4m to avoid heavy pressure and agglomeration of materials. Rainy areas are covered with rainproof sheds;

[0047] S3. Raw material testing

[0048] Selected aggregates, mineral powder, RAP, asphalt, asphalt regenerant, recycled SBS modified asphalt mixture modifier, randomly sampled...

Embodiment 1

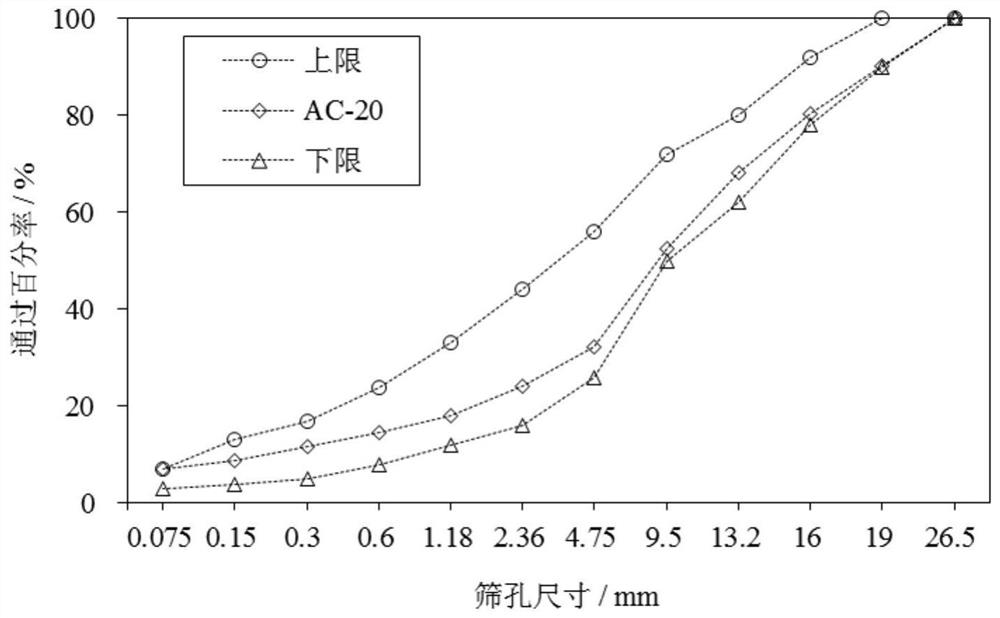

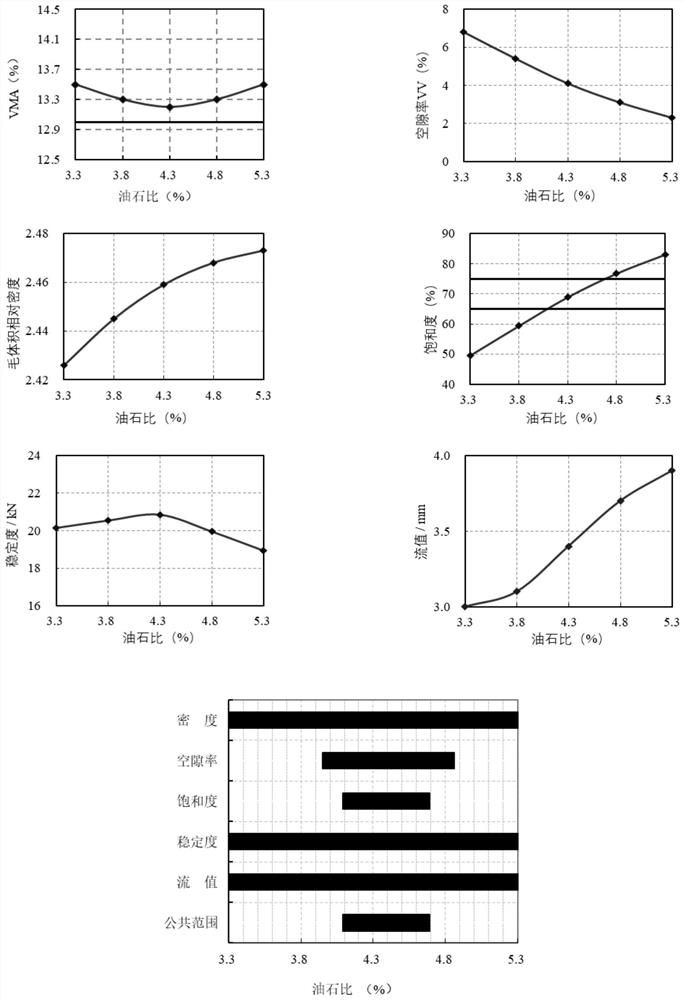

[0060] The high-volume RAP plant-mixed heat-regenerated modified asphalt mixture of the present invention is used in the medium surface layer recycled SBS modified asphalt mixture AC-20C, replacing the conventional road surface medium surface layer AC-20C hot-mixed SBS modified asphalt concrete, ensuring While improving the performance of concrete roads, it can fully utilize recycled asphalt pavement materials, reduce the amount of new aggregates, reduce the proportion of external admixtures, and achieve the effects of energy saving and emission reduction. In this example, the high-volume RAP plant-mixed heat-recycled modified asphalt mixture is formed according to the following steps:

[0061] (1) RAP crushing and screening

[0062] The mixing station fully mixes the surface layer recycled materials of a municipal road obtained by milling and planing, and then crushes them to a particle size of ≤30mm, and sieves them into 1# of 16mm~30mm and 0~16mm with a 16mm sieve hole RAP...

Embodiment 2

[0114] In this example, the high-volume RAP plant-mixed hot-recycled modified asphalt mixture is used for the mid-surface layer recycled SBS modified asphalt mixture AC-20C, which is formed according to the following steps:

[0115] (1) RAP crushing and screening

[0116] The mixing station fully mixes the recycled surface layer of an expressway obtained by milling and planing, and then crushes it to a particle size of ≤30mm, and sieves it into 1# of 15mm~30mm and 0~15mm with a 15mm sieve hole. RAP and 2#RAP.

[0117] (2) RAP is stacked in separate warehouses

[0118] The 1#RAP and 2#RAP obtained in step (1) were evenly stacked in two hardened and well-drained silos, with a stacking height of 3m.

[0119] (3) Raw material testing

[0120] The selected aggregates and mineral powders are randomly sampled to test the quality, and each index must meet the requirements of the "Technical Specifications for Highway Asphalt Pavement Recycling" (JTG / T 5521-2019) and the Technical Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Splitting strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com