Coated modified artificial graphite negative electrode material, preparation method thereof and lithium ion battery

An artificial graphite negative electrode and artificial graphite technology, applied in the direction of negative electrodes, secondary batteries, battery electrodes, etc., can solve the problems of poor battery power performance, uneven mixing, poor mixing coating effect, etc., and achieve battery power performance improvement, cycle excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

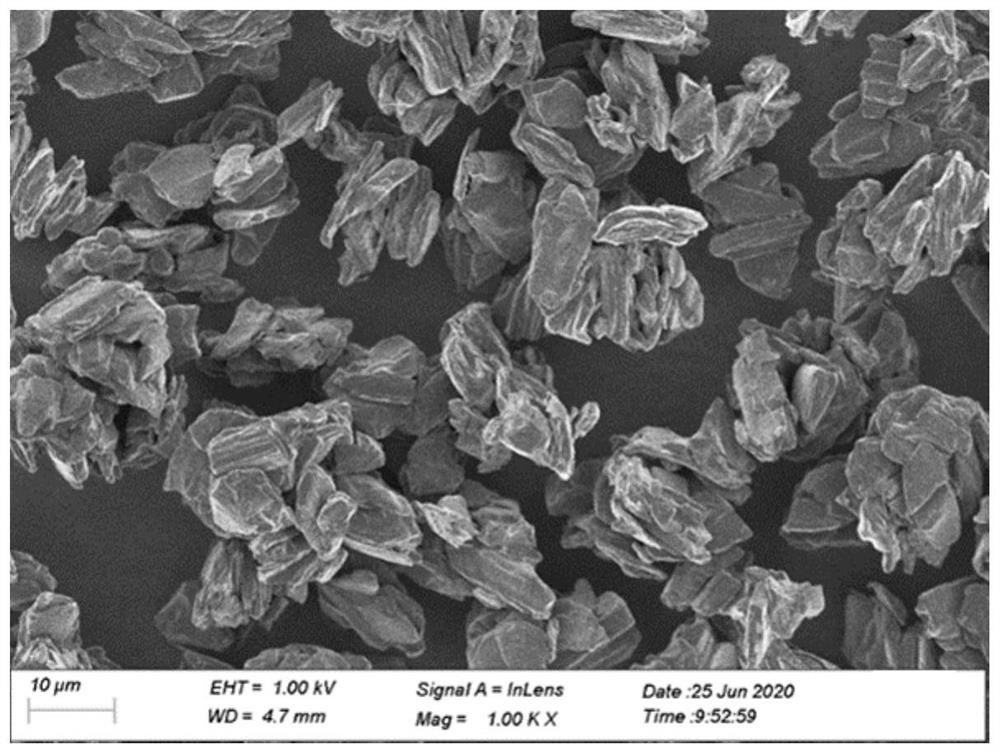

Image

Examples

Embodiment 1

[0066] The preparation method of the coated modified artificial graphite negative electrode material of the present embodiment, the specific steps are as follows:

[0067] ① Preparation of secondary particles of artificial graphite

[0068] (1) The ordinary petroleum coke raw material is pulverized by mechanical milling, and fine powder is removed by classification, and the median particle diameter D50 of the pulverized material obtained is 10.8 μm;

[0069] (2) Fully mix the pulverized material and asphalt in a CDLW-8000 ribbon mixer with a mass ratio of 100:8, and the mixing time is 50 minutes;

[0070] (3) The mixture is heat-treated in a horizontal reactor under the protection of a nitrogen atmosphere at a temperature of 700°C for 8 hours;

[0071] (4) Carry out graphitization treatment under the condition of 3000 DEG C, graphitization time is 30h, obtains the secondary particle of the artificial graphite that median diameter D50 is 15.5 μ m;

[0072] ②Secondary particle...

Embodiment 2

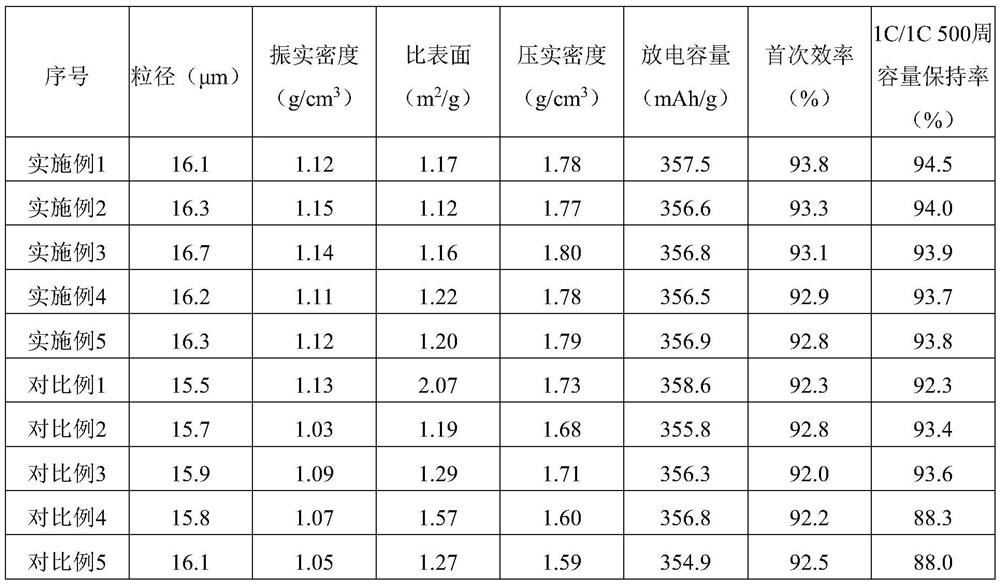

[0080] The difference between this example and Example 1 is that the graphene in the coal tar residue and the graphene slurry in step (5) is fully dispersed with a mass ratio of 6:0.02 to obtain a coated modified artificial graphite negative electrode material The median particle size D50 is 16.3μm, the particle size distribution range is 2.6-37.7μm, and the tap density is 1.15g / cm 3 , the specific surface area is 1.12m 2 / g, the discharge capacity is 356.6mAh / g, and the first efficiency is 93.3%.

Embodiment 3

[0082] The difference between this example and Example 1 is that the graphene in the coal tar residue and the graphene slurry in step (5) is fully dispersed with a mass ratio of 6:0.08 to obtain a coated modified artificial graphite negative electrode material The median particle size D50 is 16.7μm, the particle size distribution range is 3.4-38.4μm, and the tap density is 1.14g / cm 3 , the specific surface area is 1.16m 2 / g, the discharge capacity is 356.8mAh / g, and the first efficiency is 93.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com