Net cage floating pipe framework construction method

A construction method and floating tube technology, applied in the field of cage culture, can solve the problems of high time cost, obstacles in organizing the next construction, low efficiency, etc., and achieve the effect of solving the difficulty of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

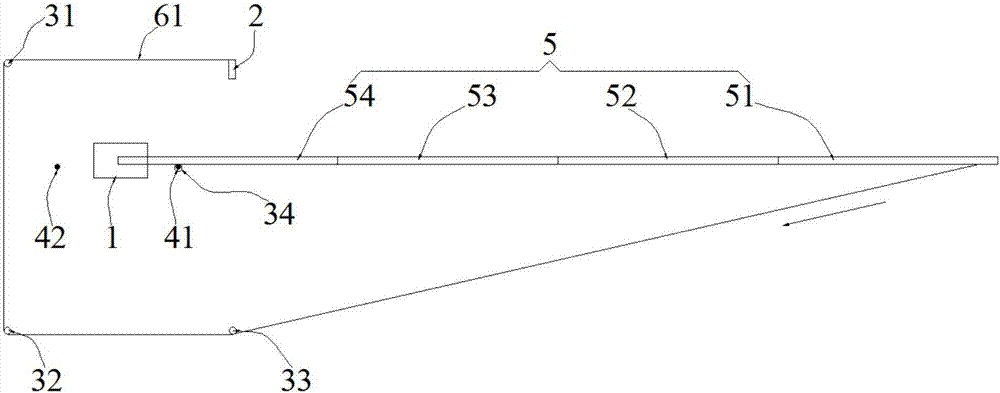

[0066] Such as Figure 9 As shown, Embodiment 1 of the present invention is based on the above-mentioned inventive concepts, and adopts the following preferred solutions:

[0067] In order to ensure that the outer end of the linear floating pipe 5 used for construction in step 4 can stretch into the slips of the heat fusion welding machine 1 along the direction from the second stop post 42 to the first stop post 41, reduce the construction cost. The impact of the elastic force of the linear floating pipe 5 itself on this process is to realize the docking of the two ports of the linear floating pipe 5 for construction. Positioning column 44; the third limiting column 43 and the fourth limiting column 44 are relatively fixed with the position of the first limiting column 41 and are all located in the quadrangular area, and the third limiting column 43 is close to the third guide roller 33 Setting, the fourth limit post 44 is set close to the second guide roller 32;

[0068] In...

Embodiment 2

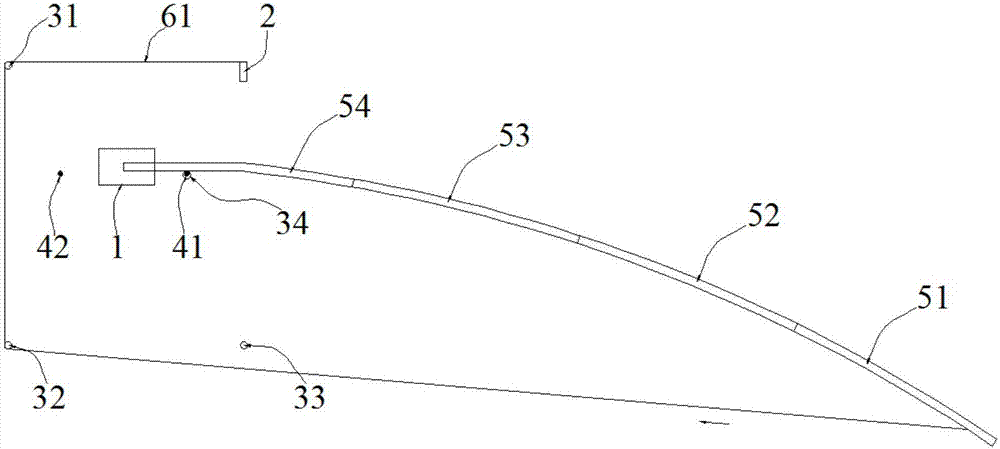

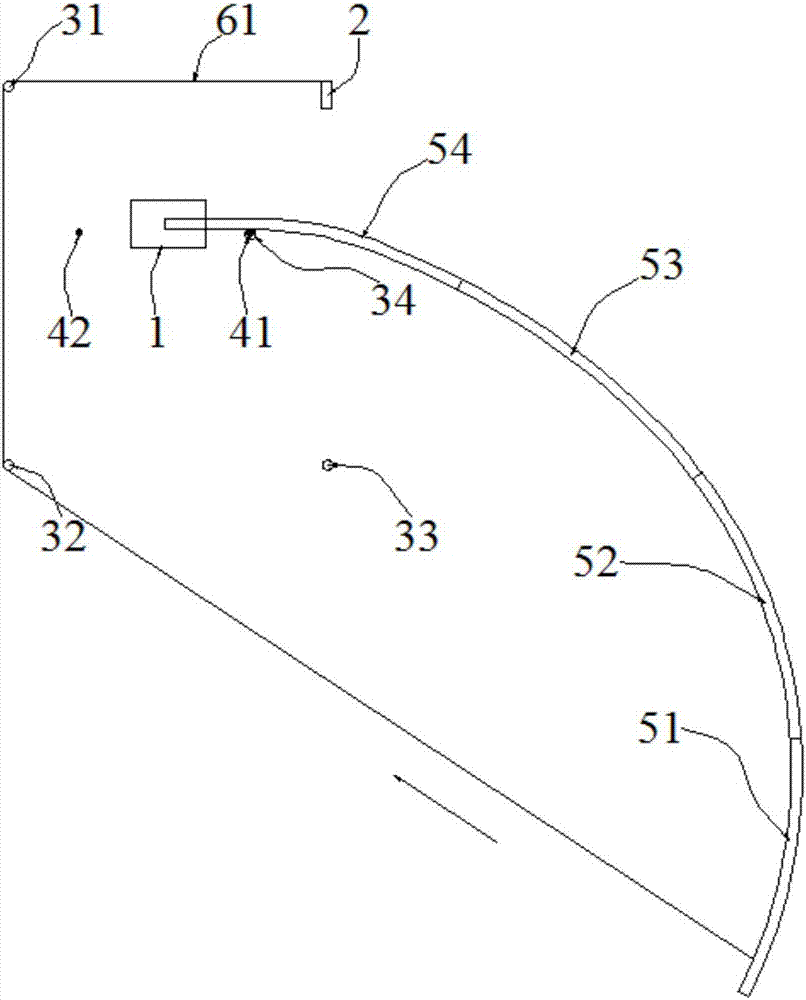

[0070] Such as Figures 10 to 12 As shown, Embodiment 2 of the present invention is basically the same as Embodiment 1 above, and their difference lies in:

[0071] The net cage floating pipe frame construction method of the second embodiment of the present invention is also implemented based on the platform 7 floating on the water surface, and the net cage floating pipe frame construction device is installed on the platform 7; The size of the facilities and platform 7 will be finally determined based on factors such as the size of the construction net cage, the number of net cages (considering how much material needs to be prepared), the size of the rest and living area of the operator, and its layout is set as a material stacking area and a welding area according to the requirements of the new technology. area and bending forming area, the platform itself has functions such as power supply equipment or connection to shore power devices, and can be used for workers to rest ...

Embodiment 3

[0076] Such as Figure 13 As shown, Embodiment 3 of the present invention can be implemented based on Embodiment 1 or Embodiment 2 above, and their differences are:

[0077] In step one of Embodiment 3 of the present invention, the linear floating pipe 5 for construction is welded sequentially by multiple standard linear floating pipes with equal lengths, and the welding method of any two adjacent standard linear floating pipes is as follows: : Firstly, fix the inner end of the previous section of the standard straight line floating pipe and the outer end of the next standard straight line floating pipe in the slips of the heat fusion welding machine 1, and the previous section of the standard straight line The inner end nozzle of the type floating pipe is connected with the outer end nozzle of the standard straight line floating pipe in the next section, and then the inner end of the standard straight line floating pipe in the previous section is connected with a hot-melt wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com