Reaction adhesive and preparation method thereof

A technology of reaction bonding and reaction container, applied in the field of reaction adhesive and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In the embodiments of the present application, the weight ratio of each component of the reactive adhesive is as follows:

[0047] 90#asphalt 38%

[0048] 10#asphalt 2%

[0049] Rubber oil 12%

[0050] SBS 4%

[0051] PE 2%

[0052] Styrene butadiene rubber 5%

[0053] Petroleum resin 0.5%

[0054] Asphalt modifier 0.5%

[0055] Stone powder 20%

[0056] Silica 3%;

[0057] Silane coupling agent 5%;

[0058] Wherein, when the ratio is used, the sum of the percentages of the content of each component in the composition is equal to 100%.

[0059] In this application, 90# asphalt in the reactive adhesive is mainly used as the main material of the reactive adhesive, which can endow the reactive adhesive with good anti-aging properties and good adhesion to the concrete base.

[0060] Rubber oil has the functions of adjusting the viscosity of the rubber, improving the processing performance of the rubber, and providing the anti-aging performance and flexibility of the rubber.

[0061] The role o...

Embodiment 3

[0082] In the embodiments of the present application, the components of the reactive adhesive also include rubber powder, and the weight ratio of each component is as follows:

[0083] 90# Asphalt 35%

[0084] 10#asphalt 3%

[0085] Rubber oil 7%

[0086] SBS 6%

[0087] PE 5%

[0088] SBR 2%

[0089] Petroleum resin 4%

[0090] Rubber powder 8%

[0091] Asphalt modifier 1%

[0092] Stone powder 21%

[0093] Silica 3%;

[0094] Silane coupling agent 5%;

[0095] Wherein, when the ratio is used, the sum of the percentages of the content of each component in the composition is equal to 100%.

Embodiment 4

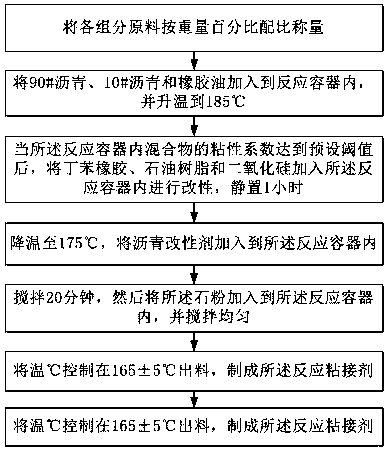

[0097] The embodiment of the present application also provides a preparation method of the reactive adhesive, which is used to prepare the reactive adhesive described in the foregoing embodiment 1. According to the components provided in the foregoing embodiment 1, the preparation method is as follows:

[0098] 1. Weigh each component raw material according to the weight percentage ratio.

[0099] 2. Add 90# asphalt, 10# asphalt and rubber oil into the reaction vessel and heat up to 185°C.

[0100] 3. Add SBS and PE into the reaction vessel and keep the temperature at 185°C for 1 hour.

[0101] 4. When the viscosity coefficient of the mixture in the reaction vessel reaches a preset threshold, add styrene butadiene rubber, petroleum resin, silica and silane coupling agent into the reaction vessel for modification, and let it stand for 1 hour.

[0102] Setting the preset threshold is mainly to make the viscosity of the mixture in the reactor meet the requirements. The preset threshold ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com