Lignin weather-resistant fiberboard adhesive and production method thereof

A production method and lignin technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the quality problems of wood-based panels or fiberboards, adhesive aging, formaldehyde release, etc., and achieve mature industrial conditions and surface The effect of low tension and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

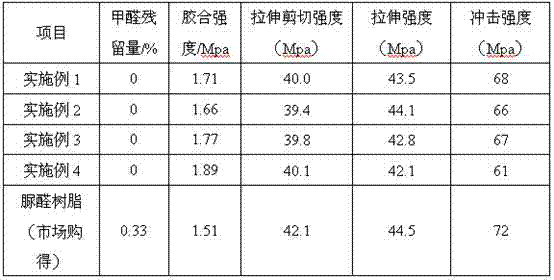

Examples

Embodiment 1

[0030] Embodiment 1 lignin weather resistance fiberboard adhesive production formula and method 1

[0031] Recipe composition:

[0032] 25 parts of lignin;

[0033] 25 parts of phenol;

[0034] 15 parts tapioca starch;

[0035] 0.5 parts of vinyltriethoxysilane;

[0036] 0.5 parts of anilinomethyltriethoxysilane;

[0037] 0.5 part of dibutyl hydroxytoluene;

[0038] Butylated hydroxyanisole 0.5 parts;

[0039] 3 parts of phenyl o-hydroxybenzoate;

[0040] Polydimethylsiloxane 0.1 part.

[0041] Production method: Firstly, pretreat the obtained lignin to obtain modified lignin, then add tapioca starch, silane coupling agent, dibutylhydroxytoluene, butylated hydroxyfennel into the stirring reaction kettle according to the formula ratio Mix ether, phenyl o-hydroxybenzoate and defoamer evenly, and then grind for 1 hour with a three-roll mill to obtain an adhesive with a viscosity of 0.20 Pa·s at 18-20°C.

[0042] Lignin modified products are prepared by the following method...

Embodiment 2

[0045] Example 2 Production formula and method of lignin weather-resistant fiberboard adhesive 2

[0046] Recipe composition:

[0047] 20 parts of lignin;

[0048] 20 parts of phenol;

[0049] 18 parts of potato starch;

[0050] Anilinomethyltriethoxysilane 1 part

[0051] 2 parts of γ-chloropropyltrimethoxysilane;

[0052] Vitamin E 1 part;

[0053] 1 part of tert-butyl hydroquinone;

[0054] 1 part of 2-(2′-hydroxy-5′-methylphenyl)benzotriazole;

[0055] 3 parts of 2,4-dihydroxybenzophenone;

[0056] 0.2 parts of tributyl phosphate.

[0057] Production method: Firstly, the obtained lignin is subjected to a pretreatment reaction to obtain a modified lignin product, and then potato starch, silane coupling agent, vitamin E, and tert-butyl terephthalate are added to the stirred reactor according to the proportion of the formula Phenol, 2-(2ˊ-hydroxy-5ˊ-methylphenyl)benzotriazole, 2,4-dihydroxybenzophenone and defoamer, mixed well, and then milled with a three-roller mil...

Embodiment 3

[0061] Embodiment 3 lignin weather resistance fiberboard adhesive production formula and method 3

[0062] Recipe composition:

[0063] 30 parts of lignin;

[0064] 30 parts of phenol;

[0065] 20 parts flour;

[0066] 2 parts of γ-methacryloxypropyltrimethoxysilane;

[0067] 1 part of 3-(2,3 glycidoxy) propyltrimethoxysilane;

[0068] 2 parts of mercaptopropyltrimethoxysilane;

[0069] 5 parts of tert-butyl hydroquinone;

[0070] 5 parts of 2-hydroxy-4-n-octyloxybenzophenone;

[0071] 0.15 parts of tributyl phosphate.

[0072] Production method: Firstly, the obtained lignin is subjected to a pretreatment reaction to obtain a modified lignin product, and then flour, silane coupling agent, tert-butylhydroquinone, 2-hydroxyl - Mix 4-n-octyloxybenzophenone and defoamer evenly, and grind for 2 hours with a three-roll mill to obtain an adhesive with a viscosity of 0.50 Pa·s at 18-20°C.

[0073] Lignin modified products are prepared by the following methods:

[0074] (1) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com