Vulcanized crosslinked asphalt waterproof coiled material

A kind of asphalt waterproof membrane, vulcanization and cross-linking technology, applied in the direction of building insulation materials, chemical instruments and methods, building components, etc., can solve the problems of long reaction time, high temperature of polymer melting, high production cost, etc., and achieve the improvement of mechanical strength and high temperature resistance, improve high temperature resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

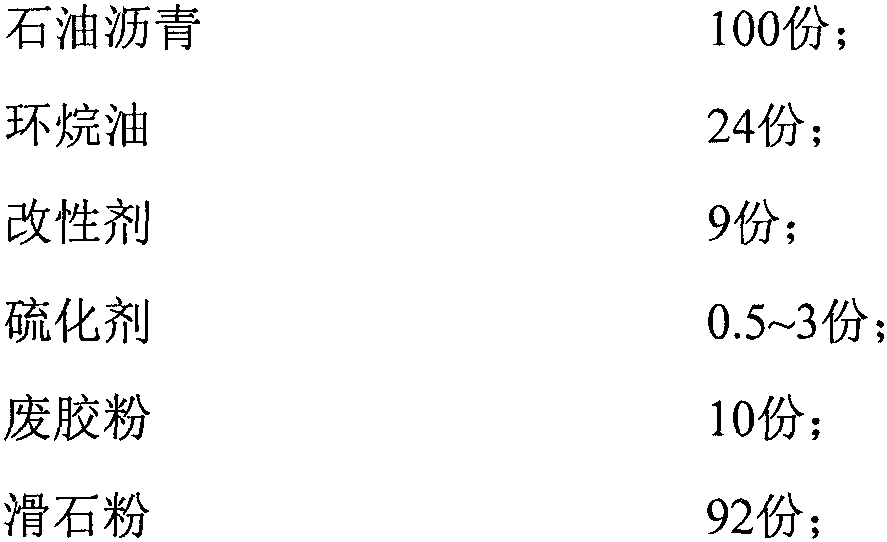

[0018] A formula of vulcanized cross-linked asphalt waterproofing membrane is: 100 parts of petroleum asphalt, 24 parts of naphthenic oil, 9 parts of modifier, 0.7 parts of vulcanizing agent BIPB, 10 parts of waste rubber powder, and 92 parts of talcum powder.

[0019] Add asphalt and naphthenic oil into the reaction kettle and mix and stir, heat up to 190°C after melting, add modifier SBS, stir and keep warm for 2 hours, until SBS is completely integrated into the asphalt system, add the measured vulcanizing agent, stir and keep warm for 0.5h, add Waste rubber powder, stir and keep warm for 1 hour, add talcum powder, stir and keep warm for 1 hour, and then get modified asphalt. Subsequent steps such as impregnation, compound molding and curling are carried out on the tire base.

Embodiment 2

[0021] A formula of vulcanized cross-linked asphalt waterproofing membrane is: 100 parts of petroleum asphalt, 24 parts of naphthenic oil, 9 parts of modifier, 0.9 parts of vulcanizing agent BIPB, 10 parts of waste rubber powder, and 92 parts of talcum powder.

[0022] Add asphalt and naphthenic oil into the reaction kettle and mix and stir, heat up to 190°C after melting, add modifier SBS, stir and keep warm for 2 hours, until SBS is completely integrated into the asphalt system, add the measured vulcanizing agent, stir and keep warm for 0.5h, add Waste rubber powder, stir and keep warm for 1 hour, add talcum powder, stir and keep warm for 1 hour, and then get modified asphalt. Subsequent steps such as impregnation, compound molding and curling are carried out on the tire base.

Embodiment 3

[0024] A formula of vulcanized cross-linked asphalt waterproofing membrane is as follows: 100 parts of petroleum asphalt, 24 parts of naphthenic oil, 9 parts of modifier, 2 parts of vulcanizing agent Shuangwuwu, 10 parts of waste rubber powder, and 92 parts of talcum powder.

[0025] Add asphalt and naphthenic oil into the reaction kettle and mix and stir, heat up to 190°C after melting, add modifier SBS, stir and keep warm for 2 hours, until SBS is completely integrated into the asphalt system, add the measured vulcanizing agent, stir and keep warm for 0.5h, add Waste rubber powder, stir and keep warm for 1 hour, add talcum powder, stir and keep warm for 1 hour, and then get modified asphalt. Subsequent steps such as impregnation, compound molding and curling are carried out on the tire base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com