Composition for modifying asphalt, modified asphalt, production methods of the composition and modified asphalt, and asphalt mixture

A technology of asphalt modification and manufacturing method, which is applied in the field of asphalt mixture and asphalt modification composition, which can solve the problems of high crushing process requirements and insufficient stability of modified asphalt, and reduce production costs and production costs , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146]With the usage amount of rock asphalt as 100%, and the amount of surfactant as 1.5%, after rock asphalt and surfactant A (polyoxyalkylene alkylphenyl ether) are uniformly mixed, the particle size of the mineral particles is obtained through a pulverizer. Rock bitumen less than 800 mesh. Then according to the consumption of asphalt softener (aromatic oil) is 30%, the consumption of initiator A (di(2-ethylhexyl) peroxydicarbonate) is 2%, the consumption of crosslinking agent A (propylene glycol dimethacrylate) 1%, the amount of coupling agent A (silane coupling agent) is 2%, and the above-mentioned materials are mixed uniformly by using mechanical stirring at 90°C to obtain a composition for asphalt modification. With respect to base asphalt (70# asphalt) 100%, the amount of the asphalt modification composition is 25%, and then the asphalt modification composition is added to the reaction kettle containing base asphalt at 120°C and stirred at high speed for 30 minutes, and...

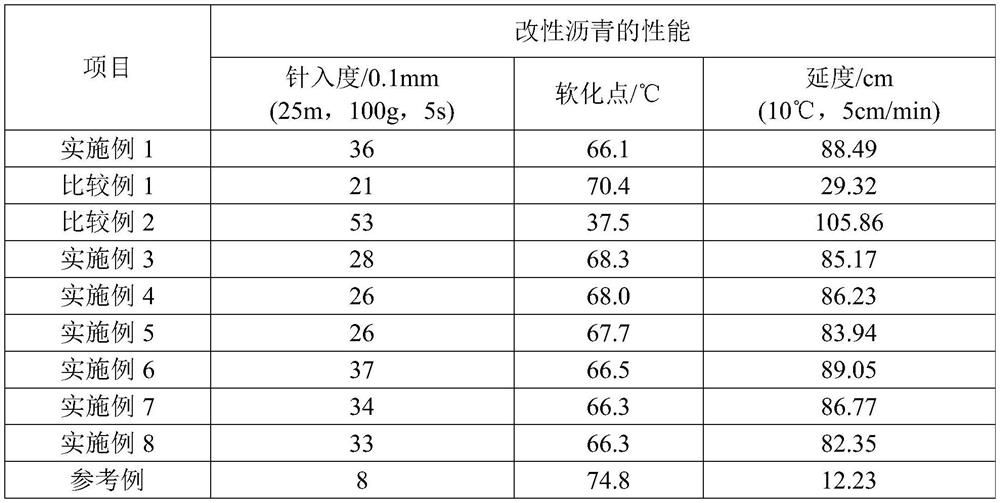

Embodiment 2~8、 comparative example 1~2

[0148] In Examples 2 to 8 and Comparative Examples 1 to 2, except that the amount of each component used to prepare the composition for asphalt modification was changed according to Table 1, the asphalt modification was prepared in the same manner as in Example 1. Composition and modified bitumen.

Embodiment 9

[0150] With the amount of rock asphalt used as 100%, and the amount of surfactant as 1.5%, after evenly mixing rock asphalt and surfactant B (alkylaryl sulfonate), the rock asphalt with a particle size of less than 800 meshes is obtained through a pulverizer . Then according to the consumption of asphalt softener (aromatic oil) is 30%, the consumption of initiator B (dibenzoyl peroxide) is 2%, and the consumption of crosslinking agent B (triallyl isocyanurate) is 1%. , the amount of coupling agent B (aluminate coupling agent) is 2%, and the above materials are mixed uniformly by mechanical stirring at 90° C. to obtain a composition for asphalt modification. With respect to 100% of base asphalt (70# asphalt), the consumption of asphalt modification composition is 25%, then the asphalt modification composition is added to 120 ℃ containing base asphalt in the reactor and stirred at high speed for 30min, then Fully react at 140-160°C for 25 minutes, and put the modified asphalt p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com