Asphalt-based hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, asphalt-based technology, applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve problems such as poor durability, weak joint bonding, and poor low-temperature viscosity. Achieve the effects of improved aging resistance, excellent stickiness and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

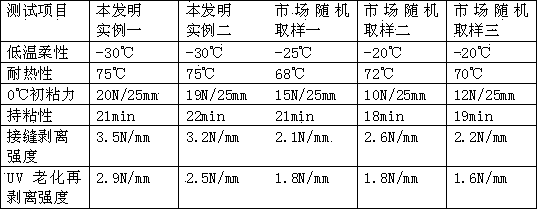

example 1

[0023] Add 300kg of 90# asphalt and 145kg of naphthenic oil into the reactor through a high-temperature liquid flowmeter. After heating to 200°C with a heat-conducting oil furnace, turn off the heating system, turn on the stirring and mixing system, and keep it for 60 minutes. Then add SBS75kg, EVA25kg, terpene resin 35kg, C5 petroleum resin 35kg, polyphosphoric acid 8kg. Stir at a high speed under the condition of 180-200°C, the stirring speed is 200-500 rpm, and the stirring time lasts for 30-90 minutes. The above-mixed materials are poured and ground through a high-speed shear mill, and the grinding time is 20-40 minutes. After grinding, add 70kg of precipitated silica and 8kg of 2,6-di-tert-butyl-p-cresol. Stirring was continued for 30 minutes. Keep the temperature at 150-180°C. Then it is poured into the coating tank through the heat preservation gear pump, scraped or rolled, and cooled to room temperature naturally.

example 2

[0025] Add 500kg of 90# asphalt and 240kg of naphthenic oil into the reactor through a high-temperature liquid flowmeter. After heating to 200°C with a heat-conducting oil furnace, turn off the heating system, turn on the stirring and mixing system, and keep it for 60 minutes. Then add SBS120kg, EVA40kg, terpene resin 50kg, C5 petroleum resin 50kg, polyphosphoric acid 11kg. Stir at a high speed under the condition of 180-200°C, the stirring speed is 200-500 rpm, and the stirring time lasts for 30-90 minutes. The above-mixed materials are poured and ground through a high-speed shear mill, and the grinding time is 20-40 minutes. After grinding, add 100kg of precipitated silica and 10kg of 2,6-di-tert-butyl-p-cresol. Stirring was continued for 30 minutes. Keep the temperature at 150-180°C. Then it is poured into the coating tank through the heat preservation gear pump, scraped or rolled, and cooled to room temperature naturally.

[0026] Material performance of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com