Asphalt flame-retardant modifier, and flame-retardant modified asphalt and preparation thereof

A technology of flame retardant modifier and modified asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of reduced structural bearing capacity, increased fire risk, damaged asphalt performance, etc., and achieves good flame retardant performance. , the effect of excellent economic and environmental protection indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

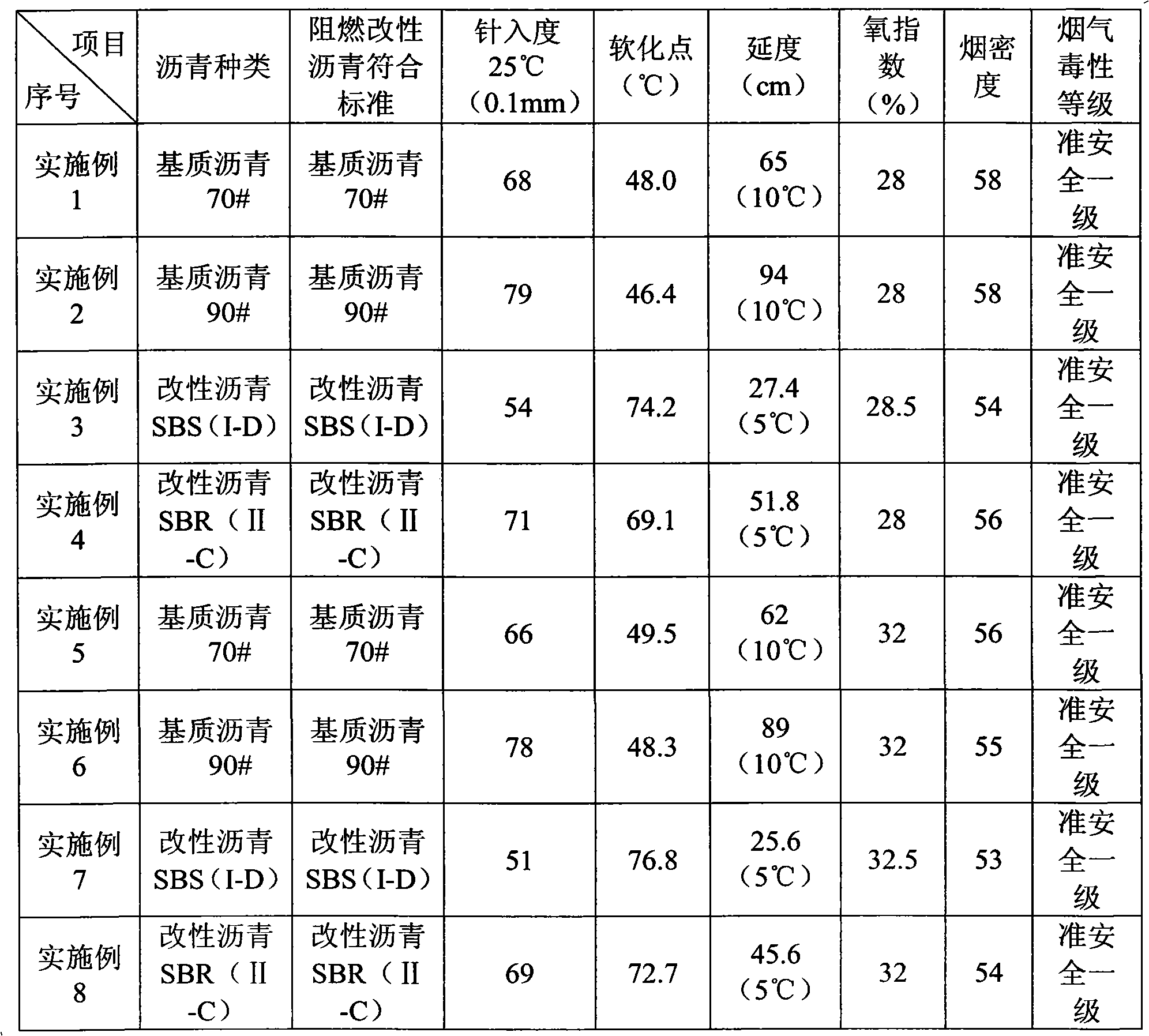

Embodiment 1

[0036] Take by weight 94 parts of 70# matrix asphalt, 6 parts of asphalt flame retardant modifier, 2 parts of blending agent, 1 part of stabilizer;

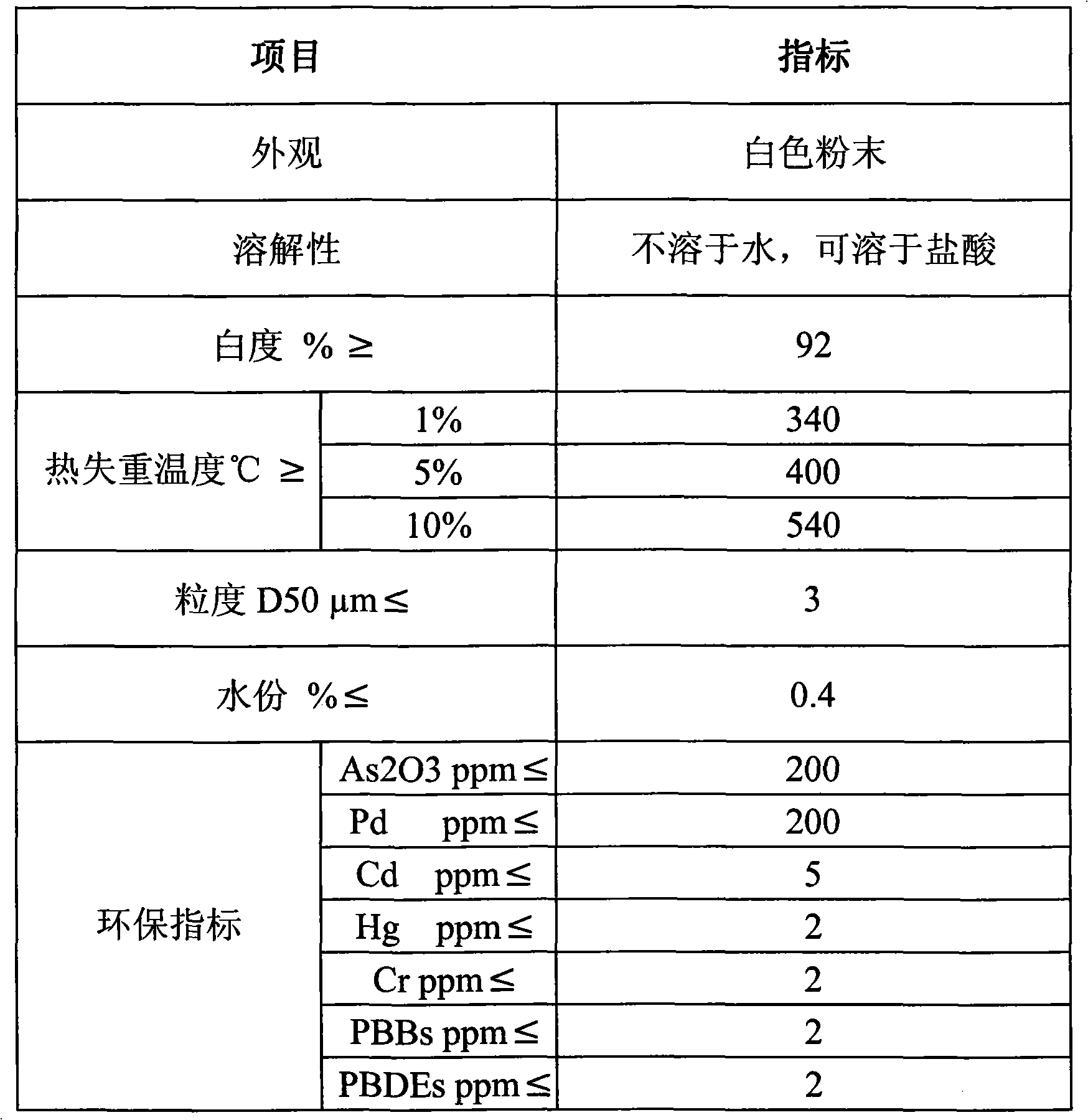

[0037] The ingredients of the asphalt flame retardant modifier are (parts by weight): decabromodiphenyl ether, 4 parts; antimony white equivalent flame retardant, 2 parts; hydrated magnesium silicate, 5 parts; smoke suppression flame retardant additive, 10 parts .

[0038] The above-mentioned smoke-suppressing and flame-retardant auxiliary agent is one of silicon dioxide, iron oxide, calcium oxide, aluminum hydroxide, magnesium hydroxide or a combination thereof.

[0039] Melting 70# base asphalt: heat the above-mentioned 70# base asphalt to 110°C to reach a molten state, stir for 20 minutes to dehydrate it, then heat it and keep it at 155°C;

[0040] Add other components: Add the asphalt flame retardant modifier to the 90# base asphalt treated by the above steps, and stir while adding. The order of addition is decabromobiphenyl...

Embodiment 2

[0042] Take by weight 94 parts of 90# matrix asphalt, 6 parts of asphalt flame retardant modifier, 2 parts of blending agent, and 1 part of stabilizer;

[0043] The ingredients of the asphalt flame retardant modifier are (parts by weight): decabromodiphenyl ether, 4 parts; antimony white equivalent flame retardant, 2 parts; hydrated magnesium silicate, 5 parts; smoke suppression flame retardant additive, 10 parts .

[0044] The above-mentioned smoke-suppressing and flame-retardant auxiliary agent is one of silicon dioxide, iron oxide, calcium oxide, aluminum hydroxide, magnesium hydroxide or a combination thereof.

[0045] Melting 90# base asphalt: heat the above-mentioned 70# base asphalt to 110°C to reach a molten state, stir for 20 minutes to dehydrate it, then heat it and keep it at 155°C;

[0046] Add other components: Add the asphalt flame retardant modifier to the 90# base asphalt treated by the above steps, and stir while adding. The order of addition is decabromobiph...

Embodiment 3

[0048] Take by weight 94 parts of SBS (I-D) polymer modified asphalt, 6 parts of asphalt flame retardant modifier, 2 parts of blending agent, 1 part of stabilizer;

[0049] The ingredients of the asphalt flame retardant modifier are (parts by weight): decabromodiphenyl ether, 4 parts; antimony white equivalent flame retardant, 2 parts; hydrated magnesium silicate, 5 parts; smoke suppression flame retardant additive, 10 parts .

[0050] The above-mentioned smoke-suppressing and flame-retardant auxiliary agent is one of silicon dioxide, iron oxide, calcium oxide, aluminum hydroxide, magnesium hydroxide or a combination thereof.

[0051] Melt polymer modified asphalt SBS (I-D): heat the above polymer modified asphalt SBS (I-D) to 120°C to reach a molten state, stir for 20 minutes to dehydrate it, then heat it and keep it at 160°C ;

[0052]Add other components: Add the asphalt flame retardant modifier to the polymer modified asphalt SBS (I-D) treated by the above steps, stir wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com