Toughened asphalt modifier, toughened compound modified asphalt, asphalt mixture and preparation method thereof

A technology of composite modified asphalt and asphalt modifier, which is applied in the fields of toughened asphalt modifier, asphalt mixture and its preparation, and toughened composite modified asphalt, which can solve the process and control links and improve the construction organization and progress of asphalt pavement And the difficulty of quality control and the work intensity of all staff, the increase of project cost, the rare material optimization and functional design research and application, etc., have achieved significant technical, economic and social significance, saving asphalt and ore raw materials, and improving the overall life expectancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

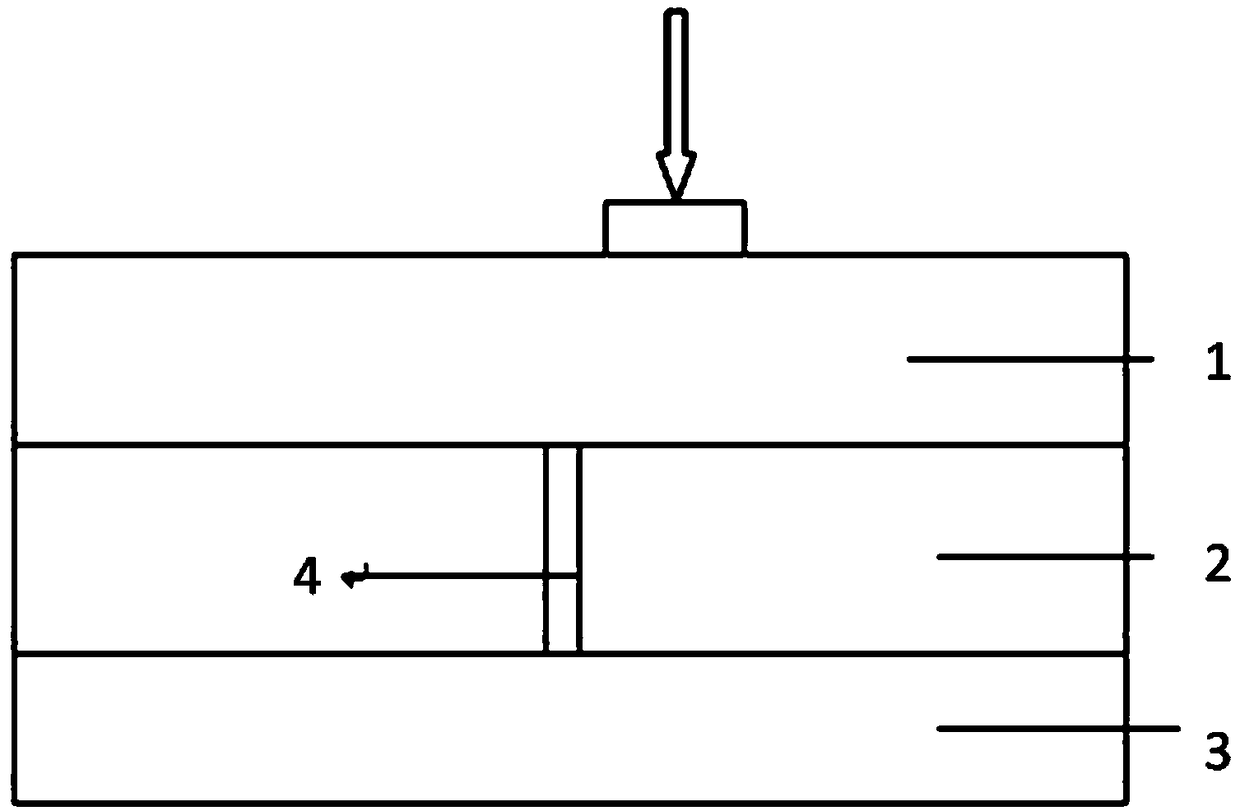

Image

Examples

preparation example Construction

[0076] [Preparation method of toughened asphalt modifier]

[0077] A kind of preparation method of toughened composite asphalt modifier, it comprises the steps:

[0078] (1), the rubber tire powder is desulfurized and plasticized to obtain the desulfurized rubber tire powder;

[0079] (2) After mixing 65-92 parts of devulcanized rubber tire powder, 0-20 parts of polyolefin plastic particles, 0-15 parts of SBS, 0-15 parts of SBR and 0-6 parts of stabilizer, the process is carried out through a twin-screw extruder Composite reaction, and then extrude and granulate through a single-screw extruder;

[0080] Wherein, in step (1), the desulfurization and plasticization can use normal pressure screw plasticizer, screw plasticizer, dynamic desulfurization tank and other rubber powder desulfurization and plasticization equipment, and the desulfurization and plasticization temperature is 200-260°C.

[0081] In step (2), the temperature of the twin-screw extruder for compound reaction ...

Embodiment 1

[0123] The present embodiment provides a kind of preparation method of asphalt mixture, it comprises the steps:

[0124] 1. Preparation of toughened asphalt modifier:

[0125] (1), the rubber tire powder is desulfurized and plasticized to obtain the desulfurized rubber tire powder;

[0126] (2), with 90 kilograms of desulfurized rubber tire powder (particle size is 26 orders), 10 kilograms of low-density polyethylene plastic particles (6% dosage modified asphalt softening point>100 ℃, melt index is 1.7g / 10min) and 2.1 kilograms of stabilizers are mixed and reacted by a twin-screw extruder, and then granulated by a single-screw extruder;

[0127] Among them, the stabilizer includes the following components: 1.6 kg of dimethyl phthalate, 0.6 kg of sodium petroleum sulfonate, 0.4 kg of styrene, and 0.5 kg of cyclic anhydride.

[0128] In step (2), the twin-screw extruder performs mixing processing first, and then extrudes at low temperature. The mixing processing temperature i...

Embodiment 2

[0139] In this embodiment, the "low-density polyethylene plastic particle" in the first step (2) section of Example 1 is replaced by "secondary PE recycled material", the melt index is 1.5g / 10min, and the dosage is changed by 6%. The softening point of asphalt is 89°C. The rest of the parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com