Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Sodium chloride nacl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium chloride (NaCl), also known as salt, is an essential compound our body uses to: absorb and transport nutrients maintain blood pressure maintain the right balance of fluid transmit nerve signals contract and relax muscles

Combined solid waste, carbon dioxide quicklime sparging, brine water, and reverse osmosis/ion exchange processes for the production of soda chemicals

InactiveUS20110217227A1Calcium/strontium/barium carbonatesSemi-permeable membranesWaste processingChemical equation

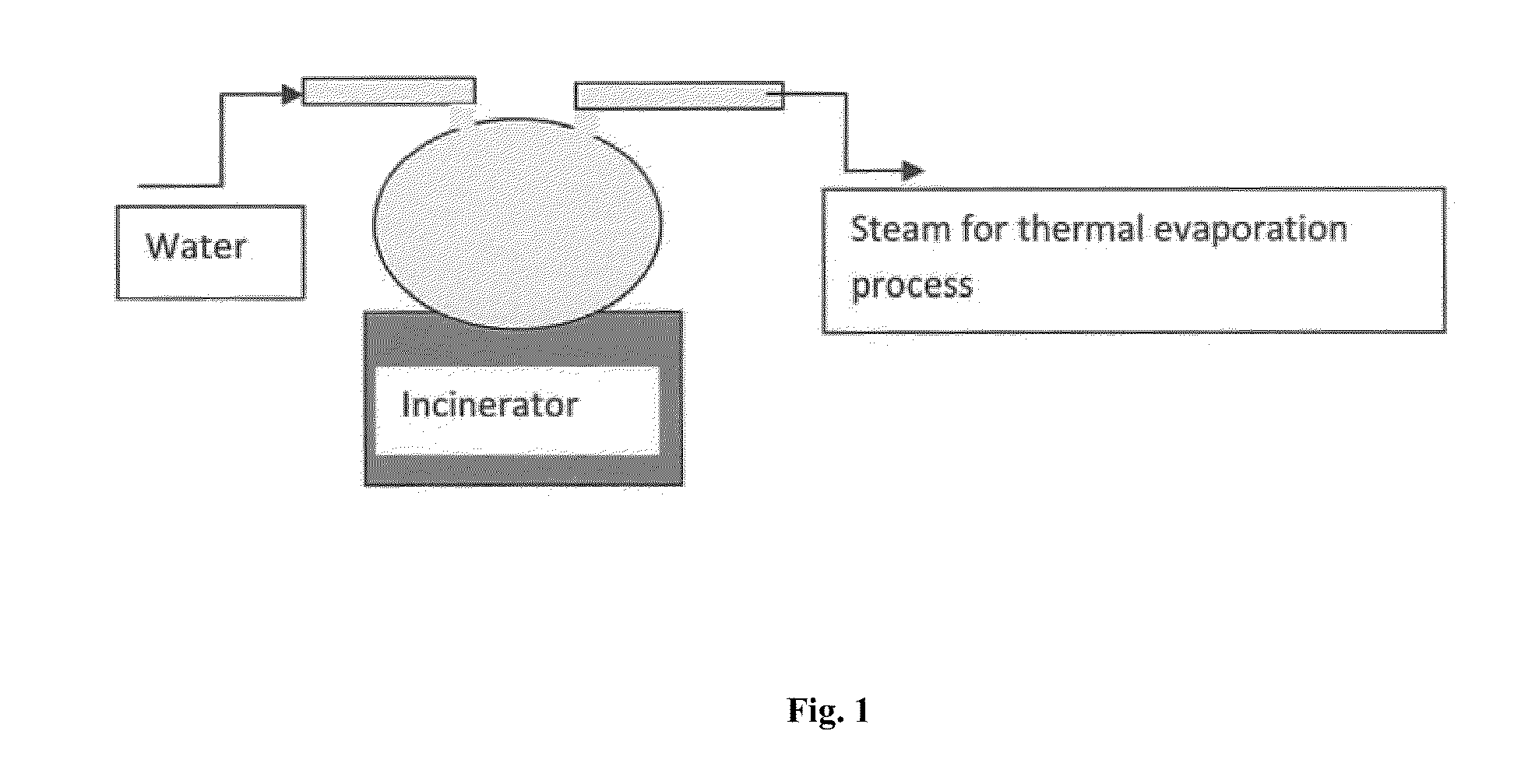

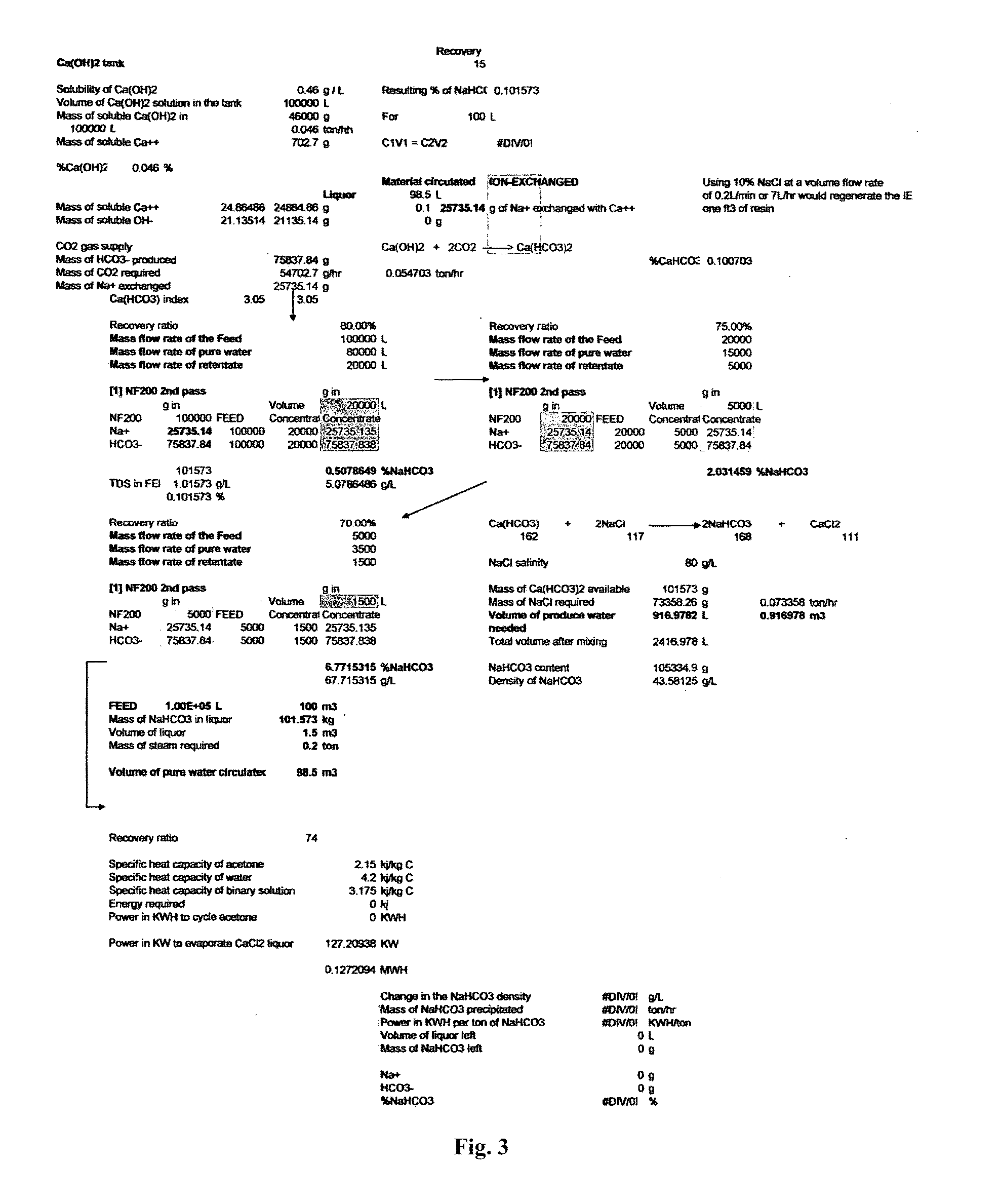

The proposed invention uses a classical chemical equation where carbon dioxide CO2 is reacted with quick lime Ca(OH)2 to produce soda carb NaHCO3 and concentrating it to 6% using advanced membrane and resin technology. The invention requires three chemicals CO2, Ca(OH)2, and sodium chloride NaCl to produce NaHCO3. The output of many industrial processes lacks waste heat and in many instances CO2 and the present invention combines a solid waste processing unit to the above processes which allows the production of solid products or high % liquors. Availability of waste heat sources can lead to high efficiency in NaHCO3, Na2CO3, and NaOH production. The process is not chloro-alkali electrochemical or Solvay column ammonia processing technique. Advanced membrane uses technologies of reverse osmosis and nanofiltration systems while resin technology uses ion exchange systems. Therefore, we conveniently call it the solid waste-quicklime membrane SWQM process.

Owner:ENGSL FZE +1

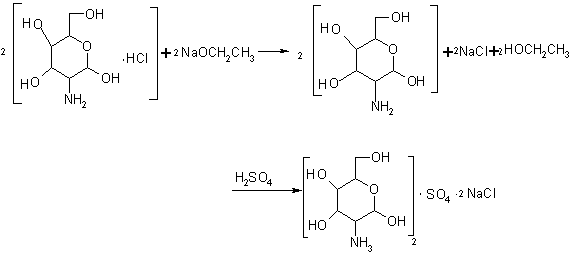

Preparation method of D-glucosamine sulfate sodium chloride salt

ActiveCN102850412AHigh purityNovel methodSugar derivativesSugar derivatives preparationChloride saltNitrogen

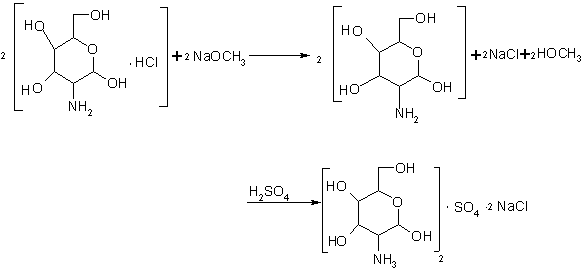

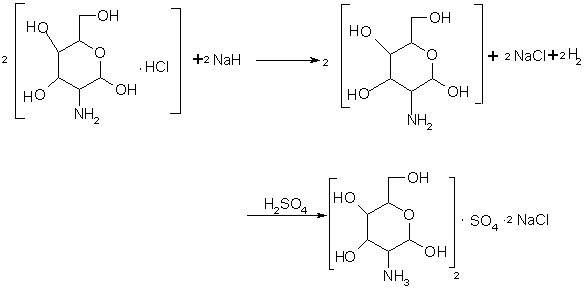

The invention discloses a preparation method of D-glucosamine sulfate sodium chloride salt. The preparation method comprises the following steps of: dissolving D-glucosamine hydrochloride in a solvent; adding a sodium-containing alkaline substance into the obtained solution at the temperature of minus 40-100 DEG C, or adding the sodium-containing alkaline substance into the obtained solution under the protection of one or more protective gas(s) of nitrogen, carbon dioxide and inert gases; adding the sodium-containing alkaline substance into the mixed solution at the maintained temperature of minus 40-90 DEG C; adding sulfuric acid into the obtained solution at the temperature of minus 25 to 90 DEG C for salifying; carrying out complexation reaction to obtain a D-glucosamine sulfate sodium chloride salt complex; and filtering and crystallizing to obtain the D-glucosamine sulfate sodium chloride salt solid. The method is novel and unique and simple and reasonable in technology, product quality is good and purity is high, and completely reaches the standard of United States patent (USP) 34 edition pharmacopeia.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

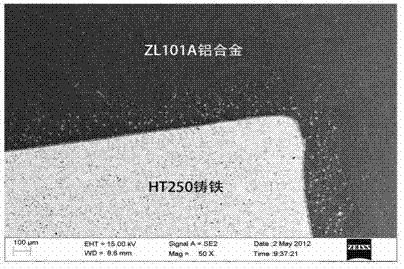

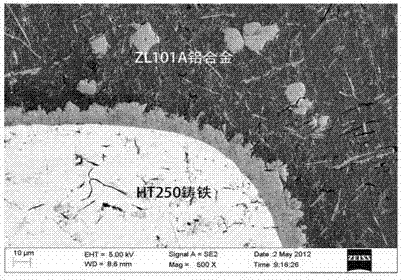

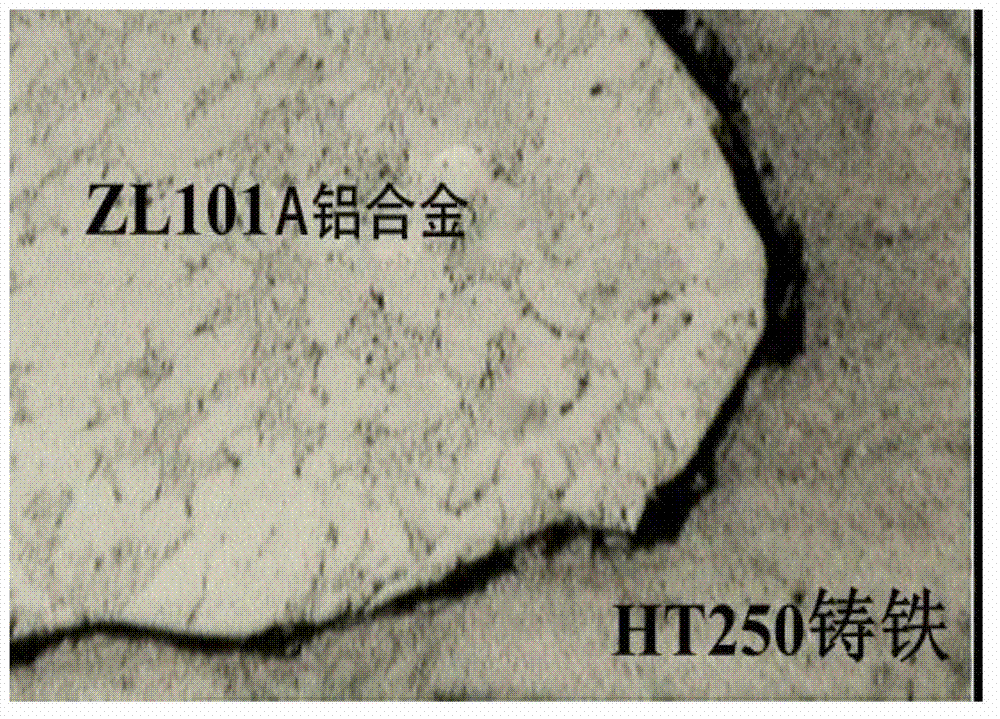

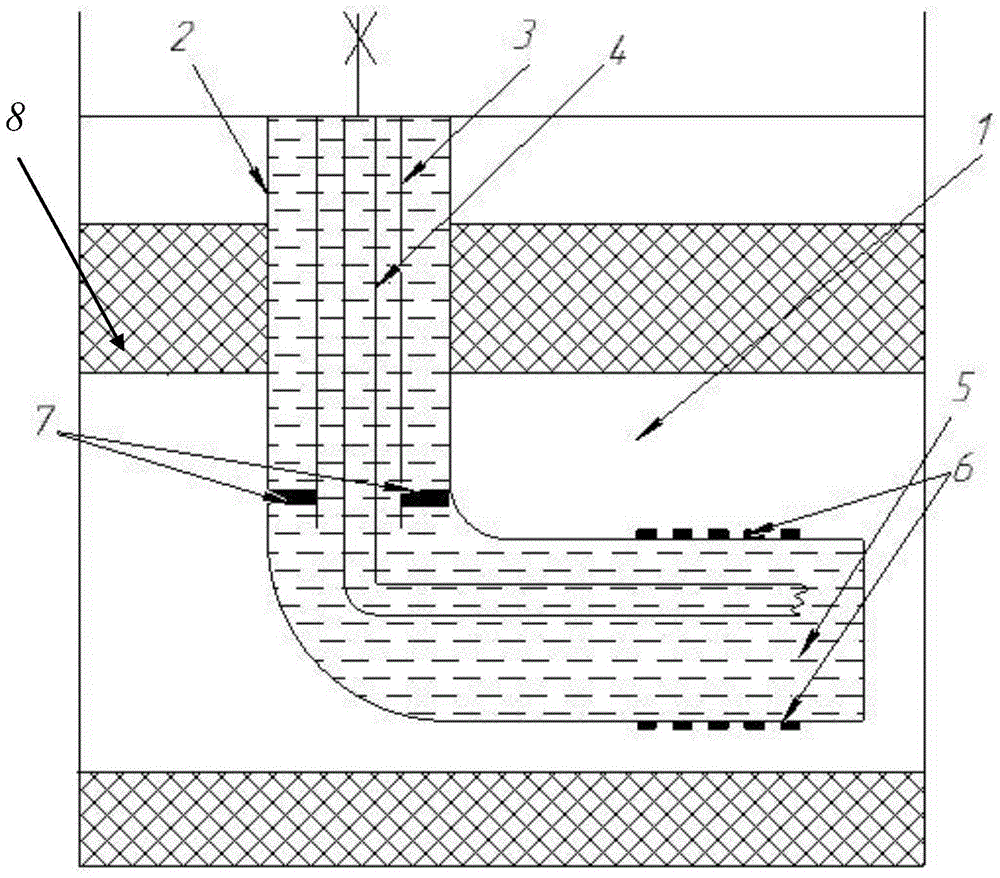

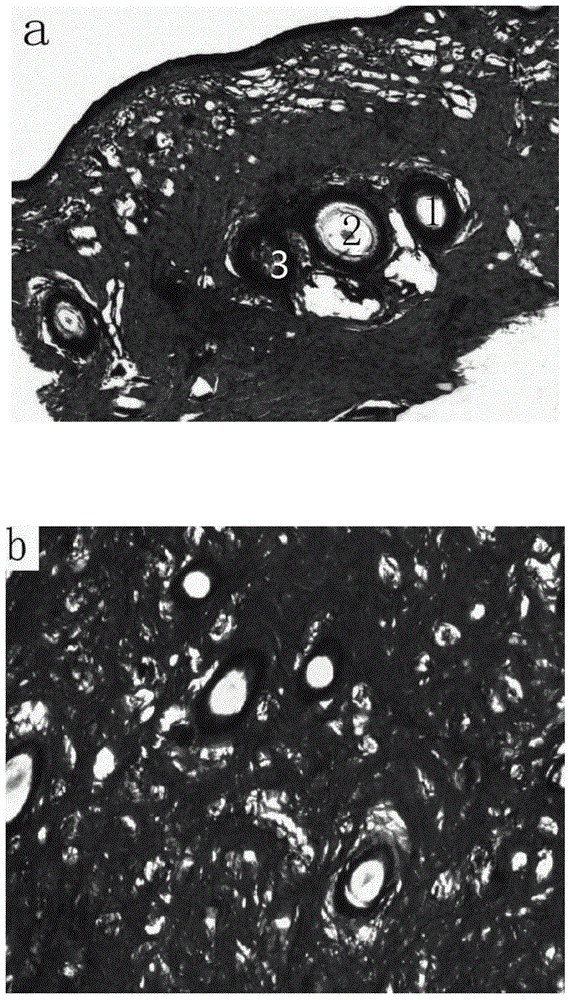

Preparation process of dual-metal engine cylinder composite material

InactiveCN102773463AGuaranteed physical propertiesEnhanced interface bindingPotassium fluorideMetallic materials

The invention relates to a preparation process of a dual-metal engine cylinder composite material, the preparation process comprises the following steps of: firstly, acid-washing a HT250 cast iron cylinder liner and carrying out surface degreasing and derusting treatment on the HT250 cast iron cylinder liner; then dipping the HT250 cast iron cylinder liner into a prepared proportional saline solution, so that the surface of the HT250 cast iron cylinder liner is soaked in the saline solution; then drying the HT250 cast iron cylinder liner, and putting the HT250 cast iron cylinder liner in a ZL101A aluminum alloy melt body for hot immersion plating; fixing the immersion-plated HT250 cast iron cylinder liner in a mold cavity of a metal mold casting mold, casting, melting and cooling a ZL101A aluminum alloy, wherein concentration of the saline solution is 100-200g / L, the saline solution is prepared by mixing water together with potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF2, and calcium chloride CaC12 according to a mass ratio of 39-46:16-26:15-21:6-15:5-10. According to the preparation process, the engine cylinder composite material is obtained through treating the ZL101A aluminum alloy and HT250 cast iron by a self-prepared surfactant and implementing a dual-metal composite casting process on the ZL101A aluminum alloy and the HT250 cast iron, wherein two metal materials of the ZL101A aluminum alloy and the HT250 cast iron are not mixed and kept with original physical properties; but the ZL101A aluminum alloy and the HT250 cast iron obtain an extremely perfect combination interface, so that casting metallurgical bonding of 99.5 percent and above is achieved.

Owner:烟台路通精密科技股份有限公司 +1

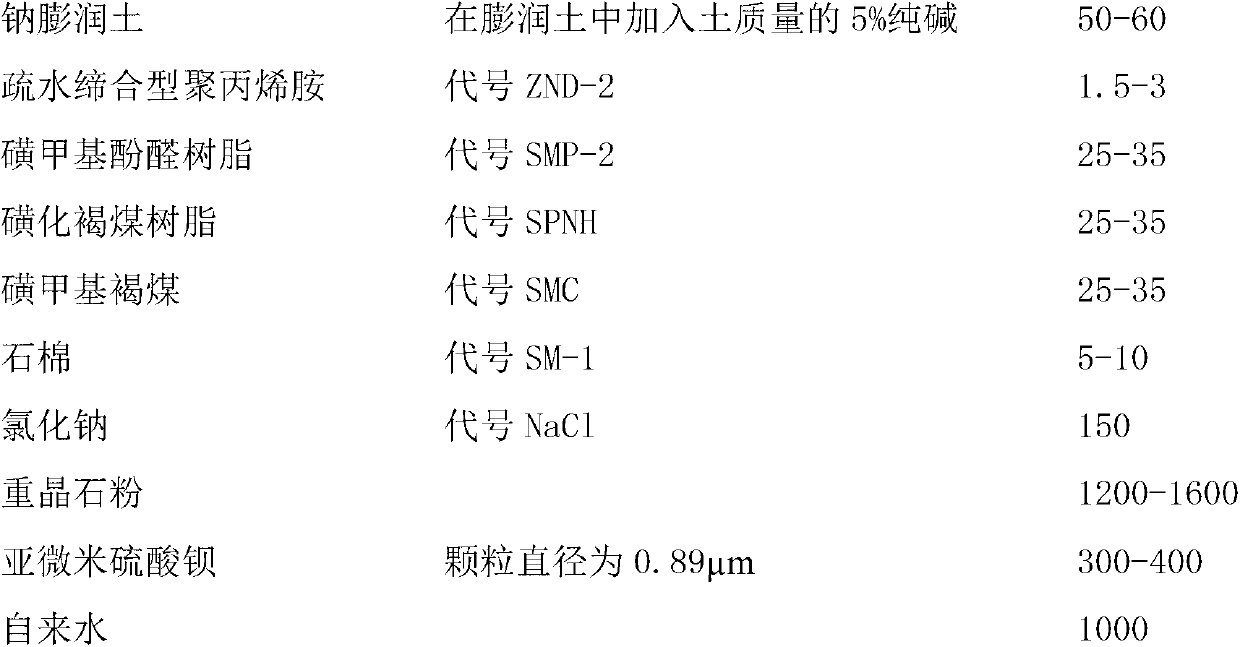

Drilling fluid for ultra deep well

Owner:SOUTHWEST PETROLEUM UNIV

A decalcification process for old bittern in high calcium salt fields

ActiveCN104817096BSimple processReduce manufacturing costCalcium/strontium/barium sulfatesAlkali metal chloridesHigh concentrationSlurry

A decalcification technique of high-calcium old brine in a salt field includes the following steps: (1), dissolving mirabilite; (2), evenly mixing mirabilite mother liquid obtained in the step (1) with the high-calcium old brine in the salt field according to a molar ratio of Ca2+ to SO42- being 1: (1-1.2) for 1-24 hours to obtain slurry; (3), filtering; (4) washing and drying; (5), returning the decalcified old brine obtained in the step (3) to the sodium chloride salt field and continuing to evaporate the old brine. The decalcification technique has the advantages that sodium sulfate resources of a salt lake or nearby places are fully used for reacting with calcium sources in the high-calcium old brine to achieve decalcification of the old brine; technological process is simple and cost is low; the technique can be implemented directly in resource locations, circular brine mixing of high-concentration magnesium chloride brine after decalcification of the high-calcium old brine can be achieved, gypsum products can be produced, sodium sulfate minerals can be digested and local environment problems of the salt lake can be relieved.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Method for purifying vegetable containing pyrethroid pesticide residue by using graphene

InactiveCN102778521AReduce dosageImprove adsorption capacityComponent separationEthylenediamineGas phase

The invention discloses a method for purifying vegetable containing pyrethroid pesticide residue by using grapheme in the field of pesticide residue analysis of vegetables. The method comprises the following steps of (1) extraction, i.e. weighing proper amount of pre-crushed homogenized vegetable sample containing pyrethroid pesticide, adding an extraction solvent into the sample, and performing vortex or vibration extraction; (2) separation, i.e. adding sodium chloride to perform salt precipitation, and performing centrifugal separation; (3) purification, i.e. taking the supernate, adding the grapheme into the supernate, and after the grapheme is fully contacted with the supernate, adding sodium chloride to perform centrifugal separation; and (4) detection, i.e. taking the supernate, adding anhydrous sodium sulfate or magnesium sulfate anhydrous into the supernate, and after the excessive water content is removed, performing gas chromatogram. The grapheme serves as a purifying material, and compared with graphitized carbon black and N-propyl ethylenediamine bonded silica gel which are conventionally used in a laboratory, the grapheme is low in using amount, strong in absorption ability and low in cost; the method is simple, quick and convenient to perform; and the accuracy is high, and the recovery rate is between 96.0 percent and 99.6 percent.

Owner:CHINA AGRI UNIV

Salt taste additive agent, low-sodium salt taste agent and preparation thereof

ActiveCN101433333AEnhance blood pressure loweringSolve balance problemsFood preparationHigh concentrationSalty taste

The invention discloses a salty additive, which is prepared by mixing of MgCl2, KCl and NH4Cl in proportion and the processes of boiling, distillation, condensation, drying and so on. The chemical formula of the product is as follows: MgCl2.0.75NH4Cl.0.25KCl.6H2O. The product is added into sodium chloride salt to obtain a low-sodium salty agent, so that the equilibrium state of sodium (Na<+>), potassium (K<+>) and magnesium (Mg<2+>) is improved, and diseases such as hypertension are prevented. Common low-sodium salt in the market has sweet taste under the condition of low concentration, has bitter taste under the condition of high concentration, and has complex taste of salty taste and sour taste under the condition of the maximum concentration, while the product effectively overcomes the defects, has pure mouthfeel, and is not bitter.

Owner:湖南汉润材料发展有限公司

Method for water sanitisation

InactiveUS20120267257A1Reduce decreaseGood choiceBiocideMagnesium chloridesAlkaline earth metalPotassium

The present invention provides a method for sanitising water in a swimming pool or the like, which method uses sources of ionic chlorine at significantly lower levels than conventional systems. The method comprises the steps of (i) forming, in the swimming pool water, an electrolyte solution containing from 500 ppm to 9000 ppm of a soluble magnesium halide salt, (ii) treating the electrolyte solution in an electrolytic halogenation cell to form an aqueous solution of hypohalous acid, and (iii) returning the water so treated back to the swimming pool. A mixture of magnesium, potassium and sodium chloride salts with small quantities of a soluble alkaline earth metal bromide, zinc halide, ascorbate, and / or zinc ascorbate may be particularly effective in the sanitisation process.

Owner:ZODIAC GROUP AUSTRALIA

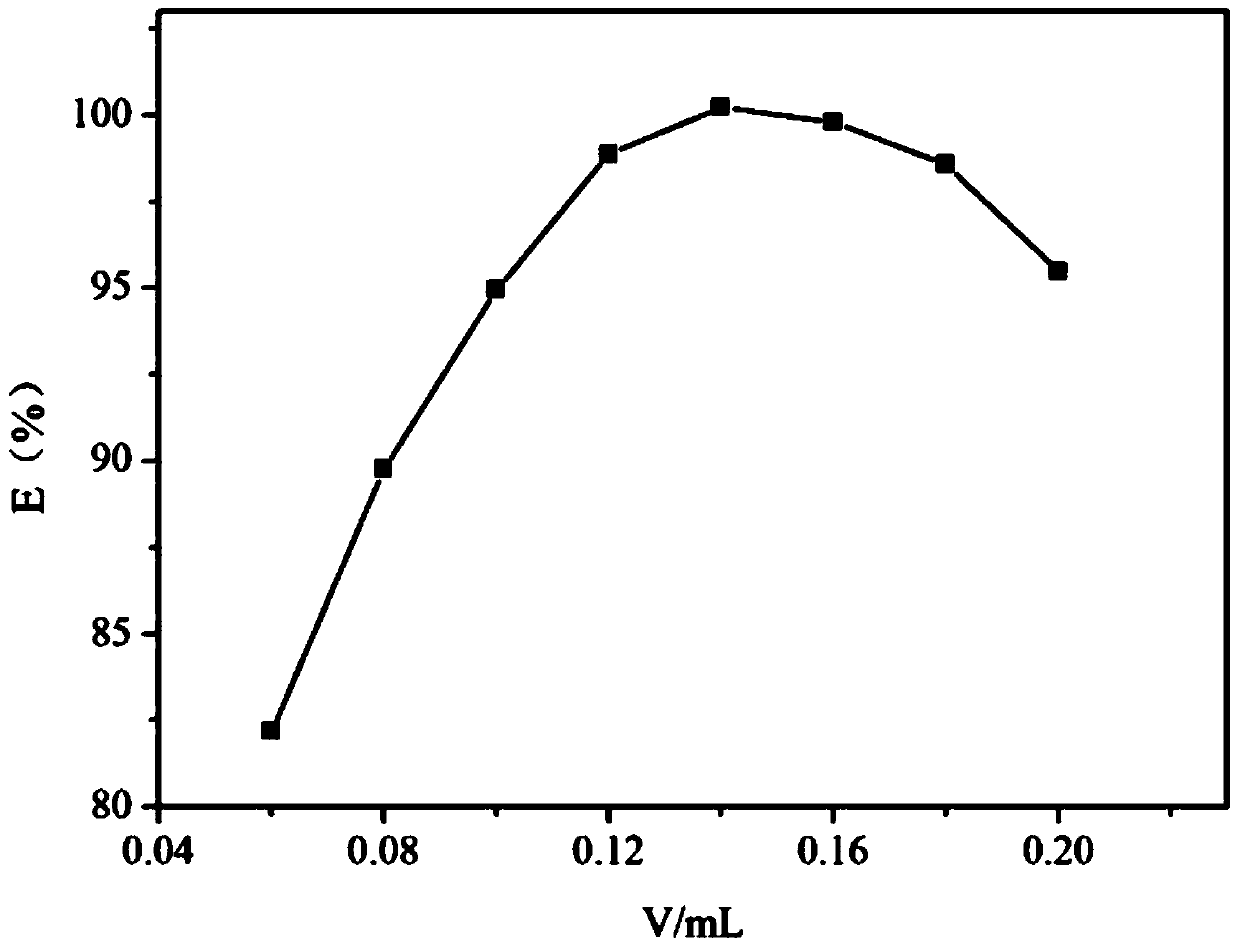

Method for detecting trace zinc ions by using cloud point extraction and ultraviolet-visible spectrophotometry

InactiveCN104198412AReduce dosageNo pollution in the processPreparing sample for investigationColor/spectral properties measurementsRelative standard deviationPhotochemistry

The invention discloses a method for detecting trace zinc ions by using cloud point extraction and ultraviolet-visible spectrophotometry. The method comprises the following steps: adding a sample to be detected to a cloud point extraction system containing an NH4Cl-NH3.H2O buffer solution with pH of 8.5, 1-(2-pyridylazo)-2-naphthol, TritonX-100, SDS (Sodium Dodecyl Sulfonate) and saturated sodium chloride NaCl; uniformly mixing and putting the mixture in a refrigerator to balance; and separating two phases by centrifuging, collecting a lower phase, diluting by using absolute ethyl alcohol and detecting the content of the zinc ions by ultraviolet-visible spectrophotometry, wherein the absorption wavelength of the spectrophotometry is 549nm. The method can be used for detecting trace zinc ions in environmental water samples and soil; the detection limit of the zinc ions is 3.3ng.mL<-1>; the enrichment factor is 38; the relative standard deviation is 2.8%; the adding standard recovery rate is 97.7%-101.5%.

Owner:CHINA WEST NORMAL UNIVERSITY

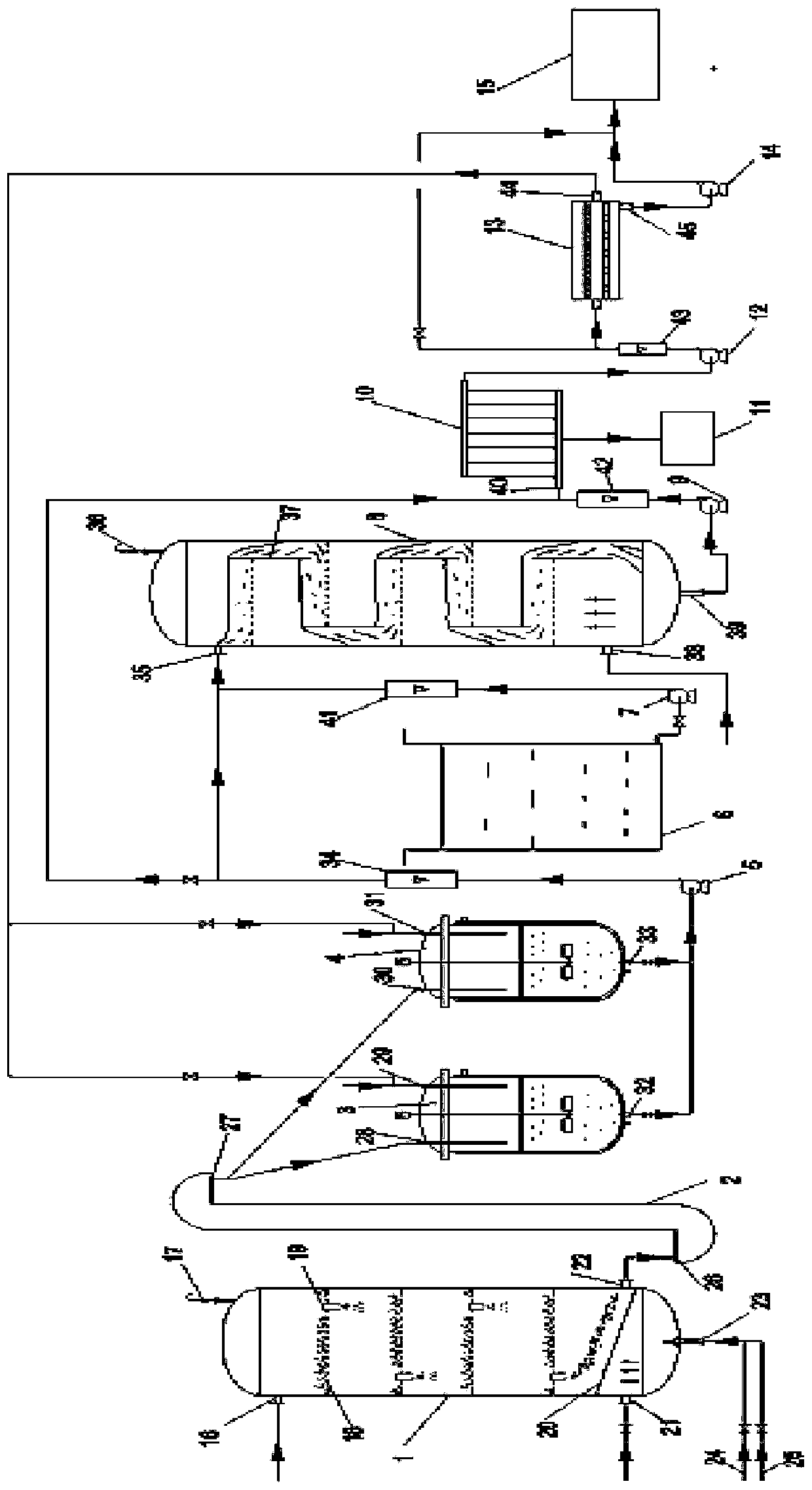

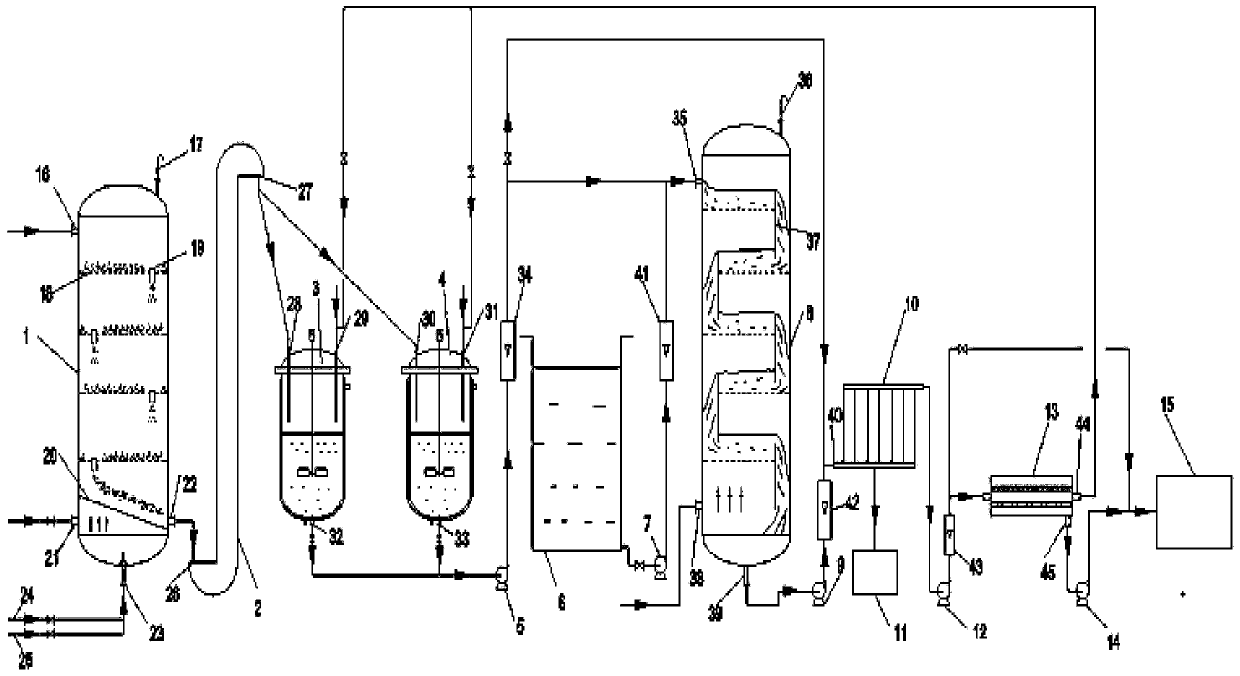

Sodium chloride-containing pesticide production wastewater resource treatment system and method

InactiveCN108128968AMaintain microbial biomassIncrease concentrationGeneral water supply conservationWater contaminantsReverse osmosisWater quality

The invention discloses a sodium chloride-containing pesticide production wastewater resource treatment system and method, and belongs to the field of a sewage treatment method. The system comprises asalt-tolerant bacterium biochemical system, a nanofiltration membrane device, an electrodialysis device and an electrocatalytic oxidation device, wherein the salt-tolerant bacterium biochemical system comprises a first salt-tolerant bacterium aerobic device, a salt-tolerant bacterium anaerobic device and a second salt-tolerant bacterium aerobic device; the second salt-tolerant bacterium aerobic device comprises a salt-tolerant bacterium MBR device; the treatment system also comprises a reverse osmosis device. The invention also discloses a wastewater treatment method. The flow process of themethod of the salt-tolerant bacterium biochemical treatment, MBR treatment, nanofiltration membrane treatment, electrodialysis treatment and electrocatalytic treatment is used; after the pesticide production wastewater is subjected to treatment, the water quality of produced water is high; when the system and the method are applied to enterprise production, water resources in the waste water are recovered; the general organic carbon content in the obtained sodium chloride salt wastewater is low; the system and the method can be used for chlor-alkali production; sodium chloride salt in the wastewater is recovered.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

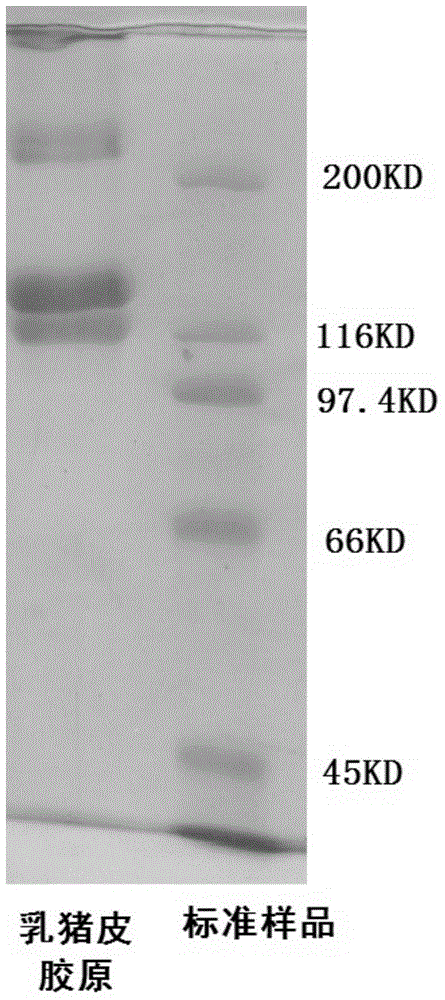

Method for preparing undenatured natural collagen from sucking pig skin

ActiveCN103601803AEffective hair removalEfficient removalConnective tissue peptidesPeptide preparation methodsHair rootsFreeze-drying

The invention discloses a method for extracting undenatured natural collagen from sucking pig skin. The method is characterized in that treatment is carried out by sub-step repeated different combinations in a manner that a degreasing agent is assisted by intermittent ultrasonic waves, an unhairing agent and a non-collagen removing agent are respectively used for unhairing and removing non-collagen, and no hair root exists in the skin after unhairing, wherein shown by determination, the fat content is lower than 0.5% and the ash content is lower than 0.3%; enzyme-soluble collagen is obtained through leaching by acetic acid-protease and is purified by high-speed centrifugation, sodium chloride salting-out and dialysis, and spongy sucking pig skin collagen is obtained after freeze-drying, wherein the collagen extraction ratio exceeds 50% (dry weight), and shown by electrophoretogram, the sucking pig skin collagen contains a beta chain and an alpha chain, of which the molecular weights are 200000 and 100000 respectively, and is free from other hybrid protein bands, so that the collagen reserves three helical structures and has relatively high purity.

Owner:SICHUAN UNIV

Combined solid waste, carbon dioxide quicklime sparging, brine water, and reverse osmosis/ion exchange processes for the production of soda chemicals

The proposed invention uses a classical chemical equation where carbon dioxide CO2 is reacted with quick lime Ca(OH)2 to produce soda carb NaHCO3 and concentrating it to 6% using advanced membrane and resin technology. The invention requires three chemicals CO2, Ca(OH)2, and sodium chloride NaCl to produce NaHCO3. The output of many industrial processes lacks waste heat and in many instances CO2 and the present invention combines a solid waste processing unit to the above processes which allows the production of solid products or high % liquors. Availability of waste heat sources can lead to high efficiency in NaHCO3, Na2CO3, and NaOH production. The process is not chloro-alkali electrochemical or Solvay column ammonia processing technique. Advanced membrane uses technologies of reverse osmosis and nanofiltration systems while resin technology uses ion exchange systems. Therefore, we conveniently call it the solid waste-quicklime membrane SWQM process.

Owner:ENGSL FZE +1

Deepwater drilling liquid

InactiveCN101705080ASolve poor rheologySolve problems such as easy formation of natural gas hydrateDrilling compositionSodium BentoniteSeawater

The invention relates to drilling liquid, in particular to deepwater drilling liquid which comprises the following components, by mass percent: 0-8% of bentonite, 0.05-5% of well wall stabilizing agent, 1-6% of visbreaking fluid loss control agent used for the drilling liquid, 1-6% of carboxymethyl sulfonated phenol formaldehyde resin used for the drilling liquid, 5% of sodium chloride NaCl to saturated sodium chloride NaCl, 5-50% of glycol and the balance of fresh water or seawater. The invention provides a formula of the drilling liquid suitable for (marine) deepwater drilling and solves the problems of poor rheological property of the drilling liquid in a deepwater drilling process, easy formation of a natural gas hydrate and the like. The formula can be suitable for deepwater drillingin the water depth within 3000m and at the temperature of 0-150 DEG C, and the long-term stability can reach 7 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

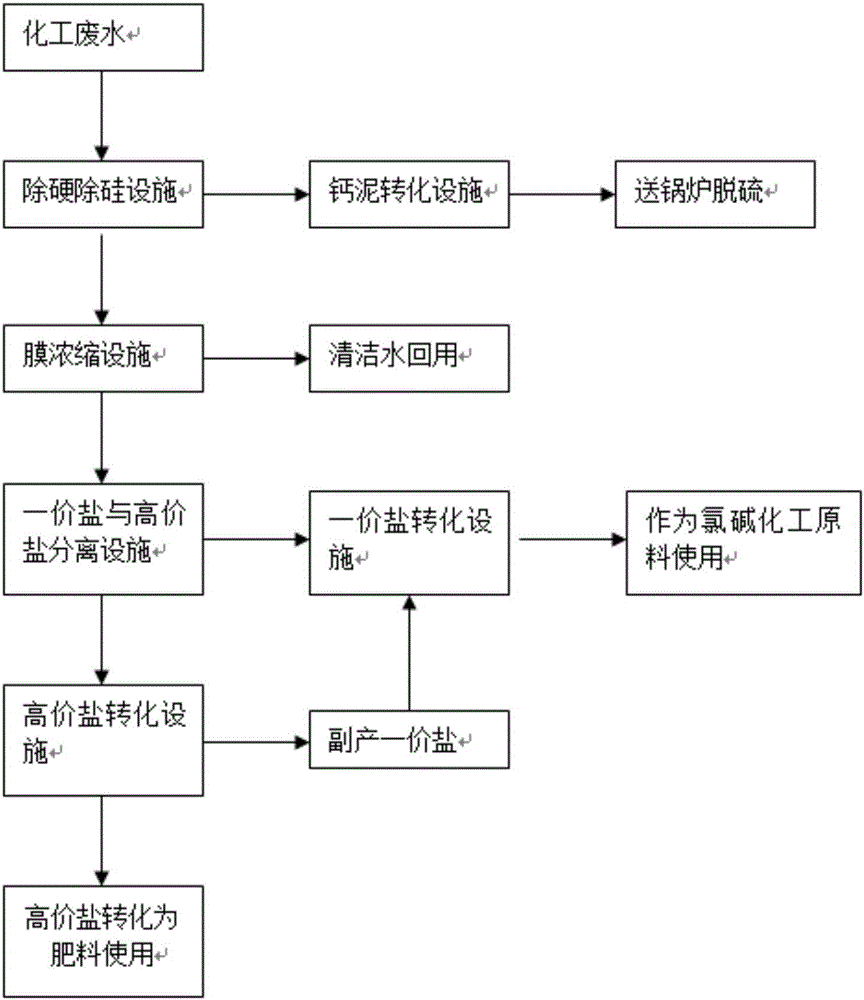

Method for reutilization of water resources and transformation and utilization of salt in waste water

InactiveCN105906129AReduce energy consumptionReduce processing costsWater softeningMultistage water/sewage treatmentSludgeFiltration

The invention discloses a method for reutilization of water resources and transformation and utilization of salt in waste water. The method includes the following steps that the pH value of the waste water is adjusted to be alkaline for hardness removal, generated settling sludge is separated out of the water and then dried to serve as a boiler desulfurizing agent, and the obtained waste water is subjected to ultra-filtration and multiple levels of reverse osmosis concentration; the waste water obtained in the former step is subjected to nano-filtration, and univalence salt and high-valence salt are separated; the univalence salt is further separated and transformed, prepared purified sodium chloride strong brine is concentrated, and the sodium chloride strong brine serves as a chloro-alkali raw material; potassium chloride is added into mixed brine which is separated out through nano-filtration and contains high-valence ions and univalence ions for a replacement reaction to generate potassium sulphate and sodium chloride, potassium sulphate and sodium chloride are separated through freezing crystallization and high-temperature evaporative crystallization, generated potassium sulphate serves as a raw material for producing chemical fertilizer, separated sodium chloride serves as a chloro-alkali production raw material, and the water and the salt in the waste water can be completely recycled.

Owner:LUXI CHEM GRP

Production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation

ActiveCN104591229ASave heatReduce water consumptionAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationTemperature controlEvaporation

The invention discloses a production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation. The production process comprises the following steps: soaking nitronatrite ore with water to form a three-salt system liquid of sodium chloride NaCl, sodium nitrate NaNO3 and sodium sulfate Na2SO4; producing sodium chloride by low-temperature salt slurry whirl in the heating treatment process; extracting sodium sulfate from high-temperature salt slurry by virtue of a liquid-liquid separator; and returning a mother liquid to an evaporation system to use in cycle, and gradually separating and washing a salt slurry separator, so that heat energy is reduced; the water consumption is reduced; industrial pollution is reduced; the production process is mainly applied to comprehensive utilization of nitronatrite ore resources; production of the sodium nitrate is achieved; by-production of the sodium chloride and the sodium sulfate is achieved; waste salt is divided into two products, namely the sodium sulfate and the sodium chloride, so that the production value is increased; and the comprehensive economic benefits are improved.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

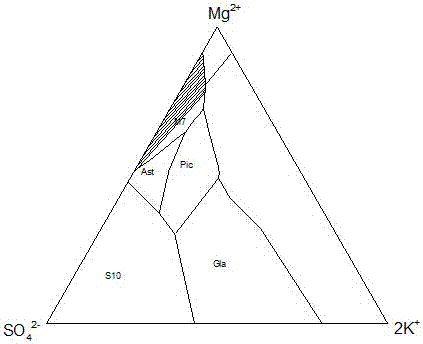

Salt pan tedding technology of high-magnesium and low-potassium sulfate brine

ActiveCN107352560ASolve the key technical problems that cannot directly produce potassium sulfateIncrease resourcesMagnesium chloridesDouble sulfate preparationHigh magnesiumSalt lake

A salt pan tedding technology of high-magnesium and low-potassium sulfate brine comprises the following steps: 1, introducing the high-magnesium and low-potassium sulfate brine into a sodium chloride salt pan, naturally tedding the brine, and introducing the brine into an epsomite salt pan when epsomite in the brine reaches saturation and epsomite precipitates; 2, evaporating the brine, and introducing the brine into first stage carnallite salt pan when the percentage of precipitated epsomite is 40-80 wt%; 3, evaporating the brine, and introducing the brine into a second stage carnallite salt pan when the percentage of precipitated carnallite is 40-60 wt%; 4, continuously evaporating the brine, continuously precipitating the carnallite, and introducing the brine into an old brine salt pan after the brine reaches an old brine point; and 5, crushing first stage carnallite ores, and decomposing and dehalogenating the crushed first stage carnallite ores. The method allows high-quality potassium sulfate to be produced from the high-magnesium and low-potassium sulfate brine which is only used to produce potassium chloride originally, and improves the resource exploitation rate of like salt lakes and underground brine resources and the added values of the product.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Method for producing methacryloxypropyltrimethoxysilane

ActiveCN105061487ANo dischargeStable outputGroup 4/14 element organic compoundsSaline waterSodium methacrylate

The invention relates to a method for producing methacryloxypropyltrimethoxysilane, which belongs to the technical field of industry of fine chemicals. The method comprises the following steps: investing gamma-choropropyltrimethoxysilane and sodium methacrylate in a reactor, adding a catalyst and a polymerization inhibitor, stirring and heating for reacting and filtering a reactant, distilling a filtrate to obtain the product; cleaning the filter residue by using saturated common salt brine with PH value to 7-8, filtering, repeating for 2-3 times, and merging a washing lotion for stationary layering, wherein the filter residue is white common salt crystal and can be used for industrial purpose; wherein a lower layer of the washing lotion is saturated common salt brine for next cycle usage; an upper layer of the washing lotion is the methacryloxypropyltrimethoxysilane crude product, and distilling to obtain the product. According to the invention, yield of methacryloxypropyltrimethoxysilane product is high, energy consumption is low, production cost is low, and more importantly, the by-product can be effectively cycled and used, and no environmental pollution is generated.

Owner:JINGZHOU JIANGHAN FINE CHEM

Device and method used for removing organic impurities in by-product sodium chloride salt

ActiveCN109956485ASolve the blockageSolve wear and tearAlkali metal halide purificationNuclear chemistryImpurity

The invention belongs to the technical field of chemical technology and equipment, and relates to a device and a method used for removing organic impurities in by-product sodium chloride salt. The device comprises a high temperature oxidation reactor, a dissolving kettle A, a dissolving kettle B, a liquid phase deep oxidation tower, a liquid solid filter, a solid residue tank, and a nanofiltrationmembrane separator. The method comprises following steps: firstly, the multi-layer fluidized bed type high temperature oxidation reactor is used for high temperature oxidation of most organic impurities in by-product sodium chloride salt, then in the liquid phase deep oxidation tower, deep oxidation of residual trace amount organic impurities is carried out, and the nanofiltration membrane separator is adopted to remove the large molecular organic matter impurities further, so that requirements on organic matter impurities in sodium chloride raw material in ionic membrane caustic soda industrial device are satisfied. The device and the method are high in operation flexibility, and organic impurity processing efficiency is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

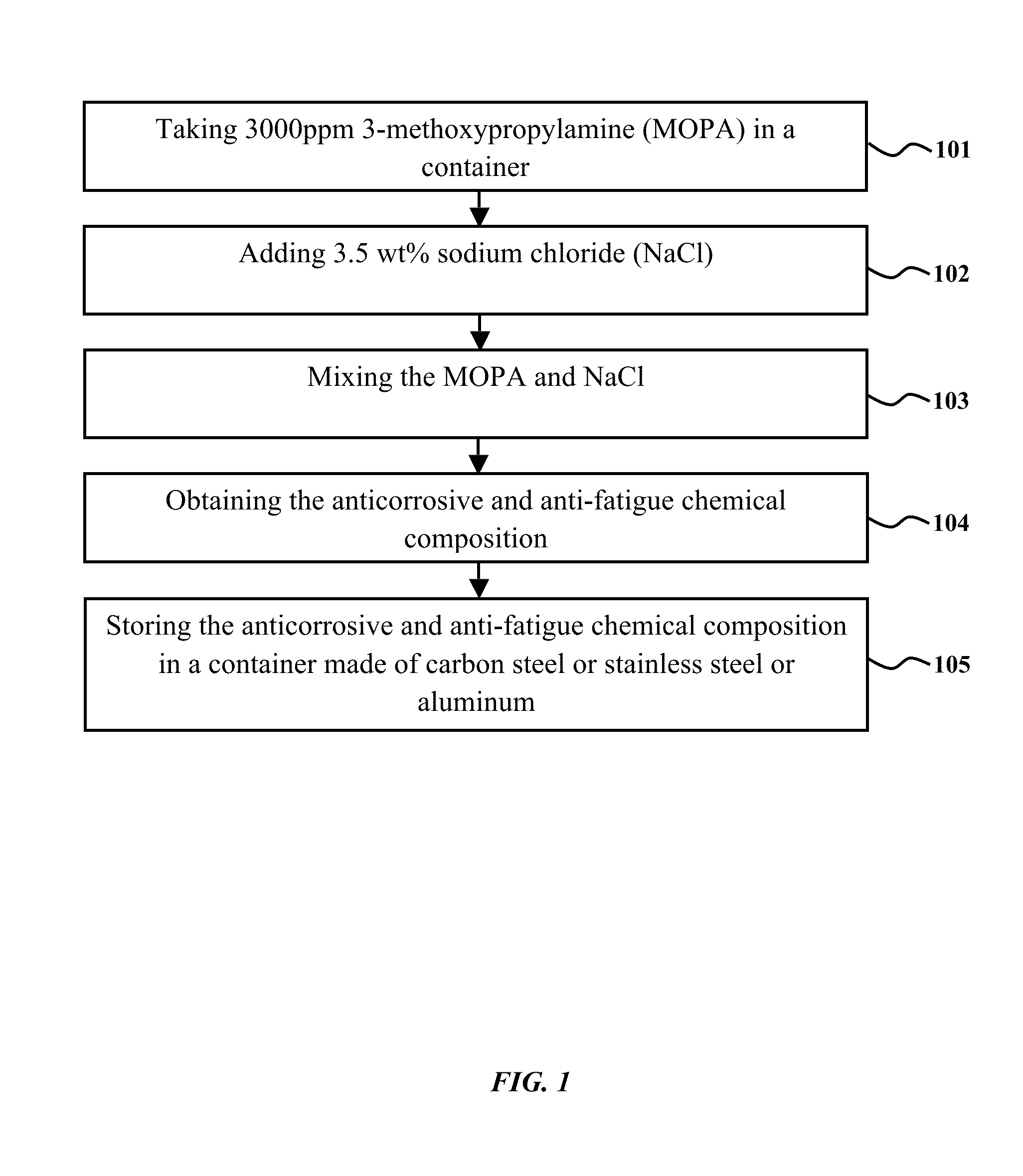

Anticorrosive and Anti-fatigue chemical composition for nickel-titanium dental instruments and a method of synthesizing the same

InactiveUS20160024311A1Increase the number of cyclesIncrease the number ofGum massageDental flossInstrumentationNickel titanium

The embodiments herein disclose a dental anti-corrosive and anti-fatigue chemical composition. The chemical composition stabilizes the passivating oxide layer and reduces the corrosion specifically fretting corrosion. The chemical composition is capable of increasing the fatigue resistance of NiTi rotary instruments lead to increased number of cyclic fatigue in the dental instruments. The chemical composition is synthesized by mixing sodium chloride NaCl (3.5 wt %) and 3-methoxypropylamine (MOPA) 3000 ppm solution (pH=11.1). The chemical composition is stored in carbon steel, stainless steel or aluminum. The chemical composition is applied to the NiTi rotary instruments are by 5 mL of the anticorrosive chemical composition for 24 hours. After root canal treatment and before next time usage the used instruments are cleaned and sterilized. After sterilization, the instruments are immersed inside the solution for 24 hours. After 24 hours the instruments are ready for the next treatment.

Owner:SAGHIRI MOHAMAD ALI +3

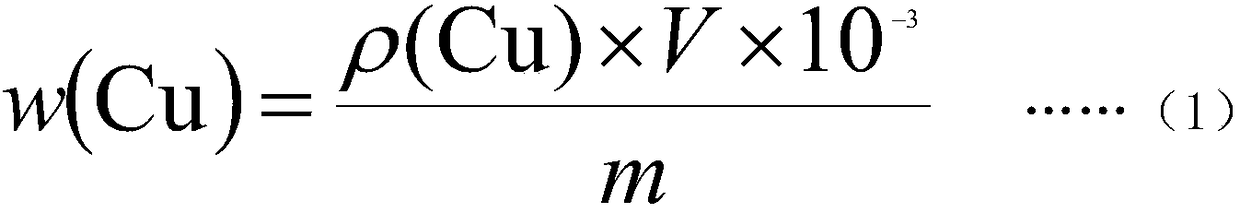

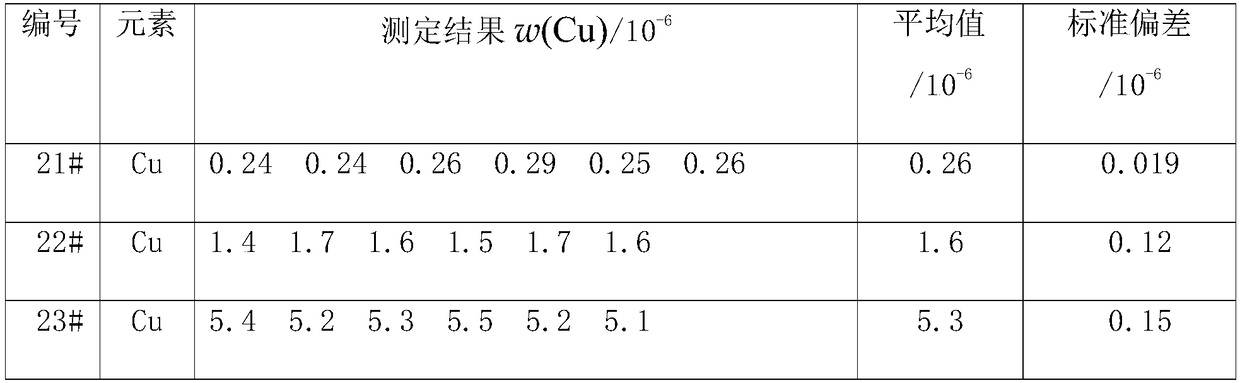

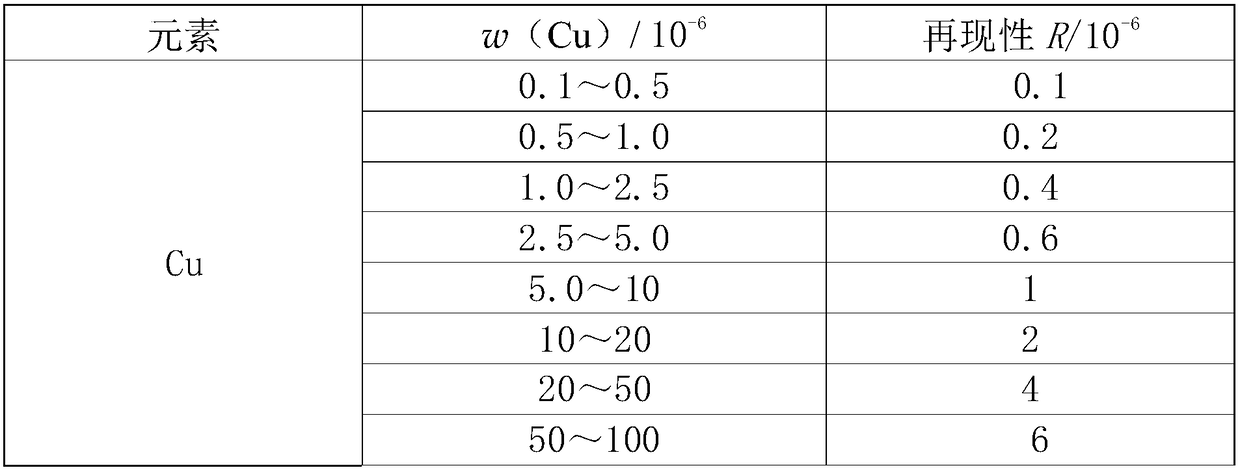

Method for measuring content of copper in sodium chloride

InactiveCN108918507AEstablishment of Quantitative Detection Method for Copper ContentEstablish a Quantitative AssayPreparing sample for investigationAnalysis by thermal excitationSalt spray testPt element

The invention discloses a method for measuring the content of copper in sodium chloride through an inductively coupled plasma atomic emission spectrometer and belongs to the technical field of chemical detection. The method comprises the steps of specimen pretreatment, adjusting of a dual-platinum-net atomizer, preparation of a copper element calibration curve and calculating of the precision degree, and thus the target of accurately detecting the content of copper in the sodium chloride is achieved. The measuring range of w(Cu) is 0.1*10<-6>~100*10<-6>. According to the method for measuring the content of copper in the sodium chloride, the detection technical problem of trace copper in the sodium chloride is solved, powerful technical support is provided for correctly selecting and evaluating a sodium chloride salt solution used for a salt spray test widely used internationally and predicting corrosion resistance and the service life of a paint film, and the advanced level of the detection field is reached.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Hydrogenated hot gas chemical solution component and application thereof in increasing yield of horizontal well

ActiveCN105694839AIncrease productionSolve the blockageFluid removalDrilling compositionChemical solutionPotassium

The invention belongs to the technical field of oil exploitation and particularly relates to a hydrogenated hot gas chemical solution component and application thereof in increasing the yield of a horizontal well. The component is formed by mixing a first solution and a second solution at 1:1 by mass. The first solution is prepared from, by the mass sum of 100%, 50-55% of ammonium nitrate NH4NO3, 8-13% of hydrocarbon fuel, 4.5-5.5% of sodium chloride NaCl or potassium chloride KCl, 7-9% of nitric acid HNO3, 0.5-3.0% of an emulsifying agent and 15-20% of water, wherein the emulsifying agent is a mixed solution of polyethylene polyamines and tall oil fatty acid at 3:(0.5-0.7) by mass. The second solution is prepared from, by the mass sum of 100%, 22-26% of sodium nitrate NaNO2, 25-31% of urea CO(NH2)2, 20-25% of sodium borohydride NaBH4 and 27-31% of tetrachloroethylene C2C14. By means of the hydrogenated hot gas chemical solution component and application thereof in increasing the yield of a horizontal well, the yield of a horizontal well is increased while the problem of blockage of a horizontal well is solved, the technology is safe, reliable and low in cost, and meanwhile a stratum is protected.

Owner:吉林贯通能源科技有限责任公司

Production method of ethylene diaminetetraacetic acid ferric sodium salt

ActiveCN109651180ARealize joint productionAchieve recyclingOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineAcetic acid

The invention discloses a production method of ethylene diaminetetraacetic acid ferric sodium salt. The production method comprises the following steps that a primary reaction is carried out, whereinferric trichloride reacts with ethylene diaminetetraacetic acid tetrasodium salt in water to obtain a stock solution A and a solid product B; the solid product B is dried to prepare the ethylene diaminetetraacetic acid ferric sodium salt; the stock solution A is subjected to chromatographic treatment to obtain a component A-1 containing sodium chloride NaCl and a component A-2 containing the ethylene diaminetetraacetic acid tetrasodium salt; the component A-1 is crystallized and separated to obtain NaCl solid C and NaCl filtrate D, the NaCl solid C is dried to prepare byproduct solid NaCl, andthe NaCl filtrate D is subjected to the operation in the filtrate treatment step again; the component A-2 containing the ethylene diaminetetraacetic acid tetrasodium salt is subjected to the primaryreaction again. The method has the advantages that the ethylene diaminetetraacetic acid ferric sodium salt and sodium chloride in reaction liquid can be separated, the separated component containing the ethylene diaminetetraacetic acid ferric sodium salt can serve as the reaction liquid to participate in the reaction as the raw material again; meanwhile, the byproduct sodium chloride is obtained and utilized.

Owner:北京海德恒生科技发展有限公司

Special salt formula for farming prawns

InactiveCN108432676AModerate salinitySufficient elementsClimate change adaptationPisciculture and aquariaSodium bicarbonateDisease

The invention relates to a special salt formula for farming prawns. The formula is prepared from the following raw materials of: in parts by weight, 60-75% of sodium chloride NaCl, 20-35% of magnesiumsulfate MgSO4, 0.1-5% of magnesium chloride hexahydrate MgCl2.6H2O, 0.1-10% of calcium chloride CaCl.2H2O, 0.1-5% of potassium chloride KCl, 1-5% of sodium bicarbonate NaHCO3 and 0.1-5% of sodium carbonate Na2CO3. Produced recovered seawater has suitable salinity and sufficient elements, can fully meet growth requirements of Penaeus vannamei, and is suitable for the growth of Penaeus vannamei, sothat the problems of stress, diseases, slow growth and the like which are caused by inconsistent ratios of elements in the farming process are solved, and the farming efficiency is improved greatly.

Owner:宁波牧海人海洋科技有限公司

Process for sulphofication of mucopolysaccharide with galactosamine hexose aldehydic acid disaccharide based structure

InactiveCN100999555AQuality improvementHigh purityOrganic active ingredientsChlorosulfuric acidDermatan sulfate

The present invention relates to process of sulfonating mucopolysaccharide with the basic galactosamine-hexuronic disaccharide structure to prepare sulfonated mucopolysaccharide product with antithrombogenic function. The process adopts chondrotin sulfate A and / or chondrotin sulfate or C or dermatan sulfate as material, and includes the steps of purifying material, dissolving in formamide, sulfonating with chlorosulfonic acid, separating sulfonated mucopolysaccharide precipitate in alcohol, mixing the water solution with the precipitate with strong alkaline anionic resin, adsorbing at pH5.0-7.5 for a night, washing with solution of sodium chloride, eluting in resin to collect eluted solution, precipitating with alcohol, dewatering with alcohol, and drying to obtain sulfonated mucopolysaccharide product. The process is simple, high in product stability and suitable for industrial production.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

Recovery system and recovery method for waste resin powder

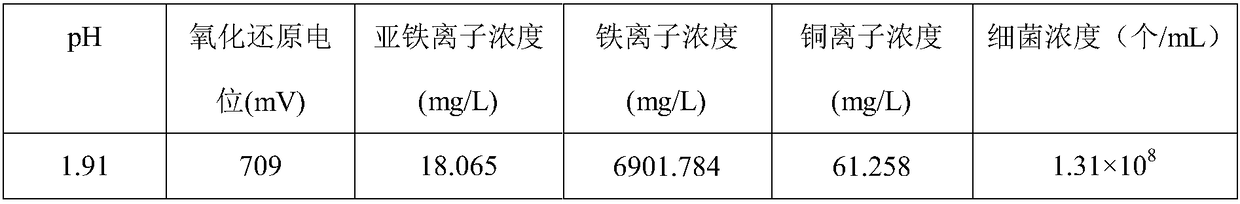

ActiveCN108070528AHigh degree of harmlessnessShorten the cycle of immersion copperBioreactor/fermenter combinationsBiological substance pretreatmentsRecovery methodRecovery stage

The invention discloses a recovery system for a waste resin powder. The recovery system comprises a microbial culture device, a leaching device, a settlement device, a copper recovery device, a brining device, a lead settling device, a washing device, a drying device and a solid liquid separating machine. The invention further discloses a recovery method for the waste resin powder. The recovery method comprises the microbial culture stage, the leaching stage, the settling stage, the copper recovery stage, the brining stage, the lead settling stage, the washing stage, and the drying stage. Thebiological copper leaching cycle of the waste resin powder is shortened, the production efficiency is improved, the sodium chloride is used in brining, the lead in the waste resin powder is effectively removed, the lead is separately recovered, the harmless degree of the leaching residue is high, and in addition, the recycling utilization of the resource is realized, the resource is saved, the useratio of the resource is also improved, and the production cost is lowered.

Owner:CENT SOUTH UNIV +1

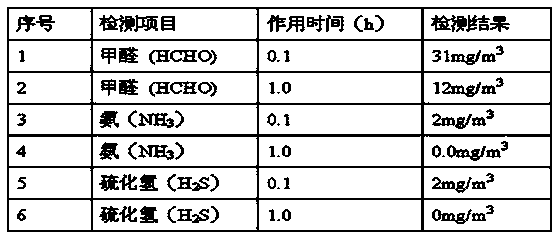

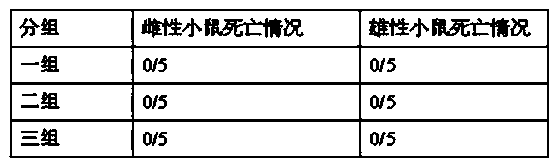

Comprehensive broad-spectrum bactericidal disinfectant

InactiveCN110959629AGood broad-spectrum sterilization and disinfection abilityNo side effectsBiocideDisinfectantsSodium bicarbonateDisinfectant

The invention discloses a comprehensive broad-spectrum bactericidal disinfectant, belonging to the technical field of disinfectant production. The comprehensive broad-spectrum bactericidal disinfectant includes 1%-10% calcium oxide CaO, 1%-10% calcium chloride CaCl2, 1%-10% sulfur S, 1%-10% of potassium chloride KCl, 1%-10% of potassium permanganate KMnO4, 1%-10% of sodium hydroxide NaOH, 1%-10% of sodium bicarbonate NaHCO3, 1%-10% of borax Na2B4O7-10H2O, 1%-10% of sodium chloride NaCl, 1%-2% of aromatic and water H2O. The disinfectant has the advantages of good sterilization and disinfectioncapability, no toxic and side effect, high temperature resistance, difficulty in combustion and selective volatilization, the disinfectant has very good sterilization, disinfection and purification effects on infectious viruses such as influenza viruses and coronaviruses, and the disinfectant is widely applied to sterilization and disinfection of various public places, is not limited by regions and weather, and is a broad-spectrum sterilization disinfectant required by various countries all over the world.

Owner:广东中创融合科技有限公司

Refining agent for novel aluminum-magnesium-silicon alloy and preparation method of refining agent

PendingCN114875263APromote meltingRapid responseProcess efficiency improvementSilicon alloySodium nitrate

The invention discloses a refining agent for a novel aluminum-magnesium-silicon alloy and a preparation method of the refining agent, and the refining agent comprises the following raw materials in parts by weight: 10-20 parts of sodium nitrate NaNO3, 5-10 parts of sodium carbonate Na2CO3, 20-30 parts of sodium chloride NaCl, 10-20 parts of magnesium chloride MgCl2, 10-20 parts of aluminum nitrate Al (NO3) 3, 5-10 parts of cryolite Na3AlF6, 10-20 parts of sodium fluoride NaF, 10-20 parts of sodium fluosilicate Na2SiF6 and the balance of graphite C. The method comprises the following steps: performing low-temperature ionization treatment on NaNO3, Na2CO3, NaCl, MgCl2 and Al (NO3) 3 in a certain weight fraction to obtain a dry raw material, crushing the dry raw material, Na3AlF6, NaF and Na2SiF6 to obtain a crushed mixture, sieving, selecting, adding graphite and part of water, continuing stirring to obtain a mixture, and granulating to obtain the refining agent. According to the refining agent for the novel aluminum-magnesium-silicon alloy and the preparation method of the refining agent, the prepared refining agent is granulated and formed, the refining agent can rapidly react with molten aluminum, the reaction process is not affected, the density of a single refining agent particle is enough for continuous reaction, and continuous reaction is guaranteed.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD

A method for preparing undenatured natural collagen from suckling pig skin

ActiveCN103601803BEffective hair removalEfficient removalConnective tissue peptidesPeptide preparation methodsHair rootsDry weight

The invention discloses a method for extracting undenatured natural collagen from sucking pig skin. The method is characterized in that treatment is carried out by sub-step repeated different combinations in a manner that a degreasing agent is assisted by intermittent ultrasonic waves, an unhairing agent and a non-collagen removing agent are respectively used for unhairing and removing non-collagen, and no hair root exists in the skin after unhairing, wherein shown by determination, the fat content is lower than 0.5% and the ash content is lower than 0.3%; enzyme-soluble collagen is obtained through leaching by acetic acid-protease and is purified by high-speed centrifugation, sodium chloride salting-out and dialysis, and spongy sucking pig skin collagen is obtained after freeze-drying, wherein the collagen extraction ratio exceeds 50% (dry weight), and shown by electrophoretogram, the sucking pig skin collagen contains a beta chain and an alpha chain, of which the molecular weights are 200000 and 100000 respectively, and is free from other hybrid protein bands, so that the collagen reserves three helical structures and has relatively high purity.

Owner:SICHUAN UNIV

Production method of recombinant human fibroblast growth factor-17

InactiveCN105420263BOptimize culture temperatureHigh purityMicroorganismsMicroorganism based processesEscherichia coliEthylenediamine

The present invention provides a method for producing recombinant human fibroblast growth factor-17 protein, at least including the following steps: step 1, recombining natural sequence human fibroblast growth factor-17 protein FGF-17 according to the preference of Escherichia coli and amplification; step 2, connecting the recombined rhFGF‑17 gene to the E. coli expression plasmid to form a recombinant expression vector, and then transforming the recombinant expression vector into the E. coli host bacterium to obtain FGF‑17 protein expression engineering bacteria; and steps 3. Cultivate the expression engineering bacteria, and then purify; wherein, in the purification process, the cell lysis buffer of the following concentration components is used: 45-55mM tris Tris, 280-320mM sodium chloride NaCl, 1.5-2.5mM ethylenediaminetetraacetic acid DTA, 0.1-0.3M sucrose, and 0.8-1.2% volume percentage of polyethylene glycol octyl phenyl ether TritonX-100, 0.1-0.3% Sodium oxycholate, 5%-10% glycerin, 0.8-1.2% phenylmethylsulfonyl fluoride PMSF. The concentration and purity of the FGF‑17 protein produced by the production method are high.

Owner:WENZHOU MEDICAL UNIV +1

Deepwater drilling liquid

The invention relates to drilling liquid, in particular to deepwater drilling liquid which comprises the following components, by mass percent: 0-8% of bentonite, 0.05-5% of well wall stabilizing agent, 1-6% of visbreaking fluid loss control agent used for the drilling liquid, 1-6% of carboxymethyl sulfonated phenol formaldehyde resin used for the drilling liquid, 5% of sodium chloride NaCl to saturated sodium chloride NaCl, 5-50% of glycol and the balance of fresh water or seawater. The invention provides a formula of the drilling liquid suitable for (marine) deepwater drilling and solves the problems of poor rheological property of the drilling liquid in a deepwater drilling process, easy formation of a natural gas hydrate and the like. The formula can be suitable for deepwater drillingin the water depth within 3000m and at the temperature of 0-150 DEG C, and the long-term stability can reach 7 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com