Preparation process of dual-metal engine cylinder composite material

An engine cylinder and composite material technology, which is applied in the field of preparation of bimetallic engine cylinder composite materials, can solve the problems of high price, huge difference in physical properties, great difficulty, etc., and achieves simple and practical preparation process, improved joint surface performance, and reduced surface area. The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

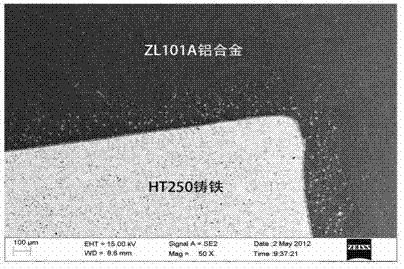

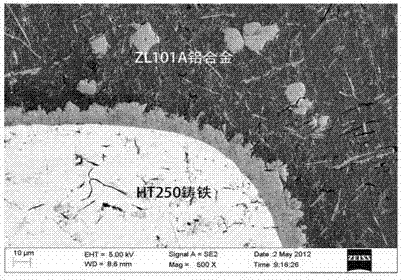

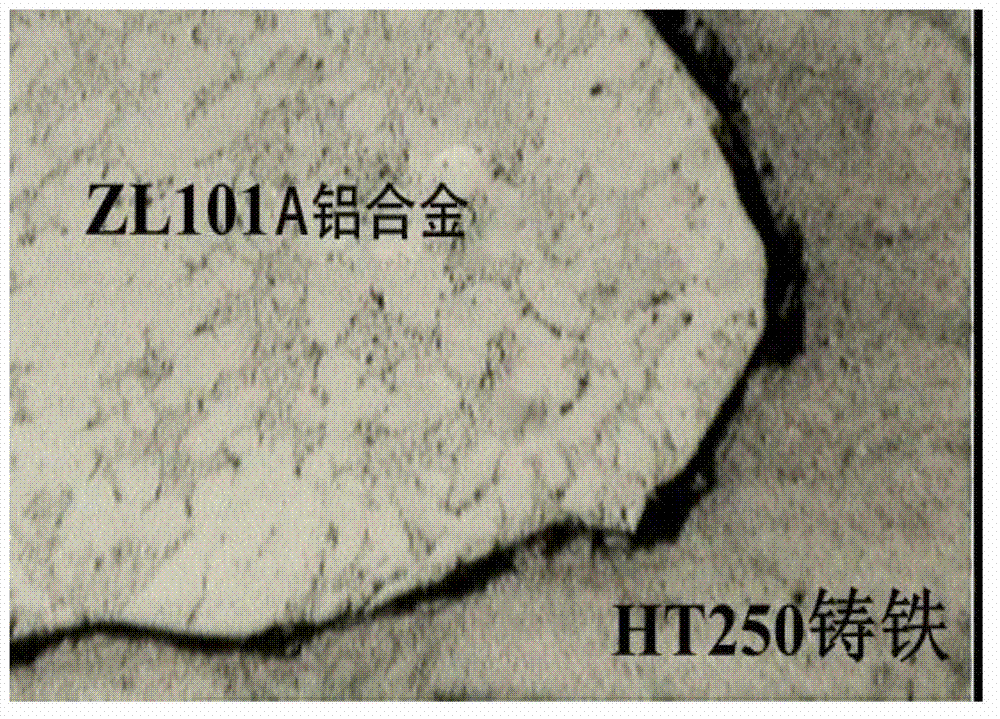

[0022] Raw materials include: HT250 cast iron cylinder liner, industrial ZL101A aluminum alloy and self-prepared surfactant (mainly composed of potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF 2 , calcium chloride CaCl 2 ).

[0023] (1) First prepare the HT250 cast iron cylinder liner used, firstly pickle the HT250 cast iron cylinder liner for surface degreasing and derusting treatment, and remove the dirt and scale on the surface of the cast iron cylinder liner;

[0024] (2) Prepare surfactants, weigh potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, and calcium fluoride CaF according to mass percentages of 39%, 20%, 18%, 15%, and 8%. 2 and calcium chloride CaCl 2 . KF, KCl, NaCl, CaF 2 , CaCl 2 Prepare an active agent with pure water at a concentration of 100g / L, then immerse the HT250 cast iron cylinder liner that has been degreased and decontaminated on the surface into the prepared surfactant solution at a t...

Embodiment 2

[0030] Raw materials include: HT250 cast iron cylinder liner, industrial ZL101A aluminum alloy and self-prepared surfactant (mainly composed of potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF 2 , calcium chloride CaCl 2 ).

[0031] (1) First prepare the HT250 cast iron cylinder liner used, firstly pickle the HT250 cast iron cylinder liner for surface degreasing and derusting treatment, and remove the dirt and scale on the surface of the cast iron cylinder liner;

[0032] (2) Prepare surfactants, weigh potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF according to the mass percentage of 46%, 16%, 15%, 13%, and 10% 2 and calcium chloride CaCl 2 . Make KF, KCl, NaCl and purified water into the active agent at a concentration of 200gL, then immerse the degreased and decontaminated HT250 cast iron cylinder liner into the prepared surfactant solution at a temperature of 110°C, take it out after 25 m...

Embodiment 3

[0038] Raw materials include: HT250 cast iron cylinder liner, industrial ZL101A aluminum alloy and self-prepared surfactant (mainly composed of potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF 2 , calcium chloride CaCl 2 ).

[0039] (1) First prepare the HT250 cast iron cylinder liner used, firstly pickle the HT250 cast iron cylinder liner for surface degreasing and derusting treatment, and remove the dirt and scale on the surface of the cast iron cylinder liner;

[0040] (2) Prepare surfactants, weigh potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, and calcium fluoride CaF according to mass percentages of 42%, 26%, 21%, 6%, and 5%. 2 and calcium chloride CaCl 2 . Prepare KF, KCl, NaCl and purified water as the active agent at a concentration of 150g / L, then immerse the degreased and decontaminated HT250 cast iron cylinder liner into the prepared surfactant solution at a temperature of 110°C for 25 minutes Take it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com