Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Silica Hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrated silica is a form of silicon dioxide, which has a variable amount of water in the formula. When dissolved in water it is usually known as silicic acid. It is found in nature, as opal (which has been mined as a gemstone for centuries), and in the cell walls of diatoms.

Method for combined production of activative carbon, white carbon black and soda by employing biomass power plant waste

InactiveCN101177264ALow costAvoid dangerSilicon compoundsAlkali metal carbonatesSilica HydrateSODIUM SILICATE SOLN

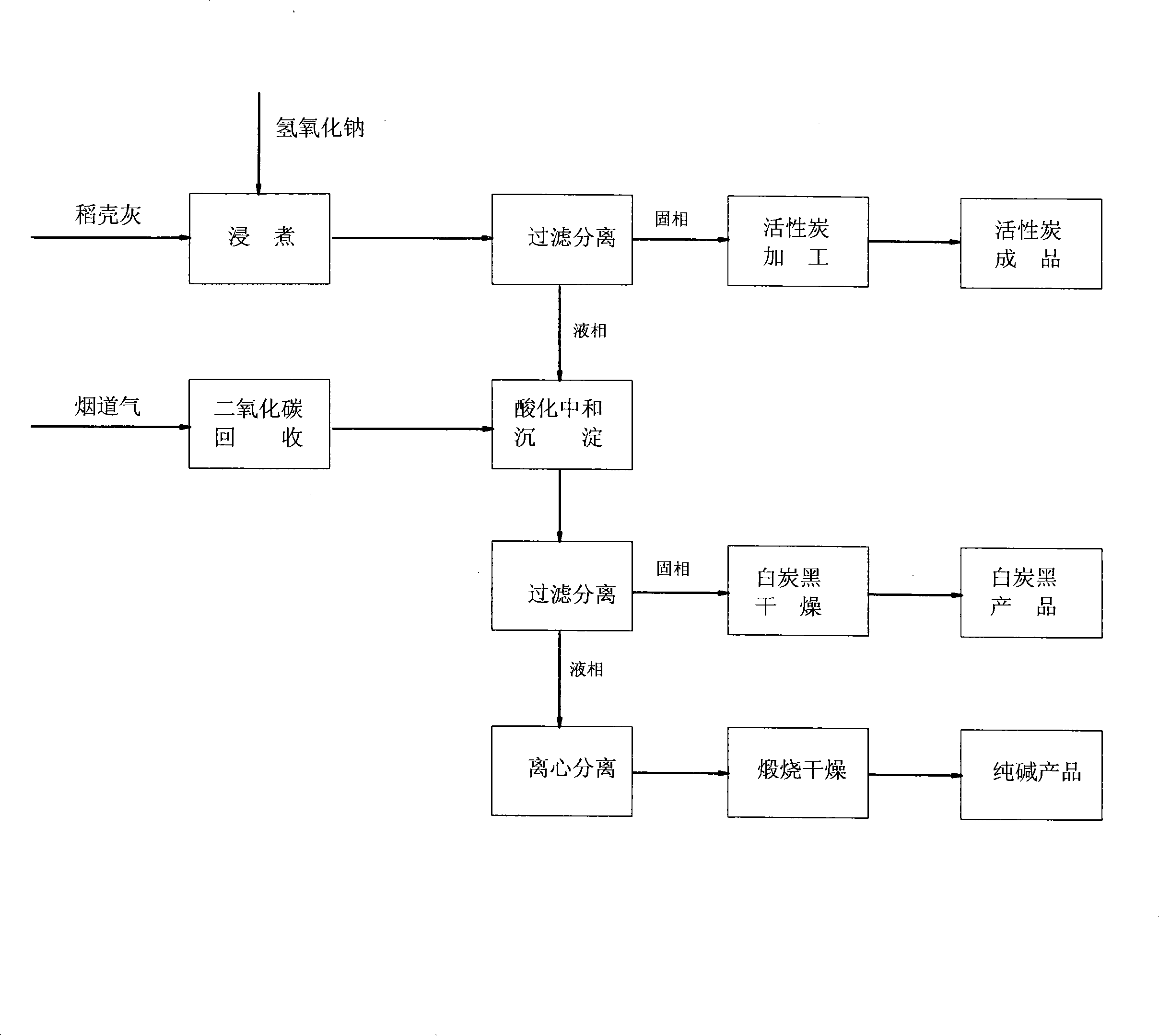

The invention relates to a combined producing method of active carbon, silica hydrated and soda with the waste of biomass power plant, which comprises the following steps: firstly, immersing and leaching the ash of rice husk of the power plant with lye to generate sodium silicate solution or sol and insoluble substance; secondly, separating the sodium silicate solution or sol from the insoluble substance, and carbonizing and neutralizing the sodium silicate solution or sol with the carbon dioxide recovered from the flue gas of the power plant to generate sedimentation of silicon dioxide and sodium carbonate solution; finally, preparing active carbon, silica and soda with the insoluble substance, the sedimentation of silicon dioxide and the sodium carbonate solution. The invention has the advantages that the ash of rice husk can be fully utilized, the carbon dioxide in the flue gas can be reasonably utilized, thereby the power plant has a great progress toward the target of zero draining, and the production cost and the energy consumption are reduced greatly, and the profit is increased obviously, and the invention has the great social and economic benefit.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

Process for preparing super activated carbon from nut shell carbon and waste liquid activation treatment method of process

The invention discloses a process for preparing super activated carbon from nut shell carbon and a waste liquid activation treatment method of the process, belonging to the field of biochemical engineering and energy materials. The process comprises the following steps: soaking nut shell carbon which is subjected to pre-washing and thermal treatment A into an oxidization substance in a vacuum reaction kettle; performing thermal treatment B on the nut shell carbon soaked into the oxidization substance, and soaking into an alkali aquo-complex activating agent in the vacuum reaction kettle; in inert gas or reductive atmosphere, heating the nut shell carbon to perform thermal treatment C so as to obtain activated nut shell carbon; adding water to leach and separate the activated nut shell carbon so as to obtain alkali activated mother liquor A and a solid; adding water into the solid for leaching again so as to obtain carbonate mother liquor B and activated carbon slurry; performing multi-stage washing and acidization treatment on the activated carbon slurry, washing with water, and separating so as to obtain a crude activated carbon product; and performing thermal treatment D of different stages on the crude activated carbon product, thereby obtaining an activated carbon product. The super activated carbon with high yield and good properties can be prepared, and meanwhile useful byproducts such as bicarbonate and hydrated silica can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

Redispersible latex powder

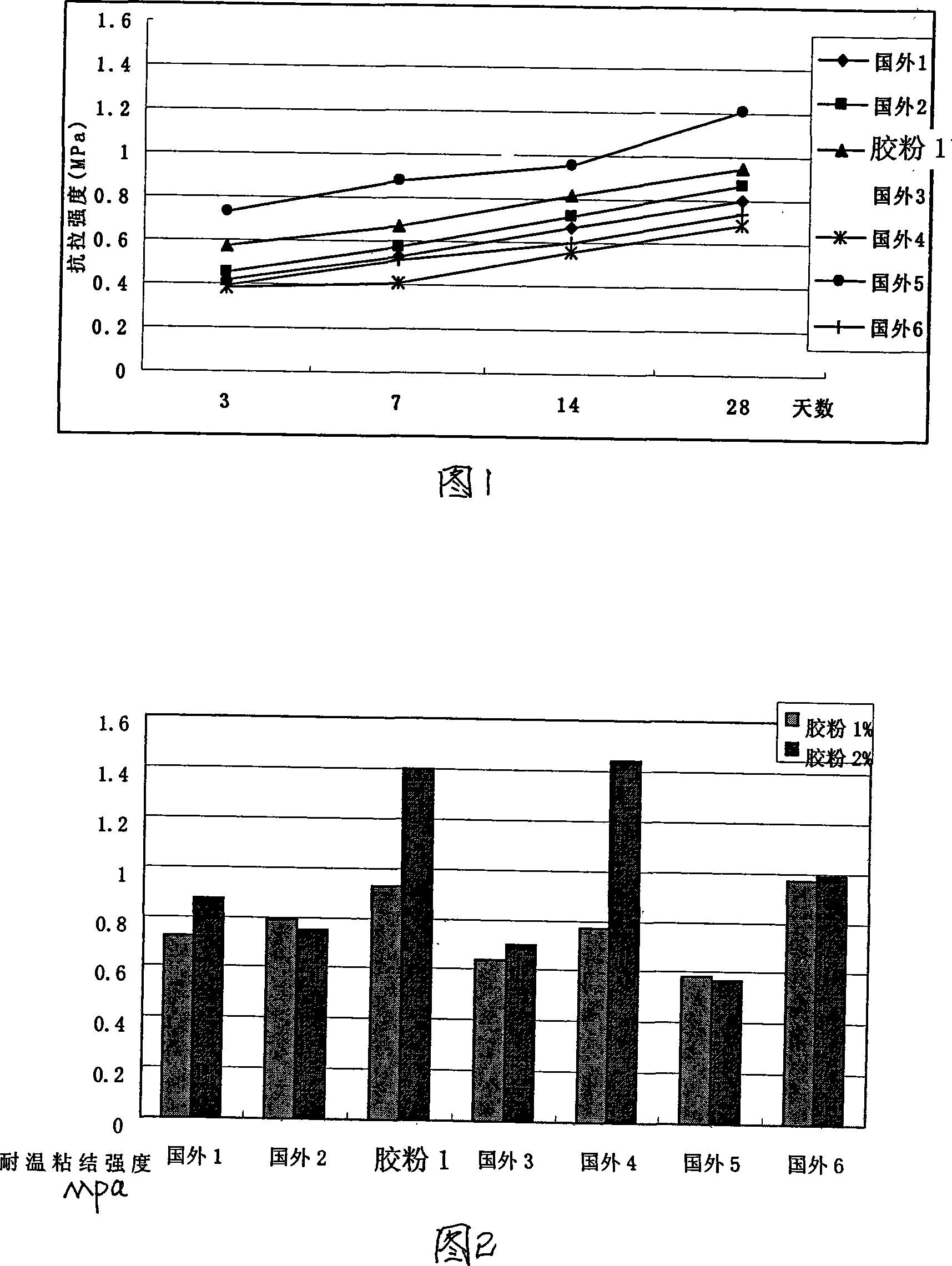

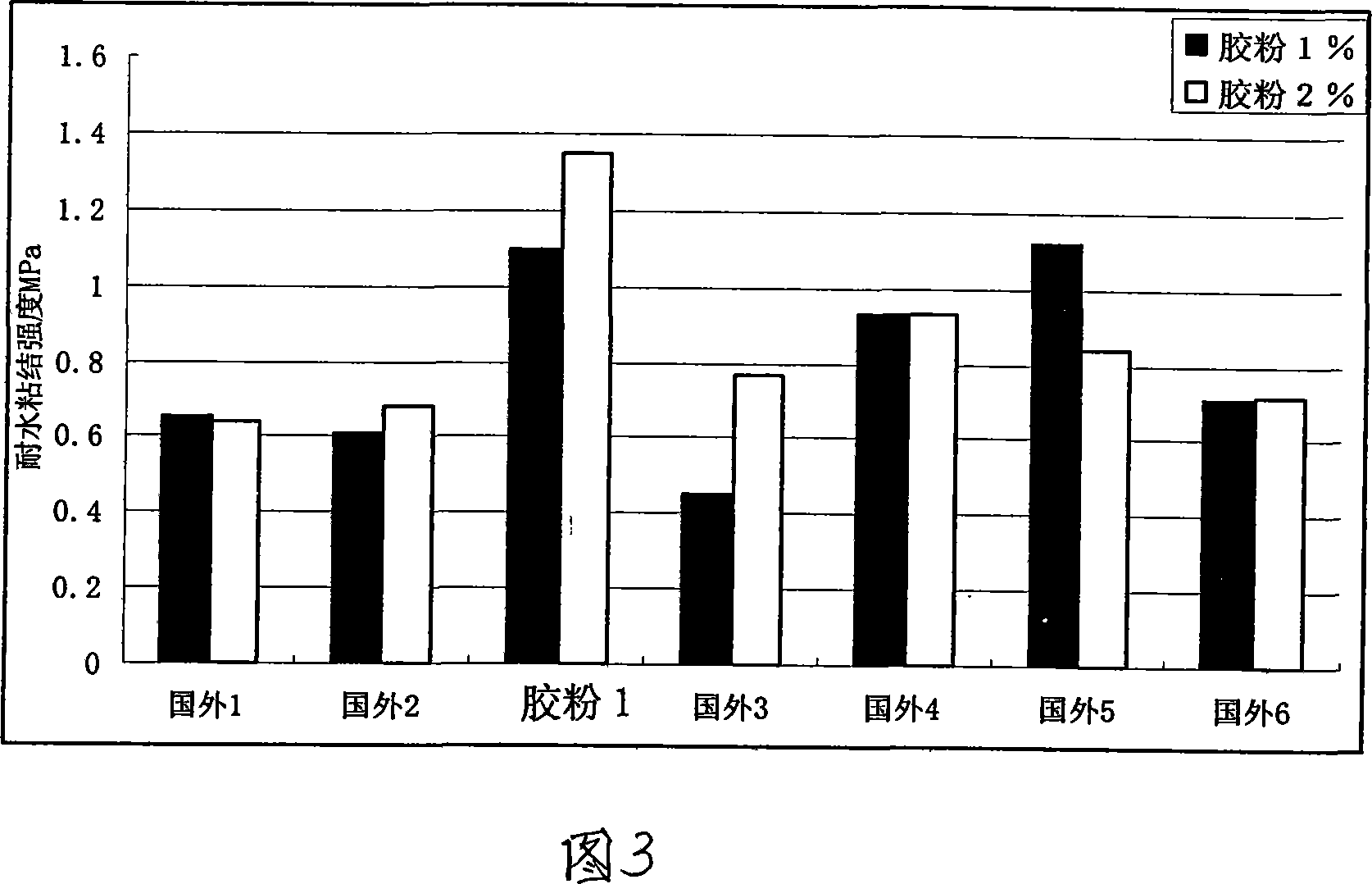

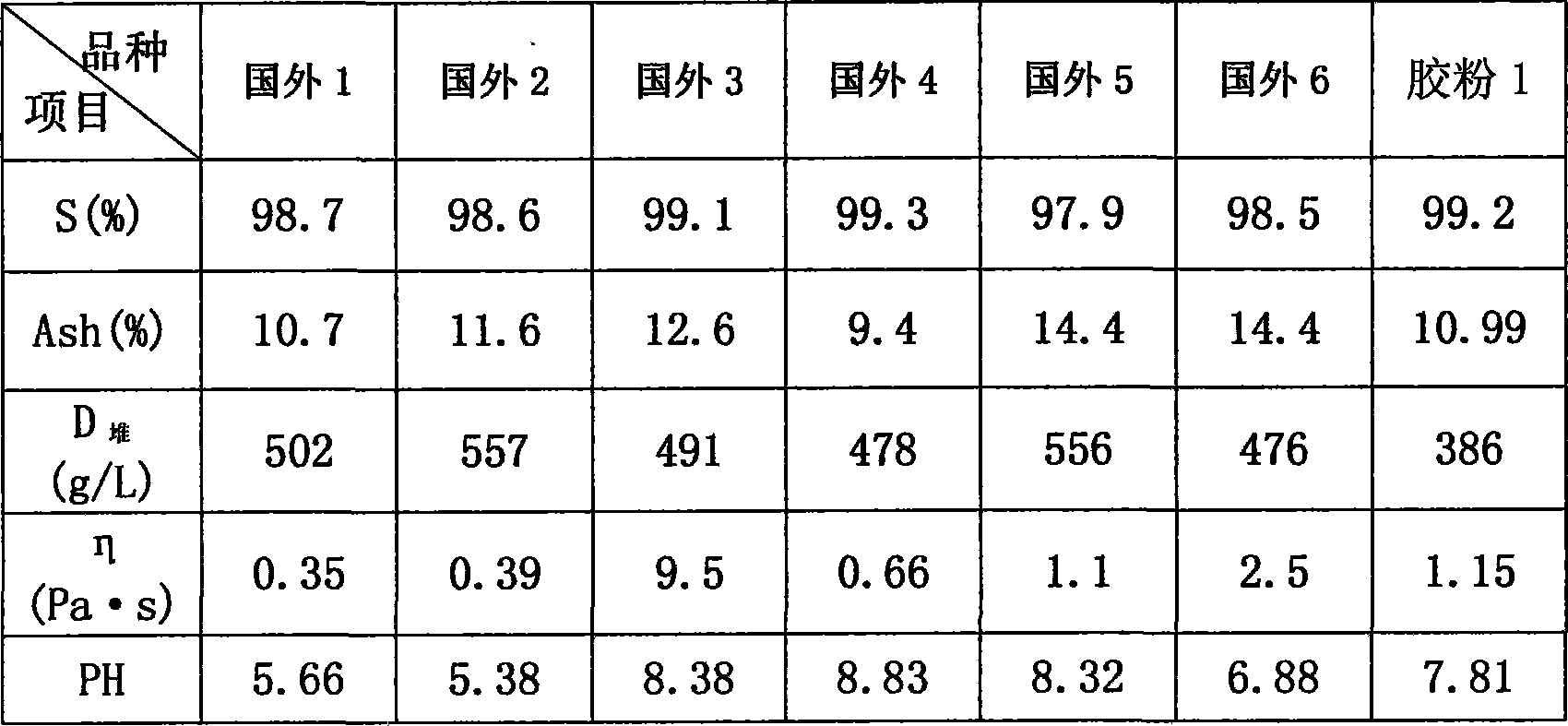

The invention relates to a latex powder, in particular to a redispersible latex powder, solving the problems of poor redispersiblity of the redispersible latex powder in the prior art and comprising the raw materials based on a proportioning ratio by weight: polyvinyl acetate copolymer emulsion 60-80 portions, polyvinyl alcohol 5-20 portions, silica hydrated 2-10 portions and calcium carbonate 5-15 portions. Compared with the same type products in China, the invention greatly promotes the technic indexes of original strength, water-proof, temperature resistance, folding ratio, etc.

Owner:山西三维华邦集团有限公司

Composition for building material and a process for the preparation thereof

ActiveUS8257486B2Simple methodHigh compressive strengthSolid waste managementOther chemical processesPotassiumBound property

Owner:COUNCIL OF SCI & IND RES

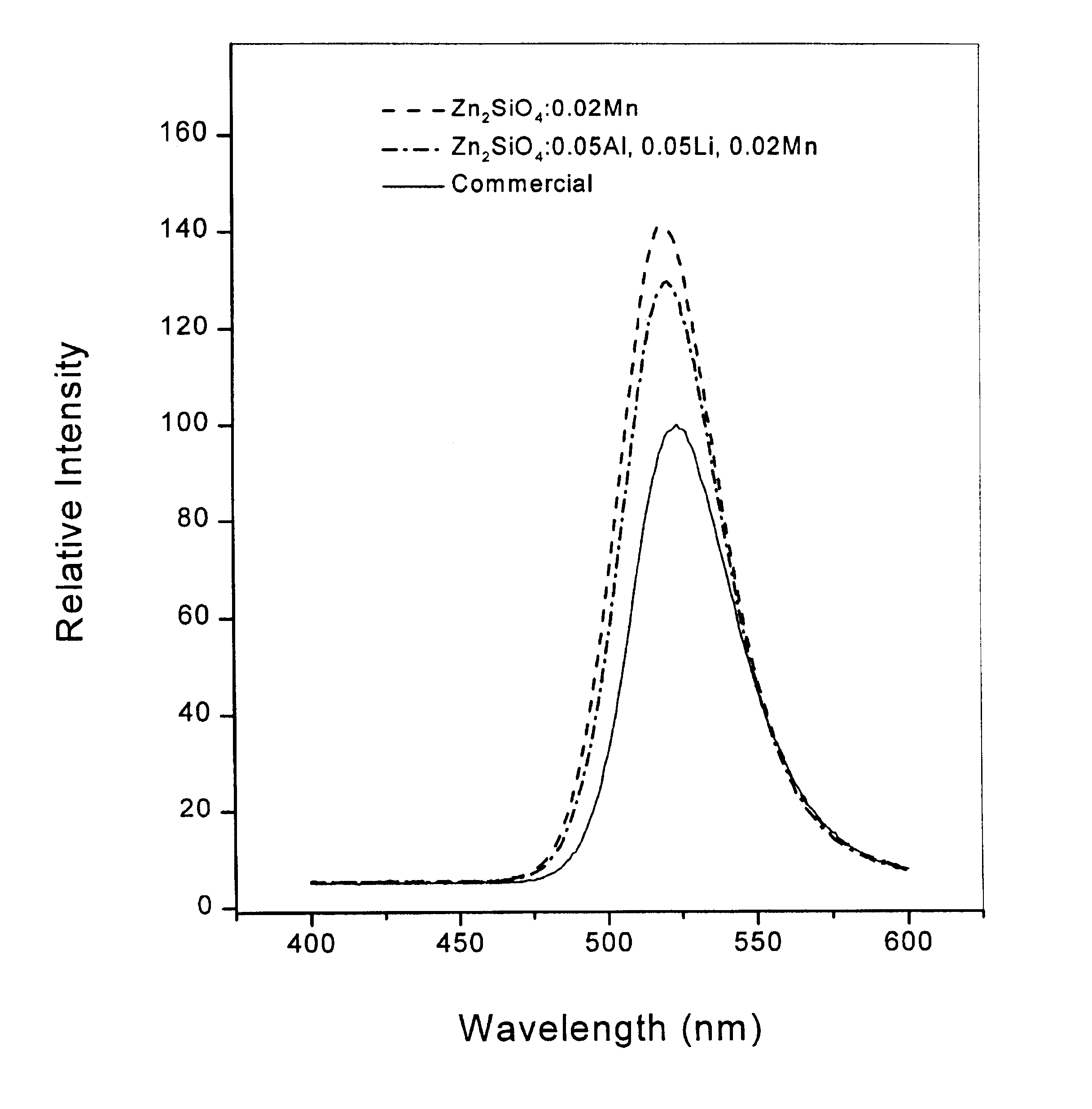

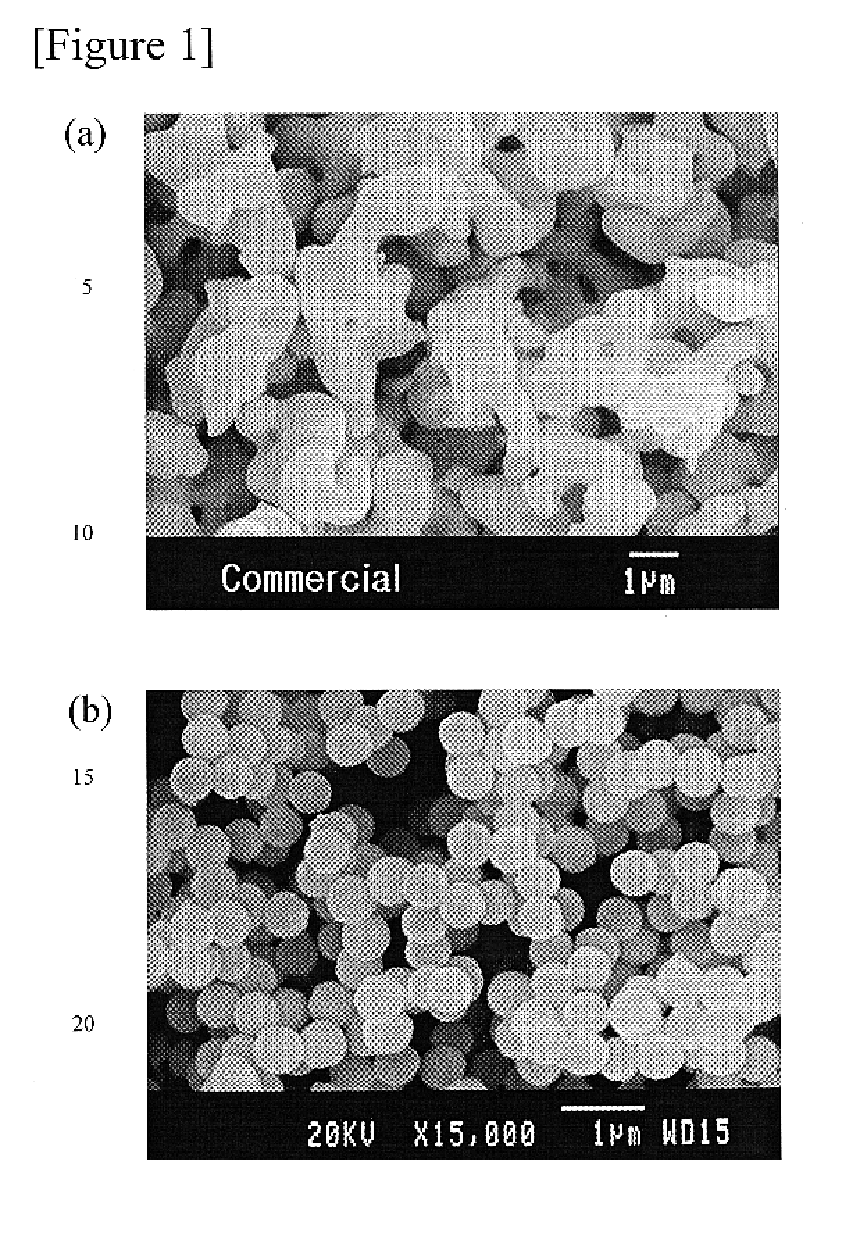

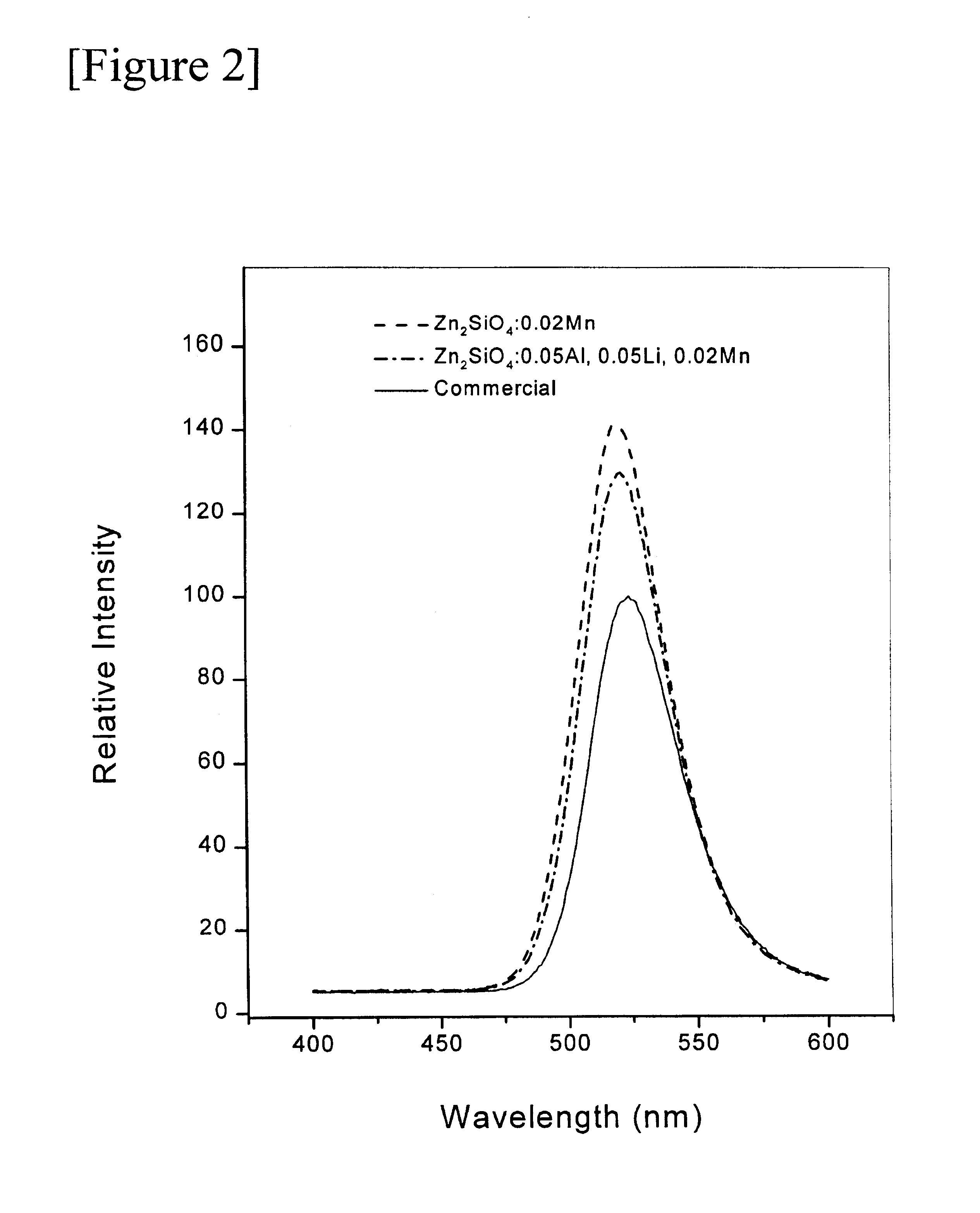

Preparing green phosphor based on zinc orthosilicate

This invention relates to a process for preparing a spherical green-emitting phosphor based on zinc orthosilicate and more particularly, to the process for a zinc orthosilicate-based green-emitting phosphor demonstrating an emission spectrum at visible regions, when excited by electron beam, via a new application of 'the homogeneous precipitation method' comprising the following steps such as i) a solution of tetraethylorthosilicate (TEOS) diluted in ethanol is hydrolyzed to obtain a hydrated silica, ii) said hydrated silica is dispersed together with the solution containing zinc and manganese components, iii) a precipitant selected from oxalic acid and oxalates is added to said dispersed solution together with a basic solution, while precipitating zinc and manganese components, iv) said admixture precipitate, so filtered off and dried, is calcined in the air and reheated under the reducing atmosphere to generate a phosphor powder; hence, the above-described phosphor particle is quite effective in a variety of display fields of industry including PDP, since it has a spherical shape with less agglomeration and homogeneous distribution of manganese, an activator, thus proving superior to the conventional phosphor prepared by the solid state reaction method in terms of brightness.

Owner:KOREA RES INST OF CHEM TECH

Synthetic rubber for nylon curtain wire on inner layer of tire

The invention relates to a synthetic rubber for a nylon curtain wire on an inner layer of a tire in the field of synthetic rubber. The technical proposal is as follows: the synthetic rubber includes the following raw materials according to the parts by weight: 90 of natural rubber, 8-12 of butadiene-styrene rubber, 40-60 of fine reclaimed rubber, 3-5 of zinc oxide, 2-3.5 of stearic acid, 3-5 of antioxidant, 1.5-3 of tackifying resin, 1.5-3 of homogenizing agent, 1-3 of plasticizer, 1.5-2.2 of silane coupling agent, 30-40 of high-abrasion furnace black, 6-8 of silica hydrated, 7.5-8.5 of aromatic oil, 2-3 of sulfur, 1-2 of vulcanization accelerator and 0.1-0.25 of antiscorcher. The invention adopts a silica hydrated and Si-69 balance vulcanization system so as to avoid over-vulcanization and then to greatly improve the whole performance of the tire. The formulation involves a great amount of fine reclaimed rubber to replace the natural rubber, thereby not only saving the cost and resources but also improving the milling and rolling property of the inner layer curtain wire rubber.

Owner:SHANDONG HENGYU RUBBER CO LTD

Skin care composition

PCT No. PCT / GB97 / 00048 Sec. 371 Date Jul. 7, 1998 Sec. 102(e) Date Jul. 7, 1998 PCT Filed Jan. 8, 1997 PCT Pub. No. WO97 / 25022 PCT Pub. Date Jul. 17, 1997The present invention relates to a method for treating spots and other symptoms of acne and related skins disorders in mammals, which comprises applying to the affected area of the skin of the mammal a non-aqueous composition comprising a dermatologically effective amount of a particulate silica, silica hydrate or precursor thereof. The invention also provides compositions for topical application to the skin which comprise particulate silica, silica hydrate or a precursor thereof in a non-aquous carrier medium.

Owner:STIEFEL LAB IRELAND

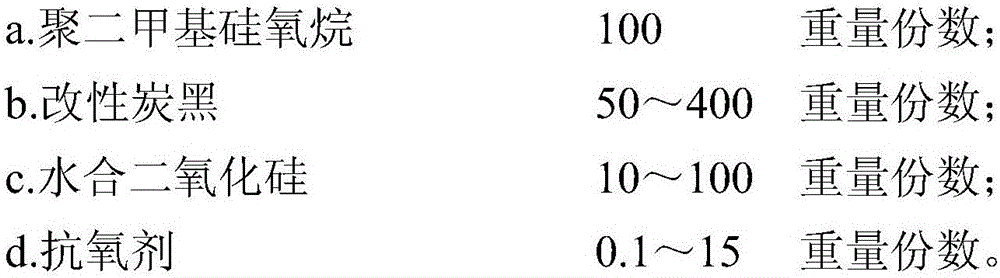

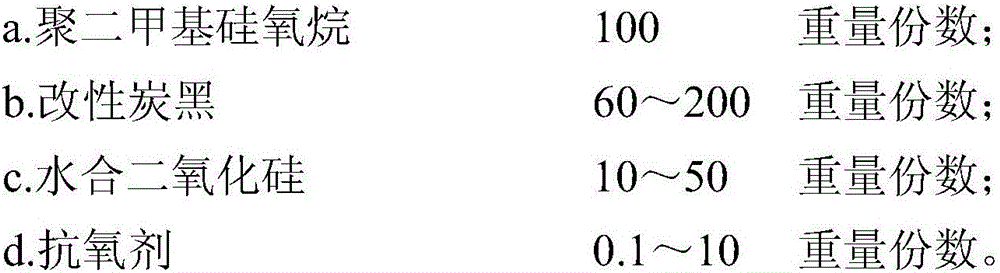

Polydimethylsiloxane carbon black master batch and preparation method thereof

The invention relates to a polydimethylsiloxane carbon black master batch and a preparation method thereof, and solves the technical problems of high performance reduction, reduction of product glossiness, accumulation of materials in a mouth mold in the extrusion of the product and affection on continuous production due to adoption of a polyethylene matrix resin and a low-molecule dispersing agent in the prior art. The polydimethylsiloxane carbon black master batch provided by the invention comprises the following mixed components: a, 100 parts by weight of polydimethylsiloxane; b, 50-400 parts by weight of modified carbon black; c, 10-100 parts by weight of hydrated silica; and d, 0.1-15 parts by weight of antioxygen. The invention also provides the preparation method of the polydimethylsiloxane carbon black master batch. The polydimethylsiloxane carbon black master batch and the preparation method of the polydimethylsiloxane carbon black master batch can be applied in the field of preparation of the carbon black master batch.

Owner:BEIJING BEIHUA GAOKE NEW TECH

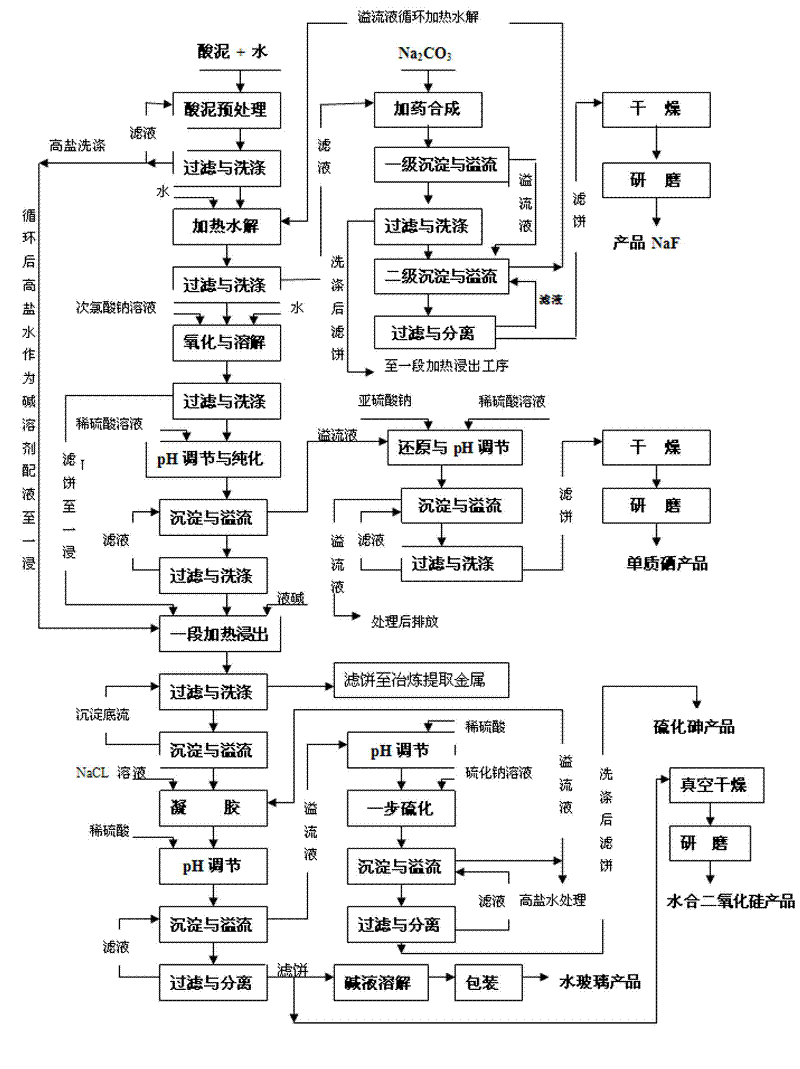

Comprehensive utilization method of acid sludge generated in acid making by smelting fume

InactiveCN102642848AIncrease added valueEasy to separateSilicaAlkali metal silicatesHydration reactionSludge

The invention provides a comprehensive utilization method of acid sludge generated in acid making by smelting fume. The acid sludge generated in acid making and containing substances such as metal, fluosilicate, selenium, selenium, arsenic and the like is taken as a raw material to prepare sodium fluoride, elementary substance selenium, silicon dioxide hydrate or water glass and arsenic sulfide products; and a material with high metal content is provided for smelting. The comprehensive utilization method breaks through the limitation that only the metal substance can be smelted and extracted in the traditional acid sludge recycling-utilizing mode, maximally recycles fluorine, selenium, arsenic, silicon and metal substances and prepares respective product of the substances, and thoroughly solves the difficult problems that fluorine, selenium and arsenic are easy to volatilize in smelting and extracting of the metal and difficult to recycle and arsenic is difficult to be separated from the metal in a liquid phase method; and extraction and preparation technologies are simple, product diversification is realized, and the utilization degree of economy refining is high. The comprehensive utilization method is wide in application range and applicable to acid sludge generated in acid making by purification of not only nonferrous smelting sulfur-containing fume but also ferrous smelting sulfur-containing fume.

Owner:宫毅 +1

Preparation method of temperature-resistant and erosion-resistant coating for walling of flue

InactiveCN101096460AImprove heat resistanceImprove acid resistanceFireproof paintsAlkali metal silicate coatingsSilanesPhosphate

The invention discloses a high temperature-resistant and corrosion resistant paint making method of flue inwall, which comprises the following steps: blending 100g potassium silicate solution, 2.5g polymethyl triethoxy silane, 0.2g carbon element and 1.7g calcium aluminate evenly; blending 7g silicon phosphate, 11g scale shaped glass, 4.5g hydrated silica and 1g chromic potassium sulfate evenly; blending two composite liquids evenly to coat on the cement board; heating to obtain the coating with thickness at 400pm to resist 350 deg. c and diluted sulfur acid.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

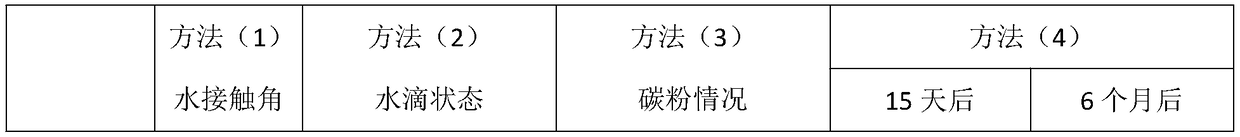

Preparation method of superhydrophobic material as well as product and application

ActiveCN108976667AWith self-cleaning anti-scalingPrevent or reduce depositionSulfatePolyvinyl chloride

The invention discloses a preparation method of a superhydrophobic material as well as a product and application. The preparation method comprises the following steps: preparing hydrated silicon dioxide by adopting sodium silicate as a raw material; modifying the hydrated silicon dioxide; polymerizing the modified hydrated silicon dioxide, an EHP initiator and vinyl chloride to generate polyvinylchloride resin, mold pressing and molding the polyvinyl chloride resin to obtain the superhydrophobic material. The superhydrophobic material has superhydrophobic and scale self-cleaning effect, so that when the superhydrophobic material is applied to an industrial pipeline, the deposition of calcium sulfate scales on the inner wall of the pipeline can be prevented or reduced on the source, and the risk caused by the calcium sulfate scales can be greatly reduced.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Method for producing silver-ion antibacterial liquid, silver-ion antibaterial liquid produced by said method, method for producing silver-ion antibaterial powder, and silver-ion antibaterial powder produced by said method

ActiveUS20140329899A1Reduce manufacturing costEasy to operateCosmetic preparationsBiocideSilica HydrateSilver ion

A method for producing silver-ion antibacterial liquid using a type A or type X silver zeolite includes a process to weigh silver zeolite for obtain its blending quantity in a range of 0.1 to 20.0 percent by weight and to weigh citric acid for obtaining its blending quantity such that its blending ratio to the silver zeolite becomes 1.2 or greater, followed by blending of the two into purified water; a process to mix under agitation the silver zeolite and citric acid blended in the purified water to prepare a mixture liquid containing at least a citric acid-silver complex and silica hydrate; and a process to remove the silica hydrate produced in the mixture liquid. The production method can produce at low cost a silver-ion antibacterial liquid offering immediate bactericidal effect.

Owner:KK TAIKI

Toothpaste containing black garlic extract

InactiveCN109692143AGood antibacterial effectImprove the bactericidal effectAntibacterial agentsCosmetic preparationsCelluloseToothpaste

The invention provides a toothpaste containing a black garlic extract, wherein the toothpaste contains the following raw material components by the weight percentage: 10%-20% of black allicin slurry extracted from fermented mature black garlic, 5% of an aloe vera extract, 1% of a peppermint extract, 1% of cellulose gum, 0.5% of sodium benzoate, 0.5% of an edible essence, 2% of xylitol, 15% of sorbitol, 2% of silica hydrate, 0.5% of sodium lauryl sulfate, 0.5% of polyethylene glycol-400, and the balance being purified water.

Owner:孔来根 +1

Metalaxyl and propamocarb wettable powder

InactiveCN102246780AImprove the effect of prevention and controlDelay drug resistanceBiocideAnimal repellantsMetalaxylMetallurgy

The invention discloses metalaxyl and propamocarb wettable powder, which comprises the following components in percentage by mass: 5.5 to 10.5 percent of metalaxyl, 12 to 18 percent of propamocarb hydrochloride, 0.5 to 1.5 percent of sodium lignin sulfonate, 15 to 25 percent of silica hydrated and 51 to 61 percent of kaolin.

Owner:王海林

Method for producing silicon dioxide hydrate from silicon recovered from wet-process phosphoric acid reaction flue gas

InactiveCN103011179AExtend the production cycleReduce cloggingSilicaDispersed particle separationHydration reactionO-Phosphoric Acid

The invention discloses a method for producing silicon dioxide hydrate from silicon recovered from wet-process phosphoric acid reaction flue gas, which comprises the following steps: preparing crystal ammonium fluoride into a 10-25% ammonium fluoride solution to be used as an SiFe gas absorbent for flue gas in wet-process phosphoric acid reaction; washing the wet-process phosphoric acid F-containing exhaust with the absorption liquid in a pump circulation mode; and finally, introducing gas ammonia into the ammonium fluosilicate solution generated by absorbing SiF4 gas by ammonium fluoride, thereby producing the silicon dioxide hydrate and ammonium fluoride. The method recovers fluorine and silicon resources in wet-process phosphoric acid reaction flue gas, so that the fluorine content in the phosphoric acid reaction flue gas is reduced from 10.5g / m<3> to 0.05g / m<3>, and the silicon content is reduced from 4.08g / m<3> to 0.02g / m<3>; and meanwhile, the method reduces the possibility of equipment pipeline blockage by silica gel, prolongs the production cycle of wet-process phosphoric acid from 7 days to 25 days, lowers the labor intensity for cleaning scales in the equipment pipeline, and enhances the operating ratio of the device.

Owner:WENGFU (GRP) CO LTD

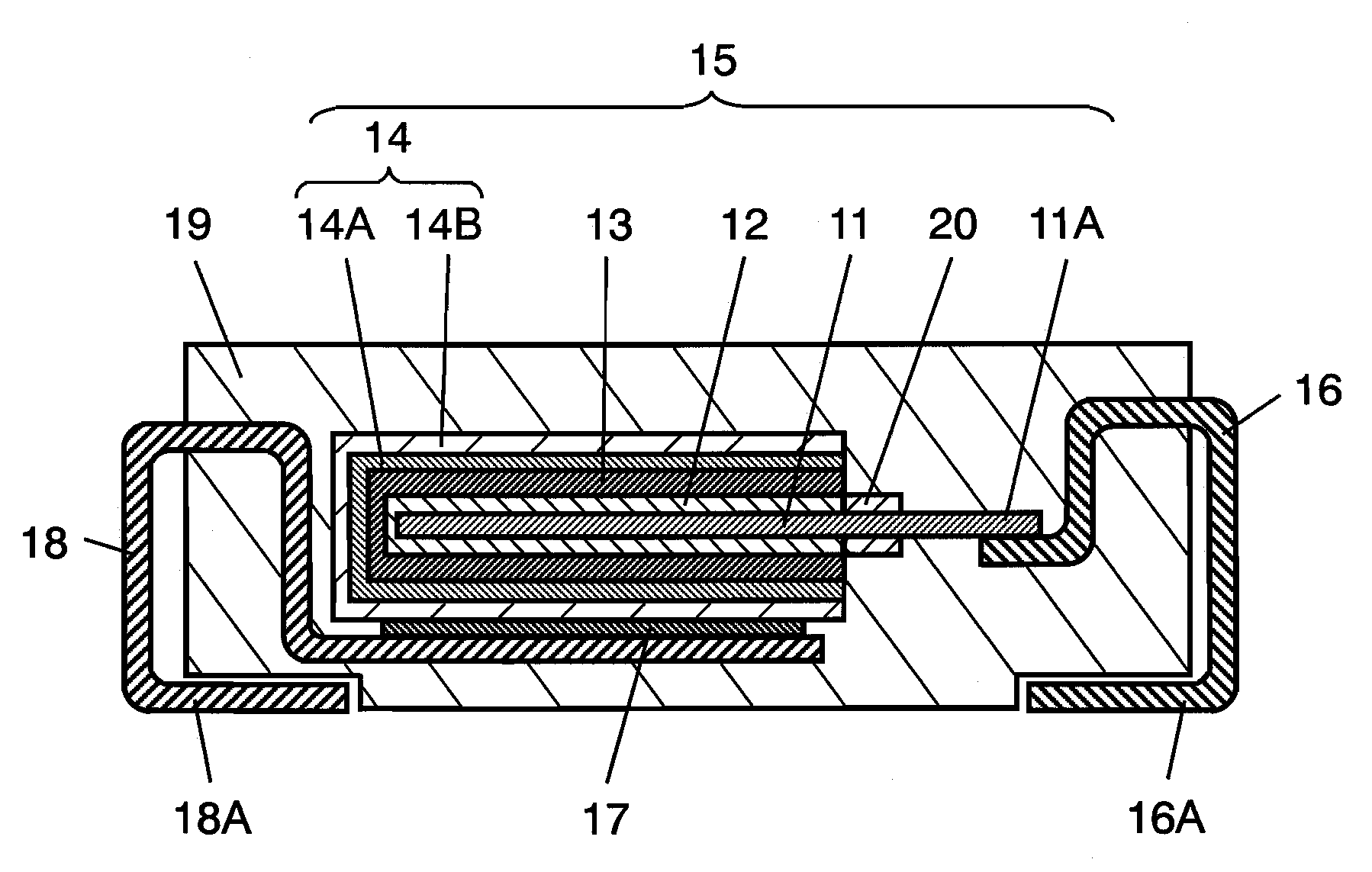

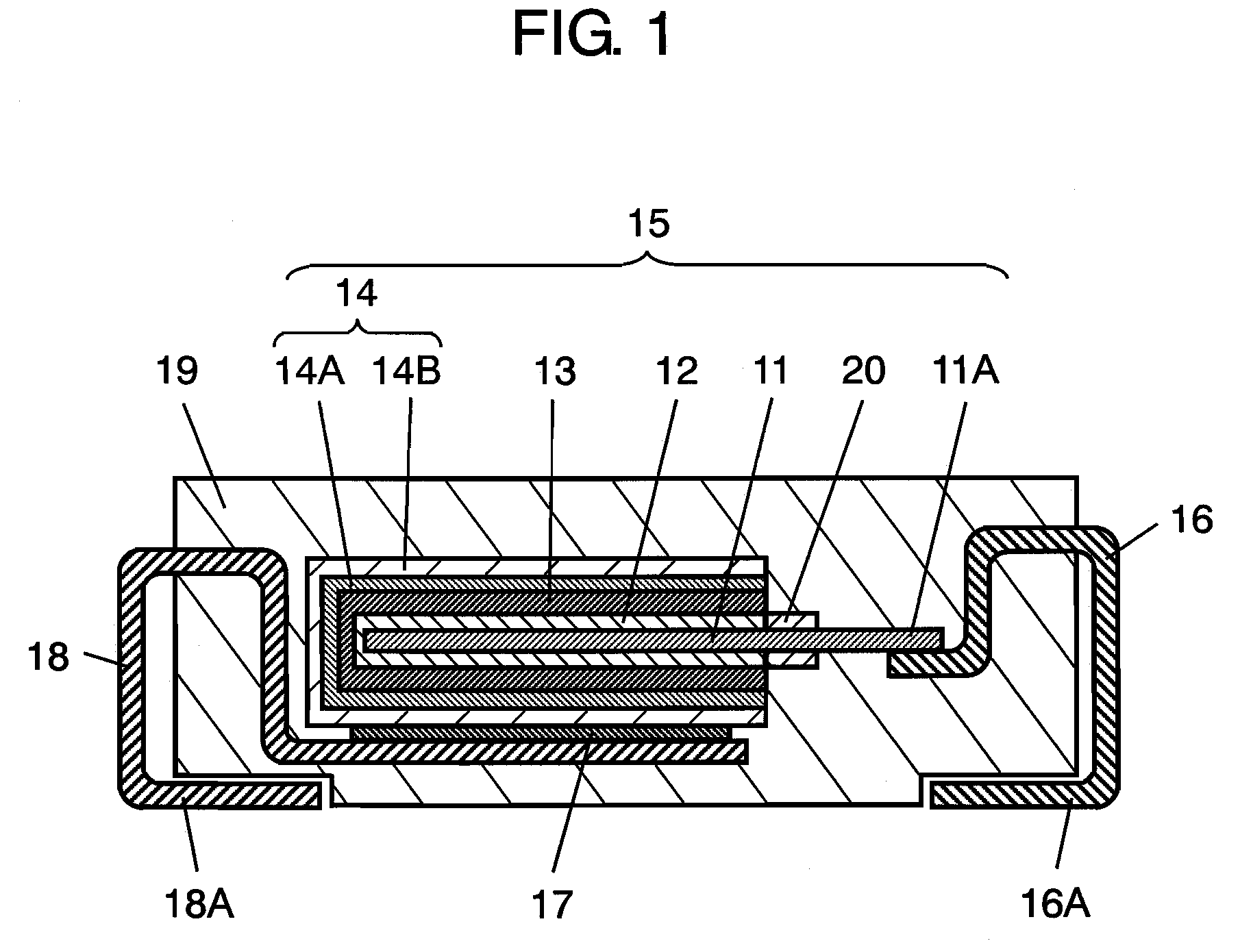

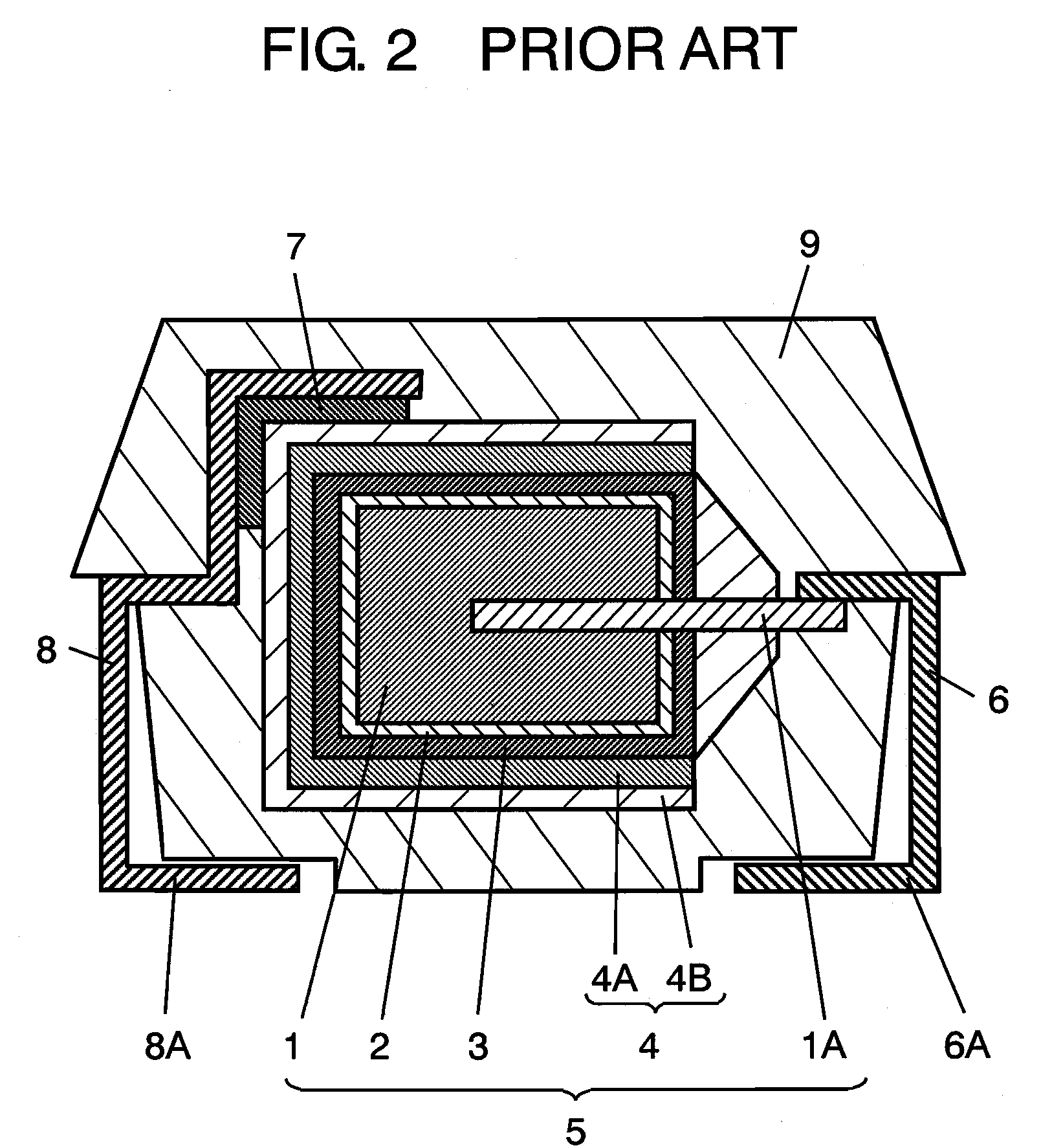

Solid electrolytic capacitor and method of manufacturing the same

ActiveUS20080247120A1Peeling can be suppressedPrevent interfacial resistanceHybrid capacitor electrolytesSolid electrolytic capacitorsCarbon layerElectrolysis

A carbon layer is formed on a solid electrolyte layer of the solid electrolytic capacitor, and a conductor layer connected to a cathode terminal is further disposed thereon. The carbon layer contains carbon particles, and a first additive or a second additive. The first additive is formed from at least one of those selected from the group consisting of hydrated silica and silicate. The second additive is formed from at least one of those selected from the group consisting of a condensation product of an aromatic sulfonic acid with formaldehyde, a condensation product of an aromatic sulfonate with formaldehyde, polystyrene sulfonic acid, and polystyrene sulfonate.

Owner:PANASONIC CORP

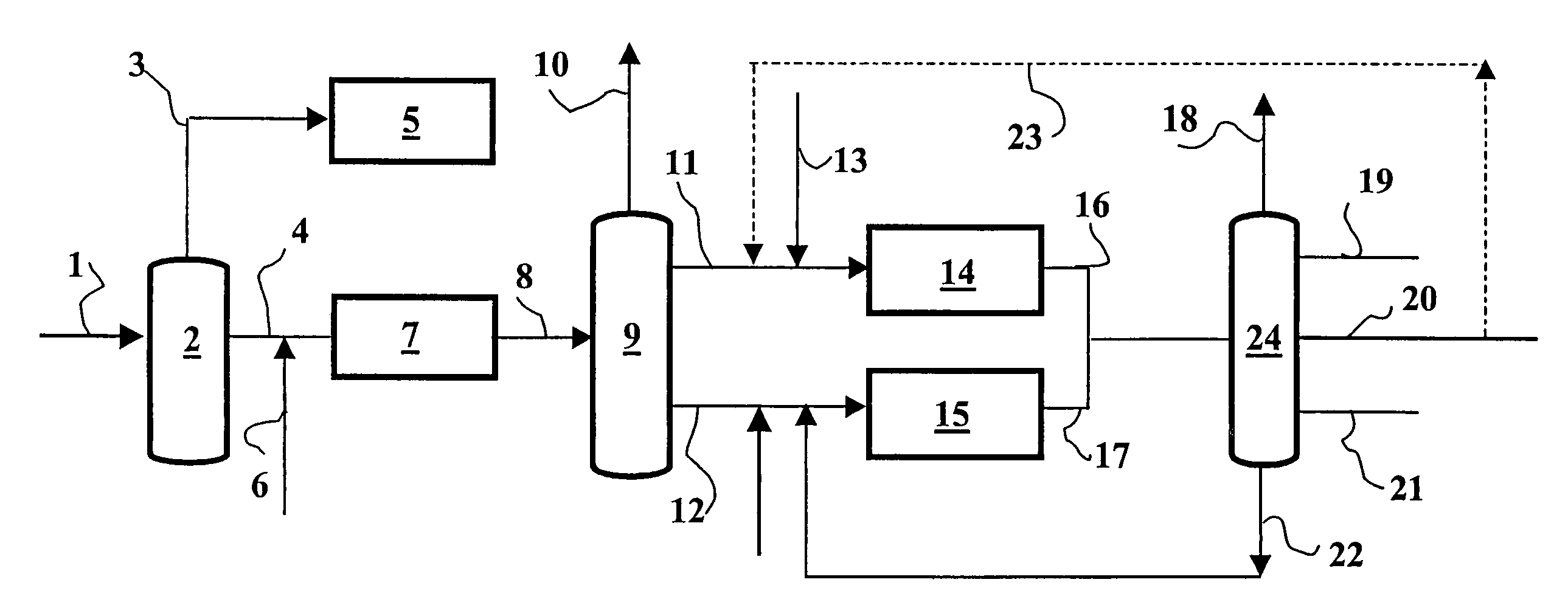

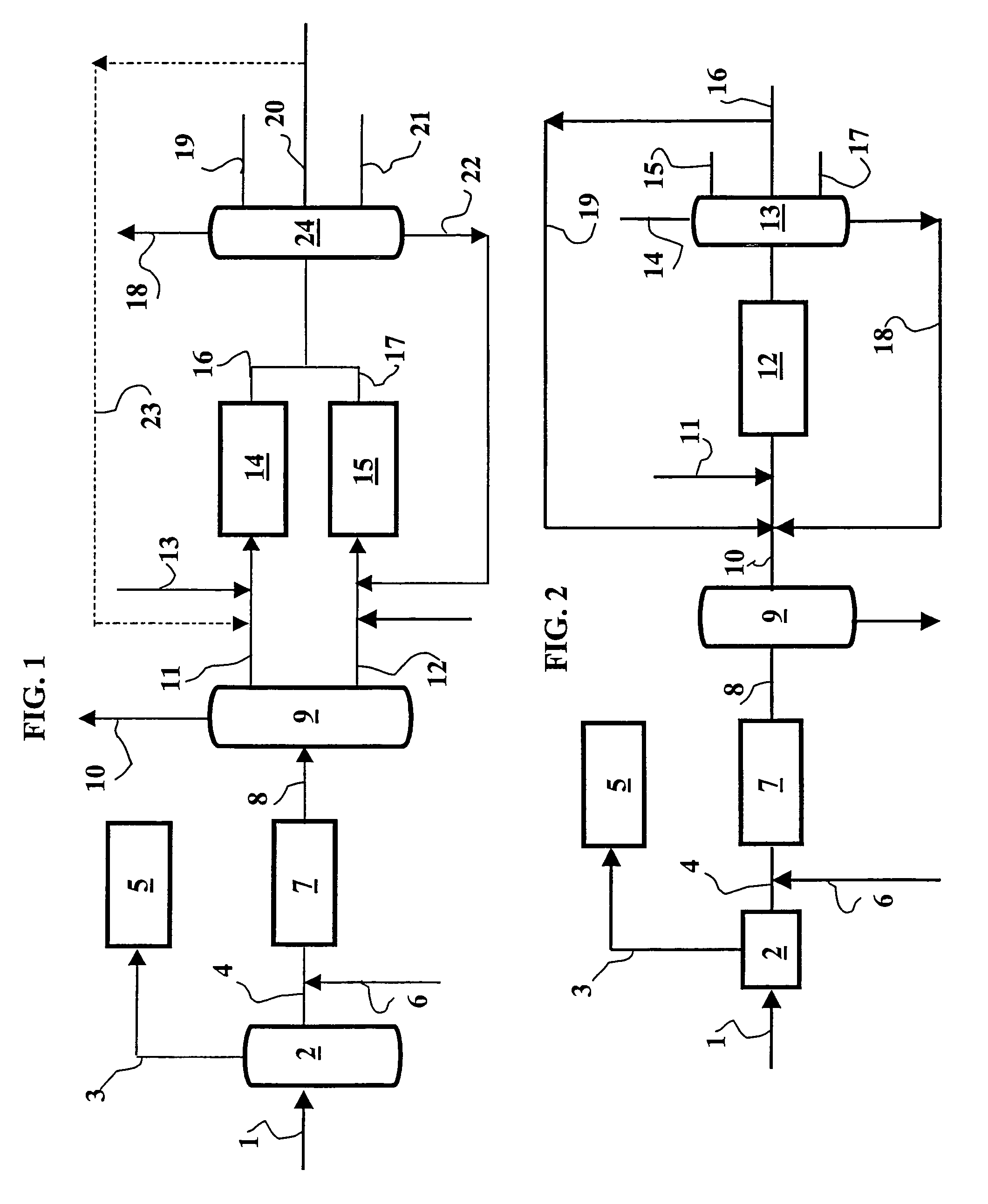

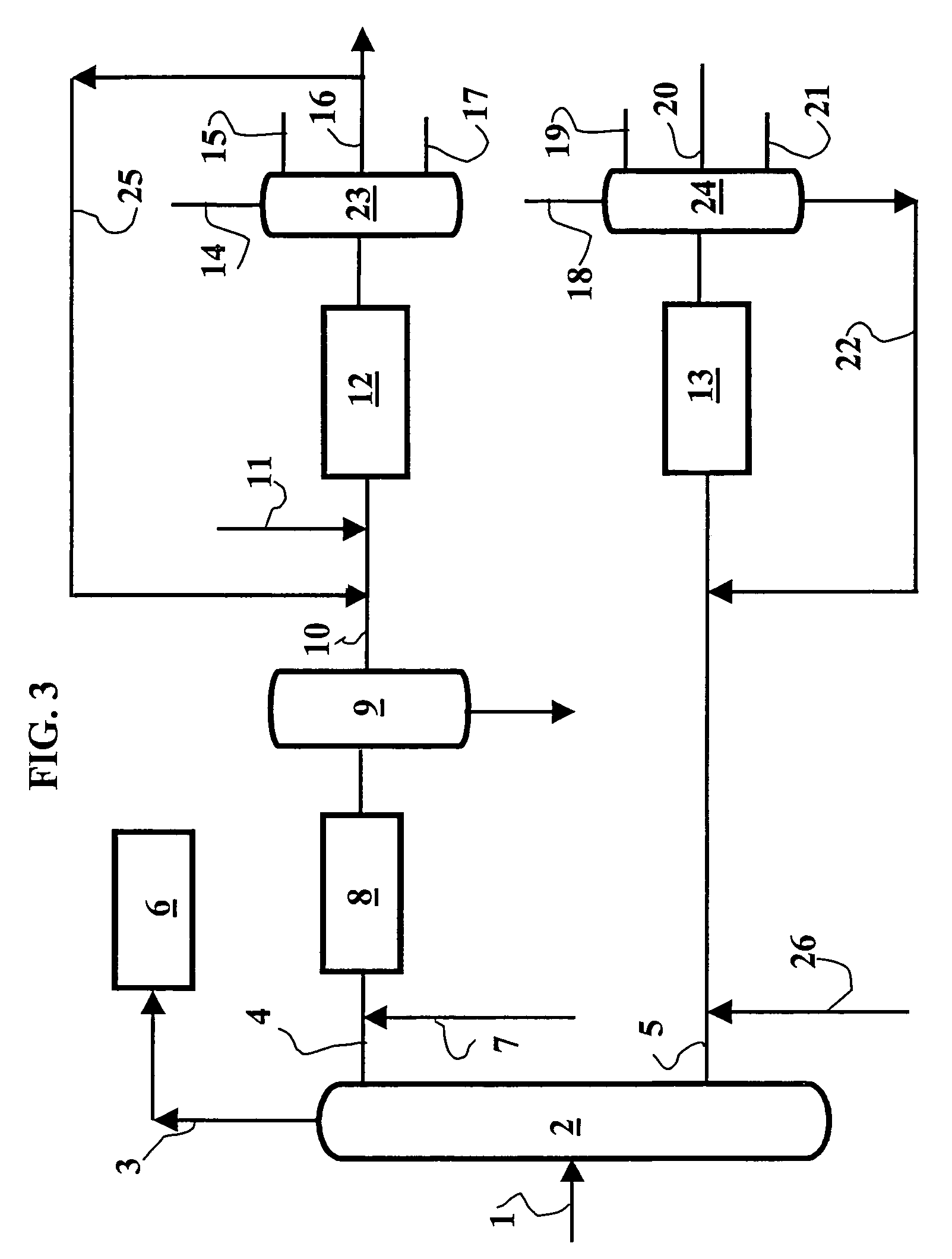

Method for the production of middle distillates by hydroisomerisation et hydrocracking of charges arising from the Fischer-Tropsch method

ActiveUS7704378B2Increase the number ofPossible to obtainOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkaneSilica Hydrate

The invention relates to a process for preparing middle distillates from a paraffinic feedstock produced by Fischer-Tropsch synthesis, using a hydrocracking / hydroisomerization catalyst which comprises at least one hydrodehydrogenating element chosen from the group formed by the noble elements of Group VIII of the periodic table, a silica-alumina-based non-zeolitic support obtained from wherein the non-zeolitic silica-alumina based support was obtained from a process comprising starting from a mixture of a partially soluble alumina compound in an acid medium with a totally soluble silica compound or with a totally soluble combination of alumina and hydrated silica, the resultant moldable mixture is concentrated to form a moldable mixture, the resultant mixture is molded and the resultant molded article is subjected to a hydrothermal or thermal treatment.

Owner:INST FR DU PETROLE +1

Sterilization moldproof aqueous putty powder and preparation method thereof

InactiveCN104945999AGood compatibilityImprove the bactericidal effectFilling pastesCelluloseTriclosan

The invention discloses sterilization moldproof aqueous putty powder and a preparation method thereof, and relates to the field of coatings. The sterilization moldproof aqueous putty powder is prepared from the following components: 25-50 parts of natural epidesmine powder, 20-35 parts of ash calcium powder, 5-10 parts of silicon dioxide dihydrate, 0.8-1.5 parts of cellulose, 2-5 parts of rubber powder, 0.5-1 part of pigment and 0.05-0.3 part of triclosan. The preparation method comprises the following steps: sequentially adding three main materials, namely, natural epidesmine powder, ash calcium powder and silicon dioxide dehydrate into a stirring machine, stirring to mix uniformly, sequentially adding four secondary materials, namely, cellulose, rubber powder, pigment and triclosan of requested mass into the stirring machine, and continuously stirring to sufficiently mix the materials, thereby obtaining the sterilization moldproof aqueous putty powder. The sterilization moldproof aqueous putty powder has the functions of sterilization, mold resistance, humidity adjustment, and air purification.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

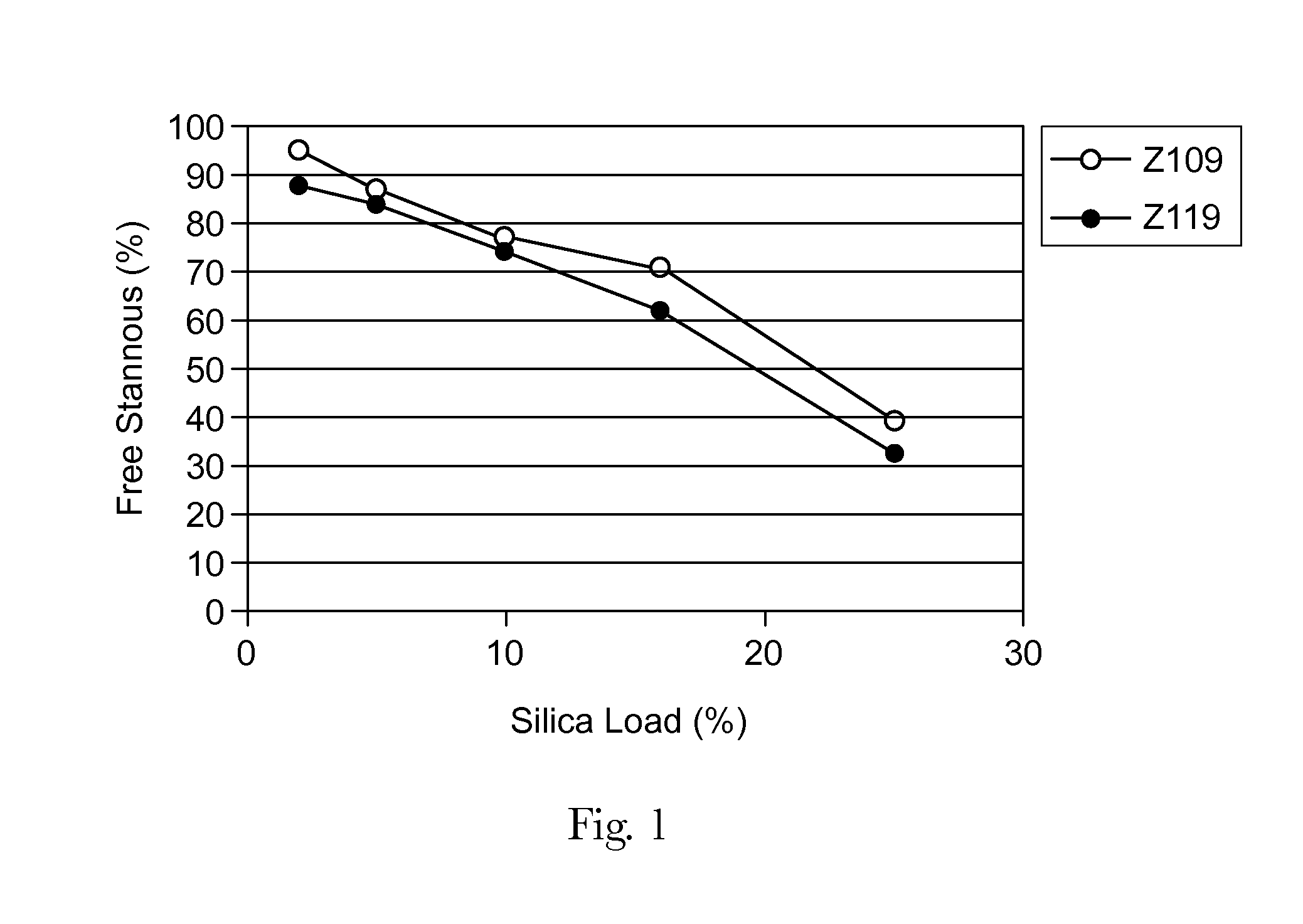

Stannous Chloride Compositions

ActiveUS20100310614A1Improve liquidityCosmetic preparationsToilet preparationsParticulatesSilica Hydrate

The invention relates to a particulate composition comprising:c) a particulate source of stannous chloride;d) and silicon dioxide (also referred to as hydrated silica or silica).The invention further relates to a method for improving the flowability of particulate stannous chloride by admixing silica with it. The composition of the invention has been found to give improved flow properties to stannous chloride when compared to the absence of an anti-caking agent, as assessed via methods of powder characterisation detailed in the European Pharmacopoeia.

Owner:THE PROCTER & GAMBLE COMPANY

Surface anti-corrosive ventilating type nanomaterial industrial paper packing bag and its application

InactiveCN1594042AGuaranteed packaging effectEfficient separationFlexible coversWrappersSilica HydrateEngineering

This invention is about a packing bag for industrial paper, to be exact, this packing bag is made of nanophase materials and its surface is permeable but antiseptic. Inside the bag is plastered a layer of film in which some tiny holes are made from internal to external. The film is made of polythene, polypropylene and polythene or polypropylene containing silica hydrated. This invention has such following advantages: 1) better antisepsis, because the invention films a kind of high molecular material( high pressure polythene or polypropylene) onto the surface of a packing bag for average paper and forms into a new type of compound paper-packing material, it is a better and more effective solution to antisepsis; 2) that the bag has a good air delivery from inside to outside and excellent feasibility, so it improves the mechanic intensity of brown packing paper and waterproofing and damp proofing; 3) its film is even spilled.

Owner:天威英利

Die cast coating material using lecithin as the principal raw material

The utility model provides a pressure casting coating material which is made mainly from lecithin, comprising 37 percent of lecithin, 1.8 percent of tiger oil, 1.8 percent of emulsible oil, 3.5 percent of scouring agent, 3.5 percent of soluble glass, 0.5 percent of silica hydrated, and 51.9 percent of water. The 37 percent of lecithin and the 1.8 percent of tiger oil are mixed together and, after being fully emulsified, the emulsible oil, is added with the scouring agent, the soluble glass and the silica hydrated and then is stirred by a stirrer. Then, the mixture is milled in a colloid mill, and then, with water added into the stirrer, is evenly stirred, hence the pressure casting coating material. The invention has the advantages of simple craft and easy formulation and excellent lubricating ability at high temperature and release ability, and effective prevention of mold sticking caused by chemical attraction, hard and breakage, distortion in mould unloading, and low cost.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

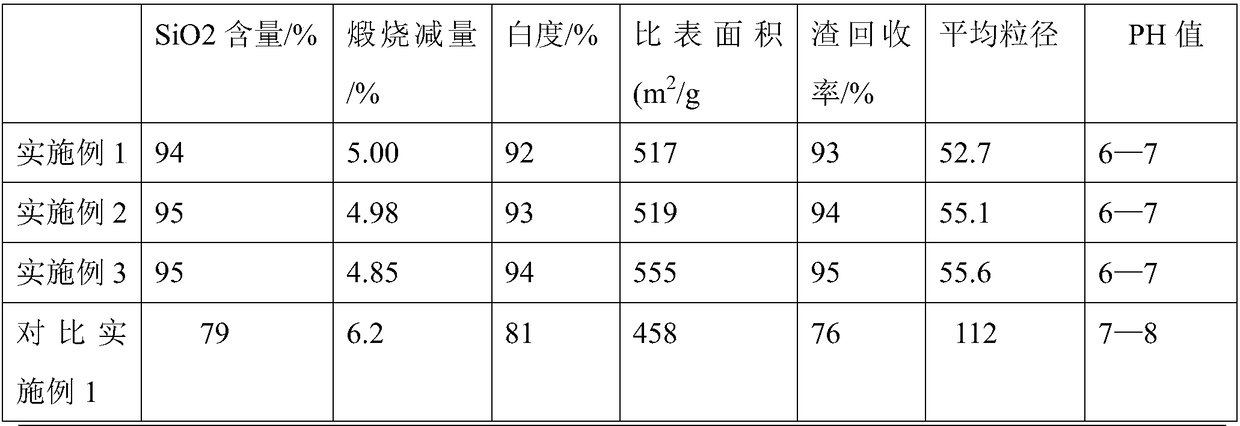

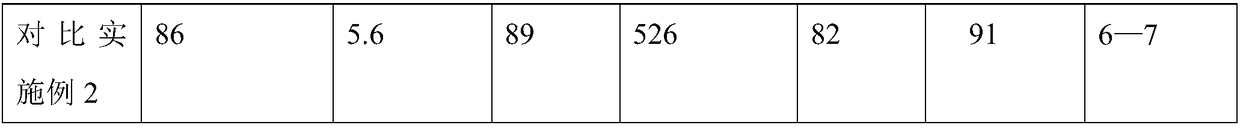

Method for preparing white carbon black by cutting zirconium silicon slag

The invention discloses a method for preparing white carbon black by cutting zirconium silicon slag. The method comprises the following steps: 1) activating zirconium silicon slag, placing the zirconium silicon slag in a rotary type dryer, drying at 130-150 DEG C for 1-2 hours, and cooling to 20-30 DEG C; 2) ultrasonically crushing the zirconium silicon slag and activating the zirconium silicon slag; 3) after the zirconium silicon slag is activated, adding water of which the size is 3-4 times that of solid, and a dispersant NH4CL with the solid mass fraction of 1%, and repeatedly scrubbing 3-4times, so as to fully melt the zirconium silicon slag; 4) adding NaOH to silica sol, stirring, and carrying out centrifugal separation for 3 times to obtain a neutral solution, so as to obtain hydrated silica; and 5) calcining hydrated silica prepared in the step 4) at 630-660 DEG C and pulverizing to obtain white carbon black. The method provided by the invention is characterized in that NaOH isadded to adjust the pH to 9, and the zirconium silicon slag is cleaned to effectively reduce the stability of SIO2 colloid and reduce the probability that impurities enter white carbon black.

Owner:CHENGDU SILICON TECH CO LTD

Method for preparing cryolite by using phosphoric acid industry waste gas

InactiveCN109665551AIncrease added valueAchieve recyclingSilicaAluminium fluoridesSodium bicarbonatePhosphoric acid

The invention relates to a method for preparing cryolite by using phosphoric acid industry waste gas. According to the method, fluorine-containing waste gas generated in a phosphoric acid preparationprocess using acid dissolving of phosphate rock is absorbed with a sodium bicarbonate solution, such that the hydrogen fluoride in the fluorine-containing gas reacts with the sodium bicarbonate to generate sodium fluoride, the SiF4 in the fluorine-containing gas reacts with the sodium bicarbonate to generate sodium fluoride and silica gel, and the silica gel is precipitated as hydrated silica; after filtering drying and calcination are performed, high specific surface active silica (white carbon black) can be prepared; after the filtrate (sodium fluoride solution) is mixed with a sodium metaaluminate solution, high molecular ratio sodium fluoroaluminate is obtained by introducing carbon dioxide gas; and filtering and drying are performed to obtain the product cryolite, wherein the step isa crystallization step, and the sodium bicarbonate solution generated in the step can return to the absorption step to repeatedly absorb the fluorine-containing gas. According to the present invention, with the method, the high added value product cryolite can be prepared by using the fluorine-containing waste gas.

Owner:杨先平

Hardener for mud cakes of drilling fluid

InactiveCN102766443APerformance is not affectedAdd lessDrilling compositionMicron scaleSilica Hydrate

The invention relates to a hardener for mud cakes of drilling fluid. The invention solves the existing problems in prior arts including high contents of activator components and changes of drilling fluid properties caused by the activators, which can influence construction requirements. The hardener is characterized in that the hardener comprises the following components in percentage by weight: 50-90% of micron-sized silicon dioxide hydrate, 5-30% of dispersing agent, 2-20% of retarding agent and 1-5% of flow pattern modifier. The hardener for mud cakes of drilling fluid has the characteristics of less dosage and no influence to the drilling fluid properties, takes effects only in the interface of water and mud, and can meet the construction requirements.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Antiseptic anti-mildew agent for leather

InactiveCN104342514AExtended service lifeAvoid breedingLeather impregnationPolymer scienceSulfite salt

The invention relates to an antiseptic anti-mildew agent for leather, which is prepared from the following raw materials in parts by weight: 5-10 parts of beeswax, 2-6 parts of polysilicone, 3-8 parts of surfactant, 3-6 parts of camphor oil, 7-11 parts of p-nitrophenol, 4-7 parts of fatty alcohol polyethenoxy ether, 5-9 parts of sodium sulfite, 1-5 parts of silicon dioxide hydrate, 4-6 parts of lignite wax, 4-10 parts of diethyl phthalate, 1-5 parts of glycerol, 4-9 parts of zinc acetate, 6-8 parts of ethyl acetate and 4-8 parts of alkyl glycoside. The antiseptic anti-mildew agent for leather can effectively inhibit various mildews and bacteria from generation, and prolongs the service life of leather.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Novel silica gel heat vulcanization bonding process

The invention discloses a novel silica gel heat vulcanization bonding process, and belongs to the technical field of silica gel heat vulcanization. The novel silica gel heat vulcanization bonding process includes raw rubber, a reinforcing filler, ferric oxide, dicumyl peroxide, diphenylsilandiol, a high temperature resistant auxiliary agent and organic peroxides; the reinforcing filler is gas phase white carbon black, and the reinforcing filler further contains hydrated silica. Accordingly, the high temperature resistant, non-combustible, tasteless, odorless and good adsorbing effects are achieved, by mixing the raw rubber, dicumyl peroxide and diphenylsilandiol, the structural phenomenon of the silicone rubber is reduced, and the processing property of the rubber is improved; ferric oxideand the high temperature resistant auxiliary agent are added simultaneously, so that the heat resistance of the silicone rubber is improved.

Owner:马春江

Method for preparing high-purity silica

The invention relates to a method for preparing high-purity silica. The method comprises the following steps: by taking high-purity ethyl orthosilicate as a raw material, adding ammonia water, hydrolyzing the ethyl orthosilicate to generate hydrated silica, drying, firing, thereby obtaining the high-purity silica. According to the method disclosed by the invention, the ethyl orthosilicate serving as the raw material is added into the ammonia water to be hydrolyzed, a hydrated silica precipitate is generated, and the high-purity silica is prepared by separating, drying and firing. According to the method, hydrolysis conditions are not needed to be strictly controlled, lots of water is not needed to be used for repeatedly washing the precipitate, the process is simple, the labor time is short, the product quality is high, the product of each batch is stable in quality and high in identity, the emission amount of liquid waste is small, and environment friendliness is promoted. The method is low in comprehensive cost and high in economic benefits. The purity of the silica is 99.99 percent, and the high-purity silica prepared by the method can be used for preparing high-purity silicon monoxide and high-purity silicon.

Owner:天津市风船化学试剂科技有限公司

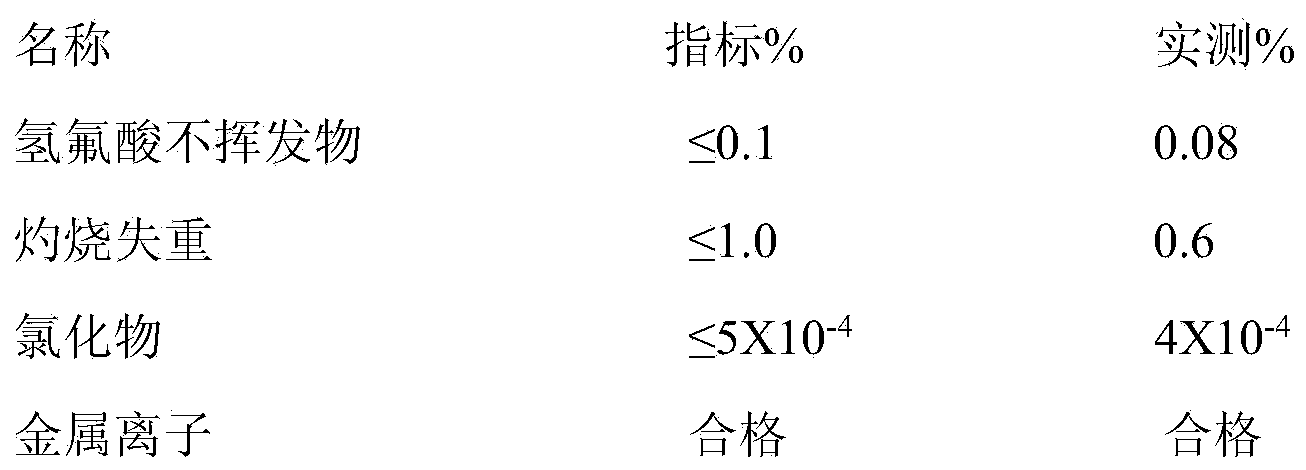

Preparation method of composite flame retardant for fireproof thermal-insulation decorative plate

ActiveCN111926934AImprove flame retardant performanceFast formingFire proofingHydration reactionSilica particle

The invention discloses a preparation method of a composite flame retardant for a fireproof thermal-insulation decorative plate. The preparation method comprises the following steps of pulverizing hydrated silica through a ball mill to obtain hydrated silica powder, and adding an acidic solution into the hydrated silica powder to obtain a mixed liquid; adding zinc carbonate to obtain a mixed liquid containing zinc carbonate; adding aluminum hydroxide particles, silicon dioxide particles and magnesium hydroxide particles to obtain a silicon-magnesium mixed solution; adding absolute ethyl alcohol into sodium silicate, uniformly stirring, and dropwise adding an acidic solution to obtain silica-containing sol; adding the silicon-containing sol and the silicon-magnesium solution into a reactionkettle, and filtering to obtain a cured mixture; and washing and drying the cured mixture with deionized water to obtain a compound machine flame retardant. According to the preparation method, the hydrated silica powder, the zinc carbonate, the aluminum hydroxide particles and other inorganic compounds are added into the flame retardant, the flame retardant property of the flame retardant is improved, and the zinc carbonate can assist in more uniform foam forming of the decorative plate.

Owner:甘肃坤远节能环保科技发展有限公司

Organic nanometer spinning paste adjuvant composition and its synthesis method

The invention discloses a weaving slurry adjuvant composition and synthesizing method, which comprises the following parts: 30-90 percent hydrated titanium oxide nanometer sol, 30-5 percent hydrated silica nanometer sol, and 39-4.27 percent deionized water, 1-3 percent azotic acid, 0-0.4 percent sodium hexametaphosphate and 0-0.03 percent boracic acid. The synthesizing method comprises the following steps: stirring hydrated silica nanometer sol, azotic acid and water; dripping the composition in the hydrated titanium oxide nanometer sol; utilizing boracic acid and sodium hexametaphosphate as auxiliary disperser.

Owner:刘祥

Formula of beautiful millettia root toothpaste

The invention discloses a formula of beautiful millettia root toothpaste. The formula contains the following raw materials by percent: 0.10%-0.12% of stannous fluoride, 10%-15% of sorbitol, 1%-2% of hydrated silica, 2%-3% of sodium lauryl sulfate, 0.6%-0.9% of essence, 4%-6% of beautiful millettia root extract, 0.7%-0.9% of polyethylene glycol, 36%-40% of tetrasodium pyrophosphate, 0.2%-0.3% of saccharin sodium salt, 0.20%-0.23% of sodium tin fluoride, 1%-1.5% of viscose and the balance of refined water. The formula of beautiful millettia root toothpaste, disclosed by the invention, has the effects of preventing dental caries, resisting against bacteria, diminishing inflammation, protecting gum immunity, removing mouth odor and preventing halitosis.

Owner:广东金山百草健康产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com