Surface anti-corrosive ventilating type nanomaterial industrial paper packing bag and its application

A nanomaterial and packaging bag technology is applied in the field of surface anti-corrosion and breathable nanomaterial industrial paper packaging bags, which can solve the problems of loss of packaging capacity, corrosion and high viscosity, and achieve the effects of ensuring packaging performance, improving mechanical strength and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

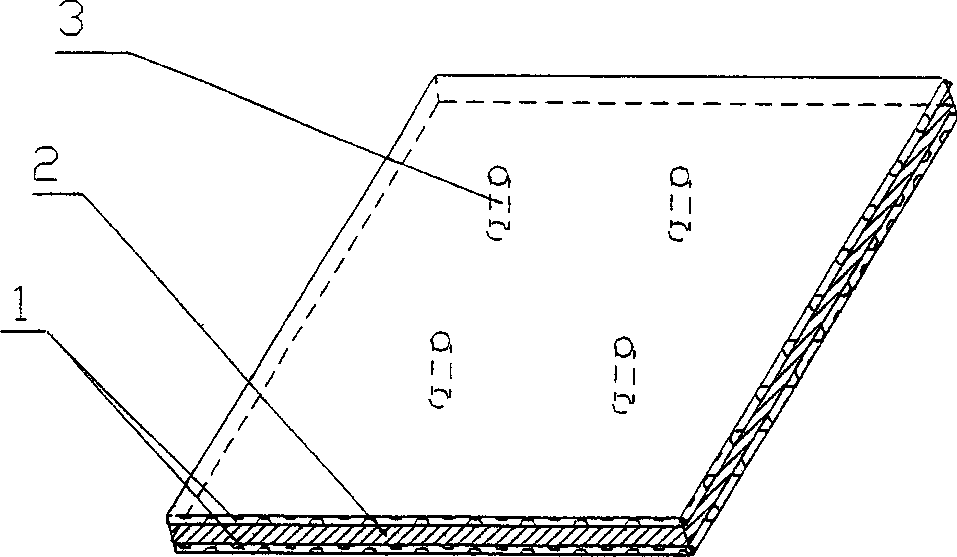

[0020] The high-pressure polypropylene is coated on one side with a coating machine (coating film) on the inner surface of the kraft wrapping paper bag 2, with a thickness of 0.1 mm; it is suitable for solid materials with a pH value in the range of 5.5-8.5;

[0021] In order to increase the venting property, punch the pores from the inside out, and use solid punching nails to roll and drill small holes 3. The vertical and horizontal arrangement of the holes is 3×5 mm, and the hole diameter is 1.0 mm.

Embodiment 2

[0023] 100 parts of high-pressure polyethylene and 5 parts of fumed white carbon black are fully mixed, and double-sided coating is used on the inner and outer surfaces of kraft packaging paper bag 2 with a coating machine, with a thickness of 0.2 mm; suitable for a pH range of 4.5-9 solid matter within;

[0024] In order to increase the venting property, punch the pores from the inside out, and use solid punching nails to roll and drill small holes 3. The vertical and horizontal arrangement of the holes is 5 × 10 mm, and the aperture is 0.7 mm.

Embodiment 3

[0026] 100 parts of high-pressure polyethylene and 10 parts of precipitated white carbon black are fully mixed, and double-sided coating is used on the inner and outer surfaces of kraft packaging paper bags 2 with a coating machine, with a thickness of 0.4 mm; suitable for pH values in the range of 4.5-9 of solid matter;

[0027] In order to increase the venting property, punch the pores from the inside out, and use solid punching nails to roll and drill small holes 3. The vertical and horizontal arrangement of the holes is 8 × 8 mm, and the aperture is 0.8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com