A rotary bonding device for beverage bottle wrapping paper

A technology of laminating device and wrapping paper, applied in the directions of packaging, packaging bottles, transportation packaging, etc., can solve the problems of difficulty in ensuring the packaging quality of beverage bottle packaging paper, poor packaging effect of beverage bottle packaging equipment, and inability to meet output requirements. , to achieve the effect of ensuring the packaging effect and quality, easy operation and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

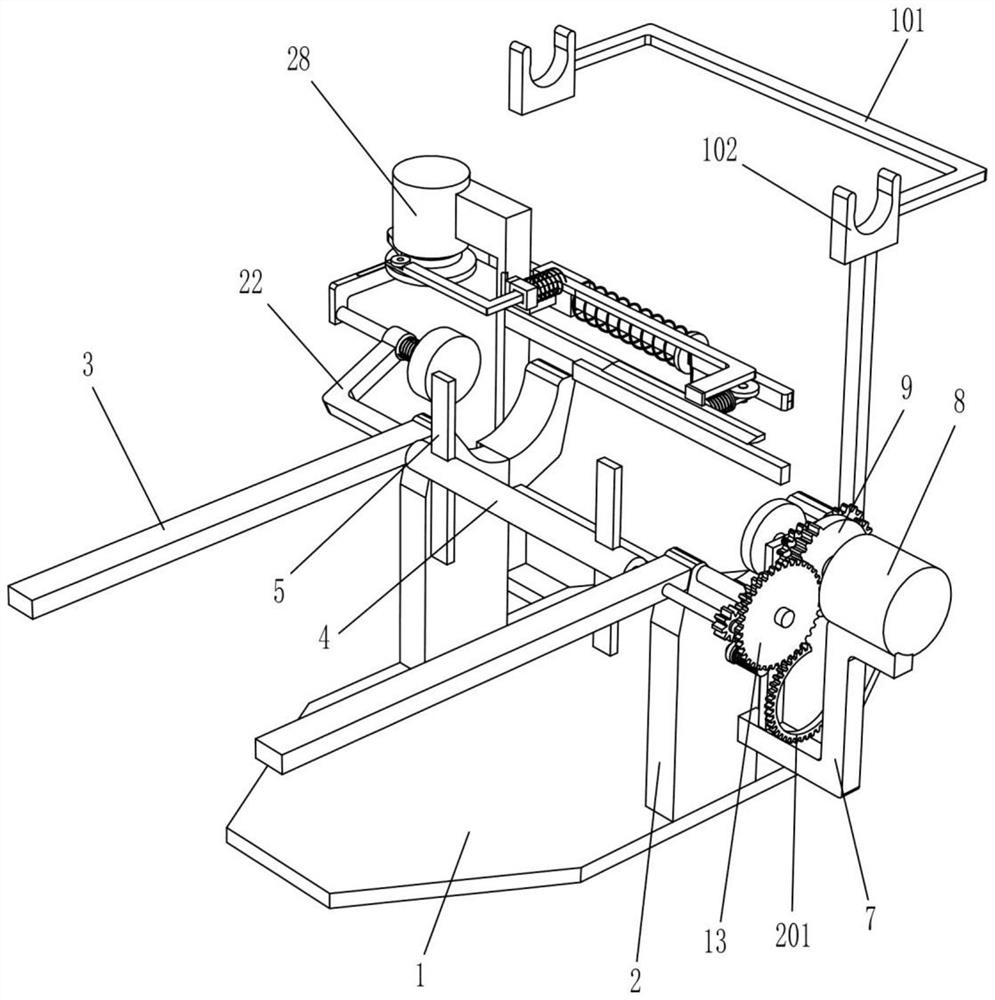

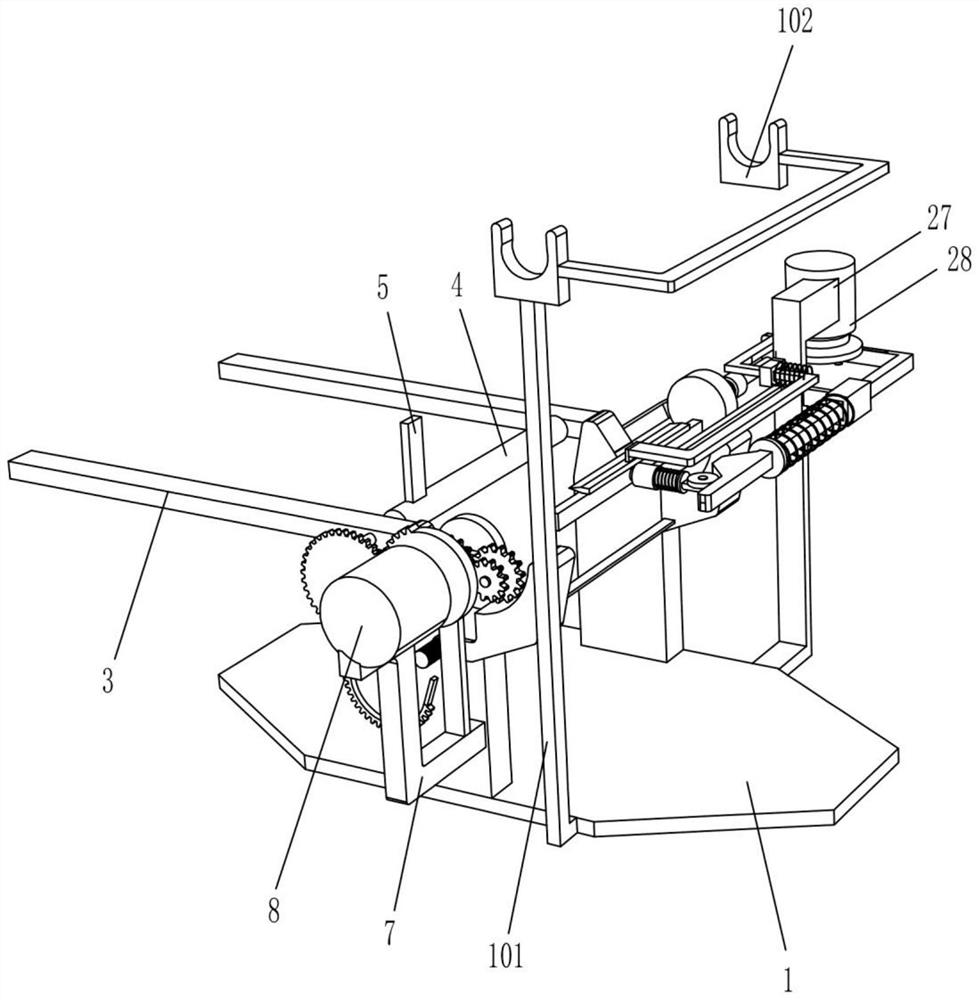

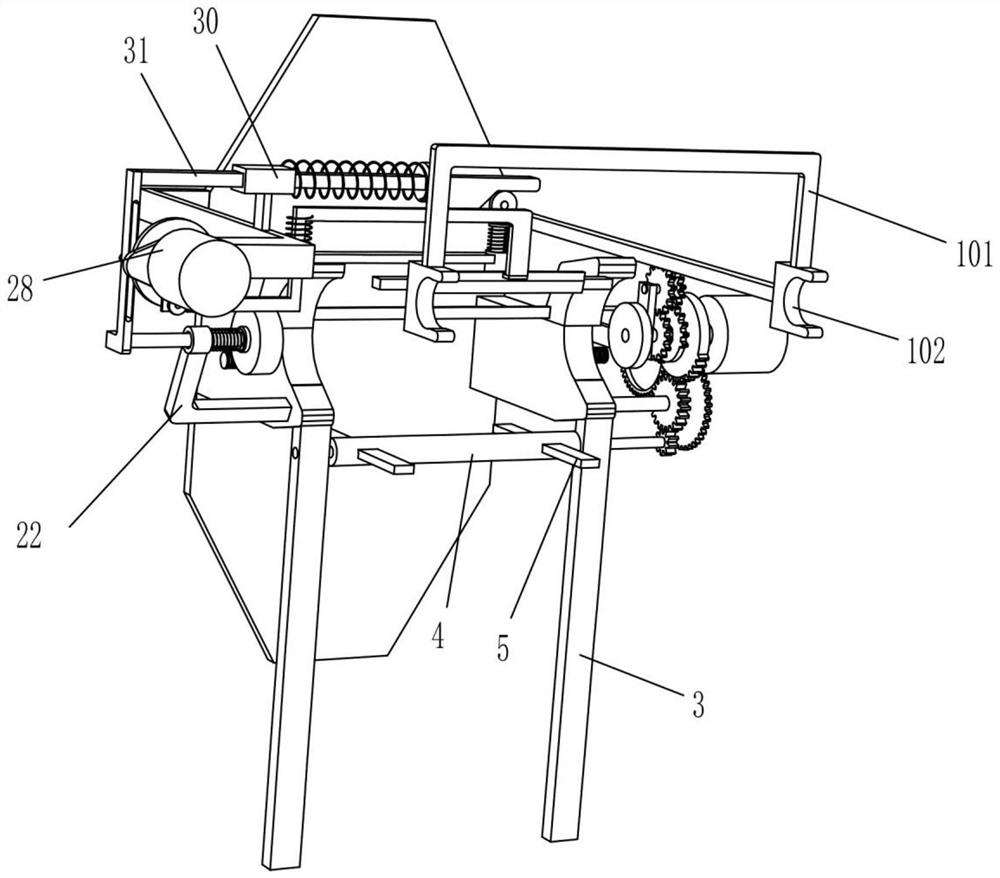

[0022] A rotary bonding device for beverage bottle packaging paper, such as Figure 1-7As shown, it includes a bottom plate 1, a support frame 101, a support sleeve 102, a support 2, a placement plate 3, a turning lever 4, a turning plate 5, a pinion 6, a first connecting plate 7, a servo motor 8, a sector gear 9, Missing tooth gear 10, rotating shaft 11, first transmission gear 12, large gear 13, second connecting plate 14, movable shaft 15, clamping rotating disc 16, second transmission gear 17, third transmission gear 103, connection gear 18 , a rotating rod 19, a swing support plate 20, an arc rack 201, a torsion spring 21, a clamping part and a fitting part, the lower end of the support frame 101 for supporting is fixedly installed on the right side of the bottom plate 1, and the two described The support sleeves 102 are fixedly installed on the support frame 101, one of the support sleeves 102 is fixedly installed on the left end of the support frame 101, and the two sup...

Embodiment 2

[0024] On the basis of Example 1, such as Figure 1-7 As shown, the clamping part that plays the role of clamping the beverage bottle includes a connecting rod 22, a telescopic rod 23, a movable rotating disk 24, a torsion return spring 25, a straight plate 26 and a third connecting plate 27, and the connecting The right end of the rod 22 is fixedly installed on the left side of the support 2, the telescopic rod 23 slides through the left end of the connecting rod 22, the movable rotating disk 24 is installed on the right end of the telescopic rod 23 through a bearing, and the torsion return spring 25 is installed on the On the telescopic rod 23 and the left end is fixedly installed on the left end of the connecting rod 22, the right end is fixedly installed on the left side of the movable rotating disk 24, the front end of the straight plate 26 is fixedly installed on the left end of the telescopic rod 23, and the lower end of the third connecting plate 27 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com