Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Fast truncation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

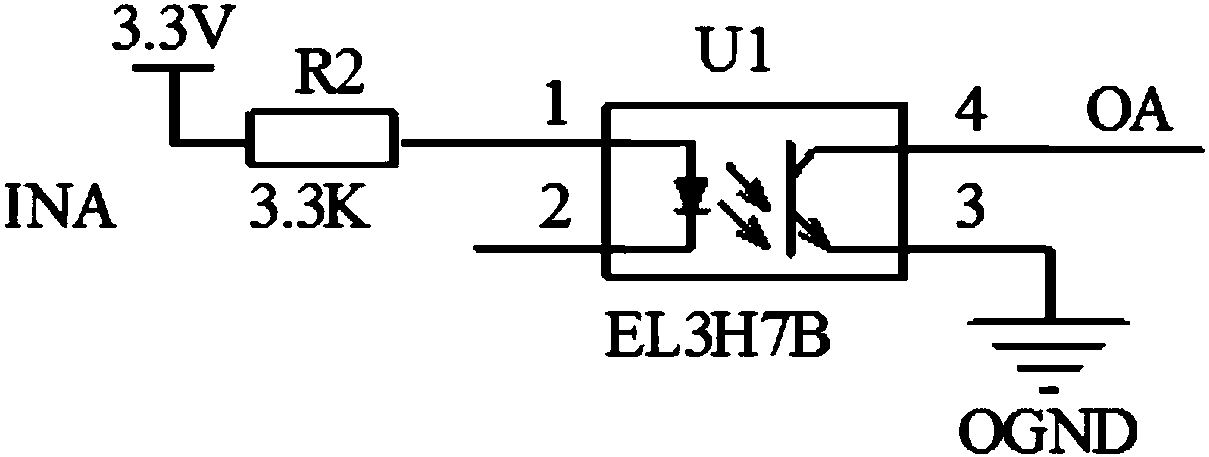

Over-current protection circuit of intrinsically safe power supply

InactiveCN102842883AFast truncationLimit energyArrangements responsive to excess currentSelf recoveryRecovery function

The invention relates to an over-current protection circuit of an intrinsically safe power supply. The over-current protection circuit is formed by connecting a detecting circuit with a driving circuit. With the over-current protection circuit, the output current can be intercepted quickly and completely once the intrinsically safe power supply is subjected to over-current output or short circuit, thus, the energy being released under such condition can be limited, and the self-recovery function can be implemented while removing the fault; and the over-current protection circuit is simple in structure, and safe and reliable, and can be widely applied.

Owner:张望

Current transformer tail current truncation method in failure protection

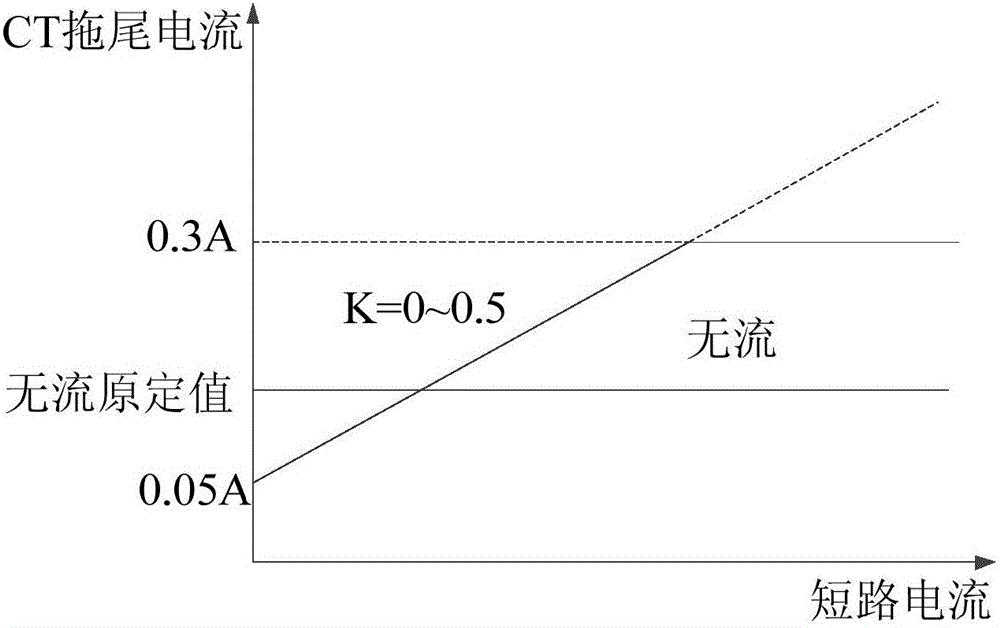

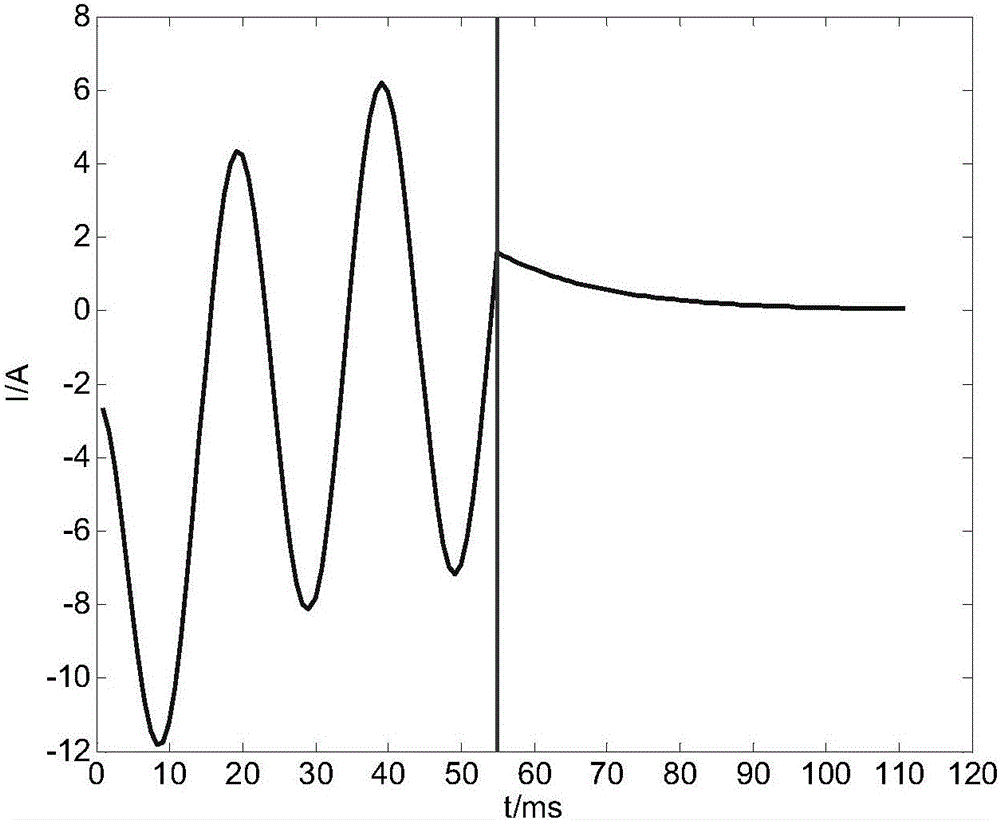

ActiveCN106451369AFast truncationReduce protection return timeEmergency protective circuit arrangementsFourier transformHarmonic

The invention relates to a current transformer tail current truncation method in failure protection. The method comprises the following steps that differential current of a sampling value is calculated; Fourier transform is performed on the differential current so as to determine the fundamental wave and the harmonic wave of the differential current; differential amplitude restoration is performed on the fundamental wave and differential amplitude restoration is not performed on the harmonic wave; CT tail current and short circuit current are determined according to the fundamental wave, the harmonic wave and amplitude restoration; and the criterion for CT tail current truncation is constructed according to the CT tail current and the short circuit current, and the braking coefficient of the criterion is corrected. According to the technical scheme, misoperation of failure protection is enabled not to perform under the condition of the CT tail current.

Owner:CHINA ELECTRIC POWER RES INST +2

High-performance wood cutting and utilizing equipment

The invention relates to wood cutting and utilizing equipment, particularly relates to high-performance wood cutting and utilizing equipment, and aims to realize the effects that the labor intensity is low, the cutting speed is high, and the operation is convenient. The wood cutting and utilizing equipment comprises a U-shaped baffle, a round frame body, a fixing frame, a first guide plate, a first rack, a first sliding rail, a first sliding block, a first gear, a second guide plate, a placing plate and the like, wherein the round frame body, the first guide plate, the first sliding rail and the second guide plate are sequentially arranged at the inner bottom of the fixing frame from left to right, and the first sliding block is connected with the first sliding rail in a sliding mode. According to the wood cutting and utilizing equipment, the effects that the labor intensity is low, the cutting speed is high and the operation is convenient can be realized, the maintenance and repair are easy, the use is convenient, the investment of manpower and material resources is reduced, the working efficiency is improved, and the time is effectively saved.

Owner:江门市焱林家具有限公司

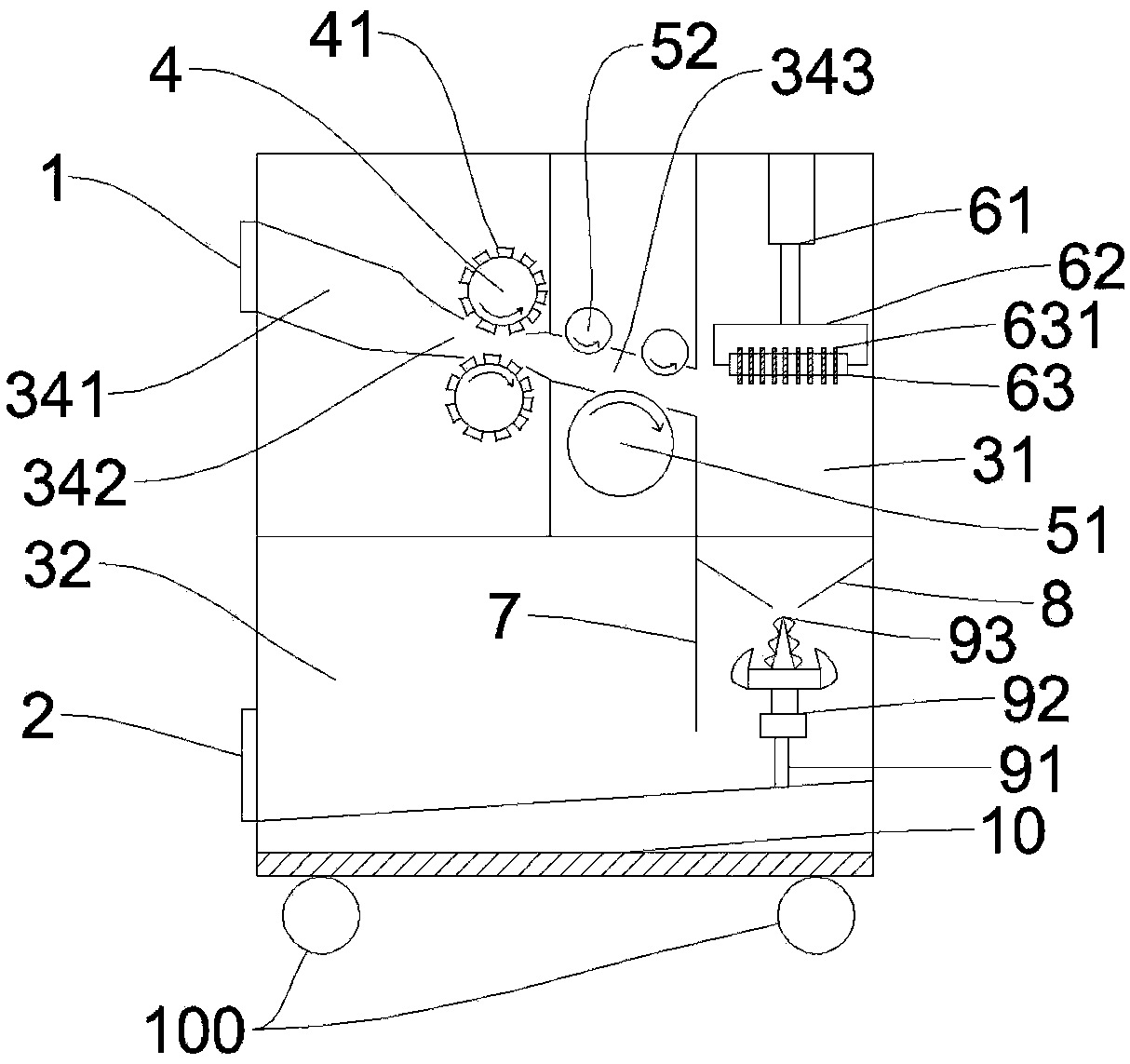

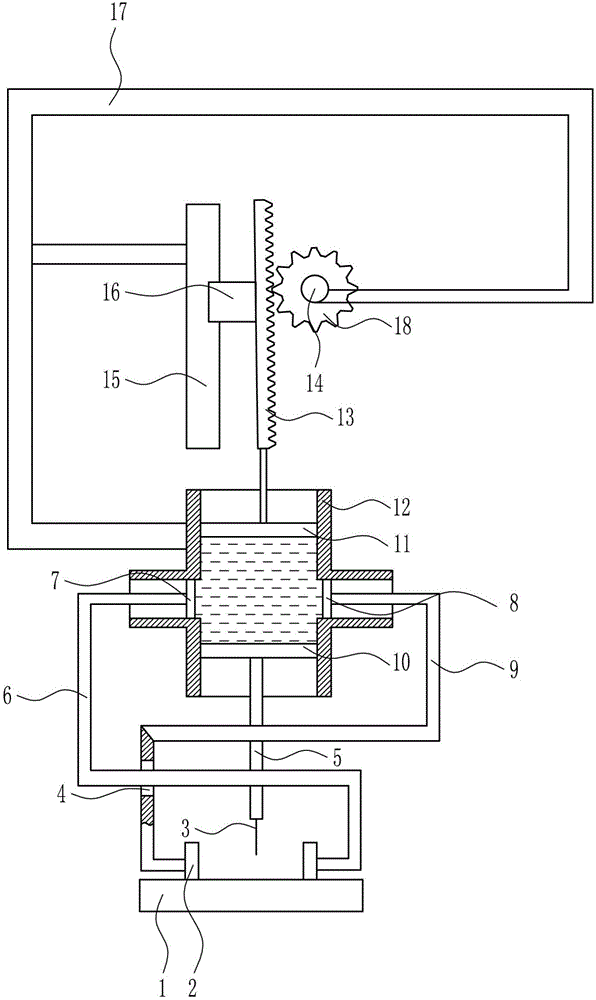

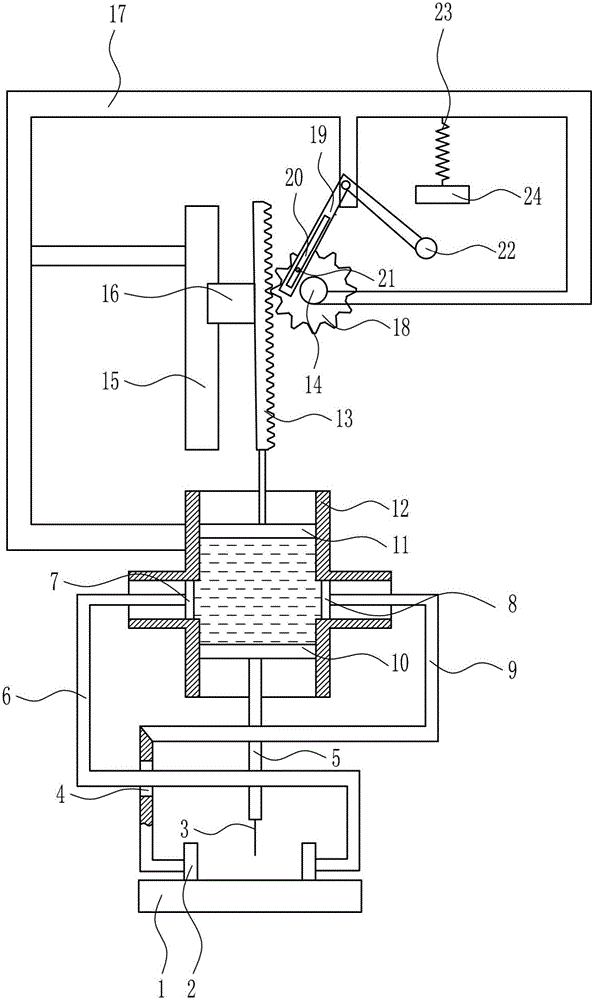

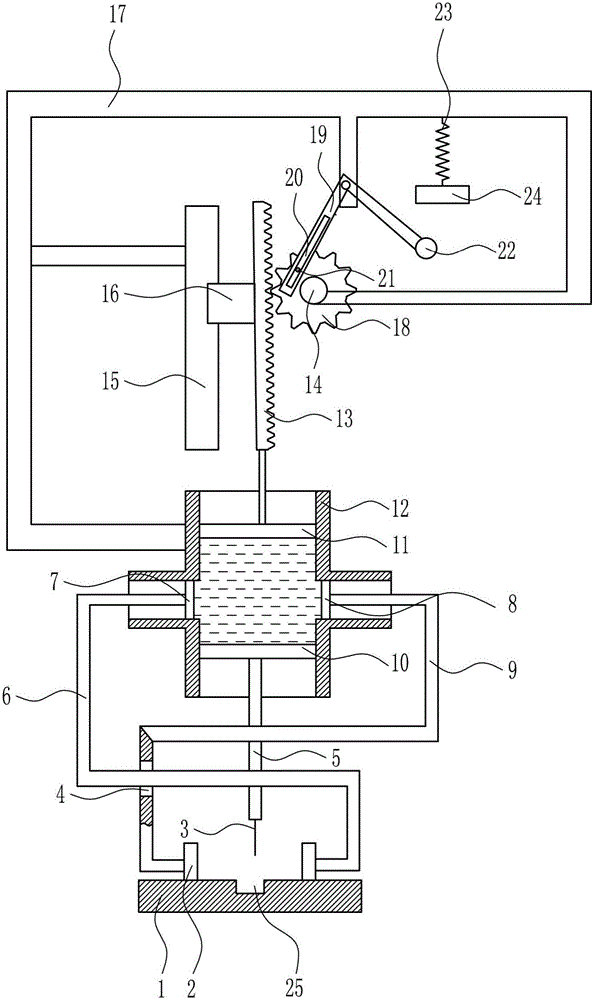

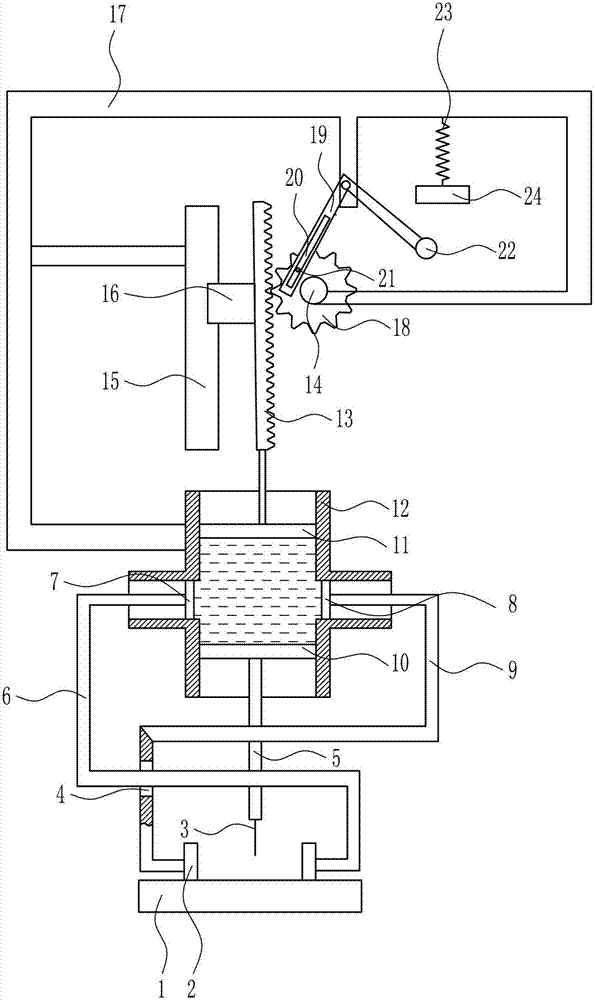

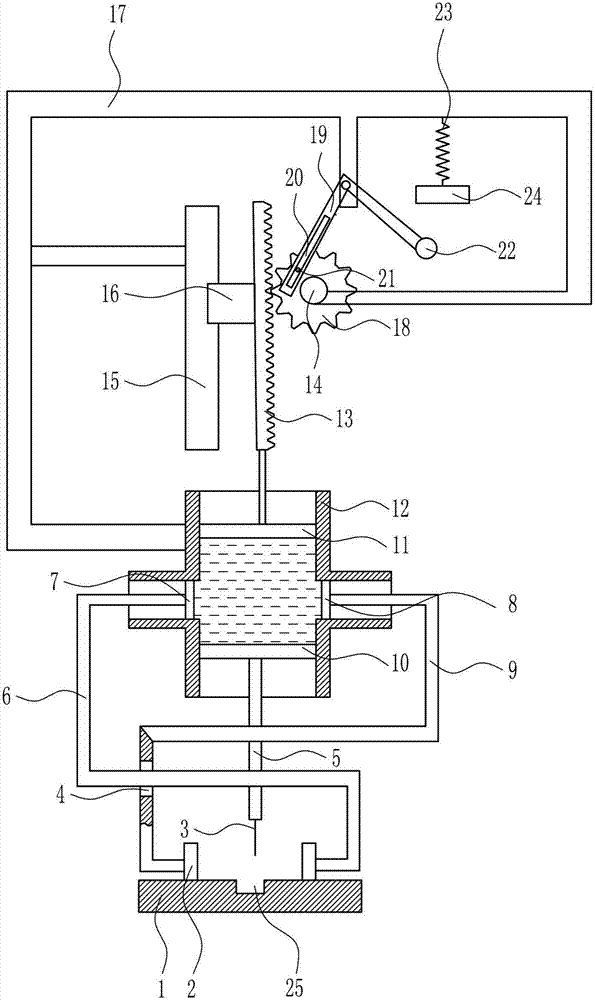

Medical artemisia argyi rapid cut-off equipment

InactiveCN111775196AEasy to placeFast truncationMetal working apparatusElectric machineryStructural engineering

The invention relates to medical rapid cut-off equipment, particularly relates to medical artemisia argyi rapid cut-off equipment, and aims to provide the medical artemisia argyi rapid cut-off equipment which can rapidly cut artemisia argyi to enable the artemisia argyi to be conveyed conveniently. According to the technical scheme, the medical artemisia argyi rapid cut-off equipment comprises a bottom plate, a gear motor and a conveying tank, wherein a discharging mechanism is installed on the bottom plate, two sliding pipes are fixedly connected to the position, at one side of the discharging mechanism, of the bottom plate, sliding rods are arranged in the sliding pipes in a sliding mode, first springs are arranged between the sliding rods and the sliding pipes correspondingly, an installation plate is fixedly connected between the top ends of the two sliding rods, the gear motor is arranged on the installation plate through a bolt, a cutter is fixedly connected to an output shaft ofthe gear motor, and the conveying tank is arranged on the position, between the two sliding pipes, of the bottom plate. According to the equipment, the artemisia argyi can be conveniently placed through the discharging mechanism, and the artemisia argyi is rapidly cut off through rotation of the cutter.

Owner:耿敏

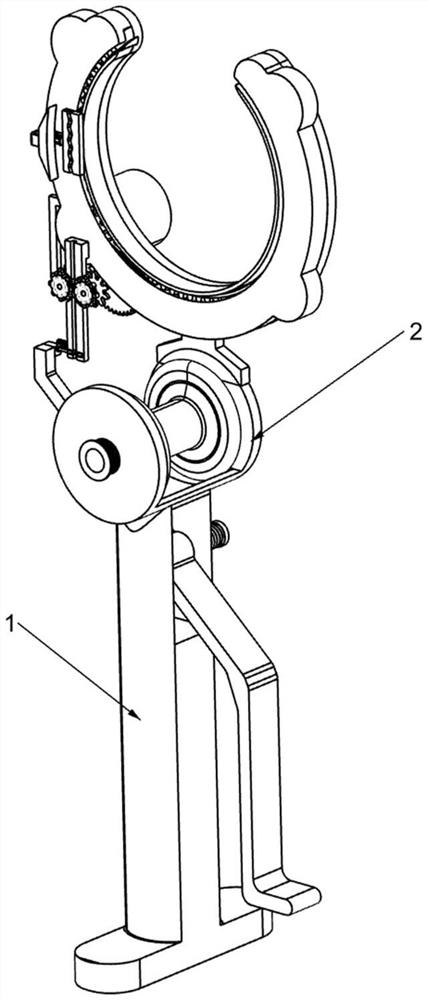

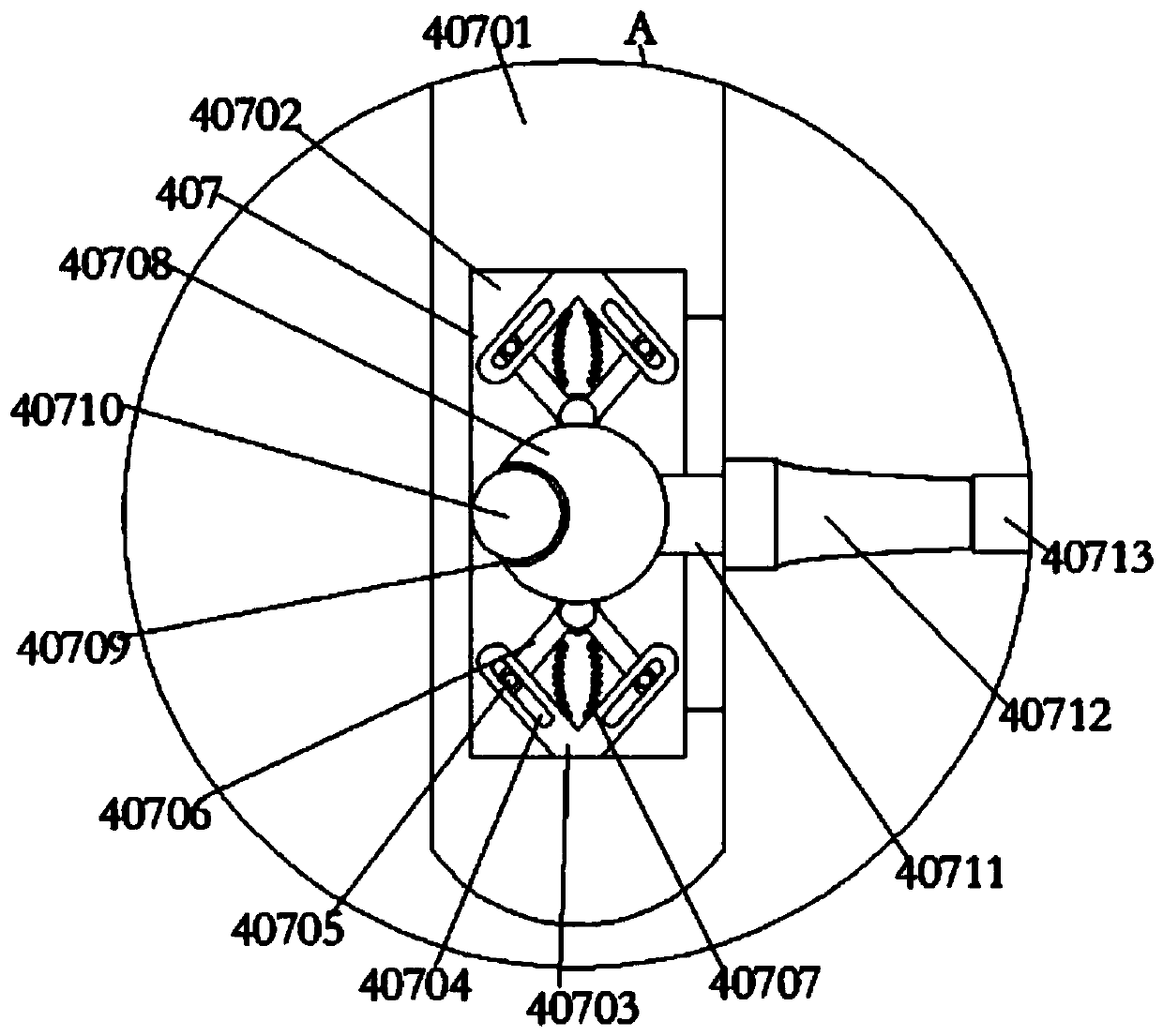

Novel steel bar binding device

The invention relates to a binding device, in particular to the novel steel bar binding device. The technical problem aims to provide the novel steel bar binding device which can automatically cut offiron wires according to the number of steel bars without manually screwing the iron wires by using a wire cutter, and can quickly and conveniently bind the steel bars. The technical embodiment of theinvention is as follows: the novel steel bar binding device comprises a cylindrical shell, a handle, a T-shaped sliding rod and the like, wherein the handle is arranged on the upper part of the outerside surface of the cylindrical shell, the left side of the cylindrical shell is arranged in an open mode, the left side in the cylindrical shell is an inclined plane, a sliding hole is formed in theright side of the cylindrical shell, and the T-shaped sliding rod is arranged in the sliding hole in a sliding mode. According to the novel steel bar binding device, the iron wires can be clamped through clamping blocks, and the clamping blocks are driven by a driving motor to rotate, so that the iron wires are screwed down; and a connecting rod can be driven to drive a cutter to cut off the ironwires through the movement of the handle, so that steel bars are binded without complicated operation, and the iron wires are cut off and screwed down quickly.

Owner:赣州市榕盛新型建材有限公司

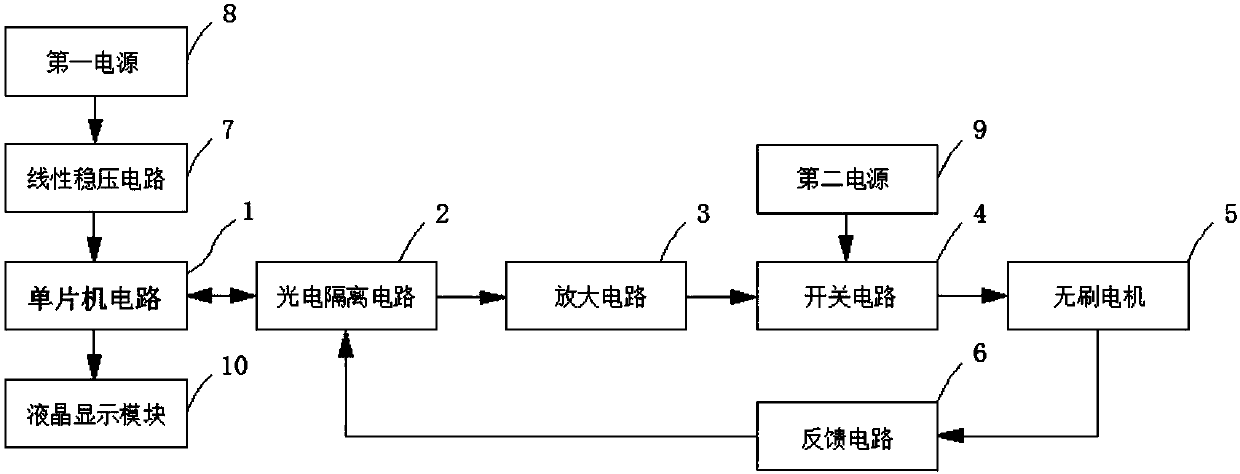

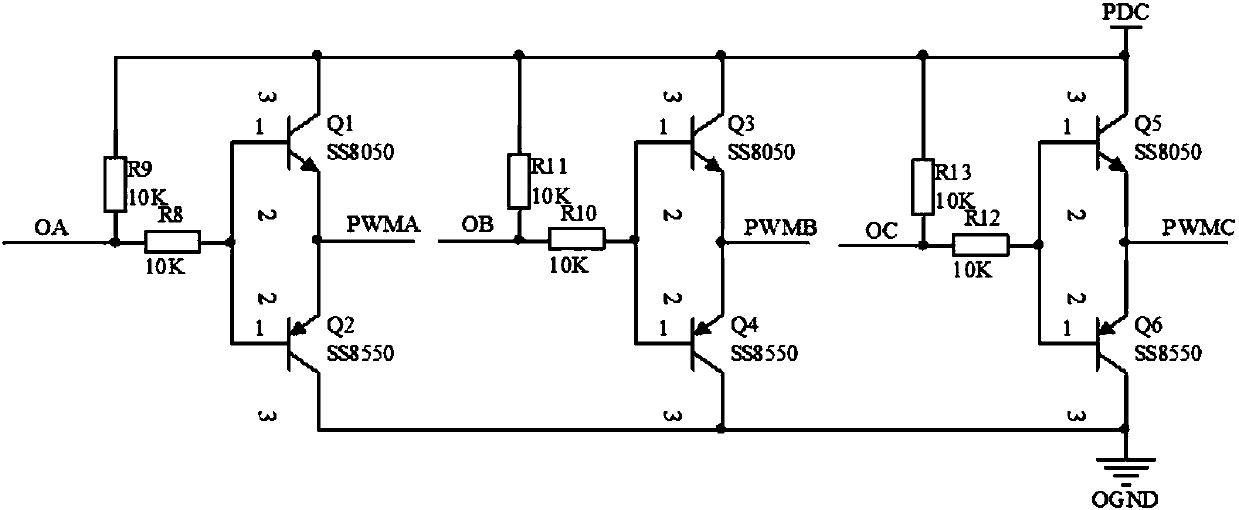

Motor controller and method

InactiveCN107565859AKnow the operation status in real timeEnsure safetyField or armature current controlMicrocontrollerBrushless motors

The invention relates to a motor controller and a method. The motor controller comprises a single-chip microcomputer circuit, a photoelectric isolation circuit, an amplifying circuit, a switch circuit, a feedback circuit and a brushless motor. The single-chip microcomputer circuit generates a pwm direct-current signal, and adjusts the output of the pwm direct-current signal according to a positionsignal and a steering signal. The photoelectric isolation circuit is used for carrying out optoelectronic isolation on the pwm direct-current signal. The amplifying circuit is used for amplifying thepwm direct-current signal. The switch circuit is used for carrying out the conduction according to the pwm direct-current signal, and generating a pwm three-phase square wave signal. The brushless motor generates a circular magnetic field in the brushless motor according to the pwm three-phase square wave signal so as to control the operation of the rotor of the brushless motor. The feedback circuit detects the input current of the brushless motor in real time, acquires the position and the steering of the rotor, generates current, position and steering signals and transmits the signals to the single-chip microcomputer circuit. Compared with the prior art, the safety of the single-chip microcomputer circuit can be effectively ensured. Meanwhile, the anti-interference capability is high, and the circular magnetic field is synthesized. The direct-current voltage utilization rate is improved, and the cost is reduced.

Owner:GUANGXI NORMAL UNIV

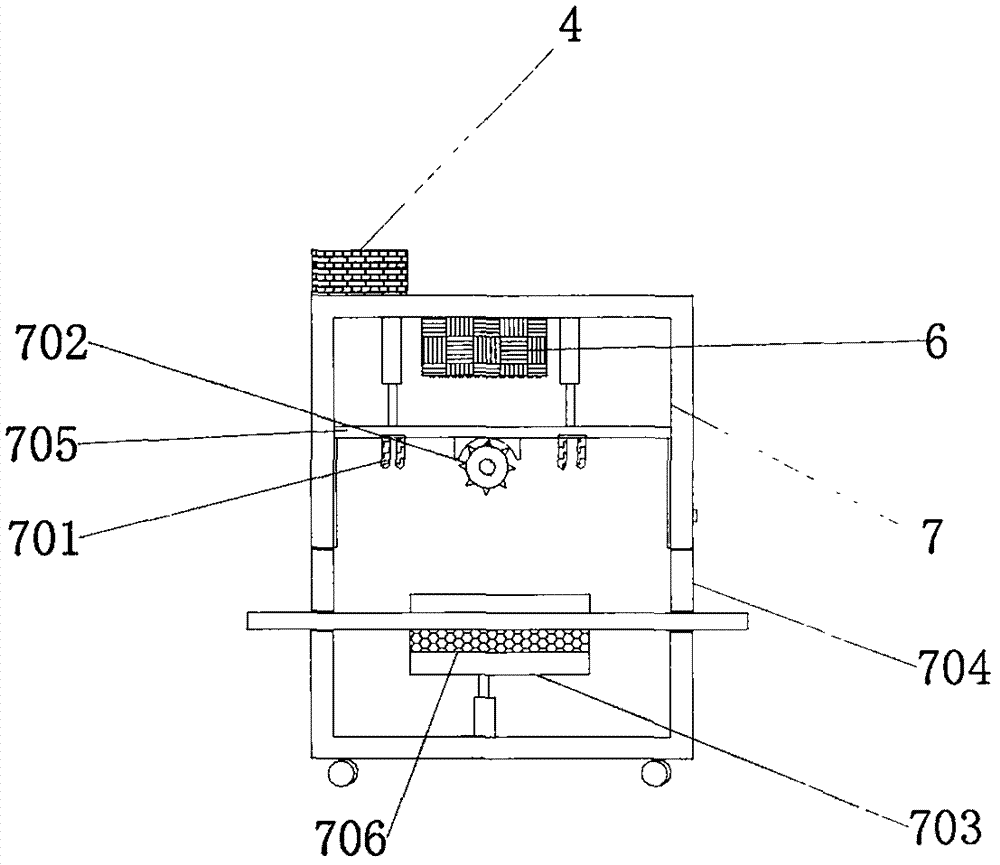

Medicine packaging box cutting device

InactiveCN109622564ASmall footprintFast truncationSolid waste disposalEngineeringMechanical engineering

The invention discloses a medicine packaging box cutting device. Themedicine packaging box cutting device comprises a shell, a milling mechanism, a cutting mechanism and a first crushing mechanism; afeed inlet and a discharge outlet are formed in the side wall of the shell, and a feeding channel, a first material containing groove, a second material containing groove are formed in the shell; themilling mechanism comprises a pair of runner wheels, and the pair of runner wheels is arranged horizontally in the axial direction; the cutting mechanism comprises one lower cutting roller and two upper cutting rollers, wherein the lower cutting roller and the two upper cutting rollers are arranged horizontally in the axial direction; and the first crushing mechanism comprises an electric telescopic rod, a rectangular frame and a crushing roller. Themedicine packaging box cutting device reduces floor area of medicine packaging boxes through storing after milling, cutting and crushing, the medicine packaging boxes are preliminary crushed, and subsequent transporting and processing are convenient.

Owner:韦海城

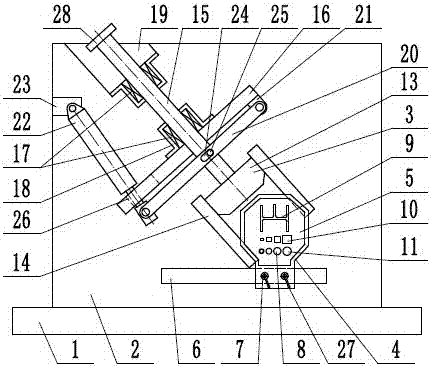

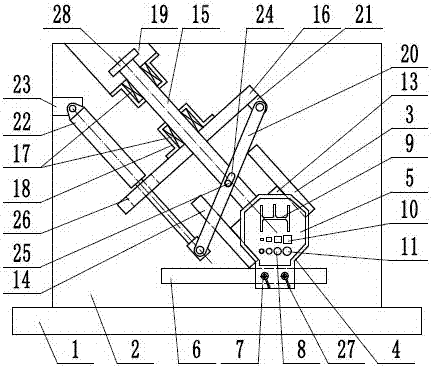

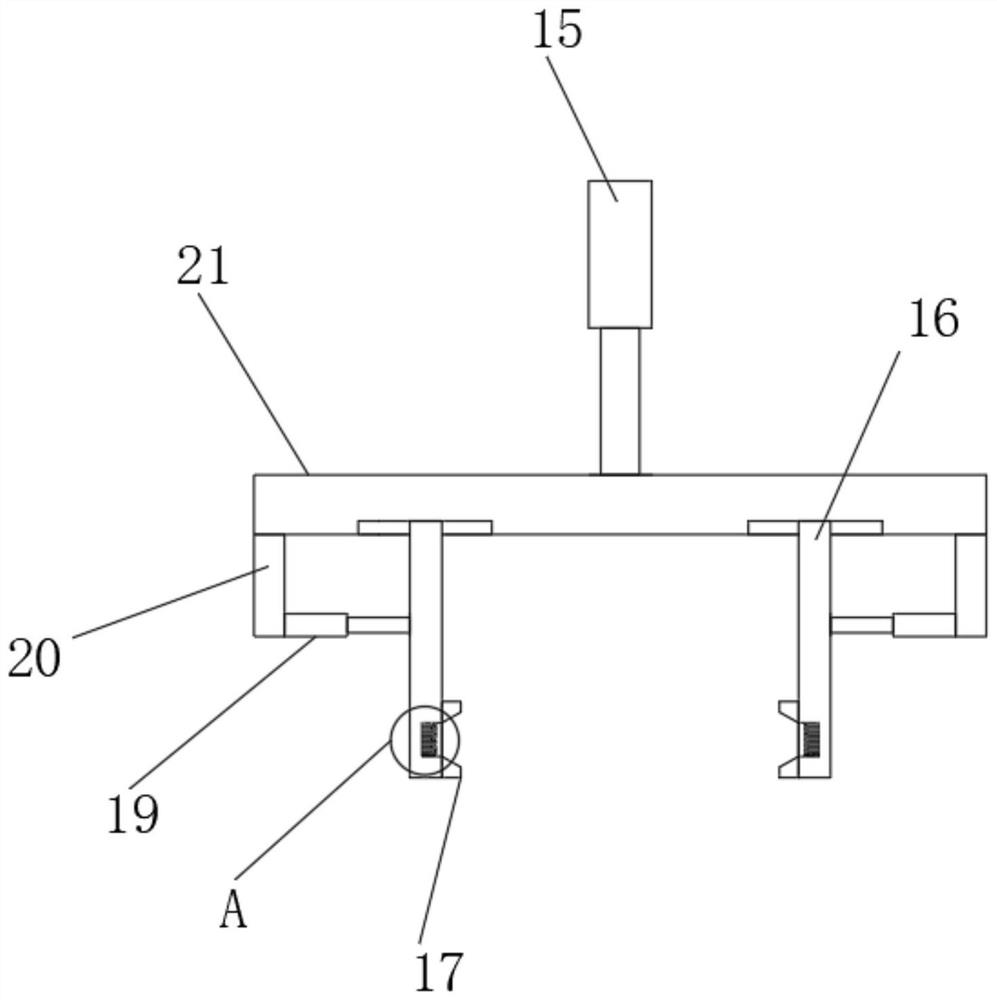

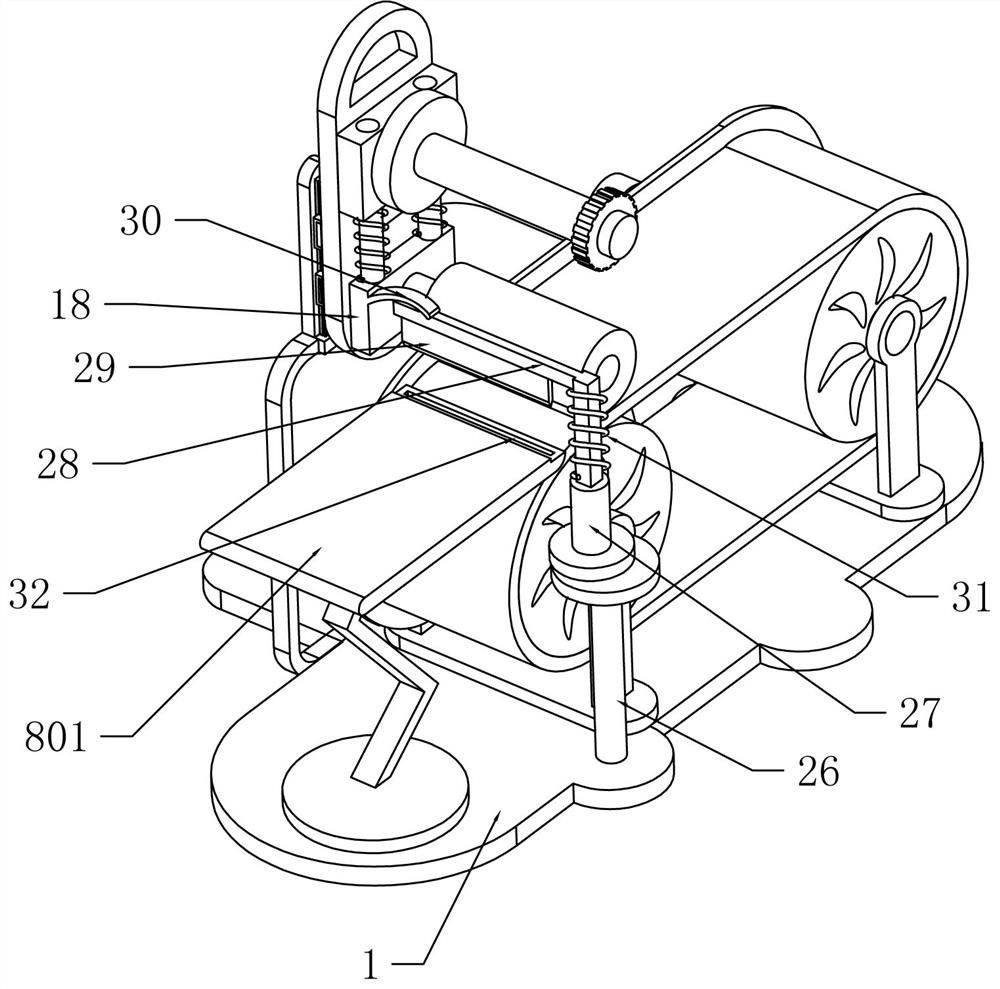

High-efficiency nail cut-off device for hardware

The invention relates to a cut-off device, in particular to a high-efficiency nail cut-off device for hardware. In order to achieve the technical purposes that the high-efficiency nail cut-off device for hardware is good in cut-off quality, good in application effect and convenient to fix in the cut-off process, the high-efficiency nail cut-off device for hardware comprises a placement plate, a fixing block, a cutter, a lifting rod, a first connecting rod, a first piston, a second piston, a second connecting rod, a third piston, a fourth piston, a cylinder body, a rack, a motor, a sliding rail, a sliding block, a support and a gear, wherein the sliding rail is arranged on the left side in the support, the sliding block is arranged on the sliding rail and provided with the rack, and the motor is arranged on the right side in the support. The high-efficiency nail cut-off device for hardware achieves the effects of the good cut-off quality, good application effect and convenient fixation in the cut-off process, thereby being high in cut-off speed, reasonable in design and convenient to apply and being a device with high practicability.

Owner:佛山市顺德区鼎丰盛五金电器有限公司

Agricultural wood cutting equipment

InactiveCN108422494APrevents the effect of truncationReduce labor intensityBand sawsAgricultural engineeringEngineering

The invention relates to cutting equipment, and particularly relates to agricultural wood cutting equipment. The technical problem to be solved by the invention is to provide agricultural wood cuttingequipment which is low in labor intensity, high in cutting speed, and capable of collecting wood shavings occurring in a cutting process, without influence on the surrounding environment. The invention provides agricultural wood cutting equipment. The agricultural wood cutting equipment comprises a bottom plate and the like, wherein a vertical plate is installed at the right side of the top of the bottom plate; a top plate is installed on the upper part of the left side surface of the vertical plate; a drive device is arranged between the right side of the front side surface of the top plateand the upper part of the front side surface of the vertical plate; a cutting device is arranged at the bottom of the top plate; the cutting device is connected with the drive device; and a lifting device is arranged at the left side of the top of the bottom plate. According to the agricultural wood cutting equipment disclosed by the invention, collection treatment can be carried out on the falling wood shavings through the collection device, so that the wood shavings are prevented from influencing the surrounding environment; and wood is fixed through an arc-shaped plate, and can be preventedfrom moving to influence the cutting effect, so that the effects of being low in labor intensity, high in cutting speed, and capable of collecting wood shavings in a cutting process, without influence on the surrounding environment are achieved.

Owner:叶成雨

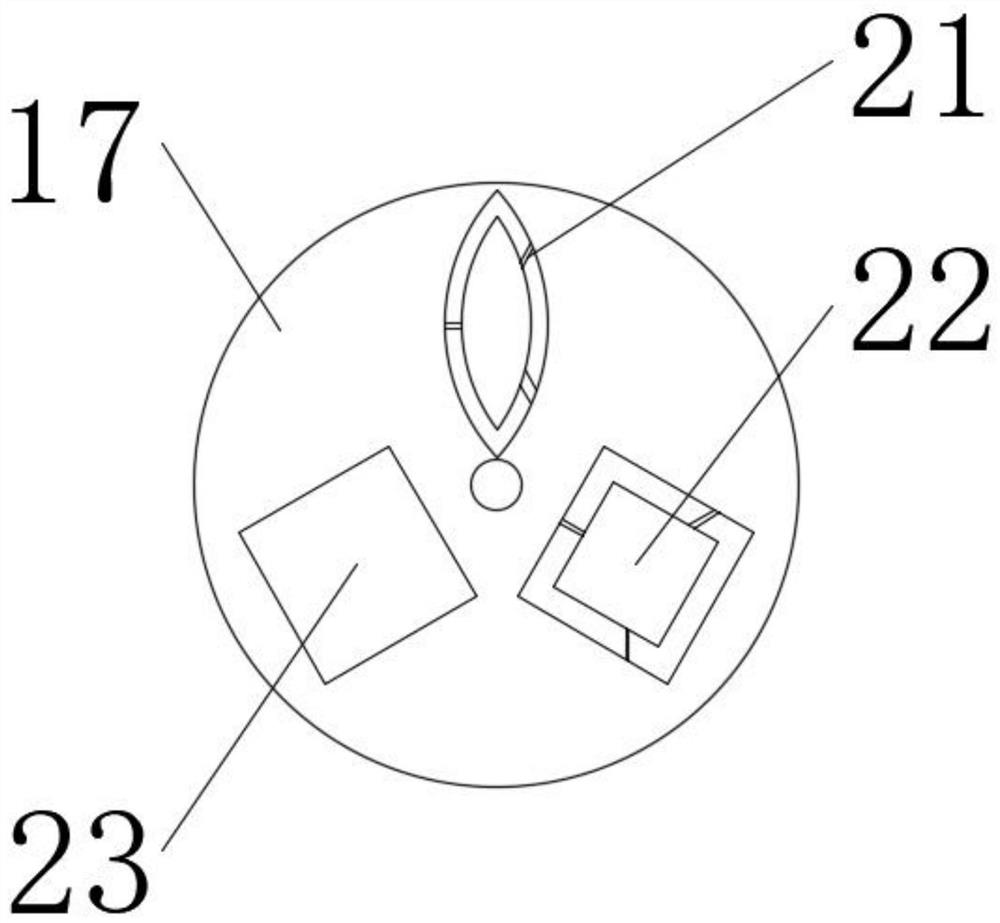

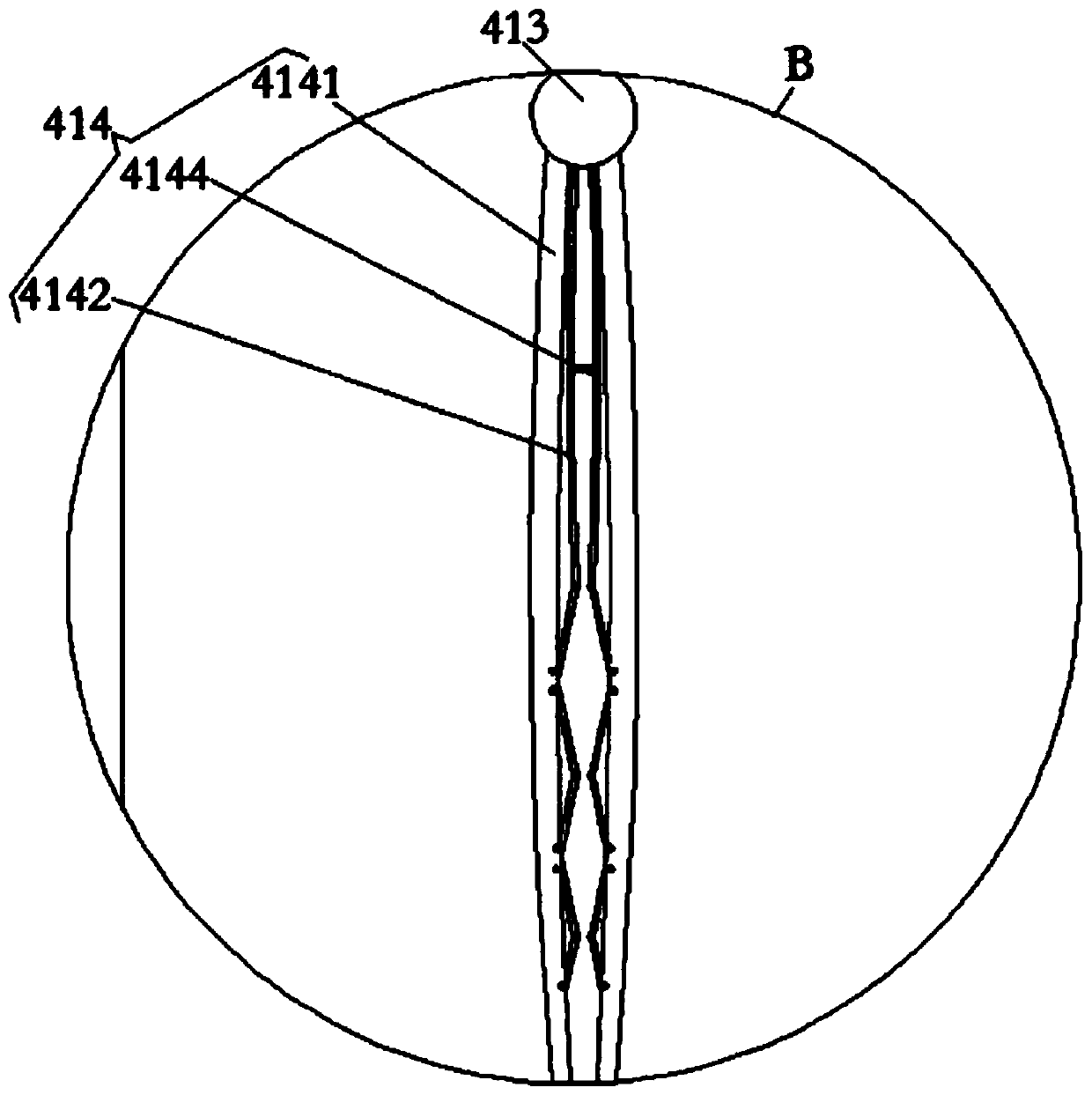

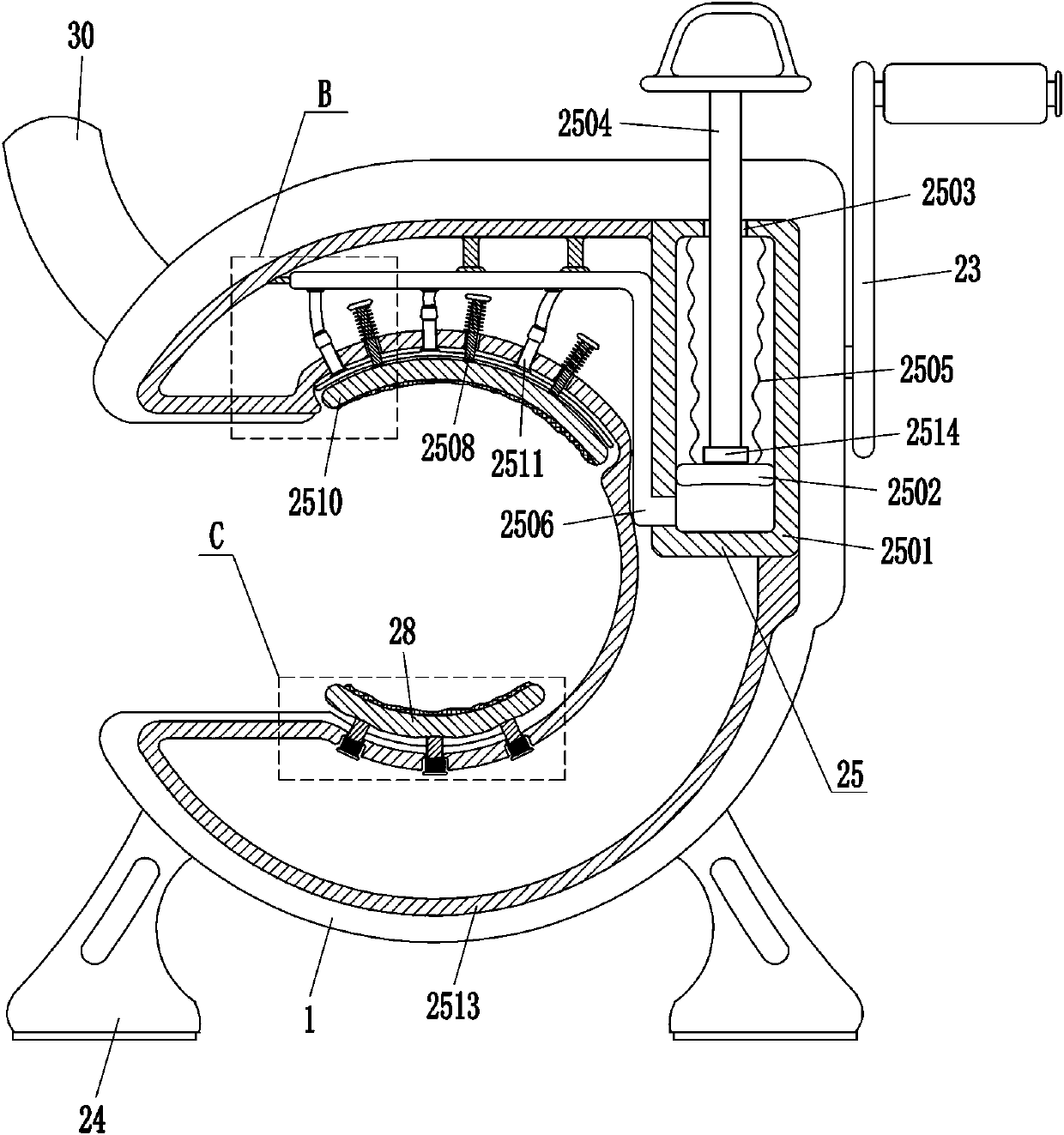

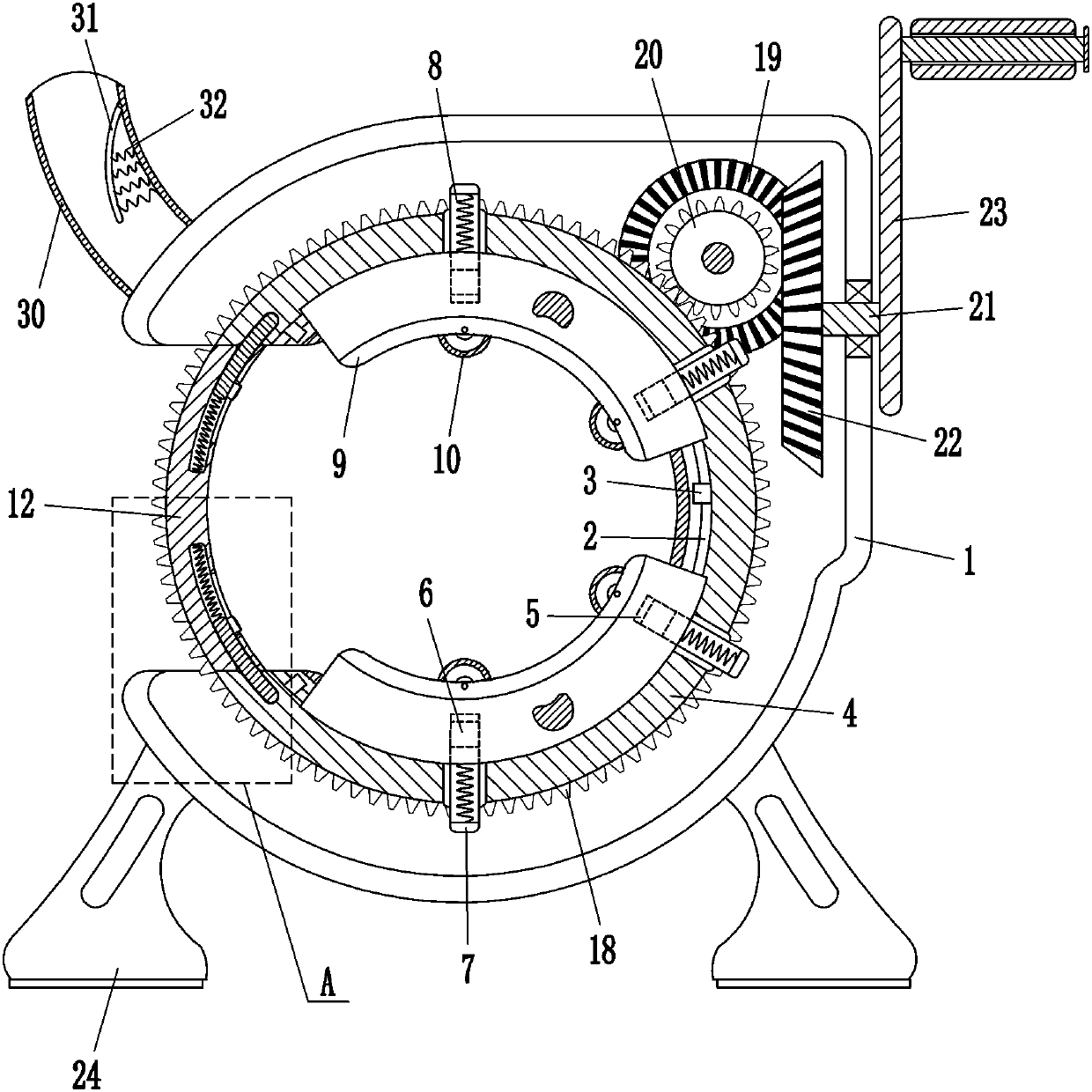

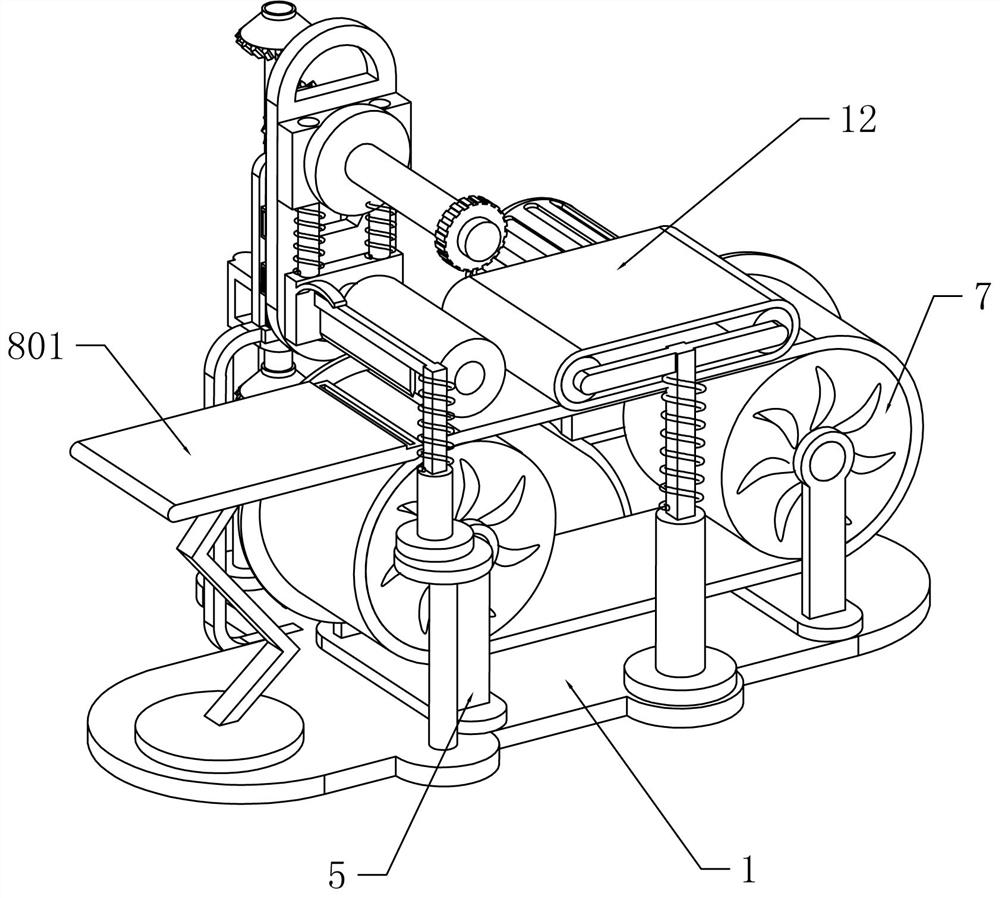

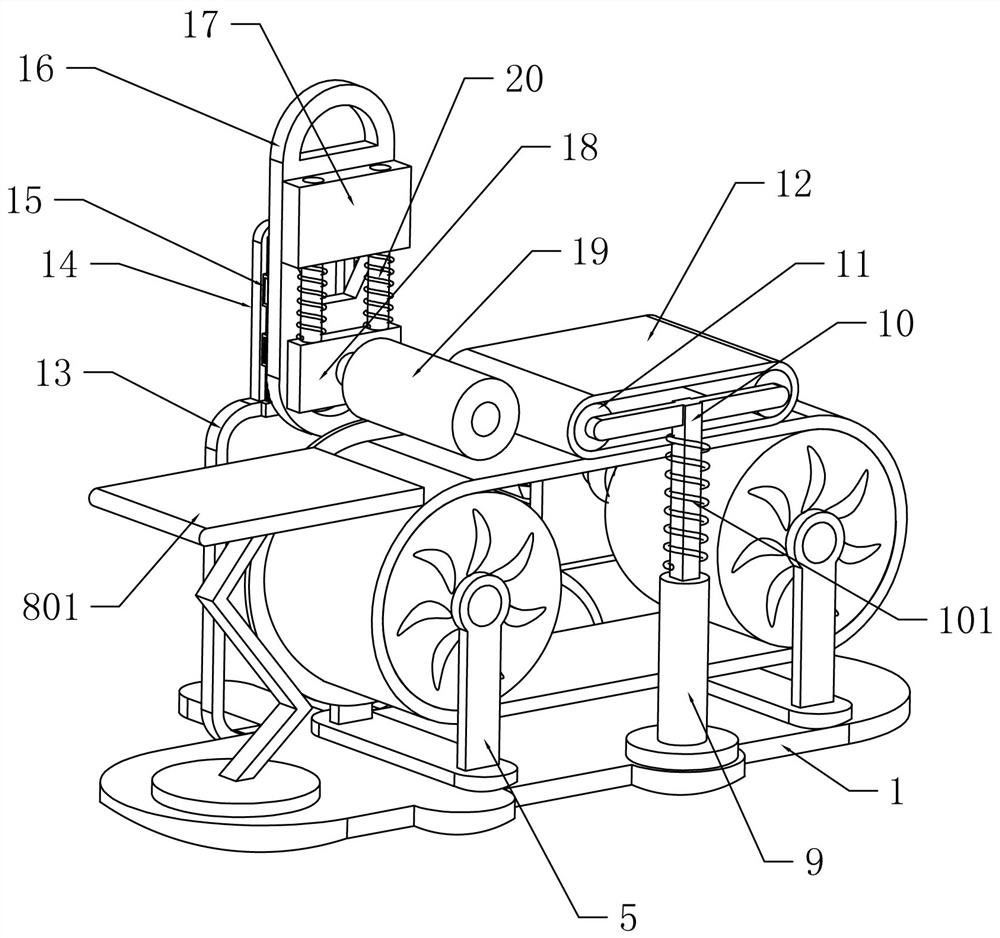

Grape branch and tendril binding device for fruit planting

ActiveCN111758477AFast windingEasy to tightenCultivating equipmentsAgricultural engineeringStructural engineering

The invention discloses a grape branch and tendril binding device for fruit planting, and relates to the technical field of grape planting. The invention aims to provide the grape branch and tendril binding device for fruit planting, which is simple and convenient to operate, high in working efficiency and capable of quickly bending iron wires to bind grape branches and tendrils. The grape branchand tendril binding device for fruit planting comprises a holding rod, an unwinding mechanism, an iron wire winding mechanism, a clamping mechanism and the like; the unwinding mechanism is fixedly installed on the holding rod, the iron wire winding mechanism is installed on the unwinding mechanism, and the clamping mechanism is installed on the iron wire winding mechanism. According to the grape branch and tendril binding device for fruit planting, by arrangement of the unwinding mechanism, the iron wires can be wound on an unwinding wheel, enough iron wires are placed on the device, an iron wire rotating mechanism is matched with the clamping mechanism, an arc-shaped rack is driven to rotate to drive the iron wires in the clamping mechanism to wind the branches and tendrils and a supporttogether, and by arrangement of an iron wire conveying mechanism, the iron wires can be conveyed upwards through two conveying discs, wherein one of the two conveying discs rotates clockwise while theother conveying disc rotates anticlockwise.

Owner:元谋县果然好农业科技有限公司

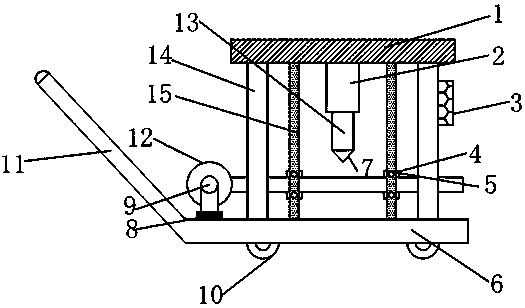

Cutting device for power cable

InactiveCN108971387AFast truncationImprove efficiencyMetal working apparatusHydraulic cylinderPower cable

The invention discloses a cutting device for a power cable. The lower end of a stand column is connected with a trolley body, a hydraulic cylinder is arranged in the middle of the lower portion of a supporting cross beam, the lower portion of the hydraulic cylinder is connected with a cable cutter through a piston rod, the upper end of a connecting rod is connected with the supporting cross beam,an electric motor is arranged at the left end of the trolley body, and is connected with a rotating shaft through a supporting part, a cable paying-off roller is arranged on the rotating shaft, a shaft is arranged at the lower end of the connecting rod, and rectangular pressing blocks are arranged on the shaft, and are vertically and symmetrically arranged with the cable as the axis. According tothe cutting device for the power cable, the electric motor drives the cable paying-off roller to carry out paying off, the four rectangular pressing blocks are used for pressing the cable, a length counter is observed, at the moment, when the length of the length counter reaches the value required by a user, the hydraulic cylinder is started for enabling the piston rod to drive the cable cutter toact so as to cut off the cable to be cut, and the device is high in cutting-off speed, high in efficiency and accurate in cutting.

Owner:钟建军

Pile-up valve for frequency conversion hydraulic elevator

InactiveCN1271338CGood lookingImprove comfortServomotor componentsElevatorsFluid controlFrequency conversion

Owner:ZHEJIANG UNIV

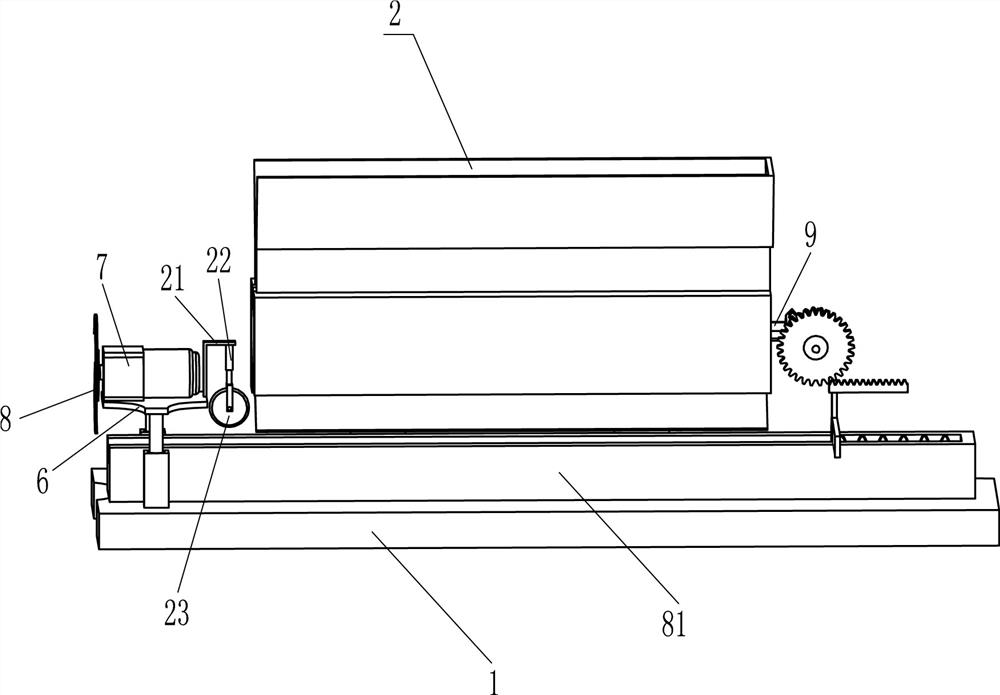

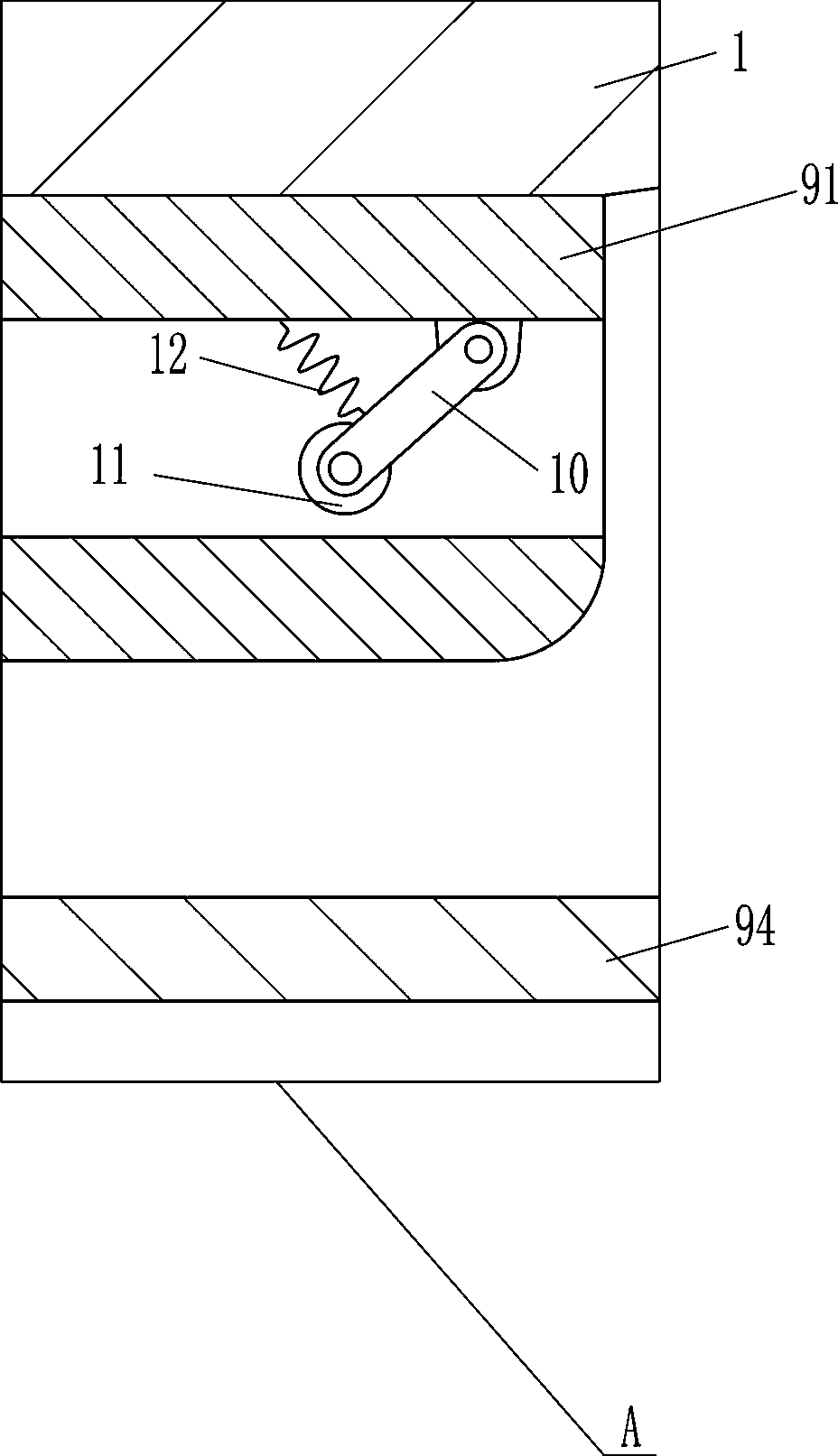

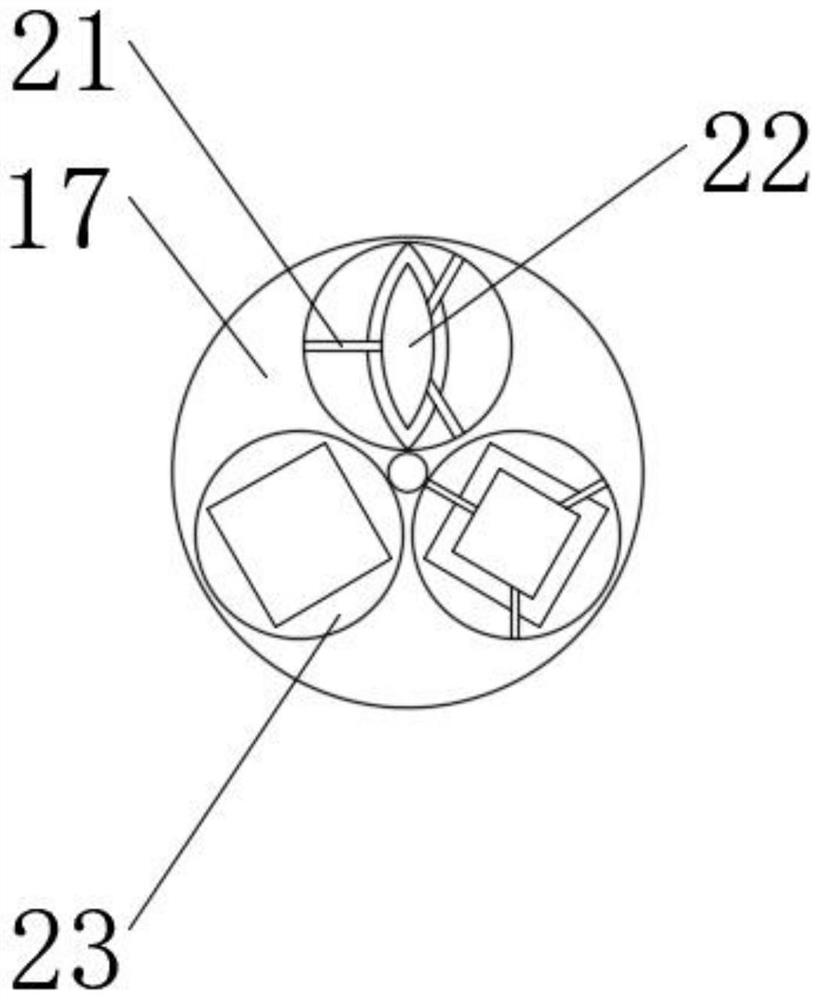

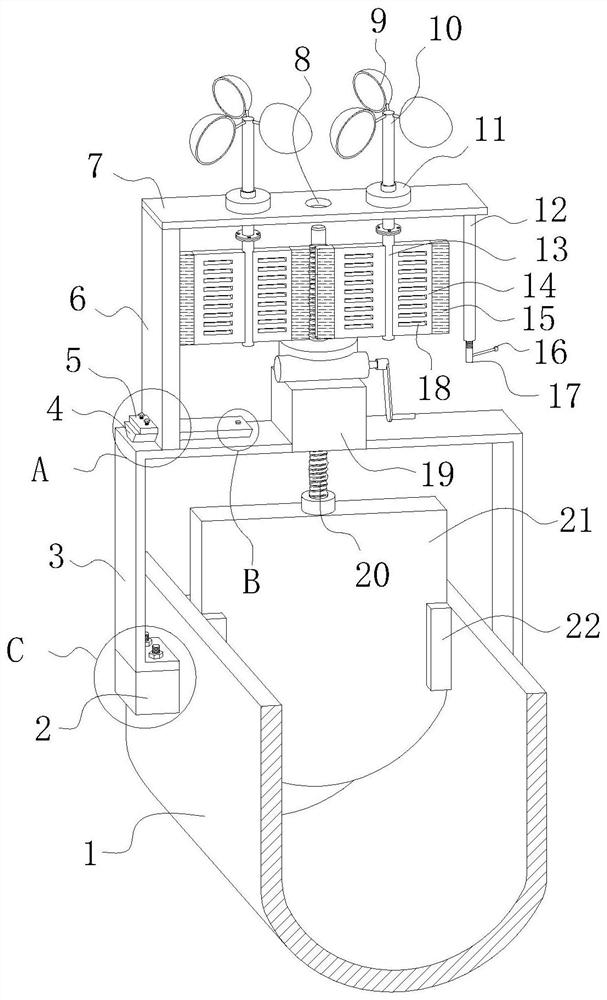

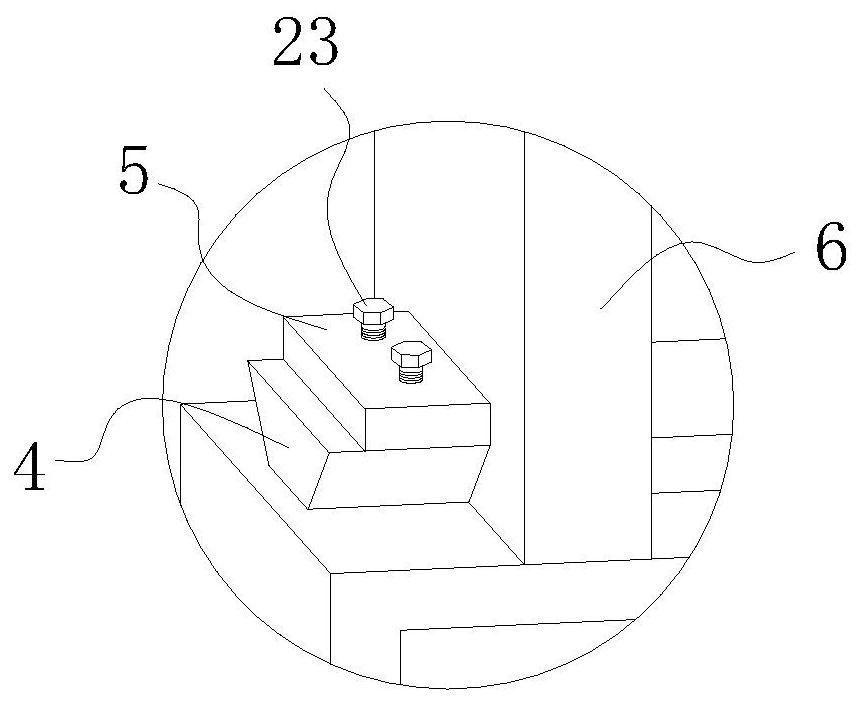

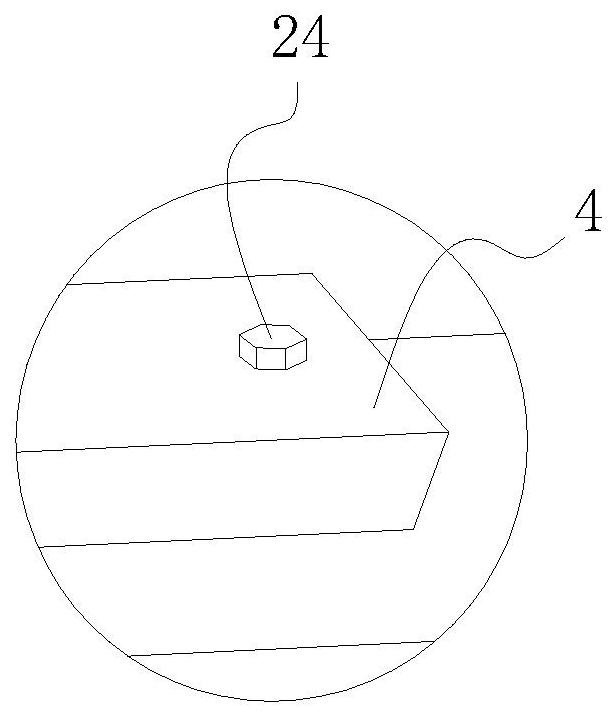

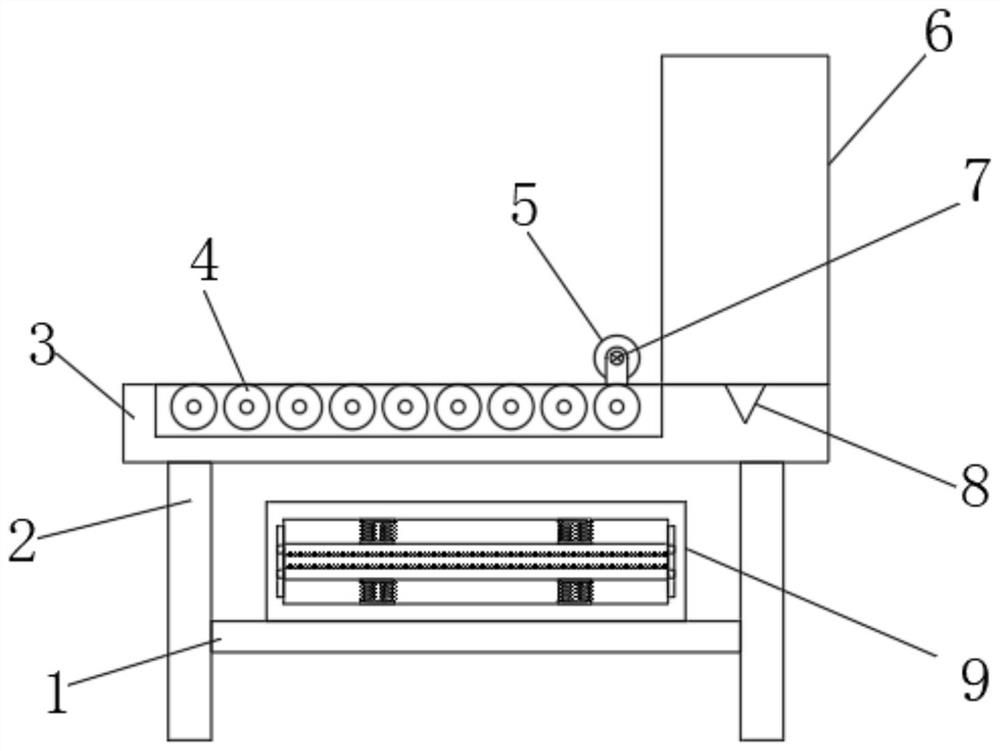

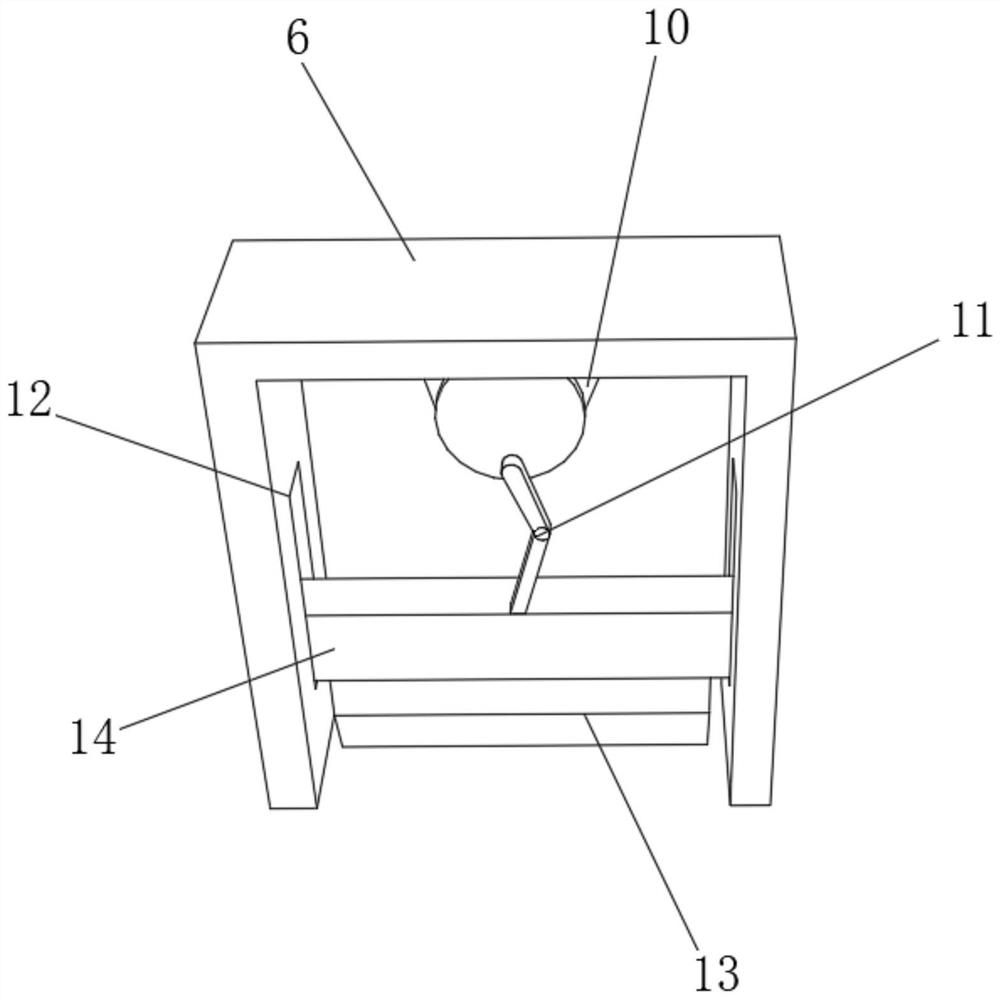

A high-performance wood cutting and utilization equipment

The invention relates to wood cutting and utilizing equipment, particularly relates to high-performance wood cutting and utilizing equipment, and aims to realize the effects that the labor intensity is low, the cutting speed is high, and the operation is convenient. The wood cutting and utilizing equipment comprises a U-shaped baffle, a round frame body, a fixing frame, a first guide plate, a first rack, a first sliding rail, a first sliding block, a first gear, a second guide plate, a placing plate and the like, wherein the round frame body, the first guide plate, the first sliding rail and the second guide plate are sequentially arranged at the inner bottom of the fixing frame from left to right, and the first sliding block is connected with the first sliding rail in a sliding mode. According to the wood cutting and utilizing equipment, the effects that the labor intensity is low, the cutting speed is high and the operation is convenient can be realized, the maintenance and repair are easy, the use is convenient, the investment of manpower and material resources is reduced, the working efficiency is improved, and the time is effectively saved.

Owner:江门市焱林家具有限公司

Improved raw material mixing and extruding equipment for tile production

InactiveCN112140289AImprove economic efficiencyBeautiful appearanceCeramic extrusion diesAuxillary shaping apparatusBuilding materialManufacturing engineering

The invention provides improved raw material mixing and extruding equipment for tile production, and belongs to the technical field of building material production and processing equipment. The improved raw material mixing and extruding equipment for tile production comprises a box body, a first motor, an adjusting motor, a second motor, a pre-assembling box, a brake cylinder and a die changing motor, wherein a mixing box is arranged in the box body and is fixedly connected with the inner side wall of the box body; and a mounting rod is arranged in the mixing box. A spiral extrusion rod slowlypushes materials forwards in the rotating process; the materials pass through material forming grooves in a die changing barrel; and due to the fact that the ends, close to an extrusion pipeline, ofthe multiple material forming grooves are round, and the ends, away from the extrusion pipeline, of the multiple material forming grooves are rectangular, oblate and square, the material forming grooves can correspond to different types of bricks and tiles, so that when the amount of demand for different kinds changes, a die can be conveniently replaced as required, so that the applicability of the equipment is greatly improved.

Owner:安徽龙钰徽派古建工艺制品有限公司

Water stop device for water conservancy project of safe large aqueduct structure

InactiveCN112411478AReduces the probability of sticking to the screwFast truncationSewer cleaningArtificial water canalsWater stopAqueduct

The invention relates to the technical field of water conservancy projects, and particularly relates to a water stop device for a water conservancy project of a safe large aqueduct structure. The water stop device comprises an aqueduct and a hoist arranged on the upper side of the aqueduct, wherein a top plate is arranged over the hoist; one end of the top plate is fixedly connected with a vertical plate; the upper surface of the top plate is provided with a penetrating hole concentric with a screw; two round holes are symmetrically formed in the upper surface of the top plate; a rotating rodis arranged in the round holes and sleeved with a bearing; the bearing is arranged on the upper sides of the round holes and fixedly connected with the top plate; three hemispherical covers are annularly installed on the outer surface of the upper end of the rotating rod at equal intervals; the lower end of the rotating rod is fixedly connected with a round rod; two supporting plates are symmetrically installed on the outer surface of the round rod; and bristles making contact with the screw are installed at the ends, away from the round rod, of the supporting plates. Compared with the prior art, the water stop device has the following beneficial effects that the purpose of sweeping rust stains on the screw is achieved, and the probability that the rust stains are attached to the screw isreduced.

Owner:杭州铭光精密机械科技有限公司

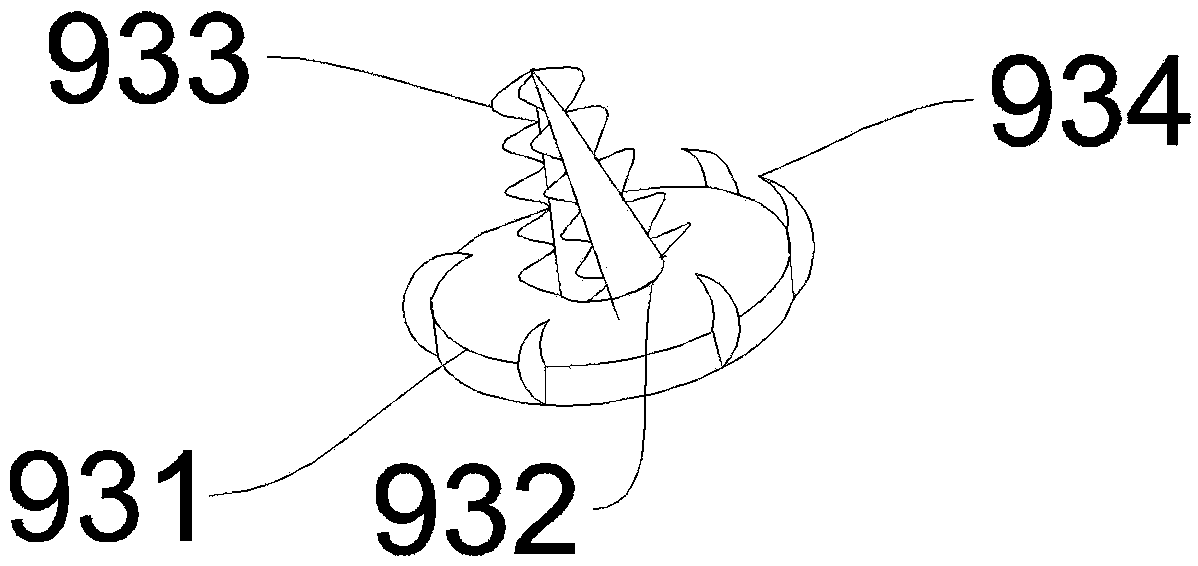

Beef steak cutting mechanism and use method thereof

InactiveCN111387258AIncreasing the thicknessIncreased efficiency of amputation of bonesMeat holding apparatusEngineeringBeef steak

The present invention relates to the technical field of beef steak processing equipment, in particular to a beef steak cutting mechanism and a use method thereof, and aims to solve the technical problems of easy blade jamming, low working efficiency and low danger coefficient of an existing bone cutting machine. The beef steak cutting mechanism comprises a processing box; the bottom of the processing box is fixedly connected with a bracket; an opening in the top of the processing box is fixedly connected with a feeding sleeve; the processing box is provided with a cutting mechanism; the outputend of the cutting mechanism is fixedly connected with one side of the processing box; and the bottom of the inner wall of the processing box is fixedly connected with a bone cushion mechanism. A cutting knife is formed by combining two bendable arc-shaped blades, and when the arc-shaped blades are pressed down to contact a bone, the middles of the two arc-shaped blades are expanded outwards, sothat the thickness of the cutting knife is increased, a gap of the bone can be expanded, and the cutting knife can be prevented from being jammed in the bone.

Owner:高宏福

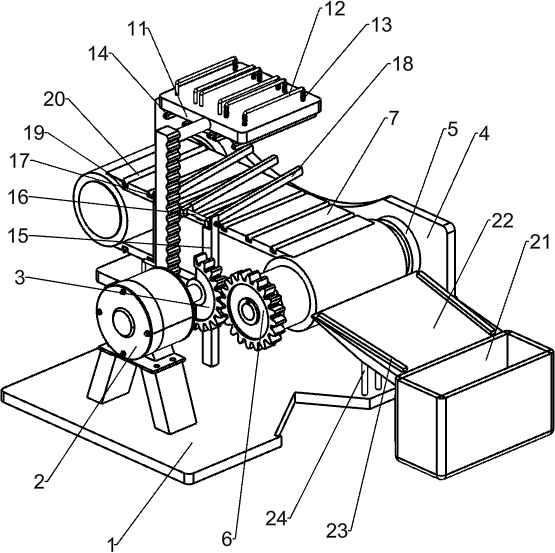

Tufted carpet segment cutting equipment applied to textile industry

The invention relates to segment cutting equipment, in particular to tufted carpet segment cutting equipment applied to the textile industry. The technical problem to be solved is to provide the tufted carpet segment cutting equipment applied to the textile industry which can realize high-precision cutting of a tufted carpet and reduce manual consumption. The tufted carpet segment cutting equipment applied to the textile industry comprises a bottom plate, a transmission assembly, a lifting assembly, a pushing assembly, and a segment cutting assembly; the bottom plate is for installing the entire equipment; the transmission assembly is installed on the bottom plate and proves power via a motor; the lifting assembly is installed on the bottom plate and realizes lifting in a sliding mode; thepushing assembly is installed on the lifting assembly, and moves to realize pushing; and the segment cutting assembly is installed on the bottom plate and realizes segment cutting in a pushing mode.Through matching of a fan-shaped gear and a complete gear, the tufted carpet can be automatically transferred, manual pulling is not required; and through matching of a sliding block and a rack, powercan be indirectly provided for cutting the tufted carpet.

Owner:林冬招

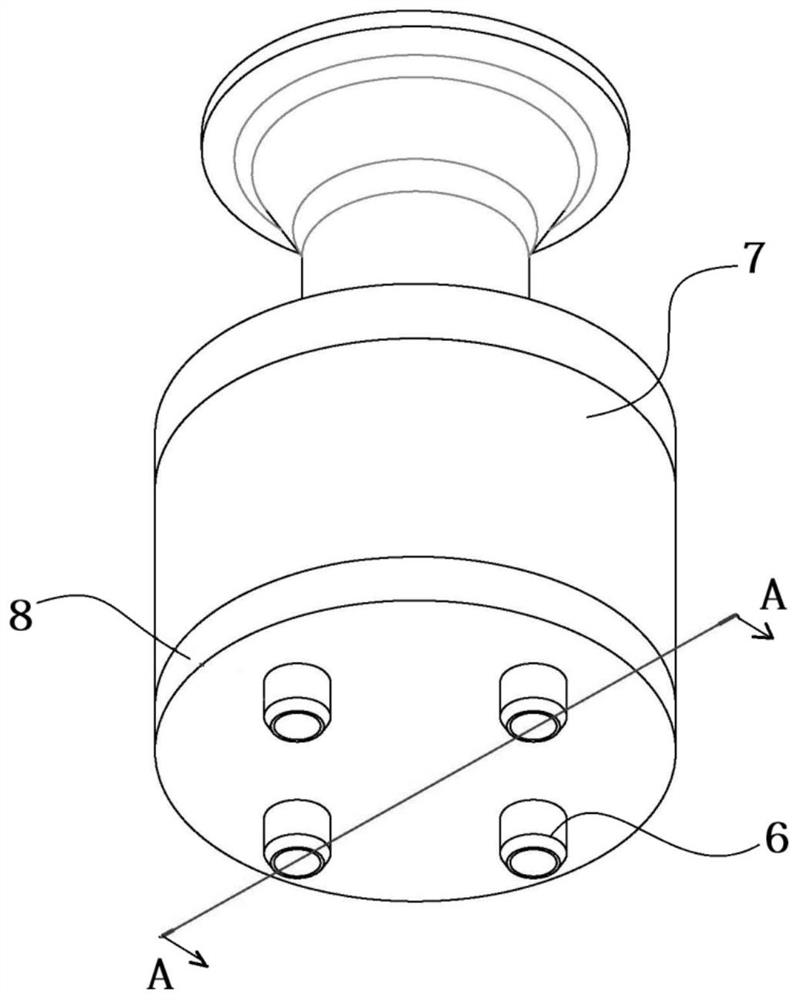

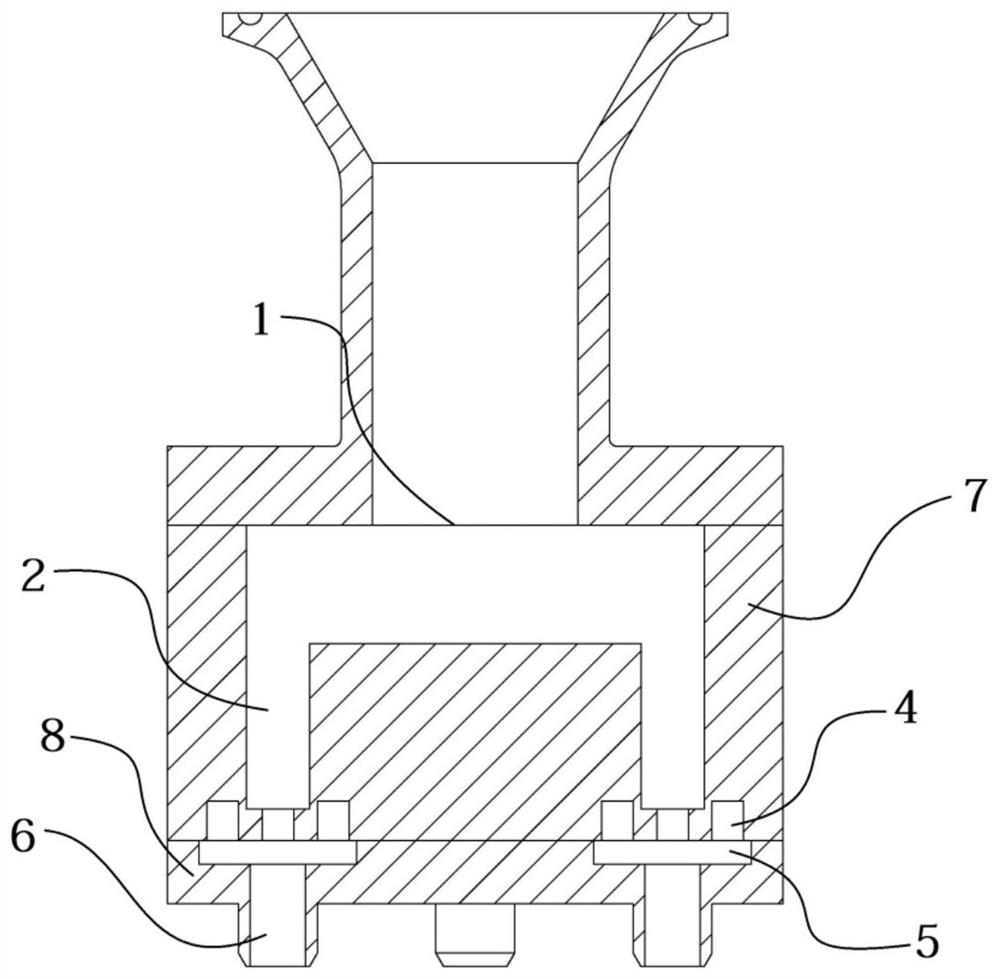

a discharge device

The present invention relates to the technical field of feed liquid filling, in particular to a discharge device, comprising: a feed liquid channel having an inflow port and an outflow port; a control valve arranged between the inflow port and the outflow port to control the The on-off of the feed liquid passage; the cut-off mechanism includes a high-pressure fluid passage located downstream of the control valve and connected to the feed liquid passage near the outlet; the control valve is closed, and the high-pressure The high-pressure fluid ejected from the fluid channel forms a high-pressure tangent surface, and the high-pressure tangent surface intercepts the flowing material liquid column. The discharge device provided by the present invention can completely cut off the viscous material liquid, which is beneficial to improve the quality of the filling product and the cleanliness of production, and is convenient for maintenance and cleaning.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Cutting method and machine for PVC pinch plates

PendingCN110385750AIncrease production capacityImprove flatnessMetal working apparatusProduction lineEngineering

The invention discloses a cutting method for PVC pinch plates. The method comprises a clamping step, a cutting clamp, a breaking step and a resetting step. A cutting knife is fixed with a pinch plateby using a clamp; and when the cutting knife and the pinch plate synchronously move along an extrusion direction, the pinch plate in advancing is transversely cut from the upper and lower surfaces ofthe pinch plate, so as to form an upper transverse notch and a lower transverse notch, which are not cut through, and the pinch plate is positively and negatively bent along the upper transverse notchand the lower transverse notch so as to break off the pinch plate along the upper transverse notch and the lower transverse notch. When the method is adopted to carry out fixed-size cutting on the pinch plates continuously output by a pinch plate extruder, the time required for the cutting can be shortened, the yield of a pinch plate production line can be improved, the cut pinch plates are goodin end edge flatness and no cutting chippings are generated in the cutting process. The invention further discloses a PVC pinch plate cutting machine which adopts the above method; and the PVC pinch plate cutting machine is shallow in cutting mouth and high in cutting speed so as to create conditions for improving the PVC pinch plate extrusion speed.

Owner:刘德存

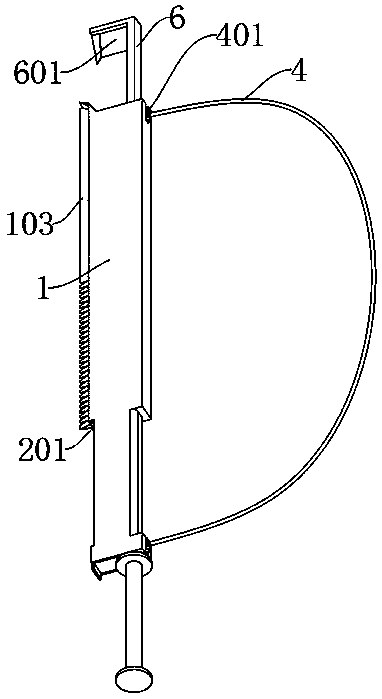

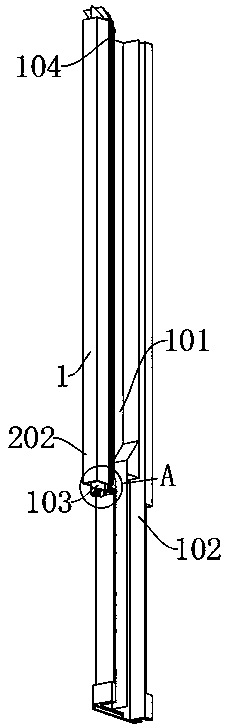

A profile cutting device

InactiveCN105921805BQuick guideFast truncationFeeding apparatusShearing machine accessoriesEngineeringMachining

The invention provides a section bar cut-off device, and belongs to the technical field of machining. The section bar cut-off device comprises a cut-off mechanism and a guide mechanism. A guide plate of the guide mechanism is installed on a bearing frame through locking screws. Section bar guide holes are formed in the guide plate. Guide grooves corresponding to the section bar guide holes in the guide plate are formed in a machine frame. A tool rest rod of the cut-off mechanism is arranged on slide guide sleeves in a slidable manner. A cut-off tool is installed at the lower end of the tool rest rod. Tool guide frames are arranged on the two sides of the cut-off tool. One end of a lever is hinged to a lever supporting lug. A U-shaped groove is formed in the middle end of the lever. A pin shaft is arranged on the tool rest rod and inserted in the U-shaped groove in the middle end of the lever. One end of a drive cylinder is hinged to a cylinder support, and the other end of the drive cylinder penetrates an anti-collision groove of a fixed support and is hinged to the other end of the lever. By means of the section bar cut-off device, section bars can be rapidly cut off, the surfaces of the section bars which are cut off are smooth, and the section bar cut-off device is suitable for the section bars of various shapes and types, reasonable in structure and high in applicability.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

Production system for color printing packaging boxes

InactiveCN112157952AImprove pass rateImprove production efficiencyPaper-makingBox making operationsColor printingWaste product

The invention belongs to the technical field of packaging box production, and particularly relates to a production system for color printing packaging boxes. According to the production system, the problems that an existing production system is generally simple in design, and interlocking between every two adjacent procedures cannot be achieved, so that the rejection rate of the produced packagingboxes in the detection process is high can be solved. According to the following scheme, the production system comprises a cutting device, a printing device, an oiling device, a veneering device, a box rolling device, a box pasting device, an inspection device and a packaging device, wherein the cutting device comprises a cutting mechanism and a storage mechanism, the cutting mechanism comprisesa feeding table, a gantry is fixed on one side of the outer wall of the top of the feeding table through screws, and a motor is fixed on the inner wall of the top of the gantry through screws. According to the production system for the color printing packaging boxes, interlocking between every two adjacent links is achieved, each link easy to generate waste products in the production process of the packaging boxes is optimized, and the qualified rate of the produced packaging boxes is generally high, so that the production benefit of enterprises is remarkably improved.

Owner:厦门市环岛包装科技有限公司

A high-efficiency cutting device for hardware nails

The invention relates to a cut-off device, in particular to a high-efficiency nail cut-off device for hardware. In order to achieve the technical purposes that the high-efficiency nail cut-off device for hardware is good in cut-off quality, good in application effect and convenient to fix in the cut-off process, the high-efficiency nail cut-off device for hardware comprises a placement plate, a fixing block, a cutter, a lifting rod, a first connecting rod, a first piston, a second piston, a second connecting rod, a third piston, a fourth piston, a cylinder body, a rack, a motor, a sliding rail, a sliding block, a support and a gear, wherein the sliding rail is arranged on the left side in the support, the sliding block is arranged on the sliding rail and provided with the rack, and the motor is arranged on the right side in the support. The high-efficiency nail cut-off device for hardware achieves the effects of the good cut-off quality, good application effect and convenient fixation in the cut-off process, thereby being high in cut-off speed, reasonable in design and convenient to apply and being a device with high practicability.

Owner:佛山市顺德区鼎丰盛五金电器有限公司

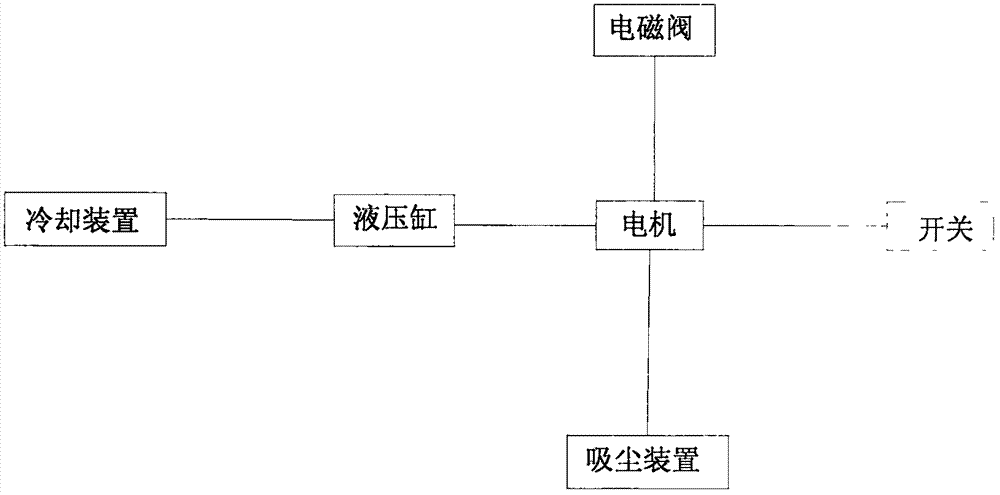

Automobile part rapid cutting-off machine

PendingCN107984019AQuick and easy to useFast truncationShearing machinesMaintainance and safety accessoriesEngineeringElectromagnetic valve

The invention discloses an automobile part rapid cutting-off machine. The machine comprises a cutting-off machine main body, a working table and a cutting-off device; the working table is arranged onthe upper side of the cutting-off machine main body and is fixedly connected with the cutting-off machine main body, the cutting-off device is arranged inside the cutting-off machine main body and isembedded in the cutting-off machine main body, and a motor is arranged on the left side of the cutting-off machine main body and is connected with the cutting-off machine main body in an embedding mode. According to the machine, a movable cutter can move left and right and up and down through a movable guide rail so that the cut-off position of a part can be more accurate and can not generate flaws, the rotary cutter is arranged so that the cutting speed can be higher, the efficiency can be higher, the automobile part can be cut off, the parts of other materials can also be cut off, the multipurpose performance of the machine is embodied, and a cooling device is further arranged in the cutting-off device so that cooling and dust clearing can be carried out on the cut part under the controlof an electromagnetic valve.

Owner:无锡市中吉橡塑机械有限公司

Portable rapid trimming and pruning device for forestry production

InactiveCN111480473APrevent fallingNo fratricideCuttersCutting implementsForest industryAgricultural engineering

The invention provides a portable rapid trimming and pruning device for forestry production. The portable rapid trimming and pruning device comprises a main body, a stress groove, a rear groove, a hanging piece, a top plate and a control rod, the main body is of a rectangular structure, and a handheld groove is formed in the bottom of the main body. The stress groove is formed in the bottom of thefront end of the main body, and the two ends of the protection piece above the stress groove are embedded into the mounting grooves; the rear groove is formed in the upper and lower ends of the rearpart of the main body; the stress groove is used for being formed in the bottom of the front end of the main body, so that the baffle can move in the stress groove, the protection piece can be fixed and blocked by the baffle when being used, and therefore the protection piece is prevented from falling, and the stress groove is of a T-shaped structure so that the baffle cannot be disengaged when being inserted into the stress groove, so that spring can eject baffle outwardly inside it, and the baffle receives the power of the spring and moves outwards, so that the front end of the baffle can bepositioned at the bottom of the protection piece, and the protection piece is blocked.

Owner:杨国丽

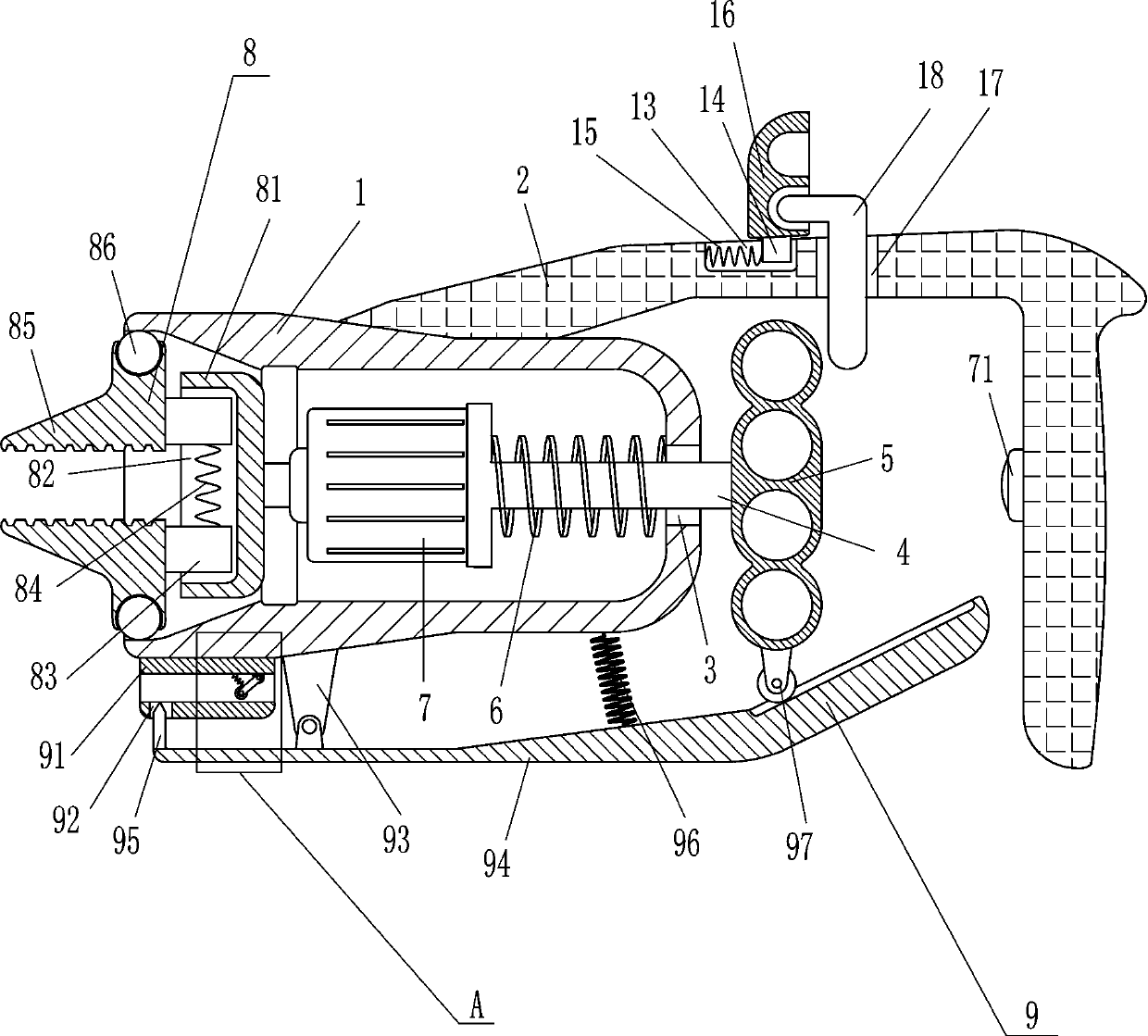

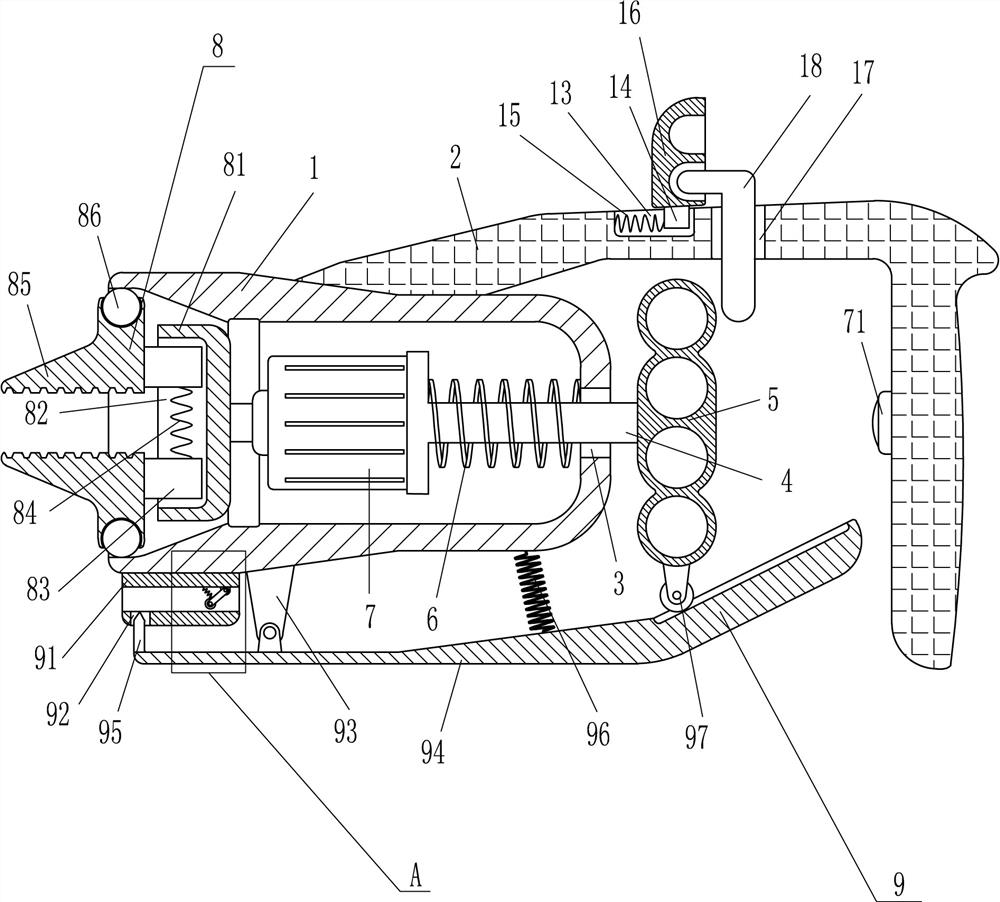

A kind of steel binding device

ActiveCN110422370BQuick clampingFast truncationBundling machine detailsClassical mechanicsElectric machinery

The invention relates to a binding device, in particular to a steel bar binding device. The technical problem to be solved is: to provide a steel bar binding device which can automatically cut the iron wire according to the quantity of the steel bars without manually tightening the iron wires with wire cutters, and can quickly and conveniently bind the steel bars. The technical embodiment of the present invention is: a steel bar binding device, including a cylindrical shell, a handle, a T-shaped slide bar, etc.; The left side of the body is an inclined plane, and the right side of the cylindrical shell is provided with a slide hole, and a T-shaped slide bar is provided for sliding in the slide hole. The present invention can clamp the iron wire through the clamp block, drive the motor to drive the clamp block to rotate, so that the iron wire can be tightened, and the connecting rod can be driven to drive the cutter to cut the iron wire through the movement of the handle. The steel bars are bundled, and the iron wires can be quickly cut and tightened.

Owner:赣州市榕盛新型建材有限公司

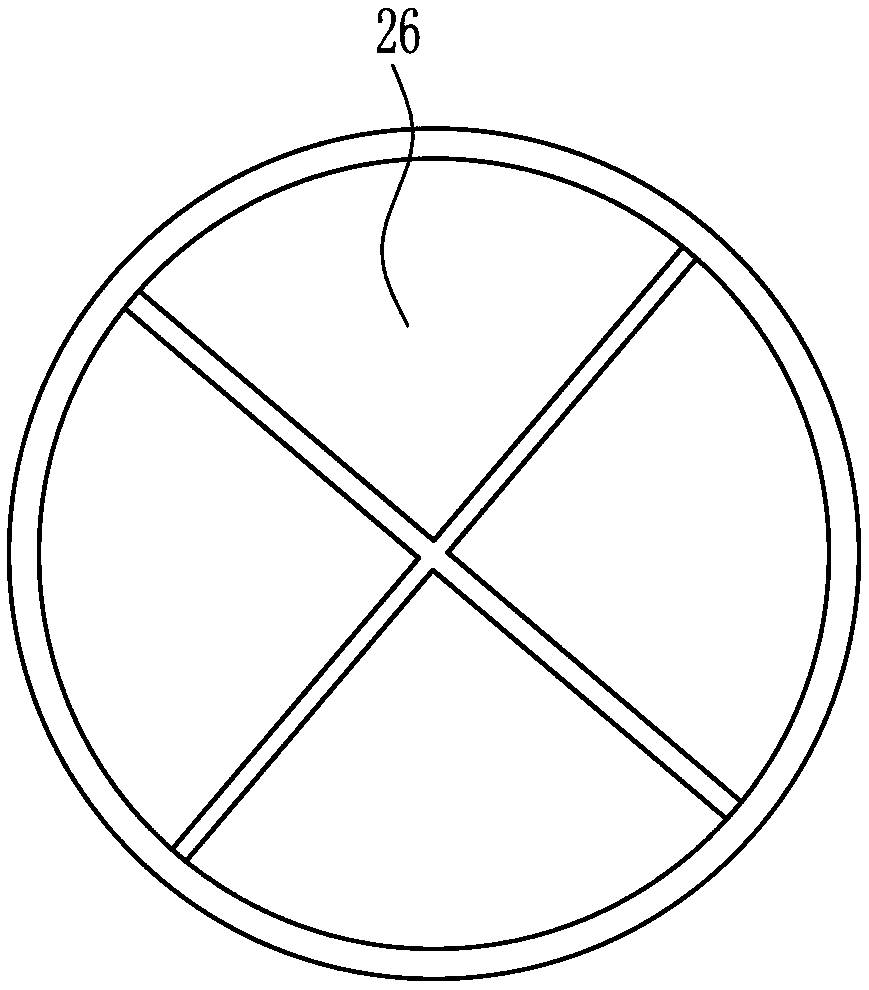

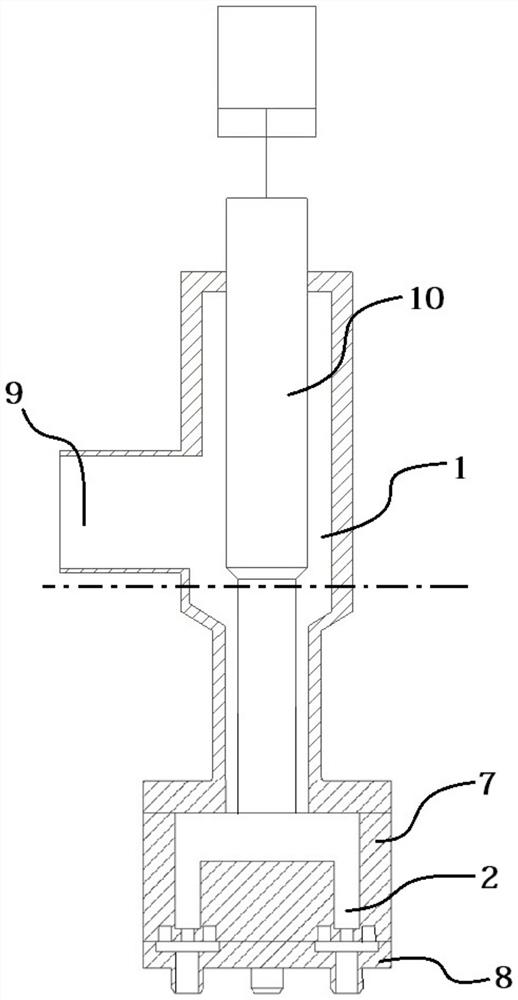

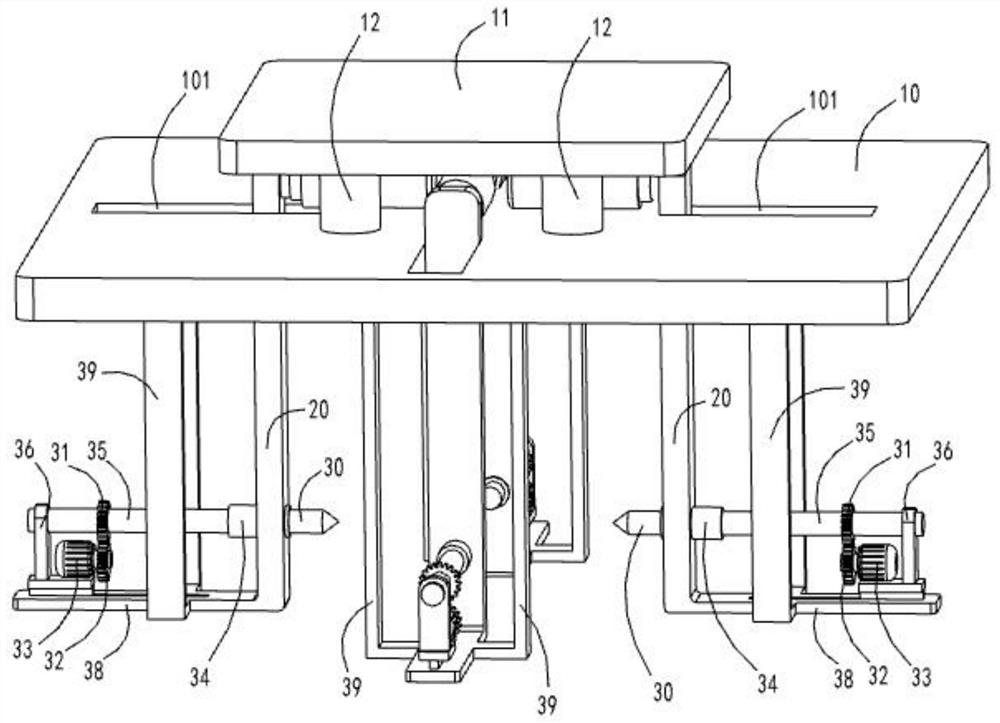

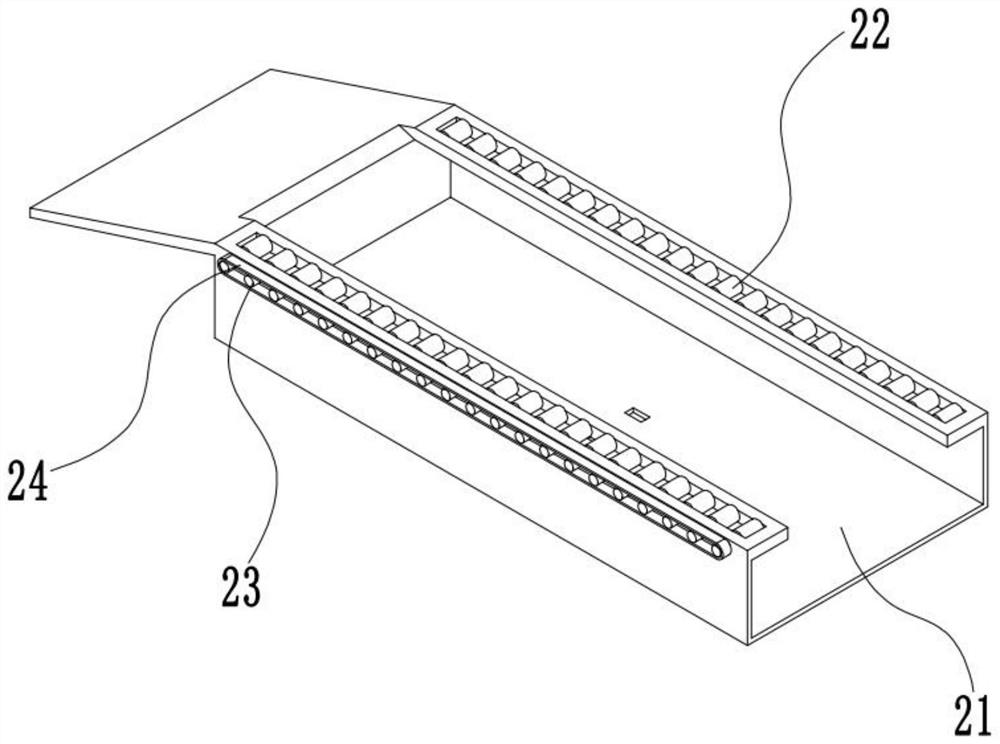

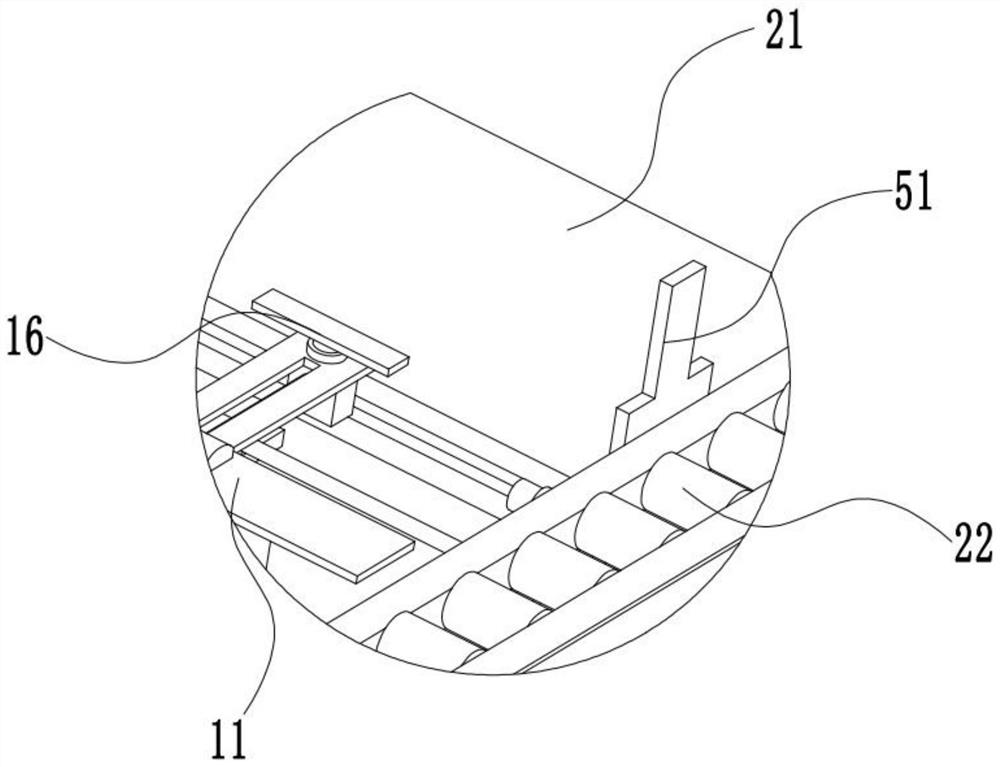

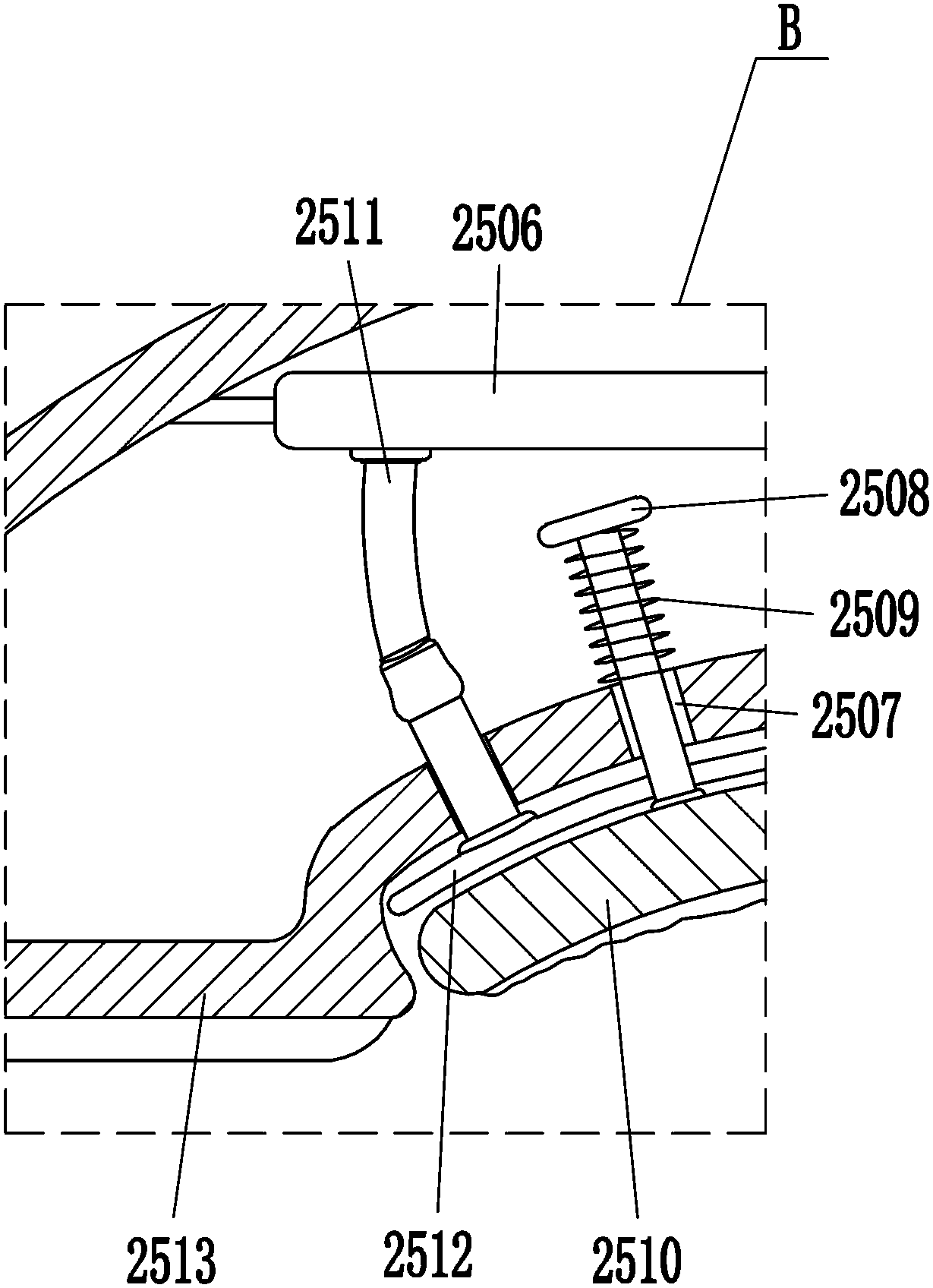

Pile cutting device for breaking concrete structure of pile head and using method thereof

ActiveCN111074891BFast truncationReduce labor intensityBulkheads/pilesArchitectural engineeringDrill pipe

The invention belongs to the technical field of building construction equipment, and in particular relates to a pile-cutting equipment for breaking a concrete structure at a pile head and an application method thereof. A pile-cutting device for breaking concrete structures at pile heads includes a base, a plurality of support plates, a plurality of adjustment devices, a plurality of drill pipes and a plurality of driving devices. The base is provided with a plurality of sliding grooves. A plurality of support plates are evenly arranged around the circumference of the pile head. The support plate corresponds to the chute one by one and is slidably connected. The adjusting device is arranged on the base and corresponds to the supporting board one by one. The first end of the adjustment device is connected with the base, and the second end is connected with the support plate, which drives the support plate to move along the chute. The drill pipe corresponds to the support plate one by one and is connected by rotation. The driving device is arranged on the support plate and connected with the drill rod to drive the drill rod to rotate. The equipment can quickly cut off the concrete structure of the pile head, save time and labor in the operation process, reduce the labor intensity of construction personnel, and improve construction efficiency.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +3

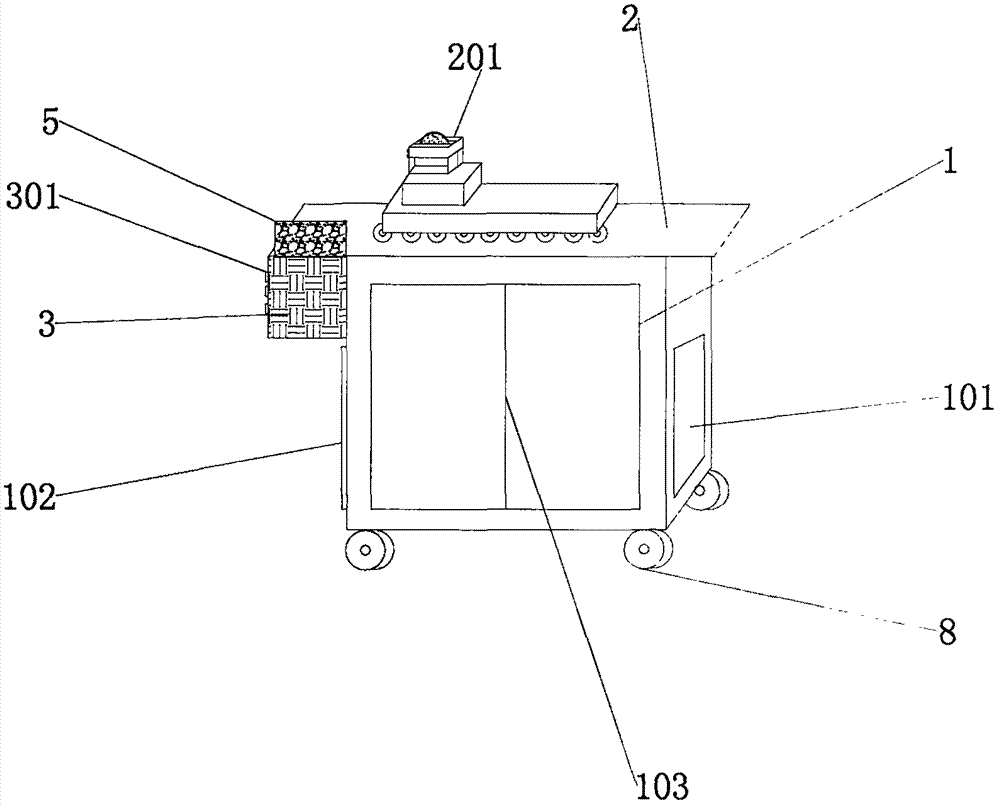

Box sealing device for intelligent warehouse logistics

InactiveCN113335641APaste firmlyFast truncationWrapper twisting/gatheringLogistics managementGear wheel

The invention relates to the technical field of logistics transportation, in particular to a box sealing device for intelligent warehouse logistics. The box sealing device has the advantage of being capable of carrying out box sealing treatment at the bottoms of cargos. The box sealing device comprises a supporting frame, a lead screw, a moving block, two hydraulic rods, a glue rolling seat, a cut-off rod, a paving block, a transportation frame, a plurality of conveying rollers, gears and cog belts, wherein the lead screw is rotationally connected to the supporting frame; the two hydraulic rods are arranged at the front end and the rear end of the supporting frame respectively; the cut-off rod and the glue rolling seat are fixedly connected to the two hydraulic rods respectively; the paving block is fixedly connected to the moving block; the moving block is in meshing transmission with the lead screw; the moving block is slidably connected into the supporting frame; and the plurality of conveying wheels are rotationally connected to the front side and the rear side of the conveying frame respectively.

Owner:哈尔滨圣盈运输有限公司

A pvc plastic pipe fitting cutter

Owner:佛山市顺德区容桂马岗行大实业有限公司

Tool for cutting off packaged flat steel and manufacturing method

InactiveCN108555379ASimple structureEasy to manufacturePortable handheld shearing machinesSheet steelEngineering

The invention provides a tool for cutting off packaged flat steel. The tool comprises a cut-off head and a handle and is characterized in that the cut-off head is triangular; the triangular cut-off head is made from a steel plate; the handle is a steel pipe (3), wherein the center point of the bottom edge of the triangular cut-off head (1) and one end of the steel pipe are fixed in a welding manner; the top end of a corner corresponding to the bottom edge is provided with a groove (2); and the center line of the groove and the axis of the steel pipe are in the same straight line. The tool forcutting off the packaged flat steel and the manufacturing method provided by the invention have the advantages that the tool is simple in structure and convenient to manufacture, the application method is simple and convenient, the tool can be used for quickly cutting off the flat steel, time and efforts are saved, and the work efficiency is improved.

Owner:MCC5 GROUP CORP SHANGHAI

An automatic laminating device for medical trays

ActiveCN111661394BFit fastIncrease in sizeWrapping material feeding apparatusElectric machineryConveyor belt

The invention relates to a film covering device, in particular to an automatic film covering device for medical trays. The technical problem to be solved by the present invention is to provide an automatic film coating device for medical trays that can automatically cover the medical trays. In order to solve the above-mentioned technical problems, the present invention provides such an automatic film covering device for medical trays, which includes: a base plate; a motor base, fixed to one side of the base plate; a servo motor, fixed to the motor base; Connected to the output shaft of the servo motor; the conveyor belt component is fixed to the bottom plate and connected with the coupling, and is located on one side of the motor seat; the transition component is fixed to the bottom plate and close to the conveyor belt component; the compression component is fixed to the bottom plate and is connected with the Conveyor belt assembly connections. The invention has a large volume and is suitable for lamination in large quantities. The medical tray and the lamination can be fast bonded through the conveyor belt assembly and the transition assembly, replacing the function of manual lamination.

Owner:SHANGDONG ZHONGBAOKANG MEDICAL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com