Tufted carpet segment cutting equipment applied to textile industry

A technology for tufted carpet and textile industry, applied in the field of section equipment, can solve the problems of low section accuracy, excessive labor, consumption, etc., and achieve the effect of saving consumption and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

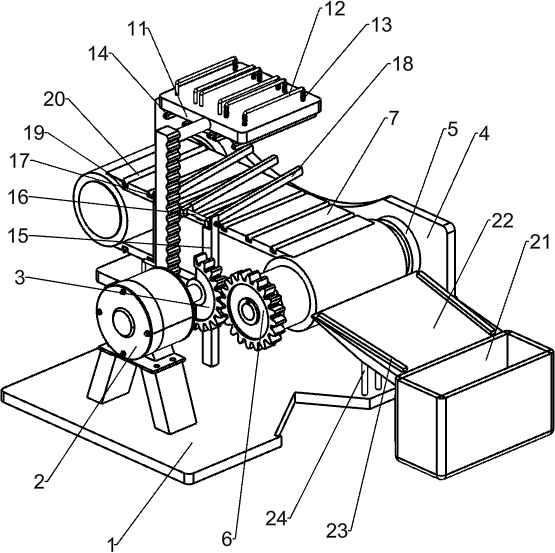

[0022] A tufted carpet sectioning machine for the textile industry, such as Figure 1-5 As shown, it includes a bottom plate 1, a transmission assembly, a lifting assembly, a push assembly and a section assembly. The bottom plate 1 is used to install the entire device. The top of the bottom plate 1 is provided with a transmission assembly, which is powered by a motor. The assembly is lifted and lowered by sliding, and the lifting assembly is provided with a push assembly, which is pushed by moving.

[0023] Such as Figure 1-4 As shown, the transmission assembly includes a reduction motor 2, a sector gear 3, a mounting plate 4, a drum 5, a full gear 6 and a conveyor belt 7, the front side of the bottom plate 1 is provided with a reduction motor 2 through bolts, and the output shaft of the reduction motor 2 is provided with a There is a sector gear 3, a mounting plate 4 is welded on the top and rear side of the bottom plate 1, and there are two rollers 5. The roller 5 is insta...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 and 2 As shown, it also includes a collecting frame 21 and a sloping plate 22. The right side of the base plate 1 is provided with a collecting frame 21, and the left side of the top of the collecting frame 21 is welded with a sloping plate 22. The sloping plate 22 cooperates with the conveyor belt 7.

[0034] On the basis of Example 1, such as figure 1and 2 As shown, it also includes a guide block 23 and a limiting plate 24. There are two guide blocks 23, a guide block 23 is welded on the top of the inclined plate 22, a limiting plate 24 is welded on the right side of the top of the bottom plate 1, and the limiting plate 24 is connected to the collection frame. 21 fits.

[0035] The specific operation process of the above-mentioned embodiment: when the cut-off tufted carpet is transported to the rightmost end of the conveyor belt 7, the tufted carpet falls onto the inclined plate 22, and then slides into the collection fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com